98/7680NT (M1845NT) - AeroTech

98/7680NT (M1845NT) - AeroTech

98/7680NT (M1845NT) - AeroTech

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

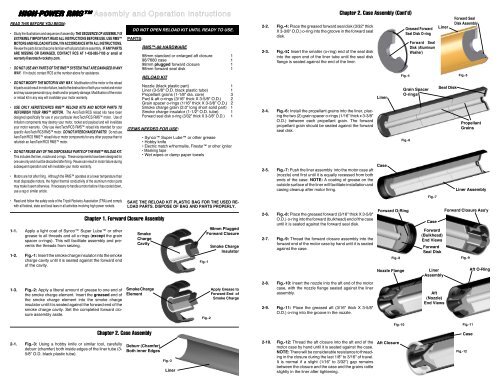

HIGH-POWER RMS Assembly and Operation InstructionsREAD THIS BEFORE YOU BEGIN:• Study the illustrations and sequence of assembly.THE SEQUENCE OF ASSEMBLY ISEXTREMELY IMPORTANT. READ ALL INSTRUCTIONS BEFORE USE. USE RMSMOTORS AND RELOAD KITS ONLY IN ACCORDANCE WITH ALL INSTRUCTIONS.Review the parts list and become familiar with all parts before assembly. IF ANY PARTSARE MISSING OR DAMAGED, CONTACT RCS AT 1-435-865-7100 or email atwarranty@aerotech-rocketry.com.• DO NOT USE ANY PARTS OF THE RMS SYSTEM THAT ARE DAMAGED IN ANYWAY. If in doubt, contact RCS at the number above for assistance.• DO NOT MODIFY THE MOTOR IN ANY WAY. Modification of the motor or the reloadkit parts could result in motor failure, lead to the destruction of both your rocket and motorand may cause personal injury, death and/or property damage. Modification of the motoror reload kit in any way will invalidate your motor warranty.• USE ONLY AEROTECH/RCS RMS RELOAD KITS AND MOTOR PARTS TOREFURBISH YOUR RMS MOTOR. The <strong>AeroTech</strong>/RCS reload kits have beendesigned specifically for use in your particular <strong>AeroTech</strong>/RCS RMS motor. Use ofimitation components may destroy your motor, rocket and payload and will invalidateyour motor warranty. Only use <strong>AeroTech</strong>/RCS RMS reload kits intended for yourspecific <strong>AeroTech</strong>/RCS RMS motor. DO NOT INTERCHANGE PARTS! Do not use<strong>AeroTech</strong>/RCS RMS reload kits or motor components for any other purpose than torefurbish an <strong>AeroTech</strong>/RCS RMS motor.• DO NOT REUSE ANY OF THE DISPOSABLE PARTS OF THE RMS RELOAD KIT.This includes the liner, nozzle and o-rings. These components have been designed forone use only and must be discarded after firing. Reuse can result in motor failure duringsubsequent operation and will invalidate your motor warranty.• Motors are hot after firing. Although the RMS operates at a lower temperature thanmost disposable motors, the higher thermal conductivity of the aluminum motor partsmay make it seem otherwise. If necessary to handle a motor before it has cooled down,use a rag or similar article.• Read and follow the safety code of the Tripoli Rocketry Association (TRA) and complywith all federal, state and local laws in all activities involving high power rockets.1-1. Apply a light coat of Synco Super Lube or othergrease to all threads and all o-rings (except the grainspacer o-rings). This will facilitate assembly and preventsthe threads from seizing.1-2. Fig.-1: Insert the smoke charge