See brochure with all the TP Models as PDF - Linddana A/S

See brochure with all the TP Models as PDF - Linddana A/S

See brochure with all the TP Models as PDF - Linddana A/S

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

”Get <strong>the</strong> JobLINDDANA<strong>Linddana</strong> are experts in wood chippers. It is that simple.We have been developing and producing a wide rangeof wood chippers for more than 30 years.Machines from <strong>the</strong> factory in Denmark are sold <strong>all</strong> over<strong>the</strong> world. Products are continu<strong>all</strong>y developed in closecollaboration <strong>with</strong> professional partners who knowwhat is needed in <strong>the</strong> industry. The result is robustmachines which meet <strong>all</strong> requirements for efficiency inlandscaping and biom<strong>as</strong>s production. <strong>TP</strong> Wood Chippersproduce wood chip of consistent high quality, which inmany c<strong>as</strong>es is a precondition for successful trading.keep it simple<strong>TP</strong> Wood Chippers have embodied operationalreliability, efficiency and user friendliness since 1980.We do not compromise on quality which we believe is<strong>the</strong> strength behind our brand. With <strong>the</strong> exception ofengines and cranes, everything is manufactured at ourown factory, expertly combining high-tech productionequipment, skilled engineering workmanship andstringent quality-controlled processes.All machines comply <strong>with</strong> <strong>the</strong> latest standard, EN13525. We know <strong>the</strong> importance of tried and testedtechnologies whose long-term validity h<strong>as</strong> been provedand we work on <strong>the</strong> principal ‘’Keep it Simple”. Amongo<strong>the</strong>r things, <strong>TP</strong> Wood Chippers are designed to bestraightforward to maintain. Replacing wearing parts mustbe e<strong>as</strong>y, so that you are soon up and running again.

Done”A selection from our dynamic range willbring results<strong>TP</strong> Wood Chippers fulfil every wood chipping need,from large private gardens to extensive projects inlandscaping or logging. With our widest ever rangeof machines and a variety of models it will always bepossible to find <strong>the</strong> right wood chipper for <strong>the</strong> job and<strong>the</strong> available space on site.Just ‘a quick overview’This <strong>brochure</strong> gives you <strong>the</strong> information and b<strong>as</strong>ictechnical specifications for <strong>the</strong> full range of <strong>TP</strong> WoodChippers. Our simple guide will help you choose <strong>the</strong>right tool for your job.To find out more, you can download detailed productspecifications and comprehensive technical dat<strong>as</strong>heetsfrom our website www.linddana.com. Feel free tocontact us or your local <strong>TP</strong> distributor to discuss youroptions.<strong>Linddana</strong> provides on-going customersupport for continuous operations<strong>Linddana</strong> provides support, so that wood chippersrun efficiently and <strong>with</strong>out problems throughout <strong>the</strong>irservice lives. You can now order a <strong>TP</strong> SERVICEBOX <strong>with</strong>spares for <strong>all</strong> <strong>the</strong> critical/vital wearing parts on <strong>the</strong>machine. Then, if <strong>the</strong> need arises, you are preparedand able to minimise downtime. In addition we offera wide selection of accessories, which enable you totailor <strong>the</strong> machine precisely to your requirements.WOOD ChIp<strong>the</strong> environment-friendly solutionIniti<strong>all</strong>y, wood chipping w<strong>as</strong> mainly used for <strong>the</strong> efficientremoval of branches and green w<strong>as</strong>te in are<strong>as</strong> such <strong>as</strong>parks and woodland, but <strong>as</strong> wood chip came to beregarded <strong>as</strong> an important natural resource, wood chippingh<strong>as</strong> taken on a new, economic dimension. Wood chip isvaluable if <strong>the</strong> quality is consistent and meets designatedrequirements. <strong>TP</strong> Wood Chippers ensure <strong>the</strong>se requirementsare met. Our entire product range is designed todeliver high quality wood chip, and on many of ourmachines <strong>the</strong> knives can be adjusted to produce differentsizes, depending on what <strong>the</strong> wood chip will be used for.Large quantities of wood chip are already being used <strong>as</strong>a fuel supply for energy and heating, and for industrialpurposes such <strong>as</strong> MDF board and paper production. Inad dition, wood chip is extensively used <strong>as</strong> ground coveror <strong>as</strong> surfacing material for paths <strong>as</strong> an environmentfriendlyweed killer, which reduces or eliminates <strong>the</strong>need for chemical sprays.

