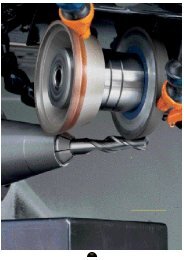

ÐÑавиÑовалÑнÑй инÑÑÑÑменÑ

ÐÑавиÑовалÑнÑй инÑÑÑÑменÑ

ÐÑавиÑовалÑнÑй инÑÑÑÑменÑ

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

210

211 EngravingEngraving toolsTable of engraving tools212 - Families of engraving tools, dimensions216Geometry225 SchnittbedingungenCutting conditions226211

TABLE OF ENGRAVING TOOLCutting materialCBN PCD CVD ND / MDCn HM n DINAC n DLCs l z On requestDiamondtools> .311DIXI 7001Ø 3.00D 1 0.05 - 0.20.216P / Unalloyed steel / Low alloyed steel< 600 / 2nP / Unalloyed steel / Low alloyed steel600 – 1500 / 2nP Lead alloyed cutting steelnPHigh alloyed steel700 – 1500 / 2nM l 400 – 700 / 2Stainless steelnH Tool steel and cast iron> 1500 / 2 (50-65 HRC)sK / Grey cast iron / Nodular iron pearlitic< 250 HBnnK / Alloyed cast iron / Nodular iron pearlitic> 250 HBnnK / Nodular iron pearlitic / Malleable cast ironnnS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloyS / Titanium / Titanium alloylznN - ( - )Copper alloy - easy to machine (brass – bronze)lnN - ( - )Copper alloy - difficult to machine / Aluminium bronze(CuAlFe)(Ampco)lnnN / Aluminium alloy / Magnesium alloylnNAluminium cast ironSi < 8%lnN Aluminium cast ironSi > 8%lznNGraphitelznNKunststoffPlasticlnNN Kevlar®, Gold, silverln212

DIXI 7002Ø 3.00D 1 0.05 - 0.20DIXI 7003Ø 3.00R 0.05 - 0.20DIXI 7013Ø 3.00D 1 0.05 - 0.20DIXI 7015Ø 3.00D 1 0.05 - 0.20DIXI 7017Ø 3.00 - 4.00D 1 0.05 - 0.20DIXI 7018Ø 3.00D 1 0.05 - 0.10. 216.217.218.220.220.221nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn n nnnnnnnnnnnnnn n nnnnnnnnnnnnnn n nnnnnn n nnnnnn n nnnn213 .214 Continued on page 214

TABLE OF ENGRAVING TOOLCutting materialCBN PCD CVD ND / MDCn HMn DINACs l z On requestDIXI 7019Ø 3.00D 1 0.05 - 0.10.221DIXI 7025Ø 3.00 - 4.00D 1 0.10 - 0.15.224P / Unalloyed steel / Low alloyed steel< 600 / 2nnP / Unalloyed steel / Low alloyed steel600 – 1500 / 2nnP Lead alloyed cutting steelnnPHigh alloyed steel700 – 1500 / 2nM l 400 – 700 / 2Stainless steelnnH Tool steel and cast iron> 1500 / 2 (50-65 HRC)K / Grey cast iron / Nodular iron pearlitic< 250 HBnnK / Alloyed cast iron / Nodular iron pearlitic> 250 HBnnK / Nodular iron pearlitic / Malleable cast ironnnS / Special alloys / Heat resisting stainless steelInconelNimonicHastelloynS / Titanium / Titanium alloynnN - ( - )Copper alloy - easy to machine (brass – bronze)nnN - ( - )Copper alloy - difficult to machine / Aluminium bronze(CuAlFe)(Ampco)nnN / Aluminium alloy / Magnesium alloynnNAluminium cast ironSi < 8%nnN Aluminium cast ironSi > 8%nnNGraphitenNKunststoffPlasticnnNN Kevlar®, Gold, silvernn214

Semi-finished style.225DIXI 7012Ø 3.00 - 10.00.218DIXI 7016Ø 2 .00 - 8.00.219DIXI 7020Ø 2.00 - 10.00.222DIXI 7024Ø 3.00 - 6.00.223215

