Piling and drilling rigs - AGD Equipment

Piling and drilling rigs - AGD Equipment

Piling and drilling rigs - AGD Equipment

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

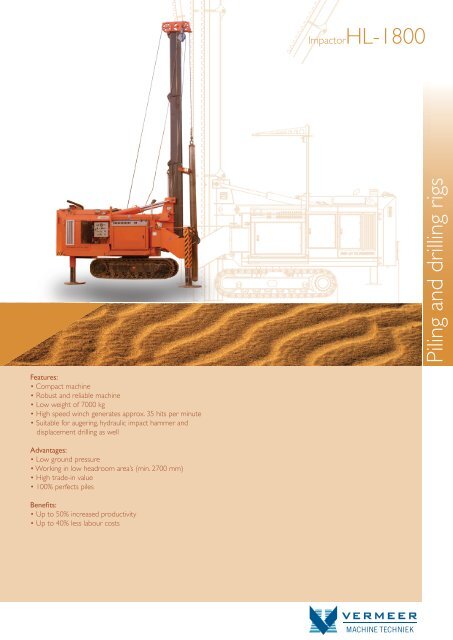

ImpactorHL-1800<strong>Piling</strong> <strong>and</strong> <strong>drilling</strong> <strong>rigs</strong>Features:• Compact machine• Robust <strong>and</strong> reliable machine• Low weight of 7000 kg• High speed winch generates approx. 35 hits per minute• Suitable for augering, hydraulic impact hammer <strong>and</strong>displacement <strong>drilling</strong> as wellAdvantages:• Low ground pressure• Working in low headroom area’s (min. 2700 mm)• High trade-in value• 100% perfects pilesBenefi ts:• Up to 50% increased productivity• Up to 40% less labour costs

HL-1800<strong>Piling</strong> machine Model HL-1800Vermeer Machine Techniek piling machines aresuitable for various foundation installationtechniques.The Vermeer MT HL-1800 is suitable for bottom<strong>and</strong> top drive piling methods <strong>and</strong> can also becombined with (hollow shaft) auger drives <strong>and</strong> theVermeerMT rotary table model SB-65 <strong>and</strong> theVermeerMT BOXER 800 hydraulic impact hammer.The machine can be diesel or electric powered.The PLC driven fully automatic piling systemprovides a continuous high frequency free fall,resulting in a excellent performance.The compact machine is of modular construction,allowing several options to be chosen e.g. trackwidening, 360° slewing ring <strong>and</strong> sliding frame.Through its size <strong>and</strong> performance theVermeer MT HL-1800 is one of the st<strong>and</strong>ards insmall piling machinery.Options:• 360° slewing ring• Exp<strong>and</strong>ing tracks (1100 - 1400 mm)• Additional service winch• Mast positioning frame(forward/backward, telescoping)• Hydraulic power outlet(max. 100 l at 200 bar)• Extended control box for driving• Electric socket (only on E version,for welding or small electric tools)• Two work lights 24 V / 70 W• Painting to customers requirements• Protection shield/v<strong>and</strong>al shield forelectric control boxTechnical Information:UndercarriageTrack width (std)Track lengthTrack plate widthTrack plate materialTorqueMain winch (free-fall)Drop hammer weight (max. / min.)Hoisting speedHits at 1 m fall heightControl (piling)Control (hoisting)Rope diameter / lengthService winchPull (max)Hoisting speedHits at 1 m fall heightHoisting controlRope diameter / lengthGuiding mastMovement of mastTransport heightmax./ min. working heightHydraulic mast extension1400 mm2250 mm300 mmsteel/vulcanised2 x 4,5 kNm1800 / 400 kg80 m / min.30 - 35 / min.fully automatichydr. proportional14 mm / 40m5 kN80 m / min.30 - 35 / min.hydr. proportional12 mm / 20 mhydraulic 8° forward, 90° backward2600 mm (excl. sheave head 2250 mm)9500 / 2700 mm (incl. sheave head)840 mmPower unitDiesel engine Cummins B3.3 34 kW (24 V)Electric motor20 kW 400 / 690 VStabilisersPositionControlWeight of st<strong>and</strong>ard machine1 behind - 2 turnable in fronthydraulicApprox. 7000 kg (without drop hammer)Notice: All technical specifications are subject to changes without prior notice.VMT_IS_HL1800D_04-07Graftermeerstraat 29-332131 AA HoofddorpP.O. Box 202130 AA HoofddorpTel.+31(0)235542300Fax.+31(0)235637133E-mail. info@vermeerMT.nlUrl. www.vermeerMT.nl