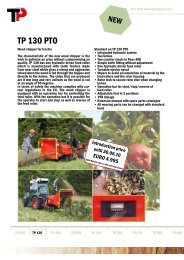

You’re off to a good starttp 100, tp 130 and tp 160Recommended if 60-70 % of <strong>the</strong> daily material h<strong>as</strong>a thickness of 10 cm or less.The sm<strong>all</strong>est group of wood chippers in <strong>the</strong> <strong>TP</strong> rangeare, despite <strong>the</strong>ir size, absolutely <strong>the</strong> most popular and –<strong>with</strong>out doubt – “best in cl<strong>as</strong>s” on <strong>the</strong> market <strong>with</strong>in thissegment. They are designed to effectively break downgreen materials.Powerful common features of <strong>TP</strong> 130 and <strong>TP</strong> 160• horizontal feed rollers• 90° chipping angle• f<strong>as</strong>t replacement of knives <strong>with</strong>out adjustment• <strong>the</strong> wood chip is highly suitable for heating purposes<strong>TP</strong> 100 PTO<strong>TP</strong> 100 – <strong>the</strong> largest of <strong>the</strong> sm<strong>all</strong>est<strong>TP</strong> 100 is a robust drum wood chipper<strong>with</strong> an upright standing funnel. It is <strong>as</strong>m<strong>all</strong>, compact and extremely efficientmachine. Particularly useful in confinedspaces and when <strong>the</strong> tractor power isbelow 40 hp.• max. wood: ø100 mm, h150 x b275 mm• power requirement: 11 - 29 kW (15 - 40 hp)• no. of knives: 2 pcs. (reversible)• wood chip size: 5 - 20 mm• capacity: up to 7m 3 /hr• weight: PTO = 195 kg<strong>TP</strong> 130 PTO<strong>TP</strong> 130 MOBILE (25 hp Kohler)<strong>TP</strong> 130 – user friendly and compact<strong>TP</strong> 130 gives you <strong>the</strong> greatest possible capacity andefficiency for your money. This wood chipper isoptimised and simplified <strong>with</strong>out compromising onquality or safety. Highlights: a hydraulic<strong>all</strong>y driven feedroller <strong>with</strong> shark-like teeth that ensure a particularlypowerful in feed, a rotating ejector spout, operating barto start and stop, reversible feed rollers and two knives.• max. wood: ø130 mm, h130 x b220 mm• power requirement: 18 - 45 kW (25 - 60 hp)• no. of knives: 2 pcs.• wood chip size: 8 mm• capacity: up to 10 m 3 /hr• weight: PTO = 516 kgMOBILE = 680 kg<strong>TP</strong> 160 PTO <strong>TP</strong> 160 MOBILE (35 hp Lombardini) <strong>TP</strong> 160 TRACK (35 hp Lombardini)<strong>TP</strong> 160 – efficient and highly versatileAn efficient working wood chipper <strong>with</strong> hydraulic in feedand two horizont<strong>all</strong>y set feed rollers to ensure a powerfuland effective in feed of branches and o<strong>the</strong>r wood w<strong>as</strong>te.Hydraulic control of <strong>the</strong> feed roller speed ensures thatyou can adjust <strong>the</strong> wood chip size from 4 to 10 mm <strong>as</strong>required. In addition <strong>the</strong> machine h<strong>as</strong> features like arotating ejector spout, operating bar to start and stop,reversible feed rollers and two knives.• max. wood: ø160 mm, h160 x b220 mm• power requirement: 22 - 59 kW (30 - 80 hp)• no. of knives: 2 pcs.• wood chip size: 4 - 10 mm• capacity: up to 18 m 3 /hr• weight: PTO = 585 kgMOBILE = 830 kgTRACK = 1195 kg