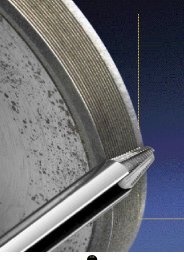

3/4, 35° 3/4, 35°DIXI 7001ENGRAVING TOOLS 3/4, 35°FINISHED STYLE.226ISO 513: P M KD 1 L 1 D h6 L HM DINAC0.05±0.014 35° 3 300.08±0.014 35° 3 300.10±0.014 35° 3 300.15±0.024 35° 3 300.20±0.024 35° 3 30 3/4, 40° 3/4, 40°ENGRAVING TOOLS 3/4, 40°FINISHED STYLEDIXI 7002 3/4 - .-- DINAC.DINACIntended for fine engraving work, these toolsare able to machine most types of steel.For stainless steel, a thin DINAC coating isnecessary.D 1 L 1 D h6 L HM DINAC0.05±0.014 40° 3 300.08±0.014 40° 3 300.10±0.024 40° 3 300.15±0.024 40° 3 300.20±0.024 40° 3 30216

DIXI 7003 3/4, 35° 3/4, 35°.226ENGRAVING TOOLS 3/4, 35°FINISHED STYLEISO 513: P M KR L 1 D h6 L HM DINAC0.05 4 35° 3 300.10 4 35° 3 300.15 4 35° 3 300.20 4 35° 3 30 , .-- DINAC.DINACIntended for fine engraving work, these toolswith radius are able to machine most types ofsteel.For stainless steel, a thin DINAC coating isnecessary.217

DIXI 7012 30° 30°ENGRAVING TOOLS 30°SEMI-FINISHED STYLE.225D 1 L 1 D h6 L HM1.00 4 30° 3 381.30 5 30° 4 501.60 7 30° 5 502.00 8 30° 6 572.60 10 30° 8 633.30 10 30° 10 72.DIXI 7013These preprofiled tools can be quickly completedby the user according to the material to bemachined and the specific form required. 30° 30°ENGRAVING TOOLS 30°SEMI-FINISHED STYLE.227ISO 513:ND 1 L 1 D h6 L HM DINAC DLC0.05±0.014 30° 3 380.10±0.024 30° 3 380.15±0.024 30° 3 380.20±0.024 30° 3 38218

DIXI 7016 60° 60°.225ENGRAVING TOOLS 60°SEMI-FINISHED STYLEL 1 D h6 L HM4 60° 2 256 60° 3 388 60° 4 5010 60° 5 5012 60° 6 5714 60° 8 63.These preprofiled tools can be quickly completedby the user according to the material to bemachined and the specific form required.219

50° 50°DIXI 7015ENGRAVING TOOLS 50°FINISHED STYLE.227ISO 513: P M KD 1 L 1 D h6 L HM DINAC0.05±0.016 50° 3 380.08±0.016 50° 3 380.10±0.026 50° 3 380.15±0.026 50° 3 380.20±0.026 50° 3 38 60° 60°DIXI 7017ENGRAVING TOOLS 60°FINISHED STYLED 1 L 1 D h6 L HM DINAC0.05±0.016 60° 3 380.10±0.026 60° 3 380.15±0.026 60° 3 380.20±0.026 60° 3 380.05±0.028 60° 4 500.10±0.028 60° 4 500.20±0.028 60° 4 50220

DIXI 7018 90° 90°.227ISO 513: P M KENGRAVING TOOLS 90°FINISHED STYLED 1 L 1 D h6 L HM DINAC0.05±0.016 90° 3 380.10±0.026 90° 3 38DIXI 7019 120° 120°ENGRAVING TOOLS 120°FINISHED STYLED 1 L 1 D h6 L HM DINAC0.05±0.016 120° 3 380.10±0.026 120° 3 38221

180° 180°DIXI 7020ENGRAVING TOOLS 180°SEMI-FINISHED STYLE.225D h6 L 1 L HM2 3 253 4 384 5 505 6 506 8 578 10 6310 12 72.These preprofiled tools can be quickly completedby the user according to the material to bemachined and the specific form required.222

DIXI 7024 60° 60°.225ISO 513: P M KENGRAVING TOOLS 60°SEMI-FINISHED STYLEL 1 D h6 L HM9 60° 3 3812 60° 4 5015 60° 6 50.These preprofiled tools can be quickly completedby the user according to the material to bemachined and the specific form required.223

