download

download

download

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Customer magazine by Putzmeister Group 78Truck-mountedconcrete pumpsThe full rangeCopper miningPM shotcrete machinesIn the land of the elephantPutzmeister in IndiaOriginals are betterCopies aren‘t worth itVisit us in Munich, April 19 – 25, 2010in Hall B6, stand 100 / 400PM 4300 GB

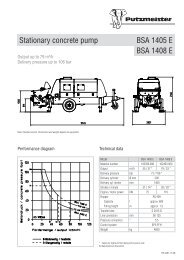

ForewordForewordTruck-mounted concrete pumps3Titel1Welcome to Bauma, welcome toPutzmeister in hall B6.New solutions in practice andthe full range at Bauma4M 49-5 – With 4 axles in the fast laneTechnologyImportant PUMI functions significantly improvedTelebelt –From specialist to attractive allrounderIncreased profitability for the prefabricated parts industryThe P 13 piston pump –the “offroad plastering machine”Bauma partner country India“Our core competences remainproduct, quality and service”Not just for India –robust and cost-effective trailer concrete pumpMining and tunnelingNew high-performance pumpfor mining tailings and fly ashThe new SPM 4207 – concrete sprayingspecially for small tunnel cross-sectionsServicesFleet management with the i-DAISYinternational web application69121322141617198Title picture: The Colorado River Bridgeon the Hoover Dam crosses the river at aheight of approx. 294m.The main contractor for the project was anObyashi/PSM Joint Venture. The sub-contractorfor concrete pumping was QuinnConcrete Pumping. From the outset, Putzmeisterwas involved in this project in anadvisory capacity. In the end, a wide rangeof PM machines was used: the stationaryconcrete pumps BSA 2107 HP-E and BSA2109 H-E, the stationary booms MX 32/36 Zand MX 36/40 Z, and the truck-mountedconcrete pumps M 42 and M 58.Due to the heat and to avoid blockages,pumping was carried out predominantlyat night.ImprintPublisher:Putzmeister Concrete Pumps GmbH,Max-Eyth-Straße 10,72631 Aichtal / Germany2The last two years have been marked bydramatic changes in the global economyand almost every company has beenaffected by this. And in many meetings, wehave learnt from you, our customers, howyou are adjusting to this in your business.We have based our trade fair appearanceon this: with new machines and plant solutions,which can also open up opportunitiesin the difficult market environment.These include the M 49-5 truck-mountedconcrete pump on 4 axles, a new shotcretemachine for small tunnel diameters andthe Telebelt TBS 130, which can be a newbusiness approach for service providers,as a semi-trailer. Consistent further developmentand staggered services aim tooptimise applications and reduce your operatingcosts.India is the partner country of this year‘sBauma. That‘s why this issue includesa brief insight into the activities of ourIndian subsidiary, which has made a goodname for itself there in just a short time.Our trade fair stand for 2010, as always, isin hall B6. This should give you an outwardsign that we, the new company management,stand for continuity in accordancewith our motto “Serve, Improve, Createvalue”.We look forward to your visit.Norbert ScheuchManaging DirectorPutzmeister Holding GmbH (Chairman) andPutzmeister Concrete Pumps GmbH (CEO)3 4Dr. Robert AbelManaging DirectorPutzmeister Concrete Pumps GmbH (CCO)Economic concrete placement beyondthe reach of truck-mounted concrete pumps10Editorial department: Volker WehnerPutzmeister Concrete Pumps GmbHBeware of cheap parts and dumping offers!Putzmeister used machines –first class from second hand2023Layout/DTP: GleisNeun GmbH,Gerbergasse 16,97877 Wertheim / GermanyPrint: Offizin Scheufele GmbH + Co. KG,Tränkestraße 17,70597 Stuttgart / Germany2 PM 4300 GB PM 4300 GB 3

Truck-mounted concrete pumpsTruck-mounted concrete pumps5Maximum reach of 20 to 70 m7M 20-4Ideal for halls, under bridges, etc. with3.9 m minimum unfolding and workingheight. It also has the smallestsupport area and is extremely manoeuvrableon the road.8M 36-4The bestseller in the 30 m class: Versatilethanks to the flexible Z foldsystem and small support area..M 42-4 in use in Emirate Scharjah (UAE)Truck-mounted concrete pumps – newsolutions in practice and the full range9Bauma tip: At the trade fair, we willbe performing a live demonstrationof the latest version of the Follow Metechnology on the M 36-4.M 42-5Allrounder on 4 axles with flexible5-arm RZ fold system.Practical detail: The container on thesupport leg gives additional storagespace.At the trade fair stand, Putzmeister willexhibit many models, from the smallest tothe biggest truck-mounted concrete pump.The machines, with vertical boom reachesof approximately 20 to 70 m are, as shownin the following overview, very specificallytailored to the needs or requirements ofindividual countries and applications.With various models, Putzmeister showsits wide range of innovative technologysuch as Follow-me, EBC (Ergonic BoomControl) or the patented TRDV variableposition support system. There is alsopractice-oriented equipment and options,such as the Sanima kit, radio remote controlwith display, solutions for the extensionof end hoses, etc. •10M 49-5Maximum reach and optimal priceperformanceratio: Available either on4 or 5 axles. On the Chinese market, aspecial version of the M 49-5 is available(see next page).The large boom for IndiaNot exhibited at Bauma in Munich:The BSS 46-5 truck-mountedconcrete pump exhibited for thefirst time at the Indian Excon lastNovember.This large boom trailer is speciallytailored to the specific requirementsof the Indian market. Aboveall, the Indian conditions for approvalfor road use had to be met. Since4-axle vehicles are limited to a maximumgross weight of 31 tons, 46 mvertical reaches are not so feasible.The answer is a 3-axle tractor unit with3-axle trailer, which is significantly underthe permissible gross weight of 44 tons.6Another important argument, in additionto the enormous reach with theflexible 5-arm boom, is the efficientindependent power unit. In addition,it is possible to pump without a tractorunit. This means the tractor unit isfree to be used for other tasks. •BSS 46-5 –the 5-arm large boomspecially designed forthe Indian market1112M 58-5The large boom on 5 axles with spacesaving,variable position TRDV support.This means the machine doesn‘ttake up any more space than is absolutelynecessary.M 70-5The world‘s longest 5-arm boom inactual construction site use. Full utilisationof the reach withoutlimiting pump torque. Theinnovative IRS support technologyensures minimum spacerequirements.4 PM 4300 GBPM 4300 GB 5

