You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

as-960HDas-990HDaDDress PrInTer<strong>User</strong> ManUal

Products presented in this guide are conform torequirements of directives nbr 2006/42/EGand 2004/108/EG.<strong>Neopost</strong> has implemented a program for therecycling of worn machines and machines atthe end of their lifetime. Contribute in a responsibleway to the environmental protectionby consulting your retailer internet site, orby contacting him. He will inform you of thecollection and treatment processes of thesemachines.

Pos: 3 /[Allgemeines]/0.0a_Note_Trademarks+Manufacturer Address NEOPOST @ 1\mod_1256739001883_912.doc @ 7153 @Pos: 4 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/0.0_Revision level_AS-960HD/990HD 3.1 @ 3\mod_1301662992031_912.doc @ 31015 @Pos: 5 /[Allgemeines]/0.2_Inhaltsverzeichnis @ 0\mod_1242731641668_912.doc @ 1625 @aCopyright© Copyright 2011All rights reserved. No part of this manual may be reproduced or transmitted in any form orby any means, copied onto electronic media or translated into any language without themanufacturer's express written permission.The manufacturer is not liable for any damage resulting either from incorrect use or fromrepairs and modifications carried out by a third unauthorized party. This manual wasproduced with great care. However, liability for any errors which it may contain is excluded.The manufacturer reserves the right to make any technical or design changes to theequipment during the development process. All specified values are purely nominal.Consequently, any legal claims made on the basis of this manual cannot be enforced.The manufacturer is not liable for any damage or disturbance resulting from the use ofoptions or accessories which are not original products or do not have the express approvalof the manufacturer.Brands:HP is a registered brand name of the Hewlett-Packard Company.Microsoft and Windows are registered brand names of the Microsoft Corporation.FlexMail is a registered brand name of Flex Systems B.V.Bulk Mailer is a registered brand name of Satori Software Inc.Manufacturer Address<strong>Neopost</strong> IndustrieZI Tivoli72800 Le LudeFrancewww.neopost.comRevision levelVersion Change description Released3.0 New document for graphic display and November 2010firmware version 4.73.1• Added descriptions for new USB 2.0and TCP/IP interfaceApril 2011• Changed description to firmwareversion 4.8• Added Device Class A note<strong>User</strong> Manual Version 3.1 3

Table of Contents1 Introduction .............................................................................101.1 Pictograms ............................................................................101.2 Notes for use of this manual.....................................................101.3 Terms and abbreviations .........................................................111.4 System requirements ..............................................................112 Safety notes .............................................................................122.1 General safety notes ...............................................................122.2 Ink safety notice.....................................................................142.3 Location of the printer .............................................................152.4 Disposal ................................................................................153 Scope of delivery and assembly................................................163.1 Scope of delivery ....................................................................163.2 Delivery ................................................................................173.3 Device overview .....................................................................193.4 Assembly ..............................................................................213.4.1 Connecting the power cable ................................................ 223.4.2 How to mount the stacking plate and the guides .................... 224 Description of device ................................................................254.1 Application range....................................................................254.2 Description of functions ...........................................................254.3 The Operator Panel .................................................................274.3.1 Key panel......................................................................... 284.3.2 Main Display ..................................................................... 305 Initial start-up of the device.....................................................335.1 How to power-on the device.....................................................335.2 How to install the ink cartridges................................................335.3 How to set up the paper transport.............................................355.3.1 How to adjust the paper separation...................................... 355.3.2 How to adjust the side guides and the feed ramp ................... 375.3.3 How to adjust the printer to the material thickness ................ 385.3.4 How to position the print area ............................................. 395.4 How to measure the print media size.........................................425.5 How to set the print direction (orientation).................................434 <strong>User</strong> Manual Version 3.1

5.6 How to perform a test print...................................................... 446 Printer menu (firmware V4.8).................................................. 457 How to connect the printer to the PC ....................................... 917.1 How to install the printer driver ................................................ 927.2 Windows XP and Windows Vista................................................ 927.2.1 Windows 7........................................................................ 937.3 How to use the USB interface................................................... 957.4 How to use the Ethernet interface............................................. 957.4.1 Adding a TCP/IP port to a printer driver ................................ 977.4.2 Connecting the printer to a local area network ..................... 1007.4.3 Using a fixed IP address ................................................... 1007.4.4 Direct Ethernet connection between the printer and the PC .... 1038 Service ................................................................................... 1058.1 Maintenance and support....................................................... 1058.1.1 How to clean an ink cartridge ............................................ 1058.1.2 How to clean the pen board contacts .................................. 1068.1.3 How to reset the printer.................................................... 1088.2 Troubleshooting ................................................................... 1098.2.1 The device cannot be turned on ......................................... 1098.2.2 No or only very weak printout with new ink cartridges........... 1098.2.3 Printed elements positioned incorrectly ............................... 1108.2.4 The printout looks partly smeared ...................................... 1118.2.5 The printed ink doesn’t dry on the substrate ........................ 1118.2.6 White streaks in printed text or graphic .............................. 1128.2.7 White streak in printed text or graphics (in between cartridges) ..1138.3 Error Messages .................................................................... 1148.3.1 How to read an error message entry................................... 1148.4 Warning Messages................................................................ 1298.4.1 How to read a warning message entry ................................ 1298.4.2 Additional Error Messages ................................................. 1358.5 Technical Support................................................................. 1399 Consumables and Accessories ................................................ 1409.1 Consumables ....................................................................... 1409.1.1 Standard inks for <strong>Neopost</strong> address printers.......................... 1409.1.2 Cleaning Towels............................................................... 1419.2 Accessories.......................................................................... 1429.2.1 Roller cleaning tool for AS-960HD and AS-990HD ................. 142<strong>User</strong> Manual Version 3.1 5

Pos: 6 /[Allgemeines]/0.3_Abbildungsverzeichnis [Figure] @ 0\mod_1250599665953_912.doc @ 2745 @9.2.2 Roller support kit..............................................................1439.2.3 Universal paper basket......................................................1449.2.4 POM separator rollers........................................................1459.3 Accessory devices................................................................. 1469.3.1 <strong>Neopost</strong> CS-800 conveyor .................................................14610 Technical Specifications ......................................................... 14711 Appendix ................................................................................ 14911.1 How to completely remove printer drivers from Windows Vistaand Windows 7 .......................................................................... 14911.2 How to completely remove printer drivers from Windows XP andWindows 2000 ........................................................................... 15011.2.1 How to use a pre-installed printer driver ..............................15111.3 USB connection............................................................... 15111.3.1 Ethernet connection..........................................................15211.3.2 How to identify the USB port used by the printer ..................15311.3.3 How to test the Ethernet connectivity ..................................15411.3.4 Sample settings for Ethernet connection ..............................15611.4 How to exchange or modify the separator rollers ................. 15811.5 How to create a print file .................................................. 16111.6 How to update the flashware............................................. 16311.6.1 How to update the flashware..............................................16311.7 Ink package ID number.................................................... 16611.7.1 ID: 6030206....................................................................16711.8 Declaration of conformity ................................................. 16812 Glossary ................................................................................. 17013 Index...................................................................................... 1766 <strong>User</strong> Manual Version 3.1

