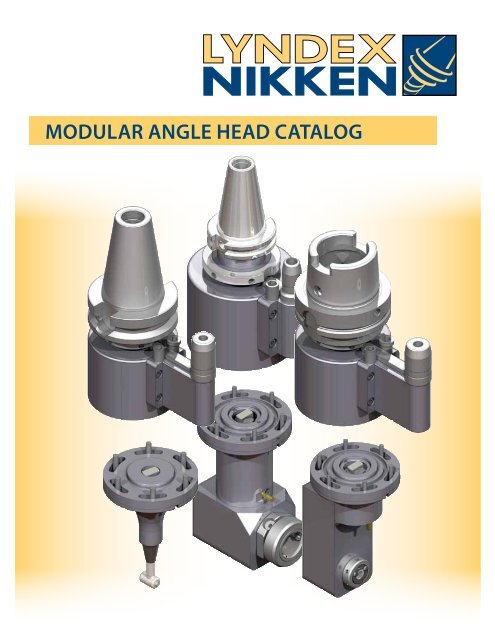

MODULAR ANGLE HEAD CATALOG - Lyndex-Nikken

MODULAR ANGLE HEAD CATALOG - Lyndex-Nikken

MODULAR ANGLE HEAD CATALOG - Lyndex-Nikken

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

JOURNAL OF BACTERIOLOGY, Nov. 2010, p. 5923–5933 Vol. 192, No. 220021-9193/10/$12.00 doi:10.1128/JB.00602-10Copyright © 2010, American Society for Microbiology. All Rights Reserved.Functional Characterization of a Cyanobacterial OmpR/PhoB ClassTranscription Factor Binding Site Controlling Light Color Responses Ryan P. Bezy and David M. Kehoe*Department of Biology, 1001 East Third Street, Indiana University, Bloomington, Indiana 47405Received 26 May 2010/Accepted 26 July 2010Complementary chromatic acclimation (CCA) allows many cyanobacteria to change the composition of theirlight-harvesting antennae for maximal absorption of different wavelengths of light. In the freshwater speciesFremyella diplosiphon, this process is controlled by the ratio of red to green light and allows the differentialregulation of two subsets of genes in the genome. This response to ambient light color is controlled in part bya two-component system that includes a phytochrome class photoreceptor and a response regulator with anOmpR/PhoB class DNA binding domain called RcaC. During growth in red light, RcaC is able to simultaneouslyactivate expression of red light-induced genes and repress expression of green light-induced genesthrough binding to the L box promoter element. Here we investigate how the L box functions as both anactivator and a repressor under the same physiological conditions by analyzing the effects of changing theposition, orientation, and sequence of the L box. We demonstrate that changes in the local sequences surroundingthe L box affect the strength of its activity and that the activating and repressing functions of the L box areorientation dependent. Also, the spacing between the L box and the transcription start site is critical for it to workas an activator, while its repressing role during light regulation requires additional upstream and downstream DNAsequence elements. The latter result suggests that the repressing function of RcaC requires it to operate inassociation with multiple additional DNA binding proteins, at least one of which is functioning as an activator.Cyanobacteria possess the ability to modify their photosyntheticlight-harvesting antennae, or phycobilisomes (PBS), inresponse to changes in a wide range of abiotic cues, includingboth light intensity and color (20–22). Color responsiveness iscalled chromatic acclimation. This process is widespread inmarine and freshwater environments and exists in multipleforms, the best characterized of which is called complementarychromatic acclimation (CCA; historically referred to as “adaptation”)(15, 30, 38, 44). The model organism for the study ofCCA and its regulation is the freshwater filamentous cyanobacteriumFremyella diplosiphon UTEX 481/Tolypothrix sp. PCC7601. During CCA, PBS production in this organism is influencedby the ratio of green light (GL) to red light (RL) in theenvironment. Growth in RL leads to the accumulation of twodifferent forms of an RL-absorbing chromoprotein called phycocyanin(PC) in the outer regions of the PBS. These twoforms are called PC1 and PC2. Growth in GL results in theaccumulation of PC1 and another chromoprotein, called phycoerythrin(PE), which maximally absorbs GL, in the outerportions of the PBS. Thus, cyanobacteria that are capable ofCCA can maximize photon capture for photosynthesis by tailoringthe color absorption profiles of their PBS to the spectraldistribution of ambient light in the green and red regions of thespectrum.CCA-controlled changes in PC2 and PE abundance have sofar been found to occur entirely at the level of transcription.Transcripts from the cpcB2A2H2I2D2 operon (hereafter calledthe cpc2 operon), which encodes the PC2 apoproteins as well* Corresponding author. Mailing address: Department of Biology,Indiana University, 1001 E. Third Street, Bloomington, IN 47405.Phone: (812) 856-4715. Fax: (812) 855-6705. E-mail: dkehoe@indiana.edu. Published ahead of print on 10 September 2010.as PBS structural proteins called linkers, are highly abundantin RL and virtually undetectable in GL (10, 12, 34). Conversely,RNA levels from the cpeBA operon, which encodes theapo-PE subunits, and the cpeCDESTR operon (hereaftercalled the cpeC operon), whose first three genes encode the PElinkers, are high in GL and low in RL (16–18, 36). Manyadditional genes are CCA regulated, including pcyA, whichencodes the biosynthetic enzyme necessary to produce thechromophore used for RL absorption by PC and is expressedfive times more highly in RL than in GL in F. diplosiphon (1).There are also many genes that are either weakly or not CCAregulated, including a number that encode components of thePBS that are present in both RL and GL, such as the operonencoding PC1, cpcB1A1 (herein called the cpc1 operon) (11,37, 43).CCA is regulated by two distinct signal transduction pathways(30). The best characterized of these is the Rca system,which is a complex two-component system. It consists of asensor called RcaE that contains a chromophore binding domainand is a member of the phytochrome superfamily (28,45), a single-domain response regulator named RcaF that appearsto act after RcaE (27), and a multidomain responseregulator called RcaC that is a member of the OmpR/PhoBfamily of transcription factors and apparently acts after RcaF(7, 27). The Rca system controls both RL- and GL-upregulatedgenes by the binding of RcaC to a 7-bp direct repeat DNAsequence, separated by 4 bp, called the L box (5-TTGCACAN 4 TTGCACA-3) (32). Each of the promoters of the genesthat are upregulated in RL, i.e., pcyA and the cpc2 operon,contains an L box, with the 3 end located at positions 22 and24, respectively, relative to the CCA-regulated transcriptionstart site, and these function as activating elements in RL (1)(Fig. 1A). There is also an L box upstream of the cpeC operon,5923

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Angle Head System2Features• Flexible for a multitude of applications• Adaptable with a wide variety of machine tapers• Bolt Style mounting system for added rigidity• Very cost effective when a variety of angle heads are required• 360 degree body and head rotation• Tapered positioning pin for alignment accuracy

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment FeaturesER11 AdapterER11 Adapter SlimER11 Adapter LongER16 AdapterER16 Adapter SlimER16 Adapter LongER20 AdapterER20 Adapter SlimER20 Adapter LongER25 AdapterER25 Adapter SlimER25 Adapter LongER16 Double OutputER25 Double OutputNSK AdapterMI32 Quick ChangeMI32 Quick Change LongMI40 Quick ChangeFeatures• Slim styles for inner bore work• Stubby styles for added milling rigidity• Extended Length style for added reach• Quick Change system for operations involving multiple tools• Double output style eliminates the necessity for two heads• NSK output for small internal engraving and light duty milling3

847-367-4800www.lyndexnikken.comModular Angle HeadsTapersCAT40Part # C40-MRAMExtensions are also available,please see page 8.• 65mm (2.56”) pitch positioning pin with 9.5mm (.374”)below gage line is standard (Part #PA65-CAT/BT).• 65mm (2.56”) pitch positioning pin available in different lengths.CAT50Part # C50-MRAMExtensions are also available,please see page 8.• 110mm (4.33”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA110-CAT).• 110mm (4.33”) pitch positioning pin available in different lengths.For spindles requiring 80mm pitch:• 80mm (3.15”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA80-CAT).• 80mm (3.15”) pitch positioning pin available in different lengths.4

847-367-4800www.lyndexnikken.comModular Angle HeadsTapersBT40Part # B40-MRAMExtensions are also available,please see page 8.• 65mm (2.56”) pitch positioning pin with 9.5mm (.374”)below gage line is standard (Part #PA65-CAT/BT).• 65mm (2.56”) pitch positioning pin available in different lengths.BT50Part # B50-MRAMExtensions are also available,please see page 8.• 110mm (4.33”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA110-BT/HSK).• 110mm (4.33”) pitch positioning pin available in different lengths.For spindles requiring 80mm pitch:• 80mm (3.15”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA80-BT/HSK).• 80mm (3.15”) pitch positioning pin available in different lengths.5