Truck-mounted concrete pumpsServicesM 49-5 – with 4 axles in the fast laneThe request for maximum reach on 4 axlesfirst came from the Chinese market. Putzmeisterexhibited its new M 49-5 truckmountedconcrete pump for the first timeat the last Bauma Shanghai. The innovationwas an immediate success there.This was due to the right balance betweenreaching the permissible gross weight forthe 4-axle chassis (HINO) established onthe market there and the minimum supportarea with a flexible 5-arm boom. Inaddition, the price for the M 49-5 shouldbe significantly lower than the M 52-5 withthe highly flexible, variable position TRDVsupport. These advantages will be presentedby Putzmeister in Europe for the firsttime at the Bauma fair.The gross weight of this machine on 4axles is approx. 40 tons. It is therefore ofinterest wherever a large boom is requiredon a low-priced chassis with a maximumreach of 50 m. The RZ fold system offerscrucial advantages in certain applicationsituations in high-rise construction(see box). •The additional 5th arm and its hinge increase flexibility, possible uses andnet reach of a truck-mounted concrete pump (top). Due to a lack of manoeuvrability,a 4-arm boom is much more difficult to slip into buildings. Itmay have to give up on attaining its net reach, depending on how great thedistance is.1314Practicaltraining isworth itPutzmeister offers its customers a wide rangeof possibilities for training and furthertraining. In theory courses, with learningmodules developed in-house by Putzmeister,and in practical courses, users of Putzmeistermachines can learn the best way touse their PM products. •Please contact us at:www.pm-akademie.deImproper handling can be preventedthrough competent training.The range of Putzmeister collector‘smodels is certainly not as wide asthe range of actual 1:1 models. Butin terms of quality and attention todetail, Putzmeister is uncompromisinghere too. All available models are“Made in Germany“ and come fromthe famous model maker Conrad.At this year‘s Bauma, you can purchasethese concrete pumps, PUMIs andmortar machines in the Putzmeisteradvertising gift shop at trade fair prices.Moreover, they are available tocollectors via the Putzmeister webshop the whole year through. •With our qualified personnel, you can learn in practical situations, thereby avoidinglater operating errors. This increases safety for man and machine.16 17 18The worldwide local training coursesensure increased competence andefficiency.Training significantly reduces maintenancerequirements and costs.Concrete pump models for collectors1519You can find our shop at:www.mycybershop.de/shopPMBeside numerous models true to the original like the Pumi you will find ourexclusive anniversary model of the 1972 truck-mounted concrete pump inour webshop.Here, the 5-arm boom of the M 49-5 shows an enormous horizontal reach.6 PM 4300 GB PM 4300 GB 7