60° 60°DIXI 7025SPIRAL ENGRAVING TOOLS 60°FINISHED STYLE.227ISO 513: P M KD 1 L 1 D h6 L HM0.10±0.029 60° 3 380.15±0.0212 60° 4 50224

-GEOMETRY OF ENGRAVING MILLS7012 7016 20° 10° 3° - 5° 30° 15° 3° - 5°. 30° 15° 3° - 5° 25° 15° 3° - 5° 30° 35° 20° 3° - 5° 25° 30° 15° 3° - 5° 25° 30° 15° 3° - 5°30° 35° 20° 3° - 5° 35° 40° 20° 3° - 5° 25° 30° 15° 3° - 5° 30° 15° 3° - 5° 40° 45° 25° 3° - 5° 30° 35° 20° 3° - 5° 40° 45° 25° 3° - 5°Werkstoffe7012 7016Werkzeugstahl 20° 10° 3° - 5°Stahl 30° 15° 3° - 5°Rostfreier Stahl 30° 15° 3° - 5°Grauguss 25° 15° 3° - 5°Kupfer 30° 35° 20° 3° - 5°Messing 25° 30° 15° 3° - 5°Neusilber 25° 30° 15° 3° - 5°Duralumin 30° 35° 20° 3° - 5°Aluminium 35° 40° 20° 3° - 5°Gold 25° 30° 15° 3° - 5°Titanlegierung 30° 15° 3° - 5°Zelluloid 40° 45° 25° 3° - 5°Kunststoffe 30° 35° 20° 3° - 5°Holz 40° 45° 25° 3° - 5°, , ( ), -. , DIXI . , -. D 1 -. D17012 7016Materials Tool steel 20° 10° 3° - 5°Steel 30° 15° 3° - 5°Stainless steel 30° 15° 3° - 5°Cast iron 25° 15° 3° - 5°Copper 30° 35° 20° 3° - 5°Brass 25° 30° 15° 3° - 5°Nickel-silver 25° 30° 15° 3° - 5°Duralumin 30° 35° 20° 3° - 5°Aluminium 35° 40° 20° 3° - 5°Gold 25° 30° 15° 3° - 5°Pure titanium 30° 15° 3° - 5°Celluloïd 40° 45° 25° 3° - 5°Plastic 30° 35° 20° 3° - 5°Wood 40° 45° 25° 3° - 5°Mainly used for engraving symbols and texts, these tools can alsobe used for machining contours (cutting of profiles) and for copyingoperations for moulds and dies.FINISHED EXECUTIONSOn request, DIXI will supply these tools ground according to thecustomer specifications.The grinding angles will correspond to the opposite table.Please indicate D 1 and material to be machined when ordering.225

DIXI 7001 - 7002 - 7003CUTTING CONDITIONS HM DINACn n Ø D 1 0.05 - 0.20 Ø D 1 0.20 - 0.40Materials to be machined[/.][/.] Vf [/.] ap [] Vf[mm/min] ap[] / < 600 / 2 20 - 35'000 50 - 200 0.05 - 0.15 50 - 230 0.20 -0.50PUnalloyed steel / Low alloyed steelPPPM / 600 – 1500 / 2Unalloyed steel / Low alloyed steel Lead alloyed cutting steel700 – 1500 / 2High alloyed steel l 400 – 700 / 2Stainless steel20 - 30'000 50 - 150 0.05 - 0.10 50 - 230 0.20 -0.5025 - 35'000 50 - 300 0.05 - 0.20 50 - 350 0.20 -0.5015 - 28'00015 - 28'000 50 - 150 0.05 - 0.10 80 - 200 0.20 -0.3020 - 35'00020 - 35'000 60 - 200 0.05 - 0.15 80 - 250 0.20 -0.50KKKSNNNNNNNN / Grey cast iron / Nodular iron pearlitic / Alloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Titanium / Titanium alloy - ( - )< 250 HB> 250 HBCopper alloy - easy to machine (brass – bronze) - . ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze / (Ampco)25 - 35'00025 - 35'000 75 - 240 0.05 - 0.15 80 - 250 0.20 -0.5020 - 30'00020 - 30'000 50 - 200 0.05 -0.10 50 - 230 0.20 -0.5020 - 30'00020 - 30'000 50 - 200 0.05 -0.10 50 - 230 0.20 -0.5020 - 35'000 60 - 200 0.05 - 0.15 60 - 250 0.20 -0.5025 - 35'00020 - 30'000 50 - 300 0.05 - 0.20 50 - 350 0.20 -0.5020 - 30'00020 - 30'000 50 - 150 0.05 - 0.10 80 - 200 0.20 -0.3020 - 35'000 50 - 300 0.05 - 0.20 80 - 350 0.20 -0.50Aluminium alloy / Magnesium alloySi < 8% 20 - 35'000 50 - 300 0.05 - 0.20 80 - 350 0.20 -0.50Aluminium cast iron 20 - 30'000Si > 8%75 - 240 0.05 - 0.15 80 - 250 0.20 -0.50Aluminium cast iron20 - 30'000 75 - 240 0.05 - 0.15 80 - 250 0.20 -0.50Graphite20 - 35'000 50 - 300 0.05 - 0.20 80 - 350 0.20 -0.50Plastic, Gold, silver20 - 35'000 50 - 300 0.05 - 0.20 80 - 350 0.20 -0.50226