Table of FiguresFigure 1: Lifting the printer out of the box, Transportation locks ................................... 17Figure 2: Removing the transportation locks, side views .............................................. 18Figure 3: overview ................................................................................................. 19Figure 4: Separator rollers, passive rollers ................................................................. 20Figure 5: overview assembled .................................................................................. 21Figure 6: Assembly of the stacking plate.................................................................... 22Figure 7: Mounted paper feed ramp .......................................................................... 24Figure 8: The AS-960HD printer ............................................................................... 25Figure 9: The AS-990HD/AS-990HD LOG printer......................................................... 25Figure 10: The operator panel.................................................................................. 27Figure 11: Main display ........................................................................................... 30Figure 12: Inserting the ink cartridge into the pen stall................................................ 34Figure 13: Lock the restraining lever ......................................................................... 34Figure 14: Separator system.................................................................................... 36Figure 15: Separator system adjustment I ................................................................. 36Figure 16: Separator system adjustment II................................................................ 36Figure 17: Separator system adjustment III............................................................... 36Figure 18: Adjusting the paper feed ramp and the slide, side view................................. 37Figure 19: Filing the stack with a fanned out pile, side view.......................................... 37Figure 20: Adjusting the printer to the material thickness ............................................ 38Figure 21: Positioning the vertical print area, AS-960HD .............................................. 39Figure 22: Unprintable area AS-960HD, top view ........................................................ 39Figure 23: Unprintable area AS-990HD, top view ........................................................ 40Figure 24: Printable area AS-960HD unit 1/2............................................................. 41Figure 25: Printable area AS-990HD unit 2................................................................ 41Figure 26: Printable area AS-990HD unit 1/3............................................................. 41Figure 27: Positioning the sand rollers outside the print image...................................... 42Figure 28: Testprint................................................................................................ 44Figure 29: Keep Alive function.................................................................................. 55Figure 30: PRINT CORR.PATT................................................................................... 56Figure 31: Horizontal alignment U1-U2...................................................................... 57Figure 32: ADJUST TOF test print ............................................................................. 59Figure 33: Difference Nor/Rev.................................................................................. 70Figure 34:LEFT MARGIN, transport direction............................................................... 70Figure 35: Encoder Pattern ...................................................................................... 82<strong>User</strong> Manual Version 3.1 7

Figure 36: Simult. PrintUnits service print.................................................................. 83Figure 37: Pattern A ............................................................................................... 83Figure 38: Pattern A with defects ............................................................................. 84Figure 39: Cartridge contacts................................................................................... 84Figure 40: Pattern B ............................................................................................... 85Figure 41: Pattern C ............................................................................................... 85Figure 42: Sample character set print ....................................................................... 86Figure 43: Sample setting dump print ....................................................................... 87Figure 44: Sample Input Buffer Dump print ............................................................... 88Figure 45: New Hardware Wizard ............................................................................. 92Figure 46: Recommended install procedure................................................................ 92Figure 47: Properties of unspecified device ................................................................ 94Figure 48: Update the printer driver.......................................................................... 94Figure 49: Update Driver Software Wizard ................................................................. 95Figure 50: Select the driver source ........................................................................... 95Figure 51: Ferrite with plastic case ........................................................................... 96Figure 52: Adding TCP/IP Port.................................................................................. 97Figure 53: TCP/IP Printer Port Wizard........................................................................ 98Figure 54: IP address of the printer .......................................................................... 98Figure 55: Custom settings...................................................................................... 98Figure 56: Custom settings of printer port ................................................................. 98Figure 57: Address printer port settings .................................................................... 99Figure 58: DHCP Table on server............................................................................ 102Figure 59: Test of fix IP (ping test on server) ........................................................... 102Figure 60: Local Area Connection Properties............................................................. 104Figure 61: TCP/IPv4 settings ................................................................................. 104Figure 62: Cleaning the nozzle plate ....................................................................... 106Figure 63: Nozzle plate and contacts....................................................................... 106Figure 64: Pen board contacts................................................................................ 107Figure 65: Position of element on material ............................................................... 110Figure 66: Smeared test print ................................................................................ 111Figure 67: White streaks in text ............................................................................. 112Figure 68: White streaks in between two cartridges .................................................. 113Figure 69: Usage of the cleaning tool ...................................................................... 143Figure 70: Paper catch tray assembly...................................................................... 145Figure 71: New hardware detected ......................................................................... 1528 <strong>User</strong> Manual Version 3.1

Pos: 7 /Bedienungsanleitungen/Geräte neutral/1.0_Ü1_Einführung_allgemein @ 0\mod_1242731723794_912.doc @ 1634 @ 1Figure 72: Found New Hardware Wizard .................................................................. 152Figure 73: Device Manager .................................................................................... 154Figure 74: Device Properties - Details ..................................................................... 154Figure 75: Command Prompt reply OK .................................................................... 155Figure 76: Command Prompt reply NOT OK ............................................................. 155Figure 77: Assembled stacking plate ....................................................................... 159Figure 78: Dismounting the stacking plate ............................................................... 159Figure 79: Exchange or modify the separator rollers.................................................. 160Figure 80: Print dialog window ............................................................................... 161Figure 81: Print to file dialog.................................................................................. 161Figure 82: Printer port properties ........................................................................... 162<strong>User</strong> Manual Version 3.1 9

Pos: 8 /Bedienungsanleitungen/Geräte neutral/1.1_Ü2_Piktogramme_allgemein @ 0\mod_1242731723997_912.doc @ 1638 @ 2Pos: 9 /Bedienungsanleitungen/Geräte neutral/1.2_Ü2_Hinweise zum Gebrauch dieses Handbuches @ 0\mod_1249459443010_912.doc @ 2613 @ 2Pos: 10 /Bedienungsanleitungen/Geräte spezifisch/Drucker/1.3_Ü2_Terms and abbreviations @ 1\mod_1260869177556_912.doc @ 8380 @ 21 IntroductionIn order to ensure both long service life of the AS-960HD/AS-990HDand its components, as well as safe conditions of use, we recommendthat you read carefully and comply with the operating instructionsand safety notes. Always be aware of all warnings and notes that areaffixed to or printed on the machine itself.All persons who are to handle this machine must also be familiar with the operating manual.Store this manual in a safe place where it is easily accessible for future reference at anytime.1.1 PictogramsGeneral warningsWarning of danger from electricity or electrical shockWarning of possible fireInformation / Note indicating important information regardingthe handling of the machine.1.2 Notes for use of this manualThis manual is structured chronologically, and therefore ordered sequentially from thereceipt of the machine packed up to its ready-for-use state.If you are unfamiliar with the machine, it is best to read through the manual from beginningto end, where you can follow easy step by step instructions to allow you to fully andcorrectly operate the machine.If you are already familiar with the AS-960HD/AS-990HD, it will make things easy if you touse this manual as a reference work.10 <strong>User</strong> Manual Version 3.1

Pos: 11 /Bedienungsanleitungen/Geräte spezifisch/Drucker/1.4_Ü2_System requirements_ONLY_619 @ 2\mod_1272530190780_912.doc @ 17229 @ 2Pos: 12 /Bedienungsanleitungen/Geräte neutral/2.0_Ü1_Sicherheitshinweise @ 0\mod_1242735234414_912.doc @ 1664 @ 11.3 Terms and abbreviationsThis <strong>User</strong> Manual uses the following terms and abbreviations related to the <strong>Neopost</strong> AS-960HD/AS-990HD:• cartridge = Crt = C, C1, C2, C3• print unit = Unit = U, U1, U2A print unit always consists of three ink cartridges.• print media width = expansion of the print media in transport direction.• print media height = expansion of the print media across the transport direction.1.4 System requirementsThe <strong>Neopost</strong> AS-960HD/AS-990HD is designed to be used in connection with a PC. Toconnect the AS-960HD/AS-990HD to the PC one free USB port or one free Ethernet (TCP/IP)port is required. The PC should be an up-to-date model and must have enough processingpower and free disk space to run the <strong>Neopost</strong> Addressing Solutions Software.We recommend using one of the following operating systems:• Microsoft Windows 2000 (SP4)• Microsoft Windows XP (SP3)• Microsoft Windows Vista (SP2) (32- or 64-bit)• Microsoft Windows 7 (32- or 64-bit)<strong>User</strong> Manual Version 3.1 11

