Visco-elastic perfectly plastic model.pdf

Visco-elastic perfectly plastic model.pdf

Visco-elastic perfectly plastic model.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

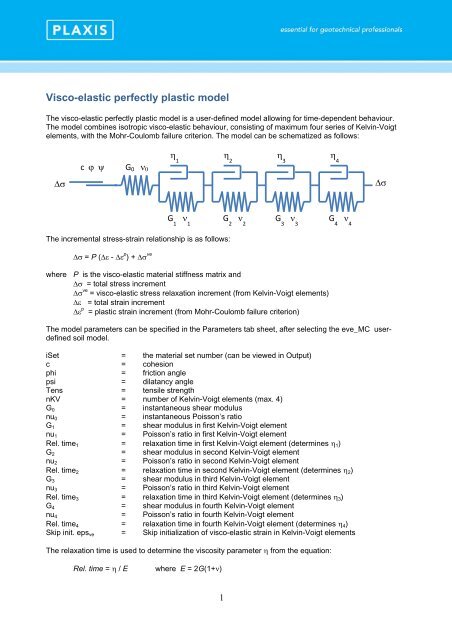

<strong>Visco</strong>-<strong>elastic</strong> <strong>perfectly</strong> <strong>plastic</strong> <strong>model</strong>The visco-<strong>elastic</strong> <strong>perfectly</strong> <strong>plastic</strong> <strong>model</strong> is a user-defined <strong>model</strong> allowing for time-dependent behaviour.The <strong>model</strong> combines isotropic visco-<strong>elastic</strong> behaviour, consisting of maximum four series of Kelvin-Voigtelements, with the Mohr-Coulomb failure criterion. The <strong>model</strong> can be schematized as follows:c G 0 1 2 3 4The incremental stress-strain relationship is as follows: = P ( - p ) + veG 1 1G 2 2G 3 3G 4 4where P is the visco-<strong>elastic</strong> material stiffness matrix and = total stress increment ve = visco-<strong>elastic</strong> stress relaxation increment (from Kelvin-Voigt elements) = total strain increment p = <strong>plastic</strong> strain increment (from Mohr-Coulomb failure criterion)The <strong>model</strong> parameters can be specified in the Parameters tab sheet, after selecting the eve_MC userdefinedsoil <strong>model</strong>.iSet = the material set number (can be viewed in Output)c = cohesionphi = friction anglepsi = dilatancy angleTens = tensile strengthnKV = number of Kelvin-Voigt elements (max. 4)G 0 = instantaneous shear modulusnu 0 = instantaneous Poisson’s ratioG 1 = shear modulus in first Kelvin-Voigt elementnu 1 = Poisson’s ratio in first Kelvin-Voigt elementRel. time 1 = relaxation time in first Kelvin-Voigt element (determines 1 )G 2 = shear modulus in second Kelvin-Voigt elementnu 2 = Poisson’s ratio in second Kelvin-Voigt elementRel. time 2 = relaxation time in second Kelvin-Voigt element (determines 2 )G 3 = shear modulus in third Kelvin-Voigt elementnu 3 = Poisson’s ratio in third Kelvin-Voigt elementRel. time 3 = relaxation time in third Kelvin-Voigt element (determines 3 )G 4 = shear modulus in fourth Kelvin-Voigt elementnu 4 = Poisson’s ratio in fourth Kelvin-Voigt elementRel. time 4 = relaxation time in fourth Kelvin-Voigt element (determines 4 )Skip init. eps ve = Skip initialization of visco-<strong>elastic</strong> strain in Kelvin-Voigt elementsThe relaxation time is used to determine the viscosity parameter from the equation:Rel. time = / Ewhere E = 2G(1+)1

Note that the <strong>model</strong> considers the ‘normal’ time and NOT the dynamic time!Note that the initial (instantaneous) strain increment is dominated by the initial stiffness E 0 , whereas thelong-term strain increment is proportional to the sum of the inverse of all stiffnesses: 0 ~ / E 0 ~ ( 1/E 0 + (1/ E i ) )(summation over all Kelvin-Voigt elements)where E i = 2G i (1+ i )The possibility of skipping initialization of visco-<strong>elastic</strong> strain is particularly relevant for material supposedto undergo stress relaxation after its activation without any change of loading. Otherwise due to thestrain initialization process, the Kelvin-Voigt chains also get pre-stressed to the initial stress value suchthat equilibrium is immediately achieved with the instantaneous stiffness branch right after the activationpreventing any stress relaxation without change of loading.2

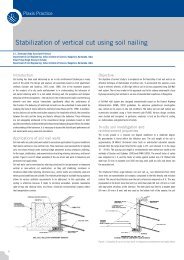

Example: One-dimensional compression and unloading with creepThis example is using the Soil Test facility to show the viscous <strong>model</strong> behaviour in one-dimensionalcompression (oedometer). Only one Kelvin-Voigt element is used. The <strong>model</strong> parameters are listedbelow and the test conditions are shown at the right-hand side:The phasing is as follows:1. Instantaneous loading to -100 kPa.2. Creep for 1000 days3. Instantaneous unloading down to -30 kPa4. Creep for 1000 days5. Slow reloading to -80 kPa6. Slow unloading down to -30 kPaFrom the results it can be seen that the stiffness during Phase 1 and Phase 3 is equal to:E oed,0 = 2G 0 = 20000 kN/m 2whereas the stiffness during Phase 5 and Phase 6 is equal to:E oed, = 2G = 2 * (1/G 0 + 1/G 1 ) -1 = 2 * (1/10000 + 1/1000) -1 = 1818 kN/m 2Moreover, it can be seen that in Phase 2 and Phase 4 the strain ‘creeps’ from the instantaneous strain tothe long-term strain as determined by the long-term stiffness.3

253164Figure 1. Stress-strain diagram1245 63Figure 2. Strain-time diagram4