Fleet management systemPumiFleet management with thei-DAISY international web applicationImportant PUMI functionssignificantly improved22With i-DAISY, Putzmeister offers simplified,Internet-based scheduling of themachine fleet with machine location,especially for customers abroad.The connection between the vehicles andthe concrete pump headquarters is establishedvia GPRS (General Packet RadioService). Access via the Internet means thesystem is available internationally. To thisend, certain technical, personnel and linguisticconditions are required on site.With i-DAISY, the company‘s entire vehiclefleet including truck mixers, silo trains,etc. can be scheduled. Likewise, an economicallyviable cooperation is possible foroperators with widespread sites and partners.These are the experiences of the RenoPumbeton AG concrete pumping service inMaienfeld, Switzerland, for example.Reno Pumpbeton AG is a joint venture of4 local concrete plants. They joined forcesin order to offer their customers a pumpingservice. Each pump is stationed ata different site and pump scheduling isperformed locally at the respective concreteplants. Mr Tobler (technical manager)reports that in the past this meantthat several calls were often required bet-Entry of customer orderTelephone reception ofcustomer orderScheduling diagram –order progressautomaticallyDisplay ofgeographical locationween the plants and the customer in orderto reserve a site use. This system was verytime-consuming and inefficient for thecustomer and for the schedulers. With theintroduction of i-DAISY at the end of 2007,the situation improved instantly.Complete overview for schedulers.At any time.Although scheduling is still decentralised,each scheduler has a full overview of theavailability of the concrete pumps and thestatus of the current orders. He can thereforebook a site use for a customer or, if thedesired pump type is not available, offeralternatives immediately.This clear plus point in service is ratedhighly by the customers and the schedulers,after initial scepticism, can no longerimagine working without i-DAISY. Inthe opinion of Reno Pumpbeton AG, experiencewith i-DAISY has shown the followingadvantages: Easy operation, minimumtraining effort, low investment costs (PCwith Internet connection), improved customerservice and increased efficiency, optimalplanability and utilisation of the fleet.Delivery noteadministration –semi-automaticTime recordingOrder processingGPS locationA further advantage is that i-DAISY increasestransparency, resulting in a morevisible site status of the vehicle, time recordingby clocking in and off in the vehicle,GPS localisation of the vehicle and displayof the vehicle and site of use on the map.In addition, fully automatic constructionsite processing is possible with i-DAISY.In other words, the construction site status,the arrival and departure from theconstruction site, as well as the start andend of pumping operations are determinedand transmitted by the vehicle equipment,BCL on-board computer, without interventionby the driver.i-DAISY can also be combined with the reducedand more cost-effective functions ofthe standalone module i-GOT-U. There, asin i-DAISY, the current vehicle positionsand, retrospectively, the routes driven,are displayed. In addition, the system cansend e-mails or text messages to definedaddressees, for example if a vehicle leavesa geographically defined region or interventionsare made on the BCT on-boardcomputer. •Order data/GPS dataInternetCentral internet serverCommunication /radio datatransmissionGPRS (TCP/IP)20The PUMI 31.89 S exhibited at the trade fair stand is also available in a version witha vertical reach of nearly 28 m.Seven years ago, we introduced theErgonic control for the PUMI. This triedand tested technology allows us to realisefurther application-oriented functionseasily. Some of these are new at BAUMA.We spoke with Frank Riderer, the headof the PUMI Business Sector, on thissubject.PM: What are the innovations in the improvedPUMI?FR: We have several interesting new options.These include, for example, a radioremote control with display.PM: This will primarily help the machineoperator. Are there other new functions tohelp the operator?FR: Yes, with the software controlled Ergonic,it is possible to realise even complexprocesses, such as an automatic drainingfunction. This is difficult or impossibleto accomplish with purely hydraulic controls.PM: What does “automatic draining function”mean?FR: With this patent-pending function, thespeed of the mixer is adapted to the deliveryrate of the pump. That is, with a lowdelivery rate, the mixer also turns slowly.Jerky start-up and braking of the mixer, aswas the case before, is therefore resolved.PM: You are exhibiting a mixer cleaningfunction. What‘s behind this?FR: If this function is activated duringpumping, for example, the mixer drumautomatically rotates briefly to the rightand then to the left, without any interventionby the operator. This causes the waterin the drum to slosh to and fro so that anyconcrete stuck in the mixing spirals nearthe outlet can be continuously rinsed andwashed away with very little water.PM: What option do you consider to be particularlyinteresting?FR: The request by a Swiss customer,who wants to add water to the mixer drummetered via the radio remote control.PM: What is the advantage of this?FR: Often, after starting to pump, theplacement team complains that the concreteis too stiff. The machine operatormust then go from the site of concreteplacement to the machine to add water tothe concrete and then mix it through again.In future, this will be possible directly fromthe radio remote control.PM: Is it actually permissible to add water tothe concrete mixer?FR: It is permissible to add water to theconcrete if it is scheduled, there is a meteringdevice and the added water volume isnoted on the delivery note. •21Die PUMI 31.89 S in operationFrank RidererBusiness SectorManagerEmail:RidererF@pmw.deThe Ergonic radio remote controlwith display23248 PM 4300 GB PM 4300 GB 9

TelebeltSolutions for the prefabricated part industry30More profitability for theprefabricated parts industryAutocor is the name Putzmeister givesto systems for the prefabricated partsindustry, in which concrete pumps andplacement systems are used to placethe concrete particularly efficiently andeconomically in the formworks.32The tried and tested Putzmeister Telebelt will in future also be available in a new version as a semi-trailer.This will turn the material transport specialist into an unbeatably versatile multi-talent.From specialist toattractive allrounderThe Putzmeister Telebelt (TelescopicBelt Conveyor) is a versatile constructionmachine for placing concrete and arange of other materials up to a diameterof 300 mm. The constant pulsationand pressure-free material transport onthe belt allows for high placement (up to450 m 3 /h) with low operating costs.The world‘s biggest population of Telebeltmachines is in the USA. There, the Telebeltis used by service providers as an additionto the truck-mounted concrete pump andplaces not only concrete, but also hardcore,gravel, sand and other materials onconstruction sites.Outside the USA, the Telebelt has previouslybeen used predominantly in damconstruction. The reason for this is itsstrength in delivering standard concretesand non-pumpable concretes, such as coarseconcrete, earth-moist concrete or rollercompacted concrete. The Telebelt is alsoexcellently suited to special placementtasks in gardening and landscaping. There,materials like sand, earth and mulchcan be conveyed.With the new semi-trailer version TBS 130,it was possible to change the fields of useworld-wide quickly from specialist to allrounder.The semi-trailer now enables operationof a wide range of tractor unitsas a Telebelt with just minimal adaptationeffort. The country-specific approvalfor road use must be checked, however,a special chassis is no longer required inEurope. •31What does this mean for the operatoror investor?• significantly lower investment• almost every make can be used as thetractor unit, even a used machine ora machine from an existing fleet• onward sale is subject to hardlyany restrictions in terms of approvalfor road use and the exhaust gasstandard of the chassis. This makesfinancing easier.• lower fuel consumption throughthe use of the independent powerunit belonging to the semi-trailer• significantly lower wear costsper m 3 than with truck-mountedconcrete pumpsThe Telebelt is therefore worth it notonly for the high placement volumesof large projects. This is reasonenough to see a familiar subjectin a new light.When identifying a solution, for example,the elimination of bottlenecks, the reductionin maintenance times or less followupwork due to improved surface qualityall play a major role. And depending onthe annual capacity, end product, availablehall, investment framework, etc. customer-specificanswers have to be developedusing modular components. Previously,such systems were predominantly usedfor the production of prestressed concretetowers for wind energy generation, noiseprotection walls, prestressed concrete pipe,manholes, bridge elements or 2-dimensionalstructural concrete components.To represent this pumping technology,Putzmeister is exhibiting the rotorpump Autocor BQ 06 at Bauma.This is just as suitable for a stationaryinstallation as for mobile jobs, for which itis transported from hall to hall to the formworks.As another alternative, the machinecan be set up on a carrier frame and therebyused flexibly in different productionhalls (see photo).The BQ 06 fills formwork with concretequickly and economically. At the sametime, there is little concrete residue andcleaning is quick and easy. The Baumamachine shows an attached crane, as specialequipment, with which the deliveryline can be easily guided. Other advantagesof the rotor system: Only one individual,quick-change wear part and lownoise emissions.For prefabricated parts plants, Putzmeisteroffers not only machines and equipment,but also competent advice for the operator,so that the system can meet his individualrequirements. •This application case shows the filling of large structural parts. The Autocor BQ 06,secured to a carrier frame, moves along the formwork.Autocor ® benefits at a glance:33 34• ideal for prefabricated concrete parts plants which produce medium or largestructural prefabricated parts and use pumpable normal concrete or self-compressingconcrete• increases the production volume by up to 60%• high quality of parts thanks to continuous concrete placement• cleaner process thanks to closed system• no expensive and time-consuming lining of the formwork thanks toflexible boom• formwork can be filled from top or bottom• separation of crane operation and concreting process12 PM 4300 GB PM 4300 GB 13

