implementation of quality tools in small medium industry - Universiti ...

implementation of quality tools in small medium industry - Universiti ...

implementation of quality tools in small medium industry - Universiti ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

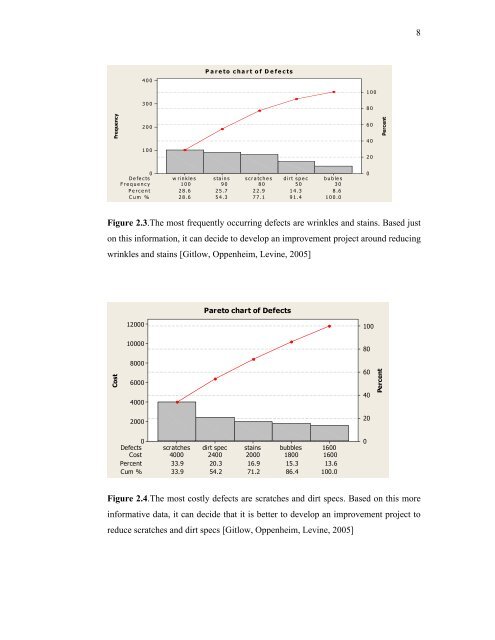

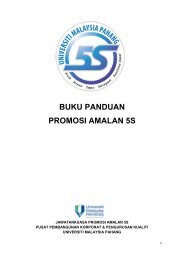

84 0 0P a r e t o c h a r t o f D e f e c t s1 0 03 0 08 0Frequency2 0 06 04 0Percent1 0 02 00D e fe c ts w r <strong>in</strong> k le s s ta <strong>in</strong> s s c r a tc h e s d ir t s p e c b u b le sF r e q u e n c y 1 0 0 9 0 8 0 5 0 3 0P e r c e n t 2 8 . 6 2 5 .7 2 2 .9 1 4 .3 8 .6C u m % 2 8 . 6 5 4 .3 7 7 .1 9 1 .4 1 0 0 .00Figure 2.3.The most frequently occurr<strong>in</strong>g defects are wr<strong>in</strong>kles and sta<strong>in</strong>s. Based juston this <strong>in</strong>formation, it can decide to develop an improvement project around reduc<strong>in</strong>gwr<strong>in</strong>kles and sta<strong>in</strong>s [Gitlow, Oppenheim, Lev<strong>in</strong>e, 2005]Pareto chart <strong>of</strong> Defects120001000010080Cost8000600040006040Percent2000200Defects scratches dirt spec sta<strong>in</strong>s bubbles 1600Cost 4000 2400 2000 1800 1600Percent 33.9 20.3 16.9 15.3 13.6Cum % 33.9 54.2 71.2 86.4 100.00Figure 2.4.The most costly defects are scratches and dirt specs. Based on this more<strong>in</strong>formative data, it can decide that it is better to develop an improvement project toreduce scratches and dirt specs [Gitlow, Oppenheim, Lev<strong>in</strong>e, 2005]