Pos: 13 /Bedienungsanleitungen/Geräte neutral/2.1a_Ü2_Allgemeine Sicherheitshinweise_Handbuch @ 0\mod_1249563586836_912.doc @ 2673 @ 2Pos: 14 /Bedienungsanleitungen/Geräte neutral/2.1c_Allgemeine Sicherheitshinweise_Aufstellen des Gerätes @ 0\mod_1242736827044_912.doc @ 1710 @Pos: 15 /Bedienungsanleitungen/Geräte neutral/2.1e_Allgemeine Sicherheitshinweise_Elektrische Gefahren_ZWEIPOLIG @ 0\mod_1242736827372_912.doc @ 1718 @Pos: 16 /Bedienungsanleitungen/Geräte neutral/2.1f_Allgemeine Sicherheitshinweise_Betriebssicherheit/Reinigung/Service @ 0\mod_1242736827200_912.doc @ 1714 @2 Safety notesPrior to initial operation, please carefully read the following instructions for the sake of bothyour own safety and the printer operating safety. Always observe any warnings andinstructions directly attached to the device. Keep this manual available in order to be able tocheck back at any time.Disregarding this manual may cause• electric shock,• injury by being drawn into the transport belt or transport rollers,• damage to the equipment.2.1 General safety notesCaution!Please read these notes with care.Keep this manual for future reference.All notes and warnings found on the machine are to be followed.Setting up themachineA safe, level position is necessary, when installing the machine.Injuries may be caused by tipping, rolling away or falling.The machine is to be protected from moisture.The machine is not suitable for outdoor use.ElectricalHazardsThe power cable must only be connected to a socket with protectivegrounding contact! The protective effect must not be compromised bythe use of an extension cable without a protective groundingconductor. All interruptions of the protective grounding conductor,within or outside of the machine, are prohibited.When fuse failure occurs, electrical machine parts can still carryvoltage.When making the connection to the mains power, be aware of theconnection values on the rating plate.Run the power cable in such a way, that no one can trip over it. Donot place any objects on the power cable.When the machine is not in use over a long period of time, it shouldbe disconnected from the power supply in order to avoid any damagein the event of a voltage surge.Protect the device from moisture. When moisture enters the machine,there is a danger of electrical shock.Never open the machine. For reasons of electrical safety, the machineshould only be opened by authorized service personnel.12 <strong>User</strong> Manual Version 3.1

Pos: 17 /Bedienungsanleitungen/Geräte neutral/2.1g_Allgemeine Sicherheitshinweise_Ersatzteile/Reparaturen/Umbauverbot @ 0\mod_1249462580902_912.doc @ 2637 @Pos: 18 /Bedienungsanleitungen/Geräte neutral/2.1h_Allgemeine Sicherheitshinweise_Hinweis Service @ 0\mod_1242737415895_912.doc @ 1746 @Pos: 19 /Bedienungsanleitungen/Geräte spezifisch/Drucker/2.2_Ü2_Ink safety notice @ 1\mod_1260870536312_912.doc @ 8392 @ 2OperatingsafetyCleaning themachineMachineinspectionsonly byauthorizedServicePartners!Never put your hands inside the machine when it is running!There is a danger that injuries can occur through being pulled in andbeing crushed on the transport belt or the rotating rollers. In addition,keep long hair and parts of loose clothing away from the machinewhile it is in operation.In order to prevent damage to the machine, only factory authorizedaccessory parts should be used.Prior to cleaning the machine, it should be disconnected from thepower outlet. When cleaning the machine, do not use liquid or spraycleaners, but only a cloth dampened with water.Additional information concerning the cleaning of the device can befound in chapter „Maintenance and support“.In the following cases, you should unplug the machine from thepower outlet and contact an authorized service technician:• When the power cable or its plug is worn or damaged.• When water or other liquid has entered the device.• When the device has been dropped/knocked over or the housing isdamaged.• When there is a significant change in the performance of themachine.Spare partsRepairsModification isnot permittedWhen repair work is carried out, only original spare parts or spareparts approved by the manufacturer may be used.Do not disassemble the machine any further than it is described inthis manual. The opening of the machine by unauthorized personnelis not permitted. Repairs may only be carried out by authorizedservice personnel.For safety reasons, your own reworking and modifications to themachine are not permitted.Please contact your authorized <strong>Neopost</strong> dealer or service partner, forall questions relating to service and repair. In this way, you ensurethe operational safety of your machine.<strong>User</strong> Manual Version 3.1 13

Pos: 20 /Bedienungsanleitungen/Geräte neutral/2.3_Ü2_Location of the device @ 0\mod_1242737912401_912.doc @ 1759 @ 22.2 Ink safety noticeKeep ink cartridges away from children. If you get into skin contactwith the ink, immediately clean off the ink under running water. In caseink has entered your eye, immediately rinse it with plenty of water.• The ink cartridge should not be shaken, dropped or hit against the palm or hardsurfaces.• Install the ink cartridge immediately after removing the protective tape. The cartridgemay not be used after date of expiry!• Do not try to open or refill a cartridge. This can damage the printer and reduce theprint quality.• For further information regarding the cleaning of the ink cartridge, please see chapter7.5.1, on page 100.14 <strong>User</strong> Manual Version 3.1

Pos: 21 /Bedienungsanleitungen/Geräte neutral/2.4_Ü2_Entsorgung @ 0\mod_1242738502378_912.doc @ 1762 @ 2Pos: 22 /Bedienungsanleitungen/Geräte neutral/3.0_Ü1_Scope of delivery and assembly @ 0\mod_1242739012009_912.doc @ 1765 @ 12.3 Location of the printerBe aware when installing the machine that it must stand on a smooth and level surface thatis larger than the printer.When placing the machine, make sure that there is enough clearance around it, so that youcan access all connections easily.The floor space for the printer must be sufficiently stable. The tipping over or falling of themachine can lead to injuries, as well as damage to the machine.When selecting the installation or storage location for the printer, keep in mind that it mustbe protected from strong temperature and humidity changes, direct sunlight and excessiveheat.The printer must not be subject to vibrations or shocks.Install the printer near a power outlet, so that the power cable can be disconnected troublefreeat all times.2.4 DisposalThe printer may not be disposed of in the conventional manner of household waste. Pleasedispose the printer in accordance with the regulations in force.<strong>User</strong> Manual Version 3.1 15

Pos: 23 /Bedienungsanleitungen/Geräte neutral/3.1_Ü2_Scope of delivery @ 0\mod_1250854288313_912.doc @ 2837 @ 2Pos: 24 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/3.1_Ü2_Lieferumfang_AS-960/AS-990_USB2.0 @ 2\mod_1269601638544_912.doc @ 13969 @Pos: 25 /Bedienungsanleitungen/Geräte neutral/3.2_Ü2_Delivery @ 0\mod_1242739526953_912.doc @ 1770 @ 23 Scope of delivery and assembly3.1 Scope of delivery• 1x AS-960HD/AS-990HD printer• 1x Addressing Solution software CD-ROM• 1x power cable• 1x paper feed ramp• 1x grounding cable• 6x or 9x Black Dye ink cartridges*• 2x or 3x Inxdinx ink cartridge box*• 1x Catch tray• 1x Network cable• 1x USB connection cable• 1x Ferrit* The amount depends on the chosen model.16 <strong>User</strong> Manual Version 3.1

Pos: 26 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/3.2_Transportation locks and Lifting_AS-960/AS-990 @ 2\mod_1271948603407_912.doc @ 17023 @3.2 DeliveryThe <strong>Neopost</strong> AS-960HD/AS-990HD is delivered in appropriate packaging so that it reachesits destination without damage via a regular mode of transport.Transportation and storage should be carried out in suitable condition. That means anambient temperature between +10°C and +31°C at 20-80% relative humidity (noncondensing).Conditions outside of these ranges may harm the machine. Damages fromwrong transportation and storage conditions may not be visible on the packaging.Warning!Don't put pressure on the print units.Don't lift up the printer by grabbing the print unit bars.Don't turn the thickness adjustment wheel until all transportationlocks are removed.How to lift theprinter fromthe box• Loosen and remove the two locks that fix the printer to the box(see arrows in Figure 1).• Do not lift the AS-960HD/AS-990HD by grabbing the print unitbars or the control panel!• Lift the printer only by grasping under the colored varnished areasin the middle (see Figure 1).• To avoid injuries, two people should lift the printer together.• Keep the transportation locks in stock.Do not lift the printer bygrabbing the print unit barsTransportationlockvarnished area to liftthe printerFigure 1: Lifting the printer out of the box, Transportation locks<strong>User</strong> Manual Version 3.1 17