…and here <strong>the</strong>re’s moretp 200 and tp 250Recommended if 60-70 % of <strong>the</strong> daily material h<strong>as</strong>a thickness of 10 cm or less.<strong>TP</strong> 200 and <strong>TP</strong> 250 provide flexibility for clearing andlandscaping. These wood chippers handle everythingfrom fairly sm<strong>all</strong> branches to trees up to 250 mm indiameter. With capacity to meet <strong>the</strong> broad requirementsof forestry technicians, contractors and o<strong>the</strong>rs, <strong>TP</strong> 200 is<strong>Linddana</strong>’s top selling wood chipper. <strong>TP</strong> 250 is b<strong>as</strong>ic<strong>all</strong>yidentical to <strong>TP</strong> 200 in design and construction, but h<strong>as</strong><strong>the</strong> strength and dimensions to handle wood <strong>with</strong> alarger diameter.Powerful common features of <strong>TP</strong> 200 and <strong>TP</strong> 250• 90° chipping angle• horizontal feed rollers• f<strong>as</strong>t replacement of knives <strong>with</strong>out adjustment• open, folding funnel <strong>with</strong> <strong>the</strong> operating bar hinged at<strong>the</strong> top• replaceable c<strong>as</strong>ing at <strong>the</strong> bottom of <strong>the</strong> rotor housingand on <strong>the</strong> ejector blades<strong>TP</strong> 200 PTO<strong>TP</strong> 200 MOBILE (52 hp Hatz)<strong>TP</strong> 200 MOBILE TURNTABLE (52 hp Hatz)<strong>TP</strong> 200 – a strong and popular wood chipperIt is not <strong>with</strong>out re<strong>as</strong>on that <strong>TP</strong> 200 is <strong>the</strong> most soldmodel among <strong>TP</strong> Wood Chippers. This model offers anoptimal combination of functionality, size and capacitywhen faced <strong>with</strong> <strong>the</strong> most frequent t<strong>as</strong>ks when attendingto parks, gardens and landscaping. Among o<strong>the</strong>rthings, <strong>TP</strong> 200 h<strong>as</strong> two hydraulic feed rollers forpowerful in feed, three knives, hydraulic adjustment of<strong>the</strong> wood chip size, rotating ejector spout, and areplaceable c<strong>as</strong>ing in <strong>the</strong> rotor housing (which helps toreduce maintenance costs).• max. wood: ø200 mm, h210 x b265 mm• power requirement: 30 - 85 kW (40 - 115 hp)• no. of knives: 3 pcs.• wood chip size: 4 - 10 mm• capacity: up to 40 m 3 /hr• weight: PTO = 700 kgMOBILE = 1350 kg (52 hp)MOBILE TURNTABLE = 1550 kg (52 hp)<strong>TP</strong> 250 PTO<strong>TP</strong> 250 PTO K<strong>TP</strong> 250 MOBILE TURNTABLE (72 hp Hatz)<strong>TP</strong> 250 – for larger and more demanding t<strong>as</strong>ks<strong>TP</strong> 250 corresponds b<strong>as</strong>ic<strong>all</strong>y to <strong>TP</strong> 200 in constructionand design, but is dimensioned to handle everythingfrom finger-thick branches to trees <strong>with</strong> a diameter upto 250 mm. Among o<strong>the</strong>r things, <strong>TP</strong> 250 is available<strong>with</strong> two hydraulic feed rollers, oil-fuelled motors pipedin par<strong>all</strong>el, three knives, hydraulic adjustment of <strong>the</strong>wood chip size, rotating ejector spout, and a replaceablec<strong>as</strong>ing in <strong>the</strong> rotor housing (which helps to reducemaintenance costs).• max. wood: ø250 mm, h260 x b350 mm• power requirement: 45 - 104 kW (60 - 140 hp)• no. of knives: 3 pcs.• wood chip size: 4 - 13 mm• capacity: up to 60 m 3 /hr• weight: PTO = 1065 kgPTO K = 1030 kg (excl. crane)MOBILE TURNTABLE = 2200 kg

