NEXTEL® - AMI-CON

NEXTEL® - AMI-CON

NEXTEL® - AMI-CON

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

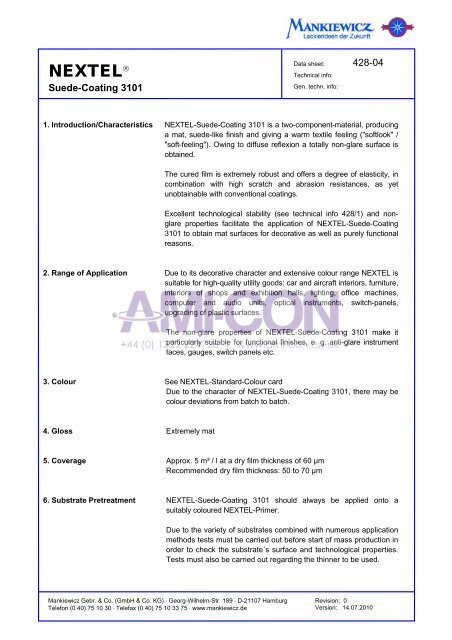

NEXTEL ®Suede-Coating 3101Data sheet: 1 428-04Technical info: 1Gen. techn. info:11. Introduction/Characteristics NEXTEL-Suede-Coating 3101 is a two-component-material, producinga mat, suede-like finish and giving a warm textile feeling ("softlook" /"soft-feeling"). Owing to diffuse reflexion a totally non-glare surface isobtained.The cured film is extremely robust and offers a degree of elasticity, incombination with high scratch and abrasion resistances, as yetunobtainable with conventional coatings.Excellent technological stability (see technical info 428/1) and nonglareproperties facilitate the application of NEXTEL-Suede-Coating3101 to obtain mat surfaces for decorative as well as purely functionalreasons.2. Range of Application Due to its decorative character and extensive colour range NEXTEL issuitable for high-quality utility goods: car and aircraft interiors, furniture,interiors of shops and exhibition halls, lighting, office machines,computer and audio units, optical instruments, switch-panels,upgrading of plastic surfaces.The non-glare properties of NEXTEL-Suede-Coating 3101 make itparticularly suitable for functional finishes, e. g. anti-glare instrumentfaces, gauges, switch panels etc.3. Colour See NEXTEL-Standard-Colour cardDue to the character of NEXTEL-Suede-Coating 3101, there may becolour deviations from batch to batch.4. Gloss Extremely mat5. Coverage Approx. 5 m² / l at a dry film thickness of 60 µmRecommended dry film thickness: 50 to 70 µm6. Substrate Pretreatment NEXTEL-Suede-Coating 3101 should always be applied onto asuitably coloured NEXTEL-Primer.Due to the variety of substrates combined with numerous applicationmethods tests must be carried out before start of mass production inorder to check the substrate´s surface and technological properties.Tests must also be carried out regarding the thinner to be used.Mankiewicz Gebr. & Co. (GmbH & Co. KG) ⋅ Georg-Wilhelm-Str. 189 ⋅ D-21107 HamburgTelefon (0 40) 75 10 30 ⋅ Telefax (0 40) 75 10 33 75 ⋅ www.mankiewicz.deRevision: 0Version: 14.07.2010

NEXTEL ®Suede-Coating 31017. Trade names Base Material NEXTEL-Suede-Coating 3101Hardener NEXTEL-Härter 6018Thinner NEXTEL-Verdünner 8061NEXTEL-Verdünner 901-68ALEXIT-Verdünner 901-268. Mixing ratio 8 parts by weight / volume NEXTEL-Suede-Coating1 part by weight / volume NEXTEL-Härter9. Application Compressed air spraying 10 to 15 % Thinner 8061 / 901-68or 20 to 25 % Thinner 901-26Efflux time (DIN 53211)40 to 60 secondsNozzle size1 to 1.8 mmPressure3 to 4 barProcessing at room temperatures of 20 to 25 °C and a relativehumidity of 50 to 65 %: use Thinners 8061 and 901-68.Processing at room temperatures of 25 to 35 °C and a relativehumidity of 50 to 65 %: use Thinner 901-26.10. Pot life Room temperature 4 to 6 hours11. Drying Room temperature dust-dry : 15 to 30 mintouch-dry : 2 to 3 hrsOven drying10 to 25 minutes flash-off30 to 40 minutes at 80 °CThe drying parameters are selected in coordination with the specificpurpose of the object to be coated.12. Packaging NEXTEL-Suede-Coating 3101including NEXTEL-Härter 6018NEXTEL-Verdünner 8061NEXTEL-Verdünner 901-68ALEXIT-Verdünner 901-261 l, 5 l, 20 l net1 l, 5 l, 20 l5 kg, 25 kg net5 kg, 25 kg netDie in diesem Typenblatt enthaltenen Angaben beruhen auf unserem Forschungs- und Entwicklungsstand. Wegen der Vielseitigkeit der Verarbeitungs- und Einsatzmöglichkeiten isteine Prüfung durch den Anwender für den vorgesehenen Zweck erforderlich – Siehe AVL – The information contained in this data sheet is based on our level of research anddevelopment. Revisal by the user with regard to the intended aim is necessary due to the diverse processing and application possibilities – see GTCS.