Pos: 27 /Bedienungsanleitungen/Geräte neutral/3.2_Delivery_mit Transportsicherung_AS-960/990/OrbitBase/3060A/2060/Base @ 2\mod_1271945715904_912.doc @ 16957 @Pos: 28 /Bedienungsanleitungen/Geräte neutral/3.3_Ü2_Device overview @ 0\mod_1250854288578_912.doc @ 2841 @ 2How toremove thetransportationlocks• Before using the printer, the additional two transportation locks onboth sides need to be removed.• Loosen the two cross-head screws on each side and remove thetransportation locks (see Figure 2).• Keep the transportation locks in stock.Do not turn thethickness adjustmentwheel until alltransportation lockshave been removed!Loosen the two crossheadscrews andremove thetransportation lock.Figure 2: Removing the transportation locks, side viewsIf the printer has to be shipped again, please store the transportation locks and thepackaging. In case the packaging is no longer needed, please dispose it in anenvironmentally suitable manner.18 <strong>User</strong> Manual Version 3.1

Pos: 29 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/3.3_Geräteübersicht_AS-960/AS-990_USB_2.0 @ 3\mod_1296822265090_912.doc @ 29999 @3.3 Device overview152678910311124Figure 3: overview1 Stacking plate 9 USB 2.0 interface to the PC forsending print datav2 Paper side guides 10 Serial interface to the PC for statusfeedbacks and service purposes3 Thickness adjustment screw 11 Ethernet (TCP/IP) interface forsending print data4 Operator panel with display 12 On/off switch5 Slot for paper feed ramp 13 Power input module6 Knurled screw for paper feed ramp 14 Contact plate7 Slide (runner) 15 Separator rollers (fixed)8 Paper feed ramp 16 Passive rollers (loose)1314<strong>User</strong> Manual Version 3.1 19

1516Figure 4: Separator rollers, passive rollers20 <strong>User</strong> Manual Version 3.1

Pos: 30 /Bedienungsanleitungen/Geräte neutral/3.3_Ü2_Assembly @ 1\mod_1264168442358_912.doc @ 10763 @Pos: 31 /Bedienungsanleitungen/Geräte neutral/3.3.1_Ü3_Connecting the power cable @ 1\mod_1264168527578_912.doc @ 10766 @ 317181920 282122232429252627Figure 5: overview assembled17 Wing screws of the paper sideguides24 Print unit bar18 Clamping lever 25 Wing screws for print unit19 Separation adjustment knob 26 Sand rollers20 Separation lock knob 27 Grounding contact21 Paper sensor 28 Side plane22 Print unit 29 Contact rollers23 Ink cartridges3.4 Assembly<strong>User</strong> Manual Version 3.1 21

Pos: 32 /Bedienungsanleitungen/Geräte neutral/5.2b_Warnhinweis Netzkabel @ 0\mod_1246016358876_912.doc @ 1980 @Pos: 33 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/3.3.2_Ü3_How to mount the paper feed ramp, side guides_AS-960/AS-990 @ 2\mod_1271945306623_912.doc @ 16866 @ 33.4.1 Connecting the power cablePower cableAttention!The device may only be used in connection to power outlets withintegrated protective conductor (earthing)!Make sure that the on/off switch is set to off. Plug the power cableinto the power input of the AS-960HD/AS-990HD. Connect the cableto the power outlet.3.4.2 How to mount the stacking plate and the guidesMounting thestacking plateThe stacking plate can be removed for transport or maintenance reasons.The plate has to be engaged with the printer.• Loosen both clamping levers inside the side panels until a gap ofabout 2.5 mm is created.• Place the stacking plate with its two recesses above the pins insidethe side panels (see arrow pointing downwards in Figure 6).• Now tip the stacking plate toward the loosened clamping leversand engage the plate with them (see curved arrow in Figure 6).Tighten the clamping levers. You may have to pull and release thelevers several times in axial direction, while fastening them stepby step.BlockClampingleverPinUpper pinpositionFigure 6: Assembly of the stacking plate22 <strong>User</strong> Manual Version 3.1

Conversion of the stacking plate for feeding thick materialFor materials thicker than approx. 6 mm / 0.25", the whole stackingplate may be mounted in an upper position. Just unscrew the metalblock (with the clamping levers on it) and mount it into the secondaryholes in the side plane (see Figure 6). You need a hexagon socketscrewdriver for that.Please consider that with the pins being in the upper position, nomaterial thinner than approx. 6 mm / 0.25" can be separated. Youneed to switch back the pins to the lower position.Mounting thepaper sideguides• Unscrew the wing screws of the paper side guides.• The two paper side guides are identical and can be mounted onboth sides of the plate. Place one guide on the left and one on theright side of the stacking plate.• Put back on the wing screws and adjust the position of the guidesbefore tightening the screws.Mounting thepaper feedramp• Loosen the knurled knob for the paper feed ramp. Don’t unscrew itcompletely.• Insert the ramp into the slot of the contact plate. Tilt the ramp andthread the flexible sheet into the gap between the small bracket ofthe knurled screw and the device itself (see Figure 7).• Put the paper feed ramp into its lowermost position and tightenthe knurled knob.<strong>User</strong> Manual Version 3.1 23

Pos: 34 /Bedienungsanleitungen/Geräte neutral/4.0_Ü1_Description of device @ 0\mod_1246003073544_912.doc @ 1919 @ 1smallbracketknurledknobflexiblesheetFigure 7: Mounted paper feed ramp24 <strong>User</strong> Manual Version 3.1

Pos: 35 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/4.1_Different Printer Versions_AS-960/AS-990/AS-990LOG @ 2\mod_1275461481545_912.doc @ 17883 @Pos: 36 /Bedienungsanleitungen/Geräte neutral/4.2_Ü2_Application range @ 0\mod_1250854288985_912.doc @ 2849 @ 2Pos: 37 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/4.2_Anwendungsgebiete_AS-960/AS-990 @ 2\mod_1271945469914_912.doc @ 16952 @Pos: 38 /Bedienungsanleitungen/Geräte neutral/4.3_Ü2_Description of functions @ 0\mod_1250854288782_912.doc @ 2845 @ 2Pos: 39 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/4.3_Funktionsbeschreibung_AS-960/AS-990 @ 2\mod_1271946664197_912.doc @ 16964 @4 Description of deviceThis <strong>User</strong> Manual is valid for the <strong>Neopost</strong> AS-960HD and the <strong>Neopost</strong> AS-990HD printer. Thedifference between these models is the number of print units respectively the number of inkcartridges (see Figure 8 and Figure 9).For the AS-990HD printer is also a LOG (Logistic) version available (see note below).LOG - Logistic functionThe LOG (Logistic) function of the AS-990HD LOG printer allows tofeed single pages, due to a special clutch-brake mechanism for thefeed roller. This makes the printer ideal for printing lot amounts ofsingle page print jobs or print jobs were exact mail sorting withoutadditional blank pages is needed.The AS-960HD and AS-990HD printer without this LOG function, willalways feed additional blank (unprinted) pages when processing aone page print job.Figure 8: The AS-960HD printerFigure 9: The AS-990HD/AS-990HD LOGprinter4.1 Application rangeThe <strong>Neopost</strong> AS-960HD/AS-990HD is an inkjet printer with high font quality.The main field of application is the printing of mass mailings with addresses and graphics orpostal elements. However, the application is not limited to this purpose.4.2 Description of functions<strong>User</strong> Manual Version 3.1 25