Bauma partner country India“Our core competences remainproduct, quality and service”Extracts from an interview with Mr.M. Schmid-Lindenmayer on the successfulPutzmeister presence on the Indiasubcontinent.PM: For around 3 years, Putzmeister hasbeen present on the Indian market with itsown plant. What were the reasons for this?SL: We have invested in our own team andproduction here in India because we areconvinced of the big future for this marketand wanted to be able to meet demand formarketable products quickly and more efficiently.35Best experiencesVascon Engineers Limited, based inMumbai, is a distinguished Indian constructionfirm with revenue of morethan EUR 100 million. It focuses on constructionprojects in the fields of infrastructure,real estate and hotels. VasconEngineers Ltd. has more than 20 yearsexperience in the planning, development,construction and administrationof a wide range of projects throughoutIndia and has already received manyawards from the Builders Association ofIndia (BAI).For its construction projects, Vasconrelies on state-of-the-art constructionmachinery. This includes 6 BSA 1407 Dstationary pumps. A very prestigious referenceis the 190 m tall „Ruby Mill“ officecomplex project in Mumbai (the currentheight of construction is 160 m). This constructionproject is a classic example of howmechanisation improves construction orcycle times and safety standards. For concreteplacement, two M 32 stationary boomsand two BSA 1408 HD concrete pumps byPutzmeister, which are more efficient thanthe BSA 1407, are used.Mr. Manoj Kallur, Vice President Projectsof Vascon Engineers Ltd. says: “We have alreadybeen collaborating with Putzmeisterfor a long time and have had excellent experiences.The Putzmeister team providesus with excellent technical support andhelps us to use the machines optimally.The extraordinary good service provisionis a big strength. The excellent boommerits particular mention. It has significantlysimplified an important processand saved us a significant amount oftime and effort in concreting.” •40PM: Have you as OEM now got a differentstrategy?SL: Our strategy rests on two pillars. Onthe one hand, we want to develop productsthat the market really needs in a short timeand bring them onto the market. And onthe other hand, we are increasingly expandingour service network. This is a criticalsuccess factor in this business, whichPutzmeister is pursuing worldwide.PM: How far have you come in thisshort time?SL: In our modern plant in Goa, withan area of 100,000 m 2 , we now produce13 machine types for the Indian marketwith 250 employees. These are the stationarypumps BSA 1404, 1407, the Moli 1404,Moli 1407 in diesel and electric versionsand the truck-mounted concrete pump modelsBSF 32.09, BSF 36.07/09, BSF 42.09and BSS 46.14.Our BSA 1404 HD, launched last September,is now our most popular trailer concretepump in India. At the Excon tradefair in November 2009, we were the firstto exhibit a homologated M 42 and a M 46in semi-trailer version - marketable withthe Indian truck. These are machines thatsurprised everyone and which are ideal asa large boom for airports, flyovers, liquidgas tanks, cooling towers and other typesof large construction projects.PM: And to what extent have you built upyour service organisation so far?SL: We now already have 13 bases, distributedthroughout the country, such as inDelhi, Mumbai, Goa, Bangalore and Chennai,to name but a few. In addition, we haveThe modern Putzmeister plant in Goa, with an area of 100,000 m 2 , produces forthe Indian market.of course also invested predominantly inthe qualification of our people in sales andservice.PM: How has this expansion been possiblein such a short time?SL: There are several reasons. One of theseis our Indian employees who are willingto learn. They have learnt very quicklywith the help of experts from Germany. Inaddition, their training was very practical:in the after-sales service, during trainingand in the consultation and implementationof concrete placement in constructionprojects.PM: Are there examples of this?SL: Our pumps have been used in verymany projects, such as the constructionof the underground railway in Delhi, thesports complexes of the CommonwealthGames, many steel and power plants, etc.The most famous projects include RubyMill (high-rise in Mumbai), the biggest refineryin the world by ESSAR and Reliancein Jamnagar as well as the airports in Delhiand Mumbai, which were realised by L&T,India‘s biggest construction firm.PM: Finally, a completely different question:What are you expecting from Bauma 2010?SL: First, we‘re excited that India is thepartner country for this year‘s Bauma. Wehope that many customers will visit us atthis worldwide trade fair for constructionmachinery, that we will be able to makenew contacts and that they will ultimatelytake away a positive impression of the capabilityof the Putzmeister Group. •Michael Schmid-LindenmayerManaging Director,PutzmeisterConcrete MachinesPvt. Ltd. in Goa,IndiaPutzmeisterGoa, IndiaPutzmeister distributors and Service areto be found all over India by now.3637The Blessing Ritual: Breaking the coconutForeign visitors who are not familiar with the traditions of the Indian subcontinent arealways amazed at certain ceremonies and rituals in India. They are usually of a religiousorigin. A very common tradition, for example, is the centuries-old ritual of „breaking thecoconut“.During the ritual, a coconut is brokenuntil its milk leaks out.In the “pooja” ceremony, thanks aregiven for the new object and a blessingis sought.3839Here, the person conducting the ceremony,knocks the hard, dry coconut shell on ahard surface until a crack appears and theshell breaks. The sweet coconut milk leaksout and the drops are sprinkled over thevenerated object.The nut is then broken up completely. The1 to 2 cm thick flesh is peeled out, cut intocubes and distributed among the peopletaking part in the ceremony as a “Prasadam”.Indians understand “Prasadam” tomean holy food, which is first offered togod and then to the bystanders.This ritual has meanwhile been adopted bynearly all religious communities in India,and is celebrated today when valuableobjects are obtained or before the start ofany new project. For example, for the firstuse of a new vehicle, the laying of the foundationstone of a new building or the dedicationof a bridge, etc.Of course, at Putzmeister too in India, thedelivery of a new truck-mounted concretepump is celebrated with a “breaking thecoconut” ritual.This usually takes place in conjunctionwith a “pooja” ceremony, during whichattention is drawn to new things, thanksare expressed to the Almighty and the blessingof the divinities is solicited. •Vishvakarma – “God of the machines”Vishvakarma is the Hindu god of handicraft.According to Indian myth, henot only constructed the cities andpalaces of the gods, but also the universeitself.He is worshipped by all tradesmen,engineers and architects on the subcontinent.•4114 PM 4300 GB PM 4300 GB 15