847-367-4800www.lyndexnikken.comModular Angle HeadsTapersHSK63APart # H63A-MRAMExtensions are also available,please see page 8.• 65mm (2.56”) pitch positioning pin with 9.5mm (.374”)below gage line is standard (Part #PA65-HSK).• 65mm (2.56”) pitch positioning pin available in different lengths.HSK100APart # H100A-MRAMExtensions are also available,please see page 8.• 110mm (4.33”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA110-BT/HSK).• 110mm (4.33”) pitch positioning pin available in different lengths.For spindles requiring 80mm pitch:• 80mm (3.15”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA80-BT/HSK).• 80mm (3.15”) pitch positioning pin available in different lengths.6

847-367-4800www.lyndexnikken.comModular Angle HeadsTapersCAPTO C6Part # C6-MRAMExtensions are also available,please see page 8.• 65mm (2.56”) pitch positioning pin with 9.5mm (.374”)below gage line is standard (Part #PA65-CAT/BT).• 65mm (2.56”) pitch positioning pin available in different lengths.CAPTO C8Part # C8-MRAMExtensions are also available,please see page 8.• 110mm (4.33”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA110-CAT).• 110mm (4.33”) pitch positioning pin available in different lengths.For spindles requiring 80mm pitch:• 80mm (3.15”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA80-CAT).• 80mm (3.15”) pitch positioning pin available in different lengths.7

847-367-4800www.lyndexnikken.comModular Angle HeadsTapersHSK80FPart # H80F-MRAM• 110mm (4.33”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA110-BT/HSK).• 110mm (4.33”) pitch positioning pin available in different lengths.For spindles requiring 80mm pitch:• 80mm (3.15”) pitch positioning pin with 3mm (.118”) below gageline is standard (Part #PA80-BT/HSK).• 80mm (3.15”) pitch positioning pin available in different lengths.TAPER EXTENSIONPart # MRAM-EXT-1008

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER11 Adapter - LN Part #MRAM-ER11FeaturesGeneral Taper Reference• 7000 RPM• 3 Nm Torque Capable• .019” to .275” range capable• Recessed ER11 Nut foradded clearance• Short design makes thisideal for light milling anddrilling applications• External Coolant standard,Internal Coolant available• Spindle and collet nutwrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 190 (7.48”) HSK63A 100 (3.94”) 200 (7.87”)CAT50 100 (3.94”) 190 (7.48”) HSK100A 100 (3.94”) 200 (7.87”)BT40 100 (3.94”) 190 (7.48”) CAPTO C6 100 (3.94”) 190 (7.48”)BT50 100 (3.94”) 200 (7.87”) CAPTO C8 100 (3.94”) 190 (7.48”)HSK80F 100 (3.94”) 200 (7.87”)ABHSK80FFor ER Collets please see page 329

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - Slim Type ER11 Adapter - LN Part #MRAM-ER11STFeaturesGeneral Taper Reference• 7000 RPM• 3 Nm Torque Capable• .019” to .275” range capable• Recessed ER11 Nut foradded clearance• Slim design makes this idealfor applications in internalbores or tight spaces• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C810General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 253 (9.96”) HSK63A 100 (3.94”) 263 (10.35”)CAT50 100 (3.94”) 253 (9.96”) HSK100A 100 (3.94”) 263 (10.35”)BT40 100 (3.94”) 253 (9.96”) CAPTO C6 100 (3.94”) 253 (9.96”)BT50 100 (3.94”) 263 (10.35”) CAPTO C8 100 (3.94”) 253 (9.96”)HSK80F 100 (3.94”) 263 (10.35”)ABHSK80FFor ER Collets please see page 32

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER11 Adapter Long- LN Part #MRAM-ER11LFeaturesGeneral Taper Reference• 7000 RPM• 3 Nm Torque Capable• .019” to .275” range capable• Recessed ER11 Nut foradded clearance• Slim design makes this idealfor applications in internalbores or tight spaces• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 245 (9.65”) HSK63A 100 (3.94”) 255 (10.04”)CAT50 100 (3.94”) 245 (9.65”) HSK100A 100 (3.94”) 255 (10.04”)HSK80FBT40 100 (3.94”) 245 (9.65”) CAPTO C6 100 (3.94”) 245 (9.65”)BT50 100 (3.94”) 255 (10.04”) CAPTO C8 100 (3.94”) 245 (9.65”)HSK80F 100 (3.94”) 255 (10.04”) For ER Collets please see page 32BA11

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER16 Adapter - LN Part #MRAM-ER16FeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• .039” to .393” range capable• Recessed ER16 Nut foradded clearance• Short design makes thisideal for milling anddrilling applications• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsBATAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 190 (7.48”) HSK63A 100 (3.94”) 200 (7.87”)CAT50 100 (3.94”) 190 (7.48”) HSK100A 100 (3.94”) 200 (7.87”)BT40 100 (3.94”) 190 (7.48”) CAPTO C6 100 (3.94”) 190 (7.48”)BT50 100 (3.94”) 200 (7.87”) CAPTO C8 100 (3.94”) 190 (7.48”)HSK80FHSK80F 100 (3.94”) 200 (7.87”) For ER Collets please see page 3312

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - Slim Type ER16 Adapter - LN Part #MRAM-ER16STFeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• .039” to .393” range capable• Recessed ER16 Nut foradded clearance• Slim design makes this idealfor applications in internalbores or tight places• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 270 (10.63”) HSK63A 100 (3.94”) 280 (11.02”)CAT50 100 (3.94”) 270 (10.63”) HSK100A 100 (3.94”) 280 (11.02”)BT40 100 (3.94”) 270 (10.63”) CAPTO C6 100 (3.94”) 270 (10.63”)BT50 100 (3.94”) 280 (11.02”) CAPTO C8 100 (3.94”) 270 (10.63”)HSK80F 100 (3.94”) 280 (11.02”)ABHSK80FFor ER Collets please see page 3313

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER16 Adapter Long - LN Part #MRAM-ER16LFeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• .039” to .393” range capable• Recessed ER16 Nut foradded clearance• Extended reach design isideal for hard to reachapplications aroundfixtures, or beyondmachine table beds• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C814General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 245 (9.65”) HSK63A 100 (3.94”) 255 (10.04”)CAT50 100 (3.94”) 245 (9.65”) HSK100A 100 (3.94”) 255 (10.04”)BT40 100 (3.94”) 245 (9.65”) CAPTO C6 100 (3.94”) 245 (9.65”)BT50 100 (3.94”) 255 (10.04”) CAPTO C8 100 (3.94”) 245 (9.65”)HSK80F 100 (3.94”) 255 (10.04”)ABHSK80FFor ER Collets please see page 33

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER20 Adapter - LN Part #MRAM-ER20FeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• .039” to .511” range capable• Recessed ER20 Nut foradded clearance• Short design makes thisideal for milling anddrilling applications• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 190 (7.48”) HSK63A 100 (3.94”) 200 (7.87”)CAT50 100 (3.94”) 190 (7.48”) HSK100A 100 (3.94”) 200 (7.87”)BT40 100 (3.94”) 190 (7.48”) CAPTO C6 100 (3.94”) 190 (7.48”)BT50 100 (3.94”) 200 (7.87”) CAPTO C8 100 (3.94”) 190 (7.48”)HSK80F 100 (3.94”) 200 (7.87”)ABHSK80FFor ER Collets please see page 3415

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - Slim Type ER20 Adapter - LN Part #MRAM-ER20STFeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• .039” to .511” range capable• Recessed ER20 Nut foradded clearance• Slim design makes this idealfor applications in internalbores or tight places• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference Dimensions16TAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 270 (10.63”) HSK63A 100 (3.94”) 280 (11.02”)CAT50 100 (3.94”) 270 (10.63”) HSK100A 100 (3.94”) 280 (11.02”)BT40 100 (3.94”) 270 (10.63”) CAPTO C6 100 (3.94”) 270 (10.63”)BT50 100 (3.94”) 280 (11.02”) CAPTO C8 100 (3.94”) 270 (10.63”)HSK80F 100 (3.94”) 280 (11.02”)ABHSK80FFor ER Collets please see page 34

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER20 Adapter Long - LN Part #MRAM-ER20LFeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• .039” to .511” range capable• Recessed ER20 Nut foradded clearance• Extended reach design isideal for hard to reachapplications around fixtures,or beyond machine table beds• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsBATAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 245 (9.65”) HSK63A 100 (3.94”) 255 (10.04”)CAT50 100 (3.94”) 245 (9.65”) HSK100A 100 (3.94”) 255 (10.04”)BT40 100 (3.94”) 245 (9.65”) CAPTO C6 100 (3.94”) 245 (9.65”)BT50 100 (3.94”) 255 (10.04”) CAPTO C8 100 (3.94”) 245 (9.65”)HSK80FHSK80F 100 (3.94”) 255 (10.04”) For ER Collets please see page 3417

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER25 Adapter - LN Part #MRAM-ER25FeaturesGeneral Taper Reference• 5000 RPM• 25 Nm Torque Capable• .039” to .629” range capable• Recessed ER25 Nut foradded clearance• Short design makes thisideal for milling anddrilling applications• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsBATAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 210 (8.27”) HSK63A 100 (3.94”) 220 (8.66”)CAT50 100 (3.94”) 210 (8.27”) HSK100A 100 (3.94”) 220 (8.66”)BT40 100 (3.94”) 210 (8.27”) CAPTO C6 100 (3.94”) 210 (8.27”)BT50 100 (3.94”) 220 (8.66”) CAPTO C8 100 (3.94”) 210 (8.27”)HSK80FHSK80F 100 (3.94”) 220 (8.66”) For ER Collets please see page 3518

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - Slim Type ER25 Adapter - LN Part #MRAM-ER25STFeaturesGeneral Taper Reference• 5000 RPM• 25 Nm Torque Capable• .039” to .629” range capable• Recessed ER25 Nut foradded clearance• Slim design makes this idealfor applications in internalbores or tight places• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 310 (12.20”) HSK63A 100 (3.94”) 320 (12.60”)CAT50 100 (3.94”) 310 (12.20”) HSK100A 100 (3.94”) 320 (12.60”)BT40 100 (3.94”) 310 (12.20”) CAPTO C6 100 (3.94”) 310 (12.20”)BT50 100 (3.94”) 320 (12.60”) CAPTO C8 100 (3.94”) 310 (12.20”)HSK80F 100 (3.94”) 320 (12.60”)ABHSK80FFor ER Collets please see page 3519

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER25 Adapter Long - LN Part #MRAM-ER25LFeaturesGeneral Taper Reference• 5000 RPM• 25 Nm Torque Capable• .039” to .629” range capable• Recessed ER25 Nut foradded clearance• Extended reach design is idealfor hard to reach applicationsaround fixtures, or beyondmachine table beds• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBAACAT40BAACAT50BBBT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)ACAT40 100 (3.94”) 260 (10.24”) HSK63A 100 (3.94”) 270 (10.63”)BCAT50 100 (3.94”) 260 (10.24”) HSK100A 100 (3.94”) 270 (10.63”)BT40 100 (3.94”) 260 (10.24”) CAPTO C6 100 (3.94”) 260 (10.24”)BT50 100 (3.94”) 270 (10.63”) CAPTO C8 100 (3.94”) 260 (10.24”)HSK80FHSK80F 100 (3.94”) 270 (10.63”) For ER Collets please see page 3520

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER16 Adapter Double Angle Head - LN Part #MRAM-ER16TSFeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• .039” to .393” range capable• Recessed ER16 Nut foradded clearance• Double sided angle head workfor applications requiring thesame machined feature onboth sides of a part• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 190 (7.48”) HSK63A 100 (3.94”) 200 (7.87”)CAT50 100 (3.94”) 190 (7.48”) HSK100A 100 (3.94”) 200 (7.87”)BT40 100 (3.94”) 190 (7.48”) CAPTO C6 100 (3.94”) 190 (7.48”)BT50 100 (3.94”) 200 (7.87”) CAPTO C8 100 (3.94”) 190 (7.48”)HSK80F 100 (3.94”) 200 (7.87”)ABHSK80FFor ER Collets please see page 3321

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - ER25 Adapter Double Angle Head - LN Part #MRAM-ER25TSFeaturesGeneral Taper Reference• 5000 RPM• 25 Nm Torque Capable• .039” to .629” range capable• Recessed ER25 Nut foradded clearance• Double sided angle head workfor applications requiring thesame machined feature onboth sides of a part• External Coolant as standard,Internal Coolant available• Spindle and colletnut wrench includedBBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsBATAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 210 (8.27”) HSK63A 100 (3.94”) 220 (8.66”)CAT50 100 (3.94”) 210 (8.27”) HSK100A 100 (3.94”) 220 (8.66”)BT40 100 (3.94”) 210 (8.27”) CAPTO C6 100 (3.94”) 210 (8.27”)BT50 100 (3.94”) 220 (8.66”) CAPTO C8 100 (3.94”) 210 (8.27”)HSK80FHSK80F 100 (3.94”) 220 (8.66”) For ER Collets please see page 3522

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - NSK Adapter - LN Part #MRAM-NSK-M17FeaturesGeneral Taper Reference• 10,000 RPM• 1 Nm Torque Capable• .039” to .629” range capable• Collets available for 1/16”,3/32”, 1/8” and 3.0mm• Miniature head works forengraving and drillingapplications in very smallor tight areas• Body can accept other NSKheads with M17 thread• Units comes standard withNSK model # IC-300BBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 266.05 (10.47”) HSK63A 100 (3.94”) 276.05 (10.87”)CAT50 100 (3.94”) 266.05 (10.47”) HSK100A 100 (3.94”) 276.05 (10.87”)BT40 100 (3.94”) 266.05 (10.47”) CAPTO C6 100 (3.94”) 266.05 (10.47”)BT50 100 (3.94”) 276.05 (10.87”) CAPTO C8 100 (3.94”) 266.05 (10.47”)HSK80F 100 (3.94”) 276.05 (10.87”)BAHSK80F23

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - MI32 Quick Change Adapter - LN Part #MRAM-MI32FeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• Utilizes patented MImodular system• Interchangeable front adaptersallow for cost effective flexibility• Recessed spindle design keepsthe body size compact evenwith front adapters• Milling, Drilling, and Tappingcan all be done with one head• External Coolant as standard,Internal Coolant available• MI Adapter wrench includedBBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 190 (7.48”) HSK63A 100 (3.94”) 200 (7.87”)CAT50 100 (3.94”) 190 (7.48”) HSK100A 100 (3.94”) 200 (7.87”)BT40 100 (3.94”) 190 (7.48”) CAPTO C6 100 (3.94”) 190 (7.48”)BT50 100 (3.94”) 200 (7.87”) CAPTO C8 100 (3.94”) 190 (7.48”)HSK80F 100 (3.94”) 200 (7.87”)BAHSK80FMI Attachments are available,please see pages 27-30.24

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - MI32 Long Quick Change Adapter - LN Part #MRAM-MI32LFeaturesGeneral Taper Reference• 6000 RPM• 10 Nm Torque Capable• Utilizes patented MI modular system• Interchangeable front adaptersallow for cost effective flexibility• Recessed spindle design keepsthe body size compact even withfront adapters• Extended reach design is ideal forhard to reach applications aroundfixtures, or beyond machine tablebeds• Milling, Drilling, and Tapping canall be done with one head• External Coolant as standard,Internal Coolant available• MI Adapter wrench includedBBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 245 (9.65”) HSK63A 100 (3.94”) 255 (10.04”)CAT50 100 (3.94”) 245 (9.65”) HSK100A 100 (3.94”) 255 (10.04”)BT40 100 (3.94”) 245 (9.65”) CAPTO C6 100 (3.94”) 245 (9.65”)BT50 100 (3.94”) 255 (10.04”) CAPTO C8 100 (3.94”) 245 (9.65”)HSK80F 100 (3.94”) 255 (10.04”)BAHSK80FMI Attachments are available,please see pages 27-30.25

847-367-4800www.lyndexnikken.comModular Angle HeadsModular Attachment - MI40 Quick Change Adapter - LN Part #MRAM-MI40FeaturesGeneral Taper Reference• 5000 RPM• 25 Nm Torque Capable• Utilizes patented MImodular system• Interchangeable front adaptersallow for cost effective flexibility• Recessed spindle design keepsthe body size compact evenwith front adapters• Milling, Drilling, and Tappingcan all be done with one head• External Coolant as standard,Internal Coolant available• MI Adapter wrench includedBBAACAT40BBAACAT50BT40BT50AABBHSK63AHSK100AAABBCAPTO C6CAPTO C8General Taper Reference DimensionsTAPER A Dim (mm) B Dim (mm) TAPER A Dim (mm) B Dim (mm)CAT40 100 (3.94”) 210 (8.27”) HSK63A 100 (3.94”) 220 (8.66”)CAT50 100 (3.94”) 210 (8.27”) HSK100A 100 (3.94”) 220 (8.66”)BT40 100 (3.94”) 210 (8.27”) CAPTO C6 100 (3.94”) 210 (8.27”)BT50 100 (3.94”) 220 (8.66”) CAPTO C8 100 (3.94”) 210 (8.27”)HSK80F 100 (3.94”) 220 (8.66”)BAHSK80FMI Attachments are available,please see pages 27-30.26

CustomTools / Live Tools Technical Accessories MMC Collet Chucks VC Collet Chucks SK Collet Chucks Shrink Fit Holders Milling Chucks28800-543-6237847-367-4800 www.lyndexnikken.comwww.lyndexnikken.comMimatic ® MI AttachmentsWeldon Toolholder DIN 1835 B258Part Number Size l1 l2 l3 d(H5) D121436 MI32 2.067” 1.457” 1.024” 6 1.654”121478 MI32 2.067” 1.457” 1.024” 8 1.654”121469 MI32 2.185” 1.614” 1.142” 10 1.654”121439 MI32 2.264” 1.811” 1.220” 12” 1.654”121449 MI32 2.067” 1.457” 1.024” 1/4” 1.654”121472 MI32 2.185” 1.614” 1.142” 3/8” 1.654”121448 MI32 2.264” 1.811” 1.220” 1/2” 1.654”155330 MI40 2.362” 1.457” 1.024” 6 1.890”155346 MI40 2.362” 1.457” 1.024” 8 1.890”155321 MI40 2.480” 1.614” 1.142” 10 1.890”155331 MI40 2.559” 1.811” 1.220” 12 1.890”155326 MI40 2.559” 1.811” 1.220” 14 1.890”155379 MI40 2.677” 1.929” 1.339” 16 1.890”121497 MI40 2.362” 1.457” 1.024” 1/4” 1.890”121475 MI40 2.480” 1.614” 1.142” 3/8” 1.890”121474 MI40 2.559” 1.811” 1.220” 1/2” 1.890”121499 MI40 2.677” 1.929” 1.339” 5/8” 1.890”155419 MI50 2.559” 1.457” 0.945” 6 2.283”155411 MI50 2.598” 1.614” 0.984” 8 2.283”155400 MI50 2.756” 1.811” 1.142” 10 2.283”155406 MI50 2.874” 1.929” 1.260” 12 2.283”155412 MI50 2.874” 1.457” 1.260” 14 2.283”155407 MI50 2.913” 1.614” 1.299” 16 2.283”155427 MI50 3.071” 1.811” 1.457” 20 2.283”121489 MI50 2.559” 1.457” 0.945” 1/4” 2.283”121529 MI50 1.575” 1.614” 1.142” 3/8” 2.283”121525 MI50 2.874” 1.811” 1.260” 1/2” 2.283”121520 MI50 2.953” 1.929” 1.339” 5/8” 2.283”121526 MI50 3.071” 2.008” 1.457” 3/4” 2.283”155470 MI63 3.189” 1.457” 1.457” 6 2.953”155459 MI63 3.228” 1.457” 1.457” 8 2.953”155490 MI63 3.346” 1.614” 1.417” 10 2.953”155509 MI63 3.484” 1.811” 1.535” 12 2.953”155463 MI63 3.484” 1.811” 1.535” 14 2.953”155482 MI63 3.583” 1.929” 1.654” 16 2.953”155474 MI63 3.661” 2.008” 1.732” 20 2.953”155464 MI63 4.331” 2.323” 2.402” 25 2.953”166815 MI63 3.189” 1.457” 1.260” 1/4” 2.953”166805 MI63 3.346” 1.614” 1.417” 3/8” 2.953”166813 MI63 3.484” 1.811” 1.555” 1/2” 2.953”166807 MI63 3.583” 1.929” 1.654” 5/8” 2.953”166804 MI63 3.661” 2.008” 1.732” 3/4” 2.953”166812 MI63 4.331” 2.323” 2.402” 1” 2.953”ModularCustomToolsAngle Heads/ Live ToolsWhistle Notch Toolholder DIN 1835 EPart Number Size l1 l2 l3 d(H5) D121463 MI32 2.067” 1.417” 1.024” 6 1.654”121464 MI32 2.067” 1.417” 1.024” 8 1.654”121443 MI32 2.185” 1.575” 1.142” 10 1.654”121453 MI32 2.264” 1.772” 1.220” 12 1.654”121442 MI32 2.067” 1.417” 1.024” 1/4” 1.654”121485 MI32 2.185” 1.575” 1.142” 3/8” 1.654”121480 MI32 2.264” 1.772” 1.220” 1/2” 1.654”155369 MI40 2.362” 1.417” 1.024” 6 1.890”155363 MI40 2.362” 1.417” 1.024” 8 1.890”155370 MI40 2.480” 1.575” 1.142” 10 1.890”155364 MI40 2.559” 1.772” 1.220” 12 1.890”155333 MI40 2.559” 1.772” 1.220” 14 1.890”155382 MI40 2.677” 1.890” 1.339” 16 1.890”121492 MI40 2.362” 1.417” 1.024” 1/4” 1.890”121493 MI40 2.480” 1.575” 1.142” 3/8” 1.890”121455 MI40 2.559” 1.772” 1.220” 1/2” 1.890”121494 MI40 2.677” 1.890” 1.339” 5/8” 1.890”155416 MI50 2.559” 1.417” 0.945” 6 2.283”155401 MI50 2.598” 1.417” 0.984” 8 2.283”155383 MI50 2.756” 1.575” 1.142” 10 2.283”155408 MI50 2.874” 1.772” 1.260” 12 2.283”155435 MI50 2.874” 1.772” 1.260” 14 2.283”155436 MI50 2.972” 1.890” 1.358” 16 2.283”155384 MI50 3.071” 1.969” 1.457” 20 2.283”166816 MI50 2.559” 1.417” 0.945” 1/4” 2.283”155440 MI50 2.756” 1.575” 1.142” 3/8” 2.283”155434 MI50 2.874” 1.772” 1.260” 1/2” 2.283”155428 MI50 2.953” 1.890” 1.339” 5/8” 2.283”155385 MI50 3.071” 1.969” 1.457” 3/4” 2.283”166104 MI63 3.189” 1.417” 1.260” 6 2.953”166105 MI63 3.228” 1.417” 1.299” 8 2.953”166110 MI63 3.346” 1.575” 1.417” 10 2.953”166112 MI63 3.484” 1.772” 1.555” 12 2.953”166113 MI63 3.484” 1.772” 1.555” 14 2.953”166114 MI63 3.583” 1.890” 1.654” 16 2.953”166115 MI63 3.661” 1.969” 1.732” 20 2.953”166116 MI63 4.331” 2.205” 2.402” 25 2.953”166797 MI63 3.189” 1.417” 1.260” 1/4” 2.953”166799 MI63 3.346” 1.575” 1.417” 3/8” 2.953”166796 MI63 3.484” 1.772” 1.555” 1/2” 2.953”166803 MI63 3.583” 1.890” 1.654” 5/8” 2.953”166798 MI63 3.661” 1.969” 1.732” 3/4” 2.953”166795 MI63 4.331” 2.205” 2.402” 1” 2.953”

SW0.106”0.134”0.193”0.244”0.276”0.315”0.354”0.106”0.134”0.193”0.244”0.276”0.315”0.354”0.472”800-543-6237847-367-4800 www.lyndexnikken.comwww.lyndexnikken.comMimatic ® MI Attachmentswith internal coolant (70 bar),only synchronizationSYNAX ® Tapping Quick Change Holderwithout internal coolant,with synchronization and lengthcompensationCustomTools / Live ToolsPart Number Size l1 l2 d D SW155389 MI40 0.669” 1.063” 6mm (.236”) 1.890” 0.193”Part Number Size l1 l2 d D SW121522 MI40 0.669” 1.063” 8mm (.315”) 1.890” 0.244”121515 MI40 1.496” 1.102” 9mm (.354”) 1.890” 0.276”121510 MI40 0.669” 0.984” 3.5mm (.138”) 1.890” 0.106”121504 MI40 1.496” 1.142” 10mm (.394”) 1.890” 0.315”155397 MI40 0.669” 0.984” 4.5mm (.177”) 1.890” 0.134”121517 MI40 1.496” 1.181” 12mm (.472”) 1.890” 0.354”155377 MI40 0.669” 1.063” 6mm (.236”) 1.890” 0.193”155432 MI50 0.650” 1.063” 6mm (.236”) 2.283” 0.193”155378 MI40 0.669” 1.063” 8mm (.315”) 1.890” 0.244”155498 MI50 0.650” 1.063” 8mm (.315”) 2.283” 0.244”155403 MI40 1.496” 1.102” 9mm (.354”) 1.890” 0.276”155473 MI50 0.650” 1.102” 9mm (.354”) 2.283” 0.276”121451 MI40 1.496” 1.142” 10mm (.394”) 1.890” 0.315”155467 MI50 0.650” 1.142” 10mm (.394”) 2.283” 0.315”121498 MI40 1.496” 1.181” 12mm (.472”) 1.890” 0.354”155446 MI50 0.650” 1.181” 12mm (.472”) 2.283” 0.354”155450 MI50 0.650” 0.984” 3.5mm (.138”) 2.283” 0.106”121534 MI50 1.732” 1.299” 16mm (.630”) 2.283” 0.472”155487 MI50 0.650” 0.984” 4.5mm (.177”) 2.283” 0.134”155422 MI50 0.650” 1.063” 6mm (.236”) 2.283” 0.193”155455 MI50 0.650” 1.063” 8mm (.315”) 2.283” 0.244”155423 MI50 0.650” 1.102” 9mm (.354”) 2.283” 0.276”155466 MI50 0.650” 1.142” 10mm (.394”) 2.283” 0.315”155449 MI50 0.650” 1.181” 12mm (.472”) 2.283” 0.354”155479 MI50 1.732” 1.299” 16mm (.630”) 2.283” 0.472”Softsynchro Chuck (Licence Emuge)with internal coolant,with push and pull lengthQuick Change AngleHeadscompensation 0.5mmPart NumberDescriptionMI50-STA-#6#6 Synax Tap AdapterMI50-STA-#8#8 Synax Tap AdapterMI50-STA-#10#10 Synax Tap AdapterMI50-STA-#12#12 Synax Tap AdapterMI50-STA-1/41/4 Synax Tap AdapterMI50-STA-5/165/16 Synax Tap AdapterMI50-STA-3/83/8 Synax Tap AdapterPart MI50-STA-7/16 Number Size Collet 7/16 Thread Synax Tap l1 Adapterd DMI50-STA-1/21/2 Synax Tap Adapter121503 MI50-STA-9/16 MI40 ER-GB169/16 M4-M12 Synax 1.870” Tap Adapter .177-.394” 1.772”121530 MI50-STA-5/8 MI50 ER-GB165/8 M4-M12 Synax Tap 1.752” Adapter .177-.394” 1.969”259CustomTools / Live Tools Technical Accessories MMC Collet Chucks VC Collet Chucks SK Collet Chucks Shrink Fit Holders Milling Chuckswith internal coolant (70 bar),only synchronizationModularCustomToolsAngle Heads/ Live ToolsPart Number Size l1 l2 d D SW155389 MI40 0.669” 1.063” 6mm (.236”) 1.890” 0.193”121522 MI40 0.669” 1.063” 8mm (.315”) 1.890” 0.244”121515 MI40 1.496” 1.102” 9mm (.354”) 1.890” 0.276”121504 MI40 1.496” 1.142” 10mm (.394”) 1.890” 0.315”121517 MI40 1.496” 1.181” 12mm (.472”) 1.890” 0.354”155432 MI50 0.650” 1.063” 6mm (.236”) 2.283” 0.193”155498 MI50 0.650” 1.063” 8mm (.315”) 2.283” 0.244”155473 MI50 0.650” 1.102” 9mm (.354”) 2.283” 0.276”155467 MI50 0.650” 1.142” 10mm (.394”) 2.283” 0.315”155446 MI50 0.650” 1.181” 12mm (.472”) 2.283” 0.354”121534 MI50 1.732” 1.299” 16mm (.630”) 2.283” 0.472”Softsynchro Chuck (Licence Emuge)with internal coolant,with push and pull lengthcompensation 0.5mmPart Number Size Collet Thread l1 d D121503 MI40 ER-GB16 M4-M12 1.870” .177-.394” 1.772”121530 MI50 ER-GB16 M4-M12 1.752” .177-.394” 1.969”29259CustomTools / Live Tools Technical Accessories MMC Collet Chucks VC Collet Chucks SK Collet Chucks Shrink Fit Holders Milling Chucks

800-543-6237847-367-4800www.lyndexnikken.comwww.lyndexnikken.comModular CustomTools Angle Heads / Live Tools30Mimatic ® MI AttachmentsShrink Fit ChuckPart Number Size l1 l2 I3 d(h6) D155381 MI40 3.701” 2.362” 1.417” 8mm (.315”) 1.890”121482 MI40 3.701” 2.362” 1.654” 10mm (.394”) 1.890”155334 MI40 3.898” 2.559” 1.850” 12mm (.472”) 1.890”121501 MI40 4.094” 2.756” 1.969” 16mm (.630”) 1.890”155421 MI50 3.976” 2.362” 1.417” 8mm (.315”) 2.283”155409 MI50 3.976” 2.362” 1.654” 10mm (.394”) 2.283”155444 MI50 4.137” 2.559” 1.850” 12mm (.472”) 2.283”155438 MI50 4.137” 2.559” 1.850” 14mm (.551”) 2.283”155430 MI50 4.370” 2.756” 1.969” 16mm (.630”) 2.283”155431 MI50 4.567” 2.953” 1.969” 18mm (.709”) 2.283”155454 MI50 4.567” 2.953” 2.047” 20mm (.787”) 2.283”Hydraulic ChuckPart Number Size l1 l2 l3 d(h6) D155391 MI40 2.520” 1.772” 1.181” 12mm (.472”) 1.890”155417 MI50 2.795” 2.047” 1.181” 20mm (.787”) 2.283”BlankPart Number Size l1 l2 D121457 MI32 3.012” 1.969” 1.654”166791 MI40 3.701” 2.362” 1.890”166789 MI50 4.370” 2.756” 2.283”121557 MI63 5.079” 3.150” 2.953”Tool Presetting UnitPart Number Size VDI A155368 MI40 2.520” 108mm155356 MI50 2.795” 110mm261ACustomTools / Live Tools Technical Accessories MMC Collet Chucks VC Collet Chucks SK Collet Chucks Shrink Fit Holders Milling Chucks

This pin, which is seated into a positioning block after changing, locks the toolholder's body into a stationary position relativeto the spindle face. With its body properly aligned and secured, the toolholder's internal mechanisms are ready to perform theirdesigned operations.800-543-6237847-367-4800Before using any of our stationary www.lyndexnikken.combody tools, a positioning block must first be attached to the machining center's spindle face.www.lyndexnikken.comyour ATC arm or any otherAngleHeads attachments.Positioning BlocksModularCustomToolsAngle Heads/ Live ToolsThe block is attached to the face by utilizing the existing drilled/tapped holes on the face. Place the positioning block in alocation which will assure that the positioning pin, when seated in the positioning block, will not interfere with the movements ofAll <strong>Lyndex</strong>-<strong>Nikken</strong> tools have features that allow them to be easily oriented with any position of your spindle's drive keys.HighA positioningtechnologyblocktoolholdersmay requirethatslightperformmodificationsbeyond thetomainaccommodatespindle's rotationalyour particularcharacteristics,machine.and toolholders that induce a sideflow of coolant through cutting tools, require a positioning pin to operate.This For pin, use which with is AngleHeads seated into a on positioning block after changing, PB-RAM 40 locks the toolholder's body PB-RAM into 50 a stationary position relativepages 246 - 256.to the spindle face. With its body properly aligned and secured, (40 and the toolholder's HSK 63 Taper) (50 and HSK 100 Taper)internal mechanisms are ready to perform theirdesigned operations.Before using any of our stationary body tools, a positioning block must first be attached to the machining center's spindle face.The block is attached to the face by utilizing the existing drilled/tapped holes on the face. Place the positioning block in alocation which will assure that the positioning pin, when seated in the positioning block, will not interfere with the movements ofyour ATC arm or any other attachments.All <strong>Lyndex</strong>-<strong>Nikken</strong> tools have features that allow them to be easily oriented with any position of your spindle's drive keys.A positioning block may require slight modifications to accommodate your particular machine.For use with with AngleHeadsonon pages 246 245. - 256.Specials For use with AngleHeadson page 245.SpecialsPB-RAM PB-RAN 40(40 and Taper) HSK 63 Taper)PB-RAN PB-RAM 50 50(50 Taper) (50 and HSK 100 Taper)CustomPB-RANstopper40blocks available,PB-RANincluding50combination blocksas(40shown,Taper)upon special request.(50 Taper)Custom stopper blocks available, including combination blocksas shown, upon special request.263263CustomTools / Live Tools Technical CustomTools Accessories / Live Tools Technical MMC Collet Chucks Accessories VC Collet Chucks MMC Collet SK Collet Chucks Chucks VC Collet Shrink Chucks Fit Holders SK Collet Milling Chucks Chucks Shrink Fit Holders31

ER/TG/DA Collet Chucks EnER8 ColletsSize range: 1.0mm-5.0mm (0.019”-0.196”)Size range: 1.0mm-5.0mm (0.019”-0.196”)METRICMETRICPartNumberSizeCollapsePartRange 847-367-4800NumberSizeCollapseRange www.lyndexnikken.comER8-039 1.0mm 1.0-0.5mmER8-039 1.0mm 1.0-0.5mmER8-059 1.5mm 1.5-1.0mmER8-059 1.5mm 1.5-1.0mmER8-078 2.0mm 2.0-1.5mmER11 ER8-078 Collets2.0mm 2.0-1.5mmER8-098 2.5mm 2.5-2.0mmER8-098 2.5mm 2.5-2.0mmER8-118 3.0mm 3.0-2.5mmER8-118 3.0mm 3.0-2.5mmER8-137 3.5mm 3.5-3.0mmER8-137 3.5mm 3.5-3.0mmER8-157 4.0mm 4.0-3.5mmER8-157 4.0mm 4.0-3.5mmER8-177 4.5mm 4.5-4.0mmER8-177 4.5mm 4.5-4.0mmER8-196 5.0mm 5.0-4.5mmER8-196 5.0mm 5.0-4.5mm9 Pieces Set 0.5mm -ER8-09S5.0mm 9 PiecesER8-09Sby Set 0.5mm 0.5mm -5.0mm by 0.5mmER/TG/DA Collet ChucksER Collet ChucksOur patented Coolant Collets aredesignedOur patentedfor useCoolantwithColletscylindricalareshankdesignedtoolsfor(nouseflats).withCuttingcylindricaltoolshouldshank toolsbe inserted(no flats).theCuttingfull lengthtooloftheshouldcollet.beIfinsertedthese conditionsthe full lengthare notofmet,the collet.coolantIf theseleakageconditionsmay result.are notSealsmet, coolantup to maximumleakage maycoolantresult.pressureSeals up toofmaximum1000PSI.coolantpressure of 1000PSI.ollapseRange0-0.5mm5-1.0mm0-1.5mm5-2.0mm0-2.5mm5-3.0mm0-3.5mm5-4.0mm0-4.5mm5-5.0mm0-5.5mm5-6.0mm0-6.5mmER11 ColletsER11 ColletsSize range: 1/32” - 17/64”Size range: 1/32” - 17/64”INCHINCHPart Size CollapseNumber Part Size Collapse RangeNumber RangeE11-002 1/32” .031-.027”E11-002 1/32” .031-.027”E11-003 3/64” .047-.031”E11-003 3/64” .047-.031”E11-004 1/16” .063-.047”E11-004 1/16” .063-.047”E11-005 5/64” .078-.063”E11-005 5/64” .078-.063”E11-006 3/32” .094-.078”E11-006 Size range: 3/16” 3/32” - 17/64” .094-.078”E11-007 7/64” .109-.094”E11-007 7/64” .109-.094”E11-008 1/8” .125-.109”E11-008 INCH-COOLANT-THRU1/8” .125-.109”E11-009 9/64” .141-.125”E11-009 Part 9/64” CollapseE11-010 5/32” Size .141-.125”Number .156-.141”E11-010 5/32” .156-.141” RangeE11-011 11/64” .172-.156”E11-011 11/64” .172-.156”E11-012- 3/16” 1/32” .187-.172” -E11-012 3/16” .187-.172”E11-013- 13/64” 3/64” .203-.187” -E11-013 13/64” .203-.187”E11-014- 7/32” 1/16” .219-.203” -E11-014 7/32” .219-.203”E11-015- 15/64” 5/64” .234-.219” -E11-015 15/64” .234-.219”E11-016- 1/4” 3/32” .250-.234” -E11-016 1/4” .250-.234”E11-017- 17/64” 7/64” .266-.250” -E11-017 17/64” .266-.250”- 1/8” -Size Our range: patented 1.0mm-7.0mm Coolant Collets are(0.019”-0.275”)Size designed range: for 1.0mm-7.0mm use with cylindrical(0.019”-0.275”)shank tools (no flats). Cutting toolMETRICshould be inserted METRIC the full length ofthe Part collet. If these Sizeconditions Collapse are notNumber Partmet, coolant leakage Size Collapse RangeNumbermay result.RangeSeals up to maximum coolantE11-039 1.0mm 1.0-0.5mmE11-039 pressure of 1000PSI. 1.0mm 1.0-0.5mmE11-059 1.5mm 1.5-1.0mmE11-059 1.5mm 1.5-1.0mmE11-078 2.0mm 2.0-1.5mmE11-078 2.0mm 2.0-1.5mmE11-098 2.5mm 2.5-2.0mmE11-098Size range: 4.0mm-7.0mm2.5mm 2.5-2.0mmE11-118 3.0mm 3.0-2.5mmE11-118 3.0mm 3.0-2.5mmE11-137 METRIC-COOLANT-THRU3.5mm 3.5-3.0mmE11-137 3.5mm 3.5-3.0mmE11-157 Part 4.0mm Size 4.0-3.5mm CollapseE11-157 Number 4.0mm 4.0-3.5mm RangeE11-177 4.5mm 4.5-4.0mmE11-177 4.5mm 4.5-4.0mmE11-196- 5.0mm 1.0mm 5.0-4.5mm -E11-196 5.0mm 5.0-4.5mmE11-216- 5.5mm 1.5mm 5.5-5.0mm -E11-216 5.5mm 5.5-5.0mm- 2.0mm -E11-236 6.0mm 6.0-5.5mmE11-236- 6.0mm - 6.0-5.5mm -E11-255- 6.5mm 2.5mm 6.5-6.0mm -E11-255 6.5mm 6.5-6.0mmE11-275- 7.0mm 3.0mm 7.0-6.5mm -E11-275 7.0mm 7.0-6.5mm- 3.5mm -Size range: 3/16” - 17/64”Size range: 4.0mm-7.0mmSize range: 3/16” - 17/64”Size range: 4.0mm-7.0mmINCH-COOLANT-THRU METRIC-COOLANT-THRUINCH-COOLANT-THRU METRIC-COOLANT-THRUPartSize Collapse PartSize CollapseNumber PartSize Collapse Range Number PartSize Collapse RangeNumberRange NumberRange- 1/32” -- 1.0mm -- 1/32” -- 1.0mm -3/64” 1.5mm - 3/64” -- 1.5mm -1/16” 2.0mm - 1/16” -- 2.0mm -5/64” - - 5/64” -- - -3/32” 2.5mm - 3/32” -- 2.5mm -7/64” 3.0mm - 7/64” -- 3.0mm -1/8” 3.5mm - 1/8” -- 3.5mm -9/64” - 9/64” - E11-157(C) 4.0mm 4.0mm - 3.5mm5/32” E11-157(C) 4.0mm 4.0mm - 3.5mm- 5/32” -11/64” E11-177(C) 4.5mm 4.5mm - 4.0mm- 11/64” - E11-177(C) 4.5mm 4.5mm - 4.0mmE11-012(C) 3/16” .187” .183” E11-196(C) 5.0mm 5.0mm 4.5mmE11-012(C) 3/16” .187” - .183” E11-196(C) 5.0mm 5.0mm - 4.5mmE11-013(C) 13/64” .203” .199” E11-216(C) 5.5mm 5.5mm 5.0mmE11-013(C) 13/64” .203” - .199” E11-216(C) 5.5mm 5.5mm - 5.0mmE11-014(C) 7/32” .218” .214”E11-014(C) 7/32” .218” - .214” E11-236(C) 6.0mm 6.0mm - 5.5mmE11-015(C) 15/64” .234” .230” E11-236(C) 6.0mm 6.0mm - 5.5mmE11-015(C) 15/64” .234” - .230”E11-016(C) 1/4” .250” .246” E11-255(C) 6.5mm 6.5mm - 6.0mmE11-016(C) 1/4” .250” - .246” E11-255(C) 6.5mm 6.5mm - 6.0mmE11-017(C) 17/64” .265” .261” E11-275(C) 7.0mm 7.0mm 6.5mmE11-017(C) 17/64” .265” - .261” E11-275(C) 7.0mm 7.0mm - 6.5mm- 9/64” -E11-157(C) 4.0mm 4.0mm - 3.5mm- 5/32” -ER11 Coolant Collets SetsER11 Coolant Collets Sets- 11/64” - E11-177(C) 4.5mm 4.5mm - 4.0mmE11-14S 14 Piece Set 1/16” 1/4” by 64thsE11-6S(C) 6 Piece Set 3/16” - 17/64” by 64thsE11-14S E11-012(C) 14 Piece 3/16” Set 1/16” .187” - 1/4” .183” by 64ths E11-196(C) 5.0mm 5.0mm - 4.5mm E11-6S(C) 6 Piece Set 3/16” - 17/64” by 64thsE11-12S E11-013(C) 12 13/64” Piece Set 1.0mm .203” - -.199”7.0mm by E11-216(C) 0.5mm 5.5mm 5.5mm - 5.0mm E11-7S(C) 7 Piece Set 3.9mm - 7.0mm by 0.5mmE11-12S 12 Piece Set 1.0mm - 7.0mm by 0.5mmE11-7S(C) 7 Piece Set 3.9mm - 7.0mm by 0.5mmE11-014(C) 7/32” .218” - .214”E11-236(C) 6.0mm 6.0mm - 5.5mmE11-015(C) 15/64” .234” - .230”E11-016(C) 1/4” .250” - .246” E11-255(C) 6.5mm 6.5mm - 6.0mmE11-017(C) 17/64” .265” - .261” E11-275(C) 7.0mm 7.0mm - 6.5mmER11 Collets SetsER11 Collets Sets4646ER11 Coolant Collets SetsE11-6S(C)E11-7S(C)6 Piece Set 3/16” - 17/64” by 64ths7 Piece Set 3.9mm - 7.0mm by 0.5mm32

800-543-6237847-367-4800 www.lyndexnikken.comwww.lyndexnikken.comER ColletER/TG/DAChucksCollet ChucksER16 ColletsSize range: 1/32” - 13/32”Size range: 1.0mm - 10.0mm(0.039”-0.393”)Size range: 3/32” - 13/32”Our patented Coolant Collets aredesigned for use with cylindricalshank tools (no flats). Cutting toolshould be inserted the full length ofthe collet. If these conditions are notmet, coolant leakage may result.Seals up to maximum coolantpressure of 1000PSI.Size range: 4.0mm-10.0mm(0.157”-0.393”)ER/TG/DA Collet Chucks End Mill HoldersPartNumberINCHSizeCollapseRangePartNumberMETRICSize CollapseRangeINCH-COOLANT-THRUPartNumberSizeCollapseRangeMETRIC-COOLANT-THRUPartNumberSizeCollapseRangeE16-002 1/32” .031” - .027”E16-004 1/16” .063” - .047”E16-006 3/32” .094”- .078”- 7/64” -E16-008 1/8” .125” - .109”- 9/64” -E16-010 5/32” .156” - .125”- 11/64” -E16-012 3/16” .187” -.156”- 13/64” -E16-014 7/32” .219” -.187”- 15/64” -E16-016 1/4” .250” - .219”- 17/64” -E16-018 9/32” .281” - .250”- 19/64” -E16-020 5/16” .312” - .281”- 21/64” -E16-022 11/32” .344” - .312”- 23/64” -E16-024 3/8” .375” - .344”- 25/64” -E16-026 13/32” .406” - .375”E16-039 1.0mm 1.0-0.5mmE16-059 1.5mm 1.5-1.0mmE16-078 2.0mm 2.0-1.5mmE16-098 2.5mm 2.5-2.0mmE16-118 3.0mm 3.0-2.5mmE16-137 3.5mm 3.5-3.0mmE16-157 4.0mm 4.0-3.5mmE16-177 4.5mm 4.5-4.0mmE16-196 5.0mm 5.0-4.5mmE16-216 5.5mm 5.5-5.0mmE16-236 6.0mm 6.0-5.5mmE16-255 6.5mm 6.5-6.0mmE16-275 7.0mm 7.0-6.5mmE16-295 7.5mm 7.5-7.0mmE16-314 8.0mm 8.0-7.5mmE16-334 8.5mm 8.5-8.0mmE16-354 9.0mm 9.0-8.5mmE16-374 9.5mm 9.5-9.0mmE16-393 10.0mm 10.0-9.5mm- 1/32” -- 1/16” -E16-006(C) 3/32” .094” - .089”E16-007(C) 7/64” .109” - .105”E16-008(C) 1/8” .125” - .121”E16-009(C) 9/64” .140” - .136”E16-010(C) 5/32” .156” - .152”E16-011(C) 11/64” .171” - .167”E16-012(C) 3/16” .187” - .183”E16-013(C) 13/64” .203” - .199”E16-014(C) 7/32” .219” - .203”E16-015(C) 15/64” .234” - .219”E16-016(C) 1/4” .250” - .234”E16-017(C) 17/64” .266” - .250”E16-018(C) 9/32” .281” -.266”E16-019(C) 19/64” .297” - .281”E16-020(C) 5/16” .312” - .297”E16-021(C) 21/64” .328” - .312”E16-022(C) 11/32” .344” - .328”E16-023(C) 23/64” .359” - .344”E16-024(C) 3/8” .375” - .359”E16-025(C) 25/64” .391” - .375”E16-026(C) 13/32” .406” - .391”- 1.0mm -- 1.5mm -- 2.0mm -- 2.5mm -- 3.0mm -- 3.5mm -E16-157(C) 4.0mm 4.0mm - 3.5mmE16-177(C) 4.5mm 4.5mm - 4.0mmE16-196(C) 5.0mm 5.0mm - 4.5mmE16-216(C) 5.5mm 5.5mm - 5.0mmE16-236(C) 6.0mm 6.0mm - 5.5mmE16-255(C) 6.5mm 6.5mm - 6.0mmE16-275(C) 7.0mm 7.0mm - 6.5mmE16-295(C) 7.5mm 7.5mm - 7.0mmE16-314(C) 8.0mm 8.0mm - 7.5mmE16-334(C) 8.5mm 8.5mm - 8.0mmE16-354(C) 9.0mm 9.0mm - 8.5mmE16-374(C) 9.5mm 9.5mm - 9.0mmE16-393(C) 10.0mm 10.0mm - 9.5mmER16 Collets SetsER16 Coolant Collets SetsE16-12SE16-09S12 Piece Set 1/32” - 13/32” by 32nds9 Piece Set 1.0mm - 10.0mm by 1mmE16-11S(C) 11 Piece Set 3/32” - 13/32” by 32ndsE16-13S(C) 13 Piece Set 4.0mm - 10.0mm by 0.5mmSee dimensional data for ER16 Collets on page 31.4733

800-543-6237847-367-4800 www.lyndexnikken.comwww.lyndexnikken.comER ColletER/TG/DAChucksCollet ChucksER/TG/DA Collet Chucks End Mill HoldersER20 ColletsSize range: 1/16” - 1/2”PartNumberINCHSizeCollapseRangeSize range: 2.0mm - 13.0mm(0.039”-0.511”)PartNumberMETRICSizeCollapseRangeSize range: 5/32” - 1/2”INCH-COOLANT-THRUPartNumberSizeCollapseRangeOur patented Coolant Collets aredesigned for use with cylindricalshank tools (no flats). Cutting toolshould be inserted the full length ofthe collet. If these conditions are notmet, coolant leakage may result.Seals up to maximum coolantpressure of 1000PSI.Size range: 5.0mm-13.0mm(0.196”-0.511”)METRIC-COOLANT-THRUPartNumberSizeCollapseRangeE20-004 1/16” .063” - .047”E20-006 3/32” .094” - .078”E20-008 1/8” .125” - .109”E20-010 5/32” .156” - .125”- 11/64” -E20-012 3/16” .187” - .156”- 13/64” -E20-014 7/32” .219” - .187”- 15/64” -E20-016 1/4” .250” - .219”- 17/64” -E20-018 9/32” .281” - .250”- 19/64” -E20-020 5/16” .312” - .281”- 21/64” -E20-022 11/32” .344” - .312”- 23/64” -E20-024 3/8” .375” - .344”- 25/64” -E20-026 13/32” .406” - .375”- 27/64” -E20-028 7/16” .437” - .406”- 29/64” -E20-030 15/32” .469” - .437”- 31/64” -E20-032 1/2” .500” - .469”E20-078 2.0mm 2.0-1.0mmE20-118 3.0mm 3.0-2.5mmE20-137 3.5mm 3.5-2.5mmE20-157 4.0mm 4.0-3.5mm- 4.5mm -E20-196 5.0mm 5.0-4.0mm- 5.5mm -E20-236 6.0mm 6.0-5.0mm- 6.5mm -E20-275 7.0mm 7.0-6.0mm- 7.5mm -E20-314 8.0mm 8.0-7.0mm- 8.5mm -E20-354 9.0mm 9.0-8.0mm- 9.5mm -E20-393 10.0mm 10.0-9.0mm- 10.5mm -E20-433 11.0mm 11.0-10.0mmE20-452 11.5mm 11.5-11.0mmE20-472 12.0mm 12.0-11.0mm- 12.5mm -E20-511 13.0mm 13.0-12.0mm- 1/16” -- 3/32” -- 1/8” -E20-010(C) 5/32” .156” - .152”E20-011(C) 11/64” .172” - .167”E20-012(C) 3/16” 187” - .183E20-013(C) 13/64” .203” - .199”E20-014(C) 7/32” .219” - .203”E20-015(C) 15/64” .234” - .219”E20-016(C) 1/4” .250” - .234”E20-017(C) 17/64” .266” - .250”E20-018(C) 9/32” .281” - .266”E20-019(C) 19/64” .297” - .281”E20-020(C) 5/16” .312” - .297”E20-021(C) 21/64” .328” - .312”E20-022(C) 11/32” .344” - .328”E20-023(C) 23/64” .359” - .344”E20-024(C) 3/8” .375” - .359”E20-025(C) 25/64” .391” - .375”E20-026(C) 13/32” .406” - .391”E20-027(C) 27/64” .422” - .406”E20-028(C) 7/16” .437” - .422”E20-029(C) 29/64” .453” - .437”E20-030(C) 15/32” .469” - .453”E20-031(C) 31/64” .484” - .469”E20-032(C) 1/2” .500” - .484”- 2.0mm -- 3.0mm -- 3.5mm -- 4.0mm -- 4.5mm -E20-196(C) 5.0mm 5.0mm - 4.5mmE20-216(C) 5.5mm 5.5mm - 5.0mmE20-236(C) 6.0mm 6.0mm - 5.5mmE20-255(C) 6.5mm 6.5mm - 6.0mmE20-275(C) 7.0mm 7.0mm - 6.5mmE20-295(C) 7.5mm 7.5mm - 7.0mmE20-314(C) 8.0mm 8.0mm - 7.5mmE20-334(C) 8.5mm 8.5mm - 8.0mmE20-354(C) 9.0mm 9.0mm - 8.5mmE20-374(C) 9.5mm 9.5mm - 9.0mmE20-393(C) 10.0mm 10.0mm - 9.5mmE20-413(C) 10.5mm 10.5mm - 10.0mmE20-433(C) 11.0mm 11.0mm - 10.5mmE20-452(C) 11.5mm 11.5mm - 11.0mmE20-472(C) 12.0mm 12.0mm - 11.5mmE20-492(C) 12.5mm 12.5mm - 12.0mmE20-511(C) 13.0mm 13.0mm - 12.5mmER20 Collets SetsER20 Coolant Collets SetsE20-15SE20-11S15 Piece Set 1/16” - 1/2” by 32nds11 Piece Set 2.0mm - 13.0mm by 1mmE20-12S(C) 12 Piece Set 5/32” - 1/2” by 32ndsE20-17S(C) 17 Piece Set 5.0mm - 13.0mm by 0.5mmSee dimensional data for ER20 Collets on page 31.3448

800-543-6237847-367-4800 www.lyndexnikken.comwww.lyndexnikken.comER/TG/DA Collet ChucksER Collet ChucksER25 ColletsSize range: 1/16” - 5/8”PartNumberINCHSizeCollapseRangeSize range: 2.0mm - 16.0mm(0.039”-0.629”)PartNumberMETRICSizeCollapseRangeSize range: 7/32” - 5/8”INCH-COOLANT-THRUPartNumberSizeCollapseRangeOur patented Coolant Collets aredesigned for use with cylindricalshank tools (no flats). Cutting toolshould be inserted the full length ofthe collet. If these conditions are notmet, coolant leakage may result.Seals up to maximum coolantpressure of 1000PSI.Size range: 6.0mm-16.0mm(0.236”-0.629”)METRIC-COOLANT-THRUPartNumberSizeCollapseRangeER/TG/DA Collet Chucks End Mill HoldersE25-004 1/16” .063” - .047”E25-006 3/32” .094” - .078”E25-008 1/8” .125” - .109”E25-010 5/32” .156” - .125”E25-012 3/16” .187” - .156”E25-014 7/32” .218” - .187”- 15/64” -E25-016 1/4” .250” - .219”- 17/64” -E25-018 9/32” .281” - .250”- 19/64” -E25-020 5/16” .312” - .281”- 21/64” -E25-022 11/32” .344” - .312”- 23/64” -E25-024 3/8” .375” - .344”- 25/64” -E25-026 13/32” .406” - .375”- 27/64” -E25-028 7/16” .437” - .406”- 29/64” -E25-030 15/32” .469” - .437”- 31/64” -E25-032 1/2” .500” - .469”- 33/64” -E25-034 17/32” .531” - .500”- 35/64” -E25-036 9/16” .563” - .531”- 37/64” -E25-038 19/32” .594” - .563”- 39/64” -E25-040 5/8” .625” - .594”E25-078 2.0mm 2.0-1.0mmE25-118 3.0mm 3.0-2.0mmE25-137 3.5mm 3.5-2.5mmE25-157 4.0mm 4.0-3.0mmE25-196 5.0mm 5.0-4.0mmE25-236 6.0mm 6.0-5.0mmE25-275 7.0mm 7.0-6.0mmE25-314 8.0mm 8.0-7.0mmE25-354 9.0mm 9.0-8.0 mmE25-393 10.0mm 10.0-9.0mmE25-433 11.0mm 11.0-10.0mmE25-452 11.5mm 11.5-11.0mmE25-472 12.0mm 12.0-11.0mmE25-511 13.0mm 13.0-12.0mmE25-551 14.0mm 14.0-13.0mmE25-590 15.0mm 15.0-14.0mmE25-629 16.0mm 16.0-15.0mm- 1/16” -- 3/32” -- 1/8” -- 5/32” -- 3/16” -E25-014(C) 7/32” .219” - .203”E25-015(C) 15/64” .234” - .219”E25-016(C) 1/4” .250” - .234”E25-017(C) 17/64” .266” - .250”E25-018(C) 9/32” .281” - .266”E25-019(C) 19/64” .297” - .281”E25-020(C) 5/16” .312” - .297”E25-021(C) 21/64” .328” - .312”E25-022(C) 11/32” .344” - .328”E25-023(C) 23/64” .359” - .344”E25-024(C) 3/8” .375” - .359”E25-025(C) 25/64” .391” - .375”E25-026(C) 13/32” .406” - .391”E25-027(C) 27/64” .422” - .406”E25-028(C) 7/16” .437” - .422”E25-029(C) 29/64” .453” - .437”E25-030(C) 15/32” .469” - .453”E25-031(C) 31/64” .484” - .469”E25-032(C) 1/2” .500” - .484”E25-033(C) 33/64” .516” - .500”E25-034(C) 17/32” .531” - .516”E25-035(C) 35/64” .547” - .531”E25-036(C) 9/16” .563” - .547”E25-037(C) 37/64” .578” -.563”E25-038(C) 19/32” .594” - .578”E25-039(C) 39/64” .609” - .594”E25-040(C) 5/8” .625” - .609”- 2.0mm -- 3.0mm -- 3.5mm -- 4.0mm -- 5.0mm -E25-236(C) 6.0mm 6.0mm - 5.5mmE25-255(C) 6.5mm 6.5mm - 6.0mmE25-275(C) 7.0mm 7.0mm - 6.5mmE25-295(C) 7.5mm 7.5mm - 7.0mmE25-314(C) 8.0mm 8.0mm - 7.5mmE25-334(C) 8.5mm 8.5mm - 8.0mmE25-354(C) 9.0mm 9.0mm - 8.5mmE25-374(C) 9.5mm 9.5mm - 9.0mmE25-393(C) 10.0mm 10.0mm - 9.5mmE25-413(C) 10.5mm 10.5mm - 10.0mmE25-433(C) 11.0mm 11.0mm - 10.5mmE25-452(C) 11.5mm 11.5mm - 11.0mmE25-472(C) 12.0mm 12.0mm - 11.5mmE25-492(C) 12.5mm 12.5mm - 12.0mmE25-511(C) 13.0mm 13.0mm - 12.5mmE25-531(C) 13.5mm 13.5mm - 13.0mmE25-551(C) 14.0mm 14.0mm - 13.5mmE25-570(C) 14.5mm 14.5mm - 14.0mmE25-590(C) 15.0mm 15.0mm - 14.5mmE25-610(C) 15.5mm 15.5mm - 15.0mmE25-629(C) 16.0mm 16.0mm - 15.5mmER25 Collets SetsER25 Coolant Collets SetsE25-19SE25-14S19 Piece Set 1/16” - 5/8” by 32nds14 Piece Set 2.0mm - 16.0mm by 1mmE25-13S(C) 13 Piece Set 1/4” - 5/8” by 32ndsE25-21S(C) 21 Piece Set 6.0mm - 16.0mm by 0.5mmSee dimensional data for ER25 Collets on page 31.4935

www.lyndexnikken.com1468 Armour BoulevardMundelein, IL 60060E-mail: inquiries@lyndexnikken.comPhone: (847) 367-4800Fax: (847) 367-4815CAT2012-MRAM