Pos: 40 /Bedienungsanleitungen/Geräte neutral/4.4_Ü2_The Operator Panel @ 0\mod_1250854289204_912.doc @ 2853 @ 2The <strong>Neopost</strong> AS-960HD/AS-990HD printer is a inkjet print system, that is designed forindustrial and professional printing. Different conveyor belts can be placed behind theprinter.The device can be used in connection with an IBM compatible PC and a vary of softwarerunning under Microsoft Windows operation systems.The print units of the <strong>Neopost</strong> AS-960HD/AS-990HD are provided with six/nine* HP inkcartridges (C1 … C9). During the printing the units stay motionless, therefore the device iscalled a Fixed Head printer. The alignment of the printed text should be parallel to the papertransport direction.The print units cover an area of 500 x 76 mm (19.6 x 3.0")* respectively 500 x 114 mm(19.6 x 4.5”)*. This corresponds to 18/27* text lines at a font size of 12 pt.The nozzles of the print cartridges can automatically be purged with a small amount of inkbefore each print start. This allows a constant print quality from the first print on.For further specifications please see chapter 10.4.1 Technical Specifications, on page 141.* The figures depend on the chosen model.26 <strong>User</strong> Manual Version 3.1

Pos: 41 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4_Operator_Panel @ 2\mod_1265967728349_912.doc @ 12018 @Pos: 42 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.1_Ü3_Key Panel_Fixed Head AS-960/990/990LOG @ 1\mod_1261137139734_912.doc @ 9007 @ 34.3 The Operator PanelFigure 10: The operator panelThe operator panel is used to easily activate often required functions and select informationfrom the main display. The operator panel is also used to navigate within the printer menus,in order to change printer and layout settings, run test modes and look up specific printerstatistics.The four LEDs (light-emitting diode) on the panel indicate the status of the printer.LEDGreen OnlineBlue OfflineOrange WarningRed ErrorStatus indicationPrinter is OnlinePrinter is OfflinePrinter displays a warning messagePrinter displays an error messageOnline and OfflineOnly when the printer is Offline you can make changes to printersettings, use the secondary functions of the arrow key or open printermenus.Please note, that when the printer is Online (= able to receive printdata from the PC), the only key that can be used is the Cancel(Offline) key. The Cancel (Offline) key will turn the printer Offline(= not able to receive print data from the PC).<strong>User</strong> Manual Version 3.1 27

4.3.1 Key panelBelow is an explanation of how the different keys of the panel work:KeyOk (Online)Cancel (Offline)HomeQuickArrow up (Test Print)Arrow right (Paper Length)Main FunctionTurns the printer online and confirms a selection in amenuTurns the printer offline and exits the current menulevel.Opens the main menu of the printerOpens the quick menu of the printerUpwards navigation in menus and increasing values inmenusNavigation to the rightArrow down (Clean Heads) Downwards navigation in menus and decreasingvalues in menusArrow left (Run Paper)Navigation to the leftThe four arrow key have secondary functions, which can be executed by hitting one of thearrow keys and the Quick key together.Secondary FunctionsPlease note, that the secondary functions will work slightly differentdepending on how long you press the keys.(Short) = hitting the two buttons just briefly(Long) = hitting the two keys, and keeping the pressed for a shortamount of time (~ 3 seconds)Below is an explanation of how the different secondary functions of the arrow keys work:Quick key + Secondary FunctionArrow up (Test Print)Arrow right (Paper Length)(Short) The printer will display Test and feed onepage and print the test pattern, using the currentprinter setting (e.g. print quality) (only valid for AS-990HD LOG).(Long) The printer will display Test and feed pagesand print the test pattern continuously, using thecurrent printer setting (e.g. print quality). To stop, hitthe Cancel (Offline) key.(Short) The printer will display PAPER WIDTH: , feedone page and measure the size of the page. Themeasured size will be shown in the display.(Long) The printer will display PAPER WIDTH: (L),feed one page and measure the size of the page. The28 <strong>User</strong> Manual Version 3.1

Pos: 43 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.2_Ü3_Main_Display @ 1\mod_1261142768887_912.doc @ 9017 @measured size will be shown in the display. The (L)indicates that the measured page size will be locked inthe printer, so that the page size cannot be changedfrom a PC program.Arrow down (Clean Heads)Arrow left (Run Paper)The printer will feed one page and print a pattern ofbars, using the currently set page size.(Short) The printer will display PapRUN and feed onepage and transport it, using the current printer setting(e.g. transport speed) (only valid for AS-990HD LOG).(Long) The printer will display PapRUN and feed andtransport pages continuously, using the currentprinter setting (e.g. transport speed). To stop hit theCancel (Offline) key.This is an useful function to check if, the separationand the material transport of the printer, are setupcorrectly.<strong>User</strong> Manual Version 3.1 29

Pos: 44 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.3_Main_Display_Fixed_Head_6_cartridges_AS3060A/OrbitBase/960/990_ONLY 619 @ 3\mod_1301663239066_912.doc @ 31022 @4.3.2 Main DisplayThe main display shows you the most important information about your current print job atone glance.J ob Current :1234 5 6 7 ←1Costs/ 1000 Pg 1 . 5 5 € ←2M eter/Secon d : 0. 5 4 0 ←3Pages/ h : 10 5 0 0 ←4BLA CK DYE←5█ █ █ █ █ █ 6x6 d p i ←6█ █ █ █ █ █ Nor ←7█ █ █ █ █ █ O n l i n U S B ←8↑ ↑ ↑ ↑ ↑ ↑999999Figure 11: Main displayItems per display linePlease note, that there are display lines which contain more that oneitem to display. To cycle through all items, select a line (e.g. line 1counters) with the arrow up or arrow down keys and then hit thearrow left or arrow right key to show the other items of this line.Display lines and data1: Counters This line shows one of the following counters:Job Current: Shows the number of printed pagesfrom the current print job (= send from the PC).Job Power On: Shows the total number of printedpages from all print jobs, since the printer was turnedon.TotalService: Shows the number of service pagesprinted (e.g. Clean Heads), since the printer wasturned on.Tot.Power On: Shows the total number of pagesprinted, since the printer was turned on. All Print jobpages + all service pages.To reset one of the counters to zero pages, select thisline and use the arrow right or arrow left key toshow the counter you want to reset and hit the Okkey. Confirm the reset by selecting Yes and hitting theOk key again.2: Ink costs and ink range This line shows one of the following information:InkCosts/Job: Calculates and shows the cost of inkfor the current print job in the set currency.30 <strong>User</strong> Manual Version 3.1

Costs/1000Pg: Calculates and shows the cost of inkper 1,000 pages of the current print job.Pages/Cartr.: Calculates and shows the number ofpages you can print, of the current print job, with theremaining amount of ink in the cartridge.Please consider that the information above arecalculated average values only. Therefore theaccuracy of the values will increase as more pages areprinted.To show information in this line, you first have to seta cost per cartridge greater than zero. To do this,select this line and hit the Ok key. Or you can openthe main menu of the printer and select the followingmenu: PRINTER CONFIG. > INK > INK COST CONFIG.3: Transport speed This line shows the currently set transport speed. Tochange the speed select this line and use the arrowright or arrow left key to change the speed.Please note that the speed you can select is limited bythe set print quality (see line 6). With a print qualityof 6 x 6 dpi, the maximum speed you can set is 0.540meter/second.4: Throughput This lines shows one of the following information:Pages/h: Shows the current throughput of themachine, calculated from the last few pages.JOB Pages/h: Shows the average through since thebeginning of this print job. This is a valuableinformation to measure the actual productivity of themachine.5: Ink type This line shows the currently set ink type.6: Print quality This lines shows the currently set print quality. Tochange the quality select this line and use the arrowright or arrow left key to change the quality.Please note that the selected print quality determinesthe maximum speed of the machine.This setting can be locked, so that a print qualitysetting, send from the PC is ignored. To lock thissetting, select this line and press the Ok key forfour seconds. A symbol appears next to the qualitysetting, showing that it is locked now.To unlock the setting select this line again and pressthe Ok key for four seconds. The symboldisappears again.7: Print direction This line shows the set print direction.Nor The print layout is printed in normal direction.Rev The print layout is printed 180° turned.<strong>User</strong> Manual Version 3.1 31