Bauma partner country IndiaMiningNot only for India – robust andcost-effective trailer concrete pumpThe BSA 1004 HD was originally developedfor the Indian market. It was to beparticularly robust, easy to use and, aboveall, cheap to purchase and operate.And to enable it to be towed from oneconstruction site to the next on the at timesvery poor roads, the extremely compactmachine was equipped with a reinforcedchassis and leaf sprung running gear. Addto this a modified trailer hitch, which isalso suitable for tractor towing.The design of the concrete pump unit tookinto account that, in some emerging markets,concrete is often pumped relativelydry, with a low cement content, unbalancedgrading curve and aggregate consistingexclusively of broken material.The specialist for site-made mixThe machine was designed to enable evenmixed concrete to be pumped reliably onthe construction site. To reduce wear, PutzmeisterIndia has retained hard-chromeddelivery cylinders as well as particularlywear-resistant spare parts in the concretearea. This concrete pump is recommendedfor outputs of 40m 3 /h and delivery heightsof up to approx. 100 m.The BSA 1004 HD has no CE mark and istherefore not intended for sale or operationin European countries as yet. As a robustand compact machine, and with its excellentprice-performance ratio, it is especiallysuitable for use in Asia and Africa. •The BSA 1004 HD in India corresponds to the BSA 1404.Working elephants are not uncommon inIndia. No wonder then, that a Putzmeistermachine feels at home here.Basic data43BSA 1004 HD**Length5,677 mmWidth1,740 mmHeight2,080 mmWeight3,500 kgTheor. delivery rate 39 / 26* m 3 /hDelivery pressure70 /105* barDiameter delivery cylinder180 mm4244New high-performancepump for mining tailingsand fly ashPutzmeister Solid Pumps GmbH presentsa particularly high-pressure resistant andexpandable high-density solids pump formaterial transport underground: the HSP25100 SP. This pump system is of particularinterest for gold, diamond and zinc/lead mines which need to stabilise theirpitheads, backfill demineralised chamberseconomically or pump fine-grainedexcavated material out of the processingplant.The HSP 25100 SP is a large-volume pumpwith two individually-controlled deliverypistons. PSP specifically designed thepump to convey mining tailings and topump fly ash over great distances. In orderto achieve as constant a delivery as possiblewithout pressure peaks, Putzmeistercan, on request, equip these mining pumpswith the PCF control (PCF: Pressure ConstantFlow).The HSP pump head is modular in design.This makes a noticeable contribution toreducing operating costs. The replacementof worn parts now only involves repla-cing the actual worn-out components andno longer encompasses the entire pumphead.Lowering operating costs withthe right servicePutzmeister Solid Pumps GmbH focusesstrongly on the subject of reducing operatingcosts. There are numerous differentways of achieving this, depending on thecountry, operational requirements and coststructure. For this purpose, Putzmeisteroffers both technical advice and trainingfor service engineers.Project consultation increasesefficiencyOne of PSP‘s strengths is professional adviseon the handling, storage and deliveryof high-density substances. In the miningindustry, the company‘s is often consultedby operators and planners long before theplant is commissioned.A key factor in this is that the engineersat Putzmeister Solid Pumps GmbH bring46together their specialist knowledge of themachines and their experiences in pumpinghigh-density solids, with the pressureand flow characteristics of the media and incalculating and configuring pump systems.This, along with details about the procedureand the desired delivery rate, allows betteralternative solutions to be developed.This pays off - in lower costs and faster processeswith increased safety. •For further information:www.putzmeister-solid-pumps.deClever detail solutions:The modular pump head of thenew Putzmeister mining pumpHSP 25100 SP474845Delivery cylinder stroke1,000 mmStrokes / minute 26 / 17*Engine power49 kWHopper volumeaprox. 600 LFilling heigth1,300 mmTransfer tubeS 2018 PNFlap straight150 mmControl SystemVHS49* Values indicate piston side; ** corresponds to the BSA1404 in IndiaAt the silver mine in San Bartolomé (Bolivia), two HSP 25100 pumps convey theresidue of washed-out sludge into a dumping ground.Simple opening of the pump headsfor quicker inspection and replacementof wear parts16 PM 4300 GB PM 4300 GB 17

