Part C (4) - Oil Tanker - Skuld

Part C (4) - Oil Tanker - Skuld

Part C (4) - Oil Tanker - Skuld

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

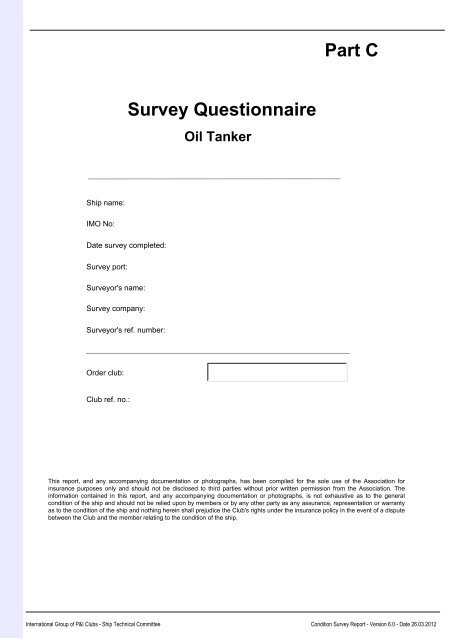

<strong>Part</strong> CSurvey Questionnaire<strong>Oil</strong> <strong>Tanker</strong>Ship name:IMO No:Date survey completed:Survey port:Surveyor's name:Survey company:Surveyor's ref. number:Order club:Club ref. no.:This report, and any accompanying documentation or photographs, has been compiled for the sole use of the Association forinsurance purposes only and should not be disclosed to third parties without prior written permission from the Association. Theinformation contained in this report, and any accompanying documentation or photographs, is not exhaustive as to the generalcondition of the ship and should not be relied upon by members or by any other party as any assurance, representation or warrantyas to the condition of the ship and nothing herein shall prejudice the Club's rights under the insurance policy in the event of a disputebetween the Club and the member relating to the condition of the ship.International Group of P&I Clubs - Ship Technical Committee Condition Survey Report - Version 6.0 - Date 26.03.2012

5. Survey Questionnaire - <strong>Oil</strong> <strong>Tanker</strong>5.1 Cargo tanks and systemsY N NA NI Remarks5.1.1 Are cargo tank coatings insatisfactory condition and freefrom defects which could impaircargoworthiness?YesNoN/ANI5.1.2 Is the structure in cargo tanksapparently free from significantcorrosion, pitting, scaling,buckling, dents, fractures,wastage, doublers, temporaryrepairs etc?YesNoN/ANI5.1.3 Is plating under suction bellmouths in apparent satisfactorycondition?YesNoN/ANI5.1.4 Are cargo pumps, ballast pumpsand stripping arrangements fullyoperational including associatedmonitoring, alarmsinstrumentation and controls?YesNoN/ANI5.1.5 If fitted, are deep well pumpcofferdams purged as permanufacturer's guidance and arerecords maintained onboard?YesNoN/ANI5.1.6 Are cargo pump emergency stopsproperly located and regularlytested?YesNoN/ANI5.1.7 Is the condition of pipe work intanks or passing through inapparent satisfactory condition?YesNoN/ANI5.1.8 Are deck cargo piping, manifoldsand relevant deck equipmentsuitably marked and in apparentsatisfactory condition?YesNoN/ANI5.1.9 Are cargo pipelines and tankcleaning lines pressure tested andmarked accordingly?YesNoN/ANIInternational Group of P&I Clubs - Ship Technical Committee Condition Survey Report - Version 6.0 - Date 26.03.2012

5.1.10 Are reducers, removable U-bendsand cargo hoses, if carried, insatisfactory condition?YesNoN/ANI5.1.11 Are hoses pressure tested,certificated and in apparentsatisfactory condition?YesNoN/ANI5.1.12 Are hoses regularly tested forcontinuity?YesNoN/ANI5.1.13 Are spill trays and savealls insatisfactory condition and freefrom oil?YesNoN/ANI5.1.14 Is the ship provided with portableinstruments as required, is spangas available and are records ofrecent calibration kept?YesNoN/ANI5.1.15 Are the fixed and portableelectrical equipment used suitablefor use in hazardous areas?YesNoN/ANI5.1.16 Are superstructure anddeckhouse doors, windows, airinlet flaps, etc. facing the cargoarea in satisfactory condition?YesNoN/ANI5.1.17 Is the pump room clean and tidyand are bilges free from cargo?YesNoN/ANI5.1.18 Are pumps and shaft bearings inapparent good condition?YesNoN/ANI5.1.19 Are pump room fans operational?YesNoN/ANI5.1.20 Is pump room floor platingsatisfactory?YesNoN/ANIInternational Group of P&I Clubs - Ship Technical Committee Condition Survey Report - Version 6.0 - Date 26.03.2012