s: 45 /Bedienungsanleitungen/Geräte spezifisch/Drucker/4.4.3_Additional Display Texts_HINWEIS_Table Top @ 2\mod_1275402350991_912.doc @ 17865 @Pos: 46 /Bedienungsanleitungen/Geräte neutral/5.0_Ü1_Initial start-up of the device @ 0\mod_1246014198984_912.doc @ 1931 @ 1Please refer to the section “Printer Menu” of thismanual, to get more detailed information about printdirection (JOB PARAMETERS > LAYOUT >ORIENTATION).This setting can be locked, so that a print directionsetting, send from the PC is ignored. To lock thissetting, select this line and press the Ok key forfour seconds. A symbol appears next to thedirection setting, showing that it is locked now.To unlock the setting select this line again and pressthe Ok key for four seconds. The symboldisappears again.8: Status This line shows the printer status and the usedinterface.OnlinUSB The printer is ready to receive print datafrom the PC via the USB interface. No changes toprinter settings via a printer menu can be made whenthe printer is Online.OnlinTCP The printer is ready to receive print datafrom the PC via the Ethernet interface. No changes toprinter settings via a printer menu can be made whenthe printer is Online.Offline The printer menus can be accessed andchanges to settings can be made when the printer isOffline.Changing from OnlinUSB or OnlinTCP to Offline: Hitthe Cancel key.Changing from Offline to Online: Select this line(line 8) in the main menu (see Figure 11) by hittingthe Cancel key or using the arrow down key andthen hit the Ok key.9: Ink level cartridge The height of the bars, shows the amount of ink leftper cartridge.To see the exact percentage of ink left, select one ofthe bars with the arrow left key. To manuallychange the amount of ink left in the cartridge, changethe value with the arrow up or arrow down keys.You can access the cartridge menu by selecting one ofthe bars with the arrow left key and hitting the Okkey. In this menu you can reset the amount of inkto 100% or change the ink type.Note:The number of bars shown, depends on your printermodel and its configuration.32 <strong>User</strong> Manual Version 3.1

Pos: 47 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.0_print_first_test_page @ 1\mod_1263302633152_912.doc @ 10181 @Pos: 48 /Bedienungsanleitungen/Geräte neutral/5.2d_Ü2_How to power-on the device @ 0\mod_1250856526091_912.doc @ 2869 @ 2Pos: 49 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.2d_Power-on the device_AS-830/930/960/990 @ 2\mod_1268401851925_912.doc @ 13319 @Pos: 50 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.2_Ü2_How to install the ink cartridges _ MEHRERE PATRONEN @ 1\mod_1260880358807_912.doc @ 8482 @ 2Pos: 51 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.2b_How to install the ink cartridge_Allgemein @ 1\mod_1261387630600_912.doc @ 10024 @5 Initial start-up of the deviceThis section describes all the necessary steps to print the first test page with your <strong>Neopost</strong>AS-960HD/AS-990HD.5.1 How to power-on the deviceTurn on the printer with the on/off switch located on the rear side of the device.The printer will start an initialization and present the following messages (from top tobottom):MessageLoader -01Version#1.1.xx#STARTING APPLICATIONVersion 4.7.xx –PPCPrinterInitializationCHECK CARTRID1,2,3INSERT ALL CARTRIDG!CODE: 25Proceed by pressing the Okdisplay will show the main view.NoteInitialization of the monitor software. The versionnumber may differ.Initialization of the printer firmware. The versionnumber may differ.Initialization of the printer functions.This notification is only shown when no cartridges areinserted in the printer.key. The printer will switch to the Online mode and the5.2 How to install the ink cartridgesCartridge mountingThe restraining lever ensures a safe contact between the ink cartridgeand the electronics of the AS-960HD/AS-990HD.Please do not force the ink cartridge to its final position by handTo avoid connection problems and damage, please install thecartridge as seen in Figure 12 and Figure 13.<strong>User</strong> Manual Version 3.1 33

Pos: 52 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/5.3_How to set up the paper transport_AS-960/AS-990 @ 2\mod_1271945307091_912.doc @ 16870 @ 2Figure 12: Inserting the ink cartridge intothe pen stallFigure 13: Lock the restraining leverInstalling theink cartridgePlease put the cartridge into the mounting (pen stall), by cautiouslypushing it downwards in a straight movement. Do not force or press thecartridge back into its pen stall by hand.The cartridge should be in a slightly inclined position. The restraininglever then tilts the cartridge into its final position.• Open the restraining lever completely.• Take the ink cartridge out of the packaging and remove theprotection tape from the print nozzles.• Insert the ink cartridges one after another with the print nozzlesfacing downwards - do not push in the direction of the restraininglever.• Lock the lever in direction of the arrow as shown in Figure 13.Thus, the ink cartridge is tilted into its final position, and thecontact is established correctly.Setting the inktypeTo ensure the best performance of the ink cartridge the correct ink typemust be set up in the printer. To set the ink type open the menuPRINTER CONFIG. > INK > SET INK TYPEHandling ink cartridgesDo not touch the contacts or the nozzle plate of an ink cartridge. Thismay lead to reduced print quality.Ink cartridgesWe recommend to use only supported <strong>Neopost</strong> inks in connectionwith this printer. Refilled ink cartridges may result in bad printingquality and may damage the printer.Please see chapter 8.1 Consumables, on page 135 for applicable ink cartridges.34 <strong>User</strong> Manual Version 3.1

Pos: 53 /Bedienungsanleitungen/Geräte spezifisch/Feeder/FD-13 / FD-15/5.4.1_Ü3_How to adjust the paper separation_Feeder/AS-960/AS-990 @ 2\mod_1268395233968_912.doc @ 13333 @ 35.3 How to set up the paper transportTo setup the paper transport you need to perform the following steps in this order:1. Adjust the paper separation2. Adjust the paper side guides and the paper feed ramp3. Adjust the material thickness4. Position the print units and the sand rollers5.3.1 How to adjust the paper separationAdjusting theseparatorrollers to themediathickness• Loosen the wing grips (F1) of the paper side guides and pushthese all the way outwards (see Figure 14).• Check that both outer adjustment knobs (F2) of the separatorsystem are centered ( ••• -Position ). Unlock the separator systemby turning the separation lock knob (F3) clockwise (see Figure 15).• Lift up the separator rollers by use of the loose separation lockknob (F3). Put one sheet of the paper under the separator rollersand drop them again (see Figure 16).• Lock the separator system by turning the center separation lockknob (F3) counter-clockwise and remove the medium.Depending on the fed paper and its thickness: widen theseparation gap by turning both outer adjustment knobs (F2)clockwise (see Figure 17).Paper separation and adjustmentsIn most cases it is recommended to use only one product for thethickness adjustment of the separator rollers. If the media are thinand narrow, so that only the inner two separator rollers are used,two sheets should be used to set the gap.When feeding thick, multiple page products (e.g. brochures), it is alsopossible to use 1½ products to set the separation.Any necessary corrections and fine adjustments can be made with theuse of the knurled adjustment knobs (F2) during a test run.Conversion of the stacking plate for feeding thick materialFor materials thicker than approx. 6 mm / 0.25", the whole stackingplate may be mounted in an upper position. Just unscrew the metalblock (with the clamping levers on it) and mount it into the secondaryholes in the side plane (see Figure 6). You need a hexagon socketscrewdriver for that.Please consider that with the pins being in the upper position, nomaterial thinner than approx. 6 mm / 0.25" can be separated. Youneed to switch back the pins to the lower position.<strong>User</strong> Manual Version 3.1 35