Mining and tunnelingDeep in the heartof the dark continentMining and tunnelingThe new SPM 4207: concrete sprayingspecially for small tunnel cross-sectionsThe Putzmeister wet shotcrete machinesare used worldwide.Here, the SPM 407 P works in a coppermine in the “copper belt”. This is the namefor Africa‘s biggest copper mining regiondeep in the heart of the continent.50 51The Bauma innovation for concretespatter in mines and tunnels is speciallydesigned for small cross-sections, withits boom reach of 8.5 m.The new SPM 4207 is the result of theexperience made on construction sitesthroughout the world in recent years withthe predecessor model SPM 407.58The highlight:52 53 5455 5657Handmade shotcreteThe SPM 702 is represented at the tradefair stand by its big brother. The lightweight,compact concrete pump can beused for a wide range of applications,such as concrete spraying, mortar injectionand other concreting projects.It is very well suited to narrow tunnelpipes and can be used optimally both forsecuring the head with shotcrete, and forfloor and arch concreting of crossways.The pump is available with a truck-mountedchassis or a carriage-like base structure.Of course, the machine operators havereceived intensive training at the time ofcommissioning. This is part of the worldwidePutzmeister Service, which ensures thatour customers are able to make the most oftheir new machines. •If equipped with an additive tank, it is constructedon a double-axle long trailer.The integrated metering device guaranteesadditive delivery proportional to the concreteoutput and therefore guarantees economicaland efficient use of the expensivechemicals. •Even in the PC variant with additionallyintegrated screw compressor, it remainsas compact and flexible as the predecessormodel. This was a particular request fromcustomers and makes its use significantlymore mobile and independent than withthe previously available machines withsimilar dimensions.The basis for this is an intelligent chassisconcept as a platform, on which differentcustomer-specific requirements can be realised.During development, great emphasiswas placed on a very robust frame, whichis adapted to the highest stresses of workingin a tunnel.Other advantages of the newshotcrete machine:• a cost-saving Additive ManagementSystem• an on-board computer with multilinguisticcolour display for showing performancedata, mixture breakdown,error diagnostics, warnings, etc.• safety driver‘s cab in accordance withthe ROPS/FOPS ordinance• xenon working lights• protected support legs• optional turbocharger for diesel enginefor use at high altitudesIn addition, there are option packages,which can be adapted to the different conditionsin mines and tunnels, such as: minetyres, cable drum with up to 100 m, catalyticconverter, diesel particle filter, integratedfire protection system, high-pressurecleaner or a water pump (operable both viadiesel and electric motor). •The SPM 4207 PC in use in a copper mine in Aljustrel (Portugal)Basic data SPM 4207 P SPM 4207 PCLenght 6,250 mm 6,970 mmWidth 2,000 mm 2,000 mmHeight 2,450 mm 2,450 mmWeight 6,900 Kg 8,400 KgSpraying arm / Reach Aliva 302 / 8,5 m Aliva 302 / 8,5 mTheoretical output 4 – 20 m 3 /h 4 – 20 m 3 /hConcrete maximal pressure 65 bar 65 barClimbing ability longitude (SAE norm) 48 % 35 %Engine 47.5 kW 47.5 kWFurther information: marketing@putzmeister.es59Dry run in simulationYou have to learn the right way to controlshotcrete machines. In order to avoidunnecessary material consumptionand beginner‘s operating errors, Putzmeisterhas developed a simulation programmewith which you can learn andpractice the operation of the controlunits virtually.You are welcome to try out oursimulation at Bauma.18 PM 4300 GB PM 4300 GB 19