5.1.21 Are safe pump room proceduresidentified and complied with?YesNoN/ANI5.1.22 Is the cargo heating systemapparently fully operational andwell maintained?YesNoN/ANI5.1.23 If a vapour emission returnsystem is fitted, is it in apparentsatisfactory condition?YesNoN/ANI5.1.24 Is the vapour manifold clearlymarked?YesNoN/ANI5.1.25 If appropriate, are fire wires ingood condition and properlyrigged?YesNoN/ANI5.1.26 Has the ship been inspected byOCIMF-Sire and / or CDIrecently?YesNoN/ANIAdditional information5.2 Inert Gas System5.2.1 Is the IGS, includinginstrumentation, alarms, trips, andpressure and oxygen recorderfully operational and calibrationrecords maintained?Y N NA NI RemarksYesNoN/ANI5.2.2 Are fans, scrubber, deck seals,PV breakers and non-returnvalves in apparent satisfactorycondition?YesNoN/ANIAdditional informationInternational Group of P&I Clubs - Ship Technical Committee Condition Survey Report - Version 6.0 - Date 26.03.2012

5.3 Tank Cleaning SystemY N NA NI Remarks5.3.1 Is tank cleaning system inapparent satisfactory conditionand fully operational?YesNoN/ANI5.3.2 Is an approved tank cleaningsystem manual provided and aretank cleaning plans prepared andadhered to?YesNoN/ANIAdditional information5.4 Closing appliancesY N NA NI Remarks5.4.1 Are closing devices, associatedgaskets and securingarrangements on the freeboarddeck in apparent satisfactorycondition?YesNoN/ANI5.4.2 Are the vapour locks for closedsampling / ullaging devicescalibrated and operational?YesNoN/ANI5.4.3 Are air locks, if applicable,operational and in a satisfactorycondition?YesNoN/ANIAdditional informationInternational Group of P&I Clubs - Ship Technical Committee Condition Survey Report - Version 6.0 - Date 26.03.2012

5.5 Cargo ControlY N NA NI Remarks5.5.1 Are cargo monitoring indicators,controls and panels in apparentsatisfactory condition?YesNoN/ANI5.5.2 Are detailed cargo handling andtank cleaning plans prepared andare operations carried out andlogged in accordance with theagreed plan?YesNoN/ANI5.5.3 Is the tank gauging system,including temperature reading iffitted, apparently operational andcross checked with manualreadings?YesNoN/ANI5.5.4 Are gas detection systems andbilge alarms operational, regularlytested and with results recorded?YesNoN/ANI5.5.5 If a fixed gas detection andmonitoring system is not fitted,are routines in place for regularmonitoring with portableinstruments?YesNoN/ANI5.5.6 Are safety guidelines regardingstatic hazards in place and strictlyadhered to?YesNoN/ANI5.5.7 Is oil discharge monitoringequipment (ODME) fitted andapparently operational?YesNoN/ANI5.5.8 Are PV valves tested on a regularbasis and are all flame screensapparently intact and free fromdebris?YesNoN/ANI5.5.9 Is the liquid level in PV breakersatisfactory and is it suitablyprotected against cold weather?YesNoN/ANIInternational Group of P&I Clubs - Ship Technical Committee Condition Survey Report - Version 6.0 - Date 26.03.2012

5.5.10 Is appropriate cargo specificinformation including MaterialSafety Data Sheets available onboard?YesNoN/ANIAdditional information5.6 Safety and Operational test (were the following tests carried out and found satisfactory?)Y N NA NI Remarks5.6.1 Engine room bilge high levelalarms.YesNoN/ANI5.6.2 Emergency fire pump on with twofire hoses on separate hydrants.YesNoN/ANI5.6.3 Emergency power sources andemergency lighting.YesNoN/ANI5.6.4 Engine room remote stops andshutdowns.YesNoN/ANI5.6.5 Relevant cargo high level alarms.YesNoN/ANIAdditional informationInternational Group of P&I Clubs - Ship Technical Committee Condition Survey Report - Version 6.0 - Date 26.03.2012