Pos: 54 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/5.4.2_Ü3_How to adjust the side guides and the feed ramp_AS-960/990 @ 2\mod_1272294118262_912.doc @ 17055 @ 3Use of the adjustment knobsThe adjustment knobs (F2) allows a precise and comfortable way tofine adjust the paper separation. You may widen or tighten one sideof the separation while the feeder is running. This for example isuseful, if you feed uneven products (e.g. filled envelopes) or if themedia gets skewed while exiting the feeder.F1F2F4F3Figure 14: Separator systemFigure 15: Separator systemadjustment IFigure 16: Separator systemadjustment IIFigure 17: Separator systemadjustment IIINarrow media and unused separator rollersWhen feeding narrow material, make sure that the position of the notused separator rollers is adjusted to the material thickness as well.Therefore make sure to put a small piece of paper under each of theunused separator rollers, when setting the paper separation.Otherwise these rollers could wear the feed roller.36 <strong>User</strong> Manual Version 3.1

5.3.2 How to adjust the side guides and the feed rampAdjusting thepaper sideguidesPlease check whether the medium to be processed is fed longitudinally ortransversally through the feeder.• Place a small stack of products centrally into the feeder.• Adjust the side guides (F4) according to the media width. Pleaseassure that the paper stack can still be moved loosely between thetwo side guides. Afterwards fix the two wing grips (F1).The ruler on the stacking plate may help you to align the productsthe best way.Adjusting thepaper feedramp and theslide (runner)Put the feed ramp (F5) to a low and centered position. Insert a smallstack of paper as shown in Figure 18.• Loosen the fixing screw of the slide (F6), mounted on the paperfeed ramp. Raise the paper feed ramp to an appropriate angle (seenote below) and fix it..• Adjust the slide (F6) as shown in Figure 18. The lowermost two orthree media should fall loosely out of the stack, so they can beeasily gripped by the feed roller.• Tighten the fixing screw of the slide.Angle of the paper feed rampThe optimal angle depends on the width of your material runningthrough the machine:flexible material, small width = steep angleinflexible material, large width = flat angleF7F6F8F9F5Figure 18: Adjusting the paper feed rampand the slide, side viewFigure 19: Filing the stack with a fanned outpile, side viewFilling thepaper stack• If not already done, fan out a small stack of products(approximately 25 mm / 1”) and put it between the paper sideguides (F7). The fanning out ensures that the media are grippedeffectively by the feed roller (F9) and that no multiple sheets arefed.<strong>User</strong> Manual Version 3.1 37

Pos: 55 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/5.4.3_Ü3_Adjusting Printer to the material thickness_AS-960/AS-990 @ 2\mod_1271946676325_912.doc @ 16969 @ 3Pos: 56 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/5.4.4_Ü3_How to position the print unit_AS-960/AS-990 @ 2\mod_1271946688251_912.doc @ 16976 @ 3• The paper stack should adapt to the shape of the fixed separatorroller (F8) (see Figure 19).• Fill the stack up to a convenient height for your particular medium.Paper format, stack heightThe height of the stack may be limited, due to the size of the mediaand the weight of the stapled products.5.3.3 How to adjust the printer to the material thicknessAdjusting thematerialthicknessTo ensure a sharp and clean print quality and a safe material transport,you have to adjust the distance between print units and the material.The setting can be applied in a range of 10 mm.• Turn the thickness adjustment screw to the maximum distance.• Put one piece of the material underneath the sand rollers of thefirst print unit (see Figure 20).• Turn the thickness adjustment screw clockwise, until the mediumis fastened between the transport rollers. Remove the medium.• For material up to 0.3 mm thickness you can use the lowestposition.MediumThicknessadjustment screwFigure 20: Adjusting the printer to the material thickness38 <strong>User</strong> Manual Version 3.1

5.3.4 How to position the print areaPositioning thevertical printareaThe vertical position of the print area must be setup manually.• Open the wing screw of each print unit and move the unit alongthe print unit bar to the desired position.• As a reference for the position of the print area, the ruler can beused. The print area is located between the two red markers ofeach print unit (see Figure 21).• Lock the wing screw again.WingscrewPositionreferencemarkerFigure 21: Positioning the vertical print area, AS-960HDUnprintable areaPlease consider that there are unprintable areas, next to the sidewalls of the machine and between the print units 1 and 3 (only forAS-990HD), which the printer cannot cover.Please see Figure 24, Figure 25 and Figure 26 in the following tablefor a detailed descriptions about the print area limitations.Print unit 1Correspondingprint areaProduct(envelope)UnprintableareasFigure 22: Unprintable area AS-960HD, top view<strong>User</strong> Manual Version 3.1 39

Print unit 1Correspondingprint areaProduct(envelope)UnprintableareasFigure 23: Unprintable area AS-990HD, top view40 <strong>User</strong> Manual Version 3.1

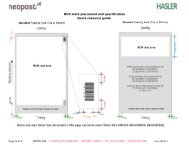

Print area <strong>Neopost</strong> AS-960HDPrint Unit 1/2Print area <strong>Neopost</strong> AS-990HDPrint Unit 2Paper transportdirectionFigure 24: Printable areaAS-960HD unit 1/2The grey box shows the printable area on a500 x 381 mm (19.7” x 15”) wide paper(Please notice the paper transport directionright-to-left).Print unit 1 and 2 may be arranged within theinner 281 mm (11”). The units may be alignedto each other to cover a print area of 76 mm(2x38 mm).Figure 25: Printable areaAS-990HD unit 2The grey box shows the printable area on a500 x 381 mm (19.7” x 15”) wide paper(Please notice the paper transport directionright-to-left).Print unit 2 may be arranged within the inner281 mm (11”).Print Unit 1/3Paper transportdirectionFigure 26: Printable areaAS-990HD unit 1/3One of the units sharing one print unit bar(Unit 1 or 3) may be arranged within amaximum area of 143 mm (5.6”).Note: Only print units 1/2 or units 2/3 may bealigned to each other to cover a print area of76 mm (2x38 mm). The minimal distancebetween unit 1 and 3 is 100 mm (3.9”). It isnot possible to cover a connected print area of3x38 mm!Positioning thesand rollersThe machine is equipped with eight separate sand rollers (four on eachprint unit bar), that transport the paper out of the printer. Their verticalposition can be adjusted to the print area.<strong>User</strong> Manual Version 3.1 41

Pos: 57 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/5.5_Ü2_Width Measurement of the Print Media_AS-960/990 @ 2\mod_1275402935026_912.doc @ 17870 @ 2• Push the rollers along the bar to a position, where they cansupport the paper transport according to the used paper format(see Figure 27).• Position the rollers “outside” the print image. Set them to aposition where they roll over unprinted paper surface only.Otherwise the roller may smear the fresh printed ink.SandrollersFigure 27: Positioning the sand rollers outside the print image5.4 How to measure the print media sizeThe printer permanently controls the size of the fed products. Therefore the AS-960HD/AS-990HD needs to know the dimension of the paper at the beginning of a new print job. Thedimension can either be measured manually or be send by a PC software. The dimensionvalues are stored in the memory of the printer as reference values, until new dimensionsare measured.PC softwareSending the correct paper dimensions to the printer, is only availablein PC software designed to work together with this <strong>Neopost</strong> printer.When you are using a PC software that is able to send the paper dimension, you do notneed to measure the paper size manually.• Measure the paper dimension manually1. Setup the feeder as described in chapter 5.3, on page 34.2. Put one media into the feeder.3. Press the Quick key and the Arrow right key together to perform themeasurement.4. Compare the measurement shown the printer display with the actual size of theprint media.5. If the difference between the size measured by the printer and the actual size42 <strong>User</strong> Manual Version 3.1