ServicesServicesThe differences between genuine (left) and copies (right) are not always as obviousas with these oil filters, but they are nearly always bad for the customer.Beware of cheap partsand dumping offers!60are perfectly adequate for a machine witha relatively low output per year. These cheaperparts can also be a good alternative inregions with less abrasive aggregates. Onthe other hand, wherever the annual outputis very high, we recommend using ourhighly wear-resistant parts, which we arecontinuously developing and optimising.PM: And is this ultimately worth it for thecustomer?UT: We are convinced that it is. Even withthe “cheap” genuine parts, the fit, qualityand interaction with the other componentsare just right. The quality requirements aredocumented during the design stage and inthe drawing and do not develop at randomduring productionThis is evident not least of all in the factthat we offer service life guarantees inmany cases, or service contracts through toa full service agreement. In this case, withour genuine parts, we take on the risk ourselvesand can say that, in our experience,this is also worth it for us.61A mobile bypass filter extends the servicelife and makes savings on oil changes63Keep costs down withinspection and maintenanceIt is in particular during times when concretepumps are utilised less that investmentsin ongoing maintenance prove tobe a kind of “insurance” against costexplosions.In such times, unplanned high costs dueto failures or the replacement of expensivecomponents can no longer be generated atshort notice via earnings.One easy way of lowering costs is to fit abypass filter, which significantly improvesthe oil quality by means of fine particle filtering.Examples from maintenance agreementswith this option show that even after4000 operating hours the hydraulic fluiddid not require replacement and there wasno damage in the hydraulic system.Installation of the filter has therefore alreadypaid for itself after the first oil changeis due, as the costs of the filter, dependingon the size of the machine, are roughlyequal to the costs of the oil change. Theoil quality is simply inspected at the 500hour service, together with the operabilityof the filter.For more information on this and on completeservice packages through to the fullmaintenance agreement, speak to thePM service specialists at the trade fairstand or anytime after the trade fair. AtPutzmeister Services, in addition to thetechnical aspect of the solution, you canalso obtain important tips on correct maintenanceand operation in the context ofinspection and training packages. •Nothing is so tempting as a low price.But imitation parts can often be moreexpensive and not everything that hasthe same number is always the same.APS manager, Uwe Tichy, describes thedifferences.PM: Mr. Tichy, with Putzmeister genuineparts, you are trying to clearly distinguishyourself from offers by so-called pirates.Why?UT: First and foremost, we want to ensurethat the machines work reliably and safelyfor our customers. The higher the availabilityof our pumps, the more satisfied ourcustomers will be. Often, however, minordetails such as poorly fitting replacementand wear parts can cause faults which leadto an unexpected failure.PM: But reality shows that they work wellat times.UT: In this case working well simplymeans that the machine runs. The questionis whether or not it pumps economically.Unnecessarily high downtimes or excessivewear costs are not noticed in somecircumstances.Here, it is clear that the price of a part isoften only one side of the coin. Service life,effects on the pumping behaviour of themachine and operational safety are just asimportant and cost-intensive, but are notas easily measurable as the price.PM: What are the differences in theimitation parts?UT: Concrete pump manufacturers needlarger quantities of parts than the imitatorsand have also learnt from the mistakes ofthe 90s and made their replacement partprices more marketable. Therefore, theimitators have to make savings in orderto remain cheaper. They do this by cuttingcosts in terms of the material, processingor by deliberately ignoring safety regulationsand standards.PM: Do you have an example?UT: Yes. If, for example, you put less naturalrubber and, consequently, more sootinto a rubber component, it will naturallybe cheaper. But the abrasion values, tearresistanceand therefore the service lifewill suffer significantly. This occurs aboveall in seals and delivery pistons.It is only partially dependent on wherethe part was produced, for manufacturerstoo make international purchases. Theonly important thing is that the part complieswith the technical requirements andquality regulations.PM: But customers must keep an eye ontheir costs, and not all of them always needa high-quality part.UT: That‘s true. That‘s why Putzmeistergenuine parts includes a wide range ofwear parts and delivery lines. The rangeincludes very cost-effective parts, whichCopies can also be dangerous.Here is a cheap hose clamp, which wascast instead of forged.PM: How can I recognise a genuine part?UT: Unfortunately, this isn‘t quite so easyas there are many counterfeits with PMmarking or which are promoted as being“from original manufacturer”. Imitatorsand dealers are not deterred by anythingin this respect. - In principle, the most reliableand easiest thing to do is to buy theparts from the manufacturer or one of itsauthorised sales partners. •Uwe TichyDirector After Salesand Parts Service62PM wear parts –top grade intwo quality levelsDepending on the region and the aggregatesavailable there, all parts that comeinto direct contact with concrete duringpumping are subject to high levels of wear.These parts include the S transfer tube,spectacle wear plate and rings, etc. andlast but not least, the delivery line. The differencein wear by low to highly abrasiveThe latest version of the PM spectaclewear plate consists completely of hardmetal and has up to 6 times higher servicelife than built-up welded parts.64materials can be extremely great. To reducepart costs and extend the replacementintervals, Putzmeister uses high-qualitygenuine PM wear parts even for standardequipment.So, for example, the Duro 22 hard builtupwelded spectacle wear plate can achievea service life of 40,000 m 3 with averageconcrete. Moreover, due to the manufacturingprocess, typical cracks occur duringthe cooling down period, which are acharacteristic of great hardness and wearresistance.In terms of even longer service lives, Putzmeisteris exhibiting a new generation ofhard metal wear parts at the trade fair. Thehard metal plates, which are applied to thefull surface with no cracks, have been additionallyreinforced at the critical edges.This has improved the wear characteristicsoverall and prevents early breakageof individual plates. •Wear under control65Anyone who values safety and wantsto use his delivery line to the full cannotavoid checking or measuring thewall thickness. Two devices for doingthis can be tried out by the machineoperator in the service area on theBauma.These are ultimatelysimple devicesfor reducingwear costs.6620 PM 4300 GB PM 4300 GB 21