DIXI 7013 - 7015 - 7017 - 7018 - 7019 - CUTTING CONDITIONS HM DINACn n Ø D 1 0.05 - 0.20 Ø D 1 0.20 - 0.50Materials to be machined[/.][/.] Vf[/.] ap [] Vf[/.] ap [] / < 600 / 225 - 40'000 75 - 240 0.05 - 0.20 75 - 240 0.20 -0.50PUnalloyed steel / Low alloyed steelPPPM / 600 – 1500 / 2Unalloyed steel / Low alloyed steel Lead alloyed cutting steel700 – 1500 / 2High alloyed steel l 400 – 700 / 2Stainless steel25 - 35'00025 - 35'000 60 - 200 0.05 - 0.20 80 - 240 0.20 -0.4030 - 40'000 100 - 240 0.05 - 0.20 120 - 300 0.20 -0.5015 - 20'000 50 - 160 0.05 - 0.10 75 - 200 0.10 -0.2020 - 35'00020 - 35'000 75 - 200 0.05 - 0.10 75 - 240 0.10 -0.25KKKSSNNNNNNN / Grey cast iron / Nodular iron pearlitic / Alloyed cast iron / Nodular iron pearlitic / Nodular iron pearlitic / Malleable cast iron / Special alloys / Heat resisting stainless steel / Titanium / Titanium alloyInconelNimonicHastelloy - ( - )< 250 HB> 250 HBCopper alloy - easy to machine (brass – bronze) - . ( - ) (CuAlFe)Copper alloy - difficult to machine / Aluminium bronze / (Ampco)Aluminium alloy / Magnesium alloySi < 8%Aluminium cast iron Si > 8%Aluminium cast ironAPlastic, Gold, silver25 - 35'000 75 - 240 0.05 - 0.20 100 - 300 0.20 -0.5015 - 20'00015 - 20'000 50 - 180 0.05 - 0.15 75 - 240 0.10 -0.2015 - 20'00015 - 20'000 50 - 180 0.05 - 0.15 75 - 240 0.10 -0.2010 - 15'000 30 - 80 0.05 - 0.05 40 - 90 0.05 -0.1020 - 30'000 75 - 200 0.05 - 0.20 75 - 240 0.20 -0.3030 - 40'000 75 - 240 0.05 - 0.20 100 - 300 0.20 -0.3020 - 30'000 50 - 200 0.05 - 0.15 75 - 240 0.10 -0.2030 - 40'000 120 - 300 0.05 - 0.30 180 - 400 0.20 -0.8025 - 30'000 75 - 240 0.05 - 0.20 100 - 320 0.20 -0.4020 - 30'000 75 - 240 0.05 - 0.20 100 - 320 0.20 -0.4030 - 40'000 100 - 240 0.05 - 0.30 180 - 350 0.20 -0.3025 - 40'000 75 - 240 0.05 - 0.20 75 - 240 0.20 -0.30227