HM 1400 TRX Total Mercury Analyser - Webshop, Gas Analysis ...

HM 1400 TRX Total Mercury Analyser - Webshop, Gas Analysis ...

HM 1400 TRX Total Mercury Analyser - Webshop, Gas Analysis ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

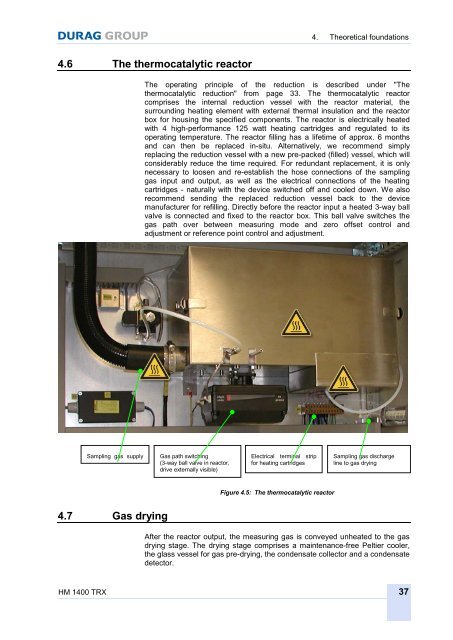

4. Theoretical foundations4.6 The thermocatalytic reactorThe operating principle of the reduction is described under "Thethermocatalytic reduction" from page 33. The thermocatalytic reactorcomprises the internal reduction vessel with the reactor material, thesurrounding heating element with external thermal insulation and the reactorbox for housing the specified components. The reactor is electrically heatedwith 4 high-performance 125 watt heating cartridges and regulated to itsoperating temperature. The reactor filling has a lifetime of approx. 6 monthsand can then be replaced in-situ. Alternatively, we recommend simplyreplacing the reduction vessel with a new pre-packed (filled) vessel, which willconsiderably reduce the time required. For redundant replacement, it is onlynecessary to loosen and re-establish the hose connections of the samplinggas input and output, as well as the electrical connections of the heatingcartridges - naturally with the device switched off and cooled down. We alsorecommend sending the replaced reduction vessel back to the devicemanufacturer for refilling. Directly before the reactor input a heated 3-way ballvalve is connected and fixed to the reactor box. This ball valve switches thegas path over between measuring mode and zero offset control andadjustment or reference point control and adjustment.Sampling gas supply<strong>Gas</strong> path switching(3-way ball valve in reactor,drive externally visible)Electrical terminal stripfor heating cartridgesSampling gas dischargeline to gas dryingFigure 4.5: The thermocatalytic reactor4.7 <strong>Gas</strong> dryingAfter the reactor output, the measuring gas is conveyed unheated to the gasdrying stage. The drying stage comprises a maintenance-free Peltier cooler,the glass vessel for gas pre-drying, the condensate collector and a condensatedetector.<strong>HM</strong> <strong>1400</strong> <strong>TRX</strong> 37