Mortar machinesServicesThe piston pump P 13 –the “offroad plastering machine”69 7067can be found. A deliberate decision wastherefore taken to use as few electroniccomponents as possible. All functions andoperating elements of the P 13 are purelymechanical and therefore particularlyrobust and insusceptible to malfunction.Diesel power package withoffroad quality71 72The robust piston pump proves its worth worldwide under the toughest conditions.To date, there has been a serious problemfor businesses wishing to processsite-made mix with a plastering machine.Although sand is locally available inabundance in regions like South Americaor the Middle East, it could often not beused even there in the pumps whichwere used. The new Putzmeister P 13 KA230 plastering machine can already processvirtually every type of sand up to agrain size of 10 mm. This has been madepossible by redesigning a KA 230 typepiston pump which can also handle themost arduous of plastering tasks.Many companies on construction sitesaround the world have themselves found away of producing their own mixes directlyon site. However, the locally availablesands which used to be employed for plasteringby hand are often unsuitable forprocessing in conventional pumps. As aresult, suitable sand has to be bought in andin some cases transported to the constructionsite across considerable distances. Thecosts which this generated were once themain reason why many companies wereunwilling to switch from manual work tomachine technology.This is no longer a problem thanks to thenew P 13 from Putzmeister with the KA230 piston pump. The KA 230 was speciallydeveloped for processing all locallyoccurring types of sand up to a grainsize of 10 mm and even the most difficultof mortars.The allrounder for all hardnessesThe new KA 230 dual piston pump has aspecially developed larger pump head andhas been specifically optimised to handledifficult types of material. It is extremelyrobust and low-wearing. It operates accordingto the successful dual piston principlewith one working piston and one compensatingpiston. It can also be used to processother materials, of course, such asprebagged internal and external plaster,bentonite slurries, finishing plaster, insulatingplaster, cement plaster, lime cementplaster and even light wall mortar. Thus,it has proven to be a surprisingly versatileallrounder that can be used in any difficultsituation.When designing the whole P 13 concept,Putzmeister kept in mind that this machineis intended for use mainly on sites aroundthe world where the harshest of conditionsThe P 13 is driven by a 2 cylinder dieselengine with 12.5 kW. With this, it achievesa delivery pressure of up to 40 bar. Thecompulsory mixer, vibrating screen andpneumatic remote control on the sprayingmachine are practical equipment that comeas standard. On request, the P 13 is alsoavailable with a fully road-approved chassis.This means, the „offroader“ can get toany construction site easily.Therefore the new piston pump from Putzmeisteris a real match for any challengearound the world. •Internet: www.mortarmachines.comPremiere at Bauma 2010This year again, Putzmeister MörtelmaschinenGmbH will be present atthe Putzmeister Group‘s stand. Here,it will exhibit an extensive crosssectionof its product line. In additionto screed conveyors, plasteringmachines and fine concrete pumps,products such as paint pumps, fineplaster spray pumps and Dynajet professionalhigh pressure cleaners willalso be on display.However, Putzmeister Mörtelmaschinenis not only presenting a full range offurther developments and innovationsat Bauma. In Munich, an exclusivecomplete product line will be presentedas an innovation.68Of course, after years of operation, the work performed is apparent on used machines.So that you do not notice its age, they are restored at Putzmeister by qualified technicians.Putzmeister used machines –first class from second handThe demand for used machines inmanufacturer quality is uninterrupted.But beware: With second hand truckmountedconcrete pumps in particular,it is not necessarily obvious whether ornot the apparently cheap offer of a usedmachine dealer is also actually worththe price.For only the manufacturer has the technicalknow-how and detailed knowledgeof the construction of individual componentsand on the method of operationof electronic or hydraulically controls.That‘s why Putzmeister is presenting thePM used machinery centre in a separatestand area.For every currently available machine,detailed documentation with photos, technicaldata, mileages, operating hours, etc. isavailable. In addition, examples show howthoroughly reworked the second hand concretepumps restored in the manufacturer‘splant actually are, or what work could stillbe performed by the manufacturer – andat what cost.This includes, for example, replacing wearparts and bearings, inspecting and, ifnecessary, replacing functional fluids, performingrefits, updates of technically compatiblesoftware and final acceptance, justlike for new machines. •Internet: www.putzmeister.deYour contact persons via e-mail:wehnera@pmw.deand marcecm@pmw.deThat is our goal: Satisfied customers with machines that are as good as new ones.7322 PM 4300 GB PM 4300 GB 23

BAUMA booth layoutPutzmeister at Bauma 201064EsserOpen air area block F9, stand no. 906 / 7BrinkmannOpen air area block F9, stand no. 906 / 8Truck-mounted conrete pumpsBSF 20-4.09 SANIMABSF 36-4.16 H LSBSF 42-5.16 H LSBSF 49-5.16 HBSF 58-5.16 H LSBSS 70-5.16 HPumi truckmixer pumpsPUMI 24-3.67 CSPUMI 31-4.89 SRotor pumping unitTelescopic Belt ConveyorTelebelt TBS 130Mining and tunnelingSika PM 4207 PCBSA 1003 DAllentown AST 25MiningHSP 25100 SPSolutions for the prefabricated parts industryBQ 06Stationary concrete pumpsMX 30-3 MultiBSA 1004 DBSA 1408 EBSA 2110 HP DBSA 14000 SHP DMortar machinesMixokret M 740 DMixokret M 760 DHBSMixokret M 700 EP 718 TDP 13 KA 230MP 25S5 EV/TMSP11 BURServicesCPD – Project consultationAPS – Customer serviceand spare partsDelivery line systemsStrobot 406 SStromixer D 1000Trans Mix 3500 LBDynajet UHP 170Dynajet 350 mdUsed machinesCustomer trainingsErgonic control systemsFleet managementDynajet 800 me PM 4300 GBAll rights and technical amendments reserved · Some of the illustrations show special machine variants and snapshots which do not always comply with theregulations of the Industrial Employers‘ Liability Insurance Association. · © 2010 by Putzmeister Concrete Pumps GmbH · Printed in Germany (3.51003)

![Data sheet BSA 1005 E (TB 1186) [.pdf; 278.88 kb]](https://img.yumpu.com/40181054/1/184x260/data-sheet-bsa-1005-e-tb-1186-pdf-27888-kb.jpg?quality=85)

![(BP 3531) [.pdf; 221.30 kb] - Putzmeister Concrete Machines Pvt. Ltd.](https://img.yumpu.com/35322592/1/184x260/bp-3531-pdf-22130-kb-putzmeister-concrete-machines-pvt-ltd.jpg?quality=85)

![Data sheet M 70-5 (BP 4311) [.PDF (kb383); 721.22 kb] - Putzmeister](https://img.yumpu.com/29333530/1/184x260/data-sheet-m-70-5-bp-4311-pdf-kb383-72122-kb-putzmeister.jpg?quality=85)