Designed for heavy worktp 230 and tp 270Recommended if 60-70 % of <strong>the</strong> daily material h<strong>as</strong>a thickness from 5 cm and upwards.<strong>TP</strong> 230 and <strong>TP</strong> 270 are obvious choices if <strong>the</strong> wood chipis to be collected in a trailer, or if wood chipping is oftendone along roads or paths. Both wood chippers havea trailer hitch. The funnel faces sideways in relation to<strong>the</strong> driving direction, which facilitates feeding materialinto <strong>the</strong> wood chipper, for instance when trimming windbreakers. Vertical feed rollers and a 45° chipping angleensure that even very twisted branches are drawn inforcefully and effectively.Powerful common features of <strong>TP</strong> 230 and <strong>TP</strong> 270• angled funnel• 45° chipping angle• vertical feed rollers• adjustable knives to <strong>all</strong>ow variable wood chip size• possible to use <strong>TP</strong> WINCH or a crane system• integrated trailer hitch• <strong>TP</strong> PILOT/<strong>TP</strong> PILOT K<strong>TP</strong> 230 PTO <strong>with</strong> <strong>TP</strong> WINCH<strong>TP</strong> 230 PTO K <strong>with</strong> crane<strong>TP</strong> 230 GREENLINE<strong>TP</strong> 230 – unique design <strong>with</strong> 90° angled funnelA powerful wood chipper <strong>with</strong> a folding funnel facing outto <strong>the</strong> side at a right angle, and an integrated trailerhitch for <strong>the</strong> collecting trailer. These both make <strong>TP</strong> 230ideal for working along roads, paths and hedges, whereeffective removal of branches and wood w<strong>as</strong>te h<strong>as</strong> highpriority. The machine is supplied <strong>with</strong> three knives,vertical feed rollers and a 45° chip ping angle, which alsoensures that very twisted branches are effectivelychipped. The replace able c<strong>as</strong>ing on <strong>the</strong> rotor housinghelps to reduce main tenance costs.• max. wood: ø230 mm, h230 x b240 mm• power requirement: 37 - 90 kW (50 - 120 hp)• no. of knives: 3 pcs.• wood chip size: 10 - 18 mm• capacity: up to 54 m 3 /hr• weight: PTO = 990 kgPTO K = 990 kg (excl. crane and crane support)GREENLINE = 2500 kg<strong>TP</strong> 270 PTO <strong>with</strong> <strong>TP</strong> WINCH<strong>TP</strong> 270 PTO K<strong>TP</strong> 270 PTO K F<strong>TP</strong> 270 – superior capacity <strong>with</strong> 45° funnelA powerful wood chipper <strong>with</strong> hydraulic feed rollers anda chipping angle of 45°, to ensure large capacity and aforceful in feed even of large trees. The funnel is at anangle of 45° to <strong>the</strong> driving direction, and providesoptimal working conditions in practic<strong>all</strong>y any situation. Themachine is equipped <strong>with</strong> three knives, rotating ejectorspout, trailer hitch and a replaceable c<strong>as</strong>ing in <strong>the</strong> rotorhousing (which helps to reduce maintenance costs).• max. wood: ø270 mm, h280 x b290 mm• power requirement: 75 - 150 kW (100 - 200 hp)• no. of knives: 3 pcs.• wood chip size: 11 - 21 mm• capacity: up to 76 m 3 /hr• weight: PTO = 1385 kgPTO K = 1345 kg (excl. crane and crane support)PTO K F = 1345 kg