Pos: 58 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.7_Ü2_How to set the print direction @ 1\mod_1260881170148_912.doc @ 8511 @ 2Pos: 59 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.7_How to set the print direction_Verweis_Fixed Head Printer/AS-Orbit/AS-OrbitBase @ 2\mod_1276076390012_912.doc @ 18021 @Pos: 60 /Bedienungsanleitungen/Geräte spezifisch/Drucker/5.9_Ü2_Test print_AS-830/930/960/990 @ 2\mod_1269248556360_912.doc @ 13721 @ 2of the print media is larger than 3 mm / 0.12” readjust the separation system andrepeat the measurement.• Set paper dimensions in PC softwarePlease refer to the manual of your PC software.5.5 How to set the print direction (orientation)Depending of the direction in which the products are fed into the printer, it could becomenecessary to turn the direction of the printed image by 180°. The <strong>Neopost</strong> AS-960HD/AS-990HD has a built-in feature that automatically turns the printed image by 180°. Thisadjustment can either be set directly in the printer menu, in the software application usedto send the data to the printer or in the printer driver.Software application and printer driverSetting the print direction (orientation), is only available in softwareapplications and printer drivers designed to work together with<strong>Neopost</strong> printers.• Set the print direction in the printer driverPlease check the setting of your driver.• Set the print direction (orientation) in the printer menu ORIENTATION, on page 68 formore details.• Set the print direction (orientation) in software applicationPlease refer to the manual of your software application.<strong>User</strong> Manual Version 3.1 43

Pos: 61 /Bedienungsanleitungen/Geräte spezifisch/Drucker/AS-960HD/AS-990HD/5.9_Testprint Scan_AS-960/AS-990 @ 2\mod_1271945307497_912.doc @ 16944 @Pos: 62 /Bedienungsanleitungen/Geräte spezifisch/Drucker/6.0_Ü1_Printer Menu (firmware V4.8) @ 3\mod_1298994979036_912.doc @ 30615 @ 15.6 How to perform a test printThe test print function allows a fast test of the printer settings. The test print can be used toget a quick impression of the print quality of the inserted ink cartridges as well. There is noneed to have a connection to a PC to use this function.You can use the following key combination (offline mode):Quick + Arrow up = TEST PRINT (multiple pages, to abort press the Cancel key)Test print troubleshooting:• The test printout shows little gaps or thin white lines. Some print nozzles may be clogged. Please use the CLEAN HEADS ( Quick +Arrow down) function to purge the nozzles. You may also clean the nozzles using acleaning cloth. Please see chapter 7.5.1 How to clean an ink cartridge, on page 100for further information.• The position of the test print is misplaced. Please check if a paper size measurement has been done. Check the position of the print unit.Figure 28: Testprint44 <strong>User</strong> Manual Version 3.1

Pos: 63 /Bedienungsanleitungen/Geräte spezifisch/Drucker/6.0_Introduction_Printer_Menu @ 2\mod_1265890955551_912.doc @ 11914 @Pos: 64.1 /Bedienungsanleitungen/Geräte spezifisch/Drucker/Menüpunkte Drucker/0000 Inhaltsverzeichnis_Menü_Drucker @ 0\mod_1253108250855_912.doc @ 3380 @6 Printer menu (firmware V4.8)This chapter provides an overview of the menu structure of your <strong>Neopost</strong> printer, as well asa description for each single item of the menu.The index below shows the pages numbers for each item of the menu, as well as thestructure of the printer menu. The indention of a menu items shows its position within themenu. For example:SERVICEHARDWARE TESTDisplay(main menu)(submenu)(sub-submenu)QUICK MENU .......................................................................................................................48PRINTER RESET .................................................................................................. 48CLEAR PRINT QUEUE ........................................................................................... 49REPEAT PAGES ................................................................................................... 49PAPER MEASUREMENT ......................................................................................... 50SINGLE PAPER RUN............................................................................................. 50RUN PAPER ........................................................................................................ 50SINGLE TEST PRINT ............................................................................................ 51TEST PRINT........................................................................................................ 51CLEAN HEADS .................................................................................................... 51PURGE HEADS .................................................................................................... 52SPEED MEASUREMENT......................................................................................... 52SHOW LAST ERRORS........................................................................................... 52MAIN MENU .........................................................................................................................53PRINTER CONFIG. ...............................................................................................................54MAINTENANCE.................................................................................................... 54AUTO CLEAN HEADS .......................................................................... 54MANUAL PURGE................................................................................. 54AUTO PURGE..................................................................................... 54KEEP ALIVE....................................................................................... 55ADJUSTMENTS ................................................................................................... 56ADJUSTMENT STEPS .......................................................................... 56PRINT CORR.PATT. ........................................................... 56CORR. U1-U2 ................................................................... 57CORR. U2-U3 ................................................................... 57CORR. U1 C1-C2 .............................................................. 58CORR. U1 C2-C3 .............................................................. 58CORR. U2 C4-C5 .............................................................. 58CORR. U2 C5-C6 .............................................................. 58CORR. U3 C7-C8 .............................................................. 58CORR. U3 C8-C9 .............................................................. 58ADJUST TOF...................................................................................... 59BOOT DEFAULTS................................................................................................. 60TEXT ROTATION ................................................................................ 60PC PROGRAM .................................................................................... 60UNIT of MEASUREM............................................................................ 60COMMUNICATION .............................................................................. 61PAGE DATA SIZE ............................................................................... 61INK................................................................................................................... 62SET INK TYPE.................................................................................... 62<strong>User</strong> Manual Version 3.1 45

RESET INK LEVEL...............................................................................63INK COST CONFIG. ............................................................................63WARMING CARTRIDGE........................................................................64PREWARMING CARTR. ........................................................................64ERROR HANDLING...............................................................................................65SOFT FONT ERROR.............................................................................65SET PAP.TOLERANCE ..........................................................................65ERROR LOW INK ................................................................................66BEEPER ............................................................................................66AUTOM.PAGE REPEAT .........................................................................66JOB PARAMETERS ............................................................................................................... 67PRINT QUALITY...................................................................................................67TRANSPORT PARAM. ............................................................................................68PAPER SPEED ....................................................................................68AUTO PAP SPEED ...............................................................................68SEPARATION .....................................................................................69PAPER TIME-OUT ...............................................................................69LAYOUT .............................................................................................................69ORIENTATION ...................................................................................70PAPER SIZE.......................................................................................70LEFT MARGIN ....................................................................................70OFFSET EDGE....................................................................................70FONT PARAMETERS .............................................................................................71FONT................................................................................................71CHARACTER SPACING.........................................................................71CHARACTER SET ................................................................................71TYPE OF BARCODE ..............................................................................................71PAPER SENSOR ...................................................................................................72DOS MODE.........................................................................................................73LINE MODE .......................................................................................73HEX TO ASCII....................................................................................73AUTO LINEFEED.................................................................................74LINE SPACING ...................................................................................74SERVICE ............................................................................................................................. 75SELECT TEST PATT. .............................................................................................75HARDWARE TEST ................................................................................................75Display .............................................................................................75Keyboard ..........................................................................................75Ram.................................................................................................75Ram Contin. ......................................................................................75NV-Ram Cont. ...................................................................................76Encoder ............................................................................................76Speed Measurment.............................................................................76Clutch ..............................................................................................76Brake ...............................................................................................76Paper Sensor.....................................................................................77Sensor&Paper Run .............................................................................77Cartridges.........................................................................................77Prewarming.......................................................................................78PEN Board.........................................................................................78LED/Beeper.......................................................................................78CONFIGURAT. INFO .............................................................................................79Firmware: .........................................................................................79Version:............................................................................................79SerNo.: ............................................................................................79Mdel: ...............................................................................................79Page cnt: ..........................................................................................79RAM .................................................................................................79Hardware:.........................................................................................8046 <strong>User</strong> Manual Version 3.1