Bredel SPX65 - Watson-Marlow

Bredel SPX65 - Watson-Marlow

Bredel SPX65 - Watson-Marlow

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

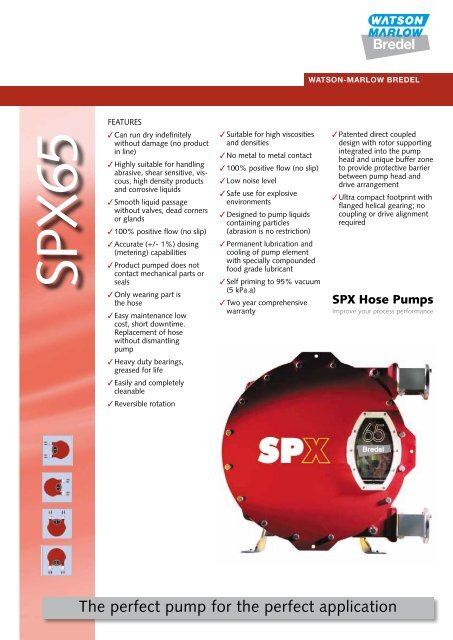

WATSON-MARLOW BREDELFeaturesspx65✓ Can run dry indefinitelywithout damage (no productin line)✓ Highly suitable for handlingabrasive, shear sensitive, viscous,high density productsand corrosive liquids✓ Smooth liquid passagewithout valves, dead cornersor glands✓ 100% positive flow (no slip)✓ Accurate (+/- 1%) dosing(metering) capabilities✓ Product pumped does notcontact mechanical parts orseals✓ Only wearing part isthe hose✓ Easy maintenance lowcost, short downtime.Replacement of hosewithout dismantlingpump✓ Suitable for high viscositiesand densities✓ No metal to metal contact✓ 100% positive flow (no slip)✓ Low noise level✓ Safe use for explosiveenvironments✓ Designed to pump liquidscontaining particles(abrasion is no restriction)✓ Permanent lubrication andcooling of pump elementwith specially compoundedfood grade lubricant✓ Self priming to 95% vacuum(5 kPa.a)✓ Two year comprehensivewarranty✓ Patented direct coupleddesign with rotor supportingintegrated into the pumphead and unique buffer zoneto provide protective barrierbetween pump head anddrive arrangement✓ Ultra compact footprint withflanged helical gearing; nocoupling or drive alignmentrequiredSPX Hose PumpsImprove your process performance✓ Heavy duty bearings,greased for life✓ Easily and completelycleanable✓ Reversible rotationThe perfect pump for the perfect application

<strong>SPX65</strong>• Maximum flow:32,200 L/h• Capacity:6.7 L/rev• Maximum discharge pressure:1,600 kPa [16 bar]• Inner diameter pump element:Ø 65 mm• Lubricant required:20 litresRequiredmotor power[kW] 11.010.08.06.04.02.031600 kPa21000 kPa5750 kPa500 kPa4Producttemperature[°C]4050607080• Minimum starting torque:1150 Nm1 6100 kPa = 1 barPump speed [rpm]Capacity [L/h]104000208000301200040160005020000602400070280008032000Continuous Duty Intermittent Duty Maximum 2 hours operation followed by minimum 1 hour stopHOW TO USE THE CURVES1. Flow required indicates pump speed2. Calculated discharge pressure3. Net motor power required4. Product temperature5. Calculated discharge pressure6. Maximum recommended pump speedNote: The area of continuous operation diminishes with increased product temperatures.For product temperatures > 40 ºC, the area of continuous operation reduces to the corresponding red temperature line.BCSx øQON BC.RL1L2EH1DHF J K M OGANLTypeABCDEFGHH1JKLmaxL1L2maxMNOPQRS<strong>SPX65</strong>105958037461526807401036525104137117214148641522050Ø18Ø181454All dimensions in [mm]

Nonfood CompoundsTECHNICAL SPECIFICATIONSSupply:up to 2.2 kW: 230/400 V - 3 phases - 50 Hz3.0 kW and larger: 400/690 V - 3 phases - 50 HzOperating Speeds:Minimum starting torque:1150 NmFluid Temperature Range*: -10 °C up to 80 °CAmbient Temperature Range**: -20 °C up to 45 °CHose Lubricant Required:20 litresFlow Range:up to 32,200 L/hrDischarge Pressure:up to 1,600 kPa [16 bar]Suction Pressure:9.5 metres lift to 200 kPa [2 bar]Available Hose Materials:NR, NBR, EPDM,Available flanges:DIN, ASA, JIS: mild steel galvanisedDIN, ASA, JIS: AISI 316Available inserts:aISI 316, PP, PVC.Optional High Level Hose Leak Sensor: NO or NC: 1A max, 250V max, 50 VA maxMATERIALS OF CONSTRUCTIONPumphousing:Cast-ironRotor:Cast-ironPressing shoes:aluminium or EpoxyCover:Mild steelBrackets:Mild steel, galvanizedSupport Frame:Mild steel, galvanizedMounting material:Mild steel, galvanizedHose Clamps: aISI 316Shaft:alloy SteelSeals:Neoprene or NitrilePumphead Weight:558 kg* Please consult your <strong>Bredel</strong> representative for lower or higher temperature operation.** Allowable ambient temperature is based on pump capabilities and may be further limited bygearbox ambient capabilities.<strong>SPX65</strong>12111098765432100 20 40 60 80Pump speed [rpm]Number of shims1600 kPa - 16 bar - 232 psi1250 kPa - 12.5 bar - 181 psi1000 kPa - 10 bar - 145 psi750 kPa - 7.5 bar - 109 psi500 kPa - 5 bar - 72.5 psi250 kPa - 2.5 bar - 36 psi0 kPa - 0 bar - 0 psiSHIMS SPECIFICATIONS.When the temperatures are above 60 °C alwaysuse one shim less than indicated in the diagrams.Always round up the number of shims.www.bredel.comSluisstraat 7 - P.O. Box 47 - NL-7490 AA Delden - The NetherlandsTel.: +31 74 3770000 - Fax: +31 74 3761175 - Email: hosepumps@wmpg.com12072010-<strong>SPX65</strong>The information contained in this document is believed to be correct at the time of publication, but <strong>Watson</strong>-<strong>Marlow</strong> <strong>Bredel</strong> accepts no liability forany error it contains, and reserves the right to alter specifications without prior notice. All mentioned values in this document are values undercontrolled circumstances at our test bed. Actual flow rates achieved may vary because of changes in temperature, vis cosity, inlet and dischargepressures and/or system configuration. SPX, DuCoNite ® , Bioprene ® and <strong>Bredel</strong> are registered trademarks.Program Listed (H1)(Registration 123204)NEN-EN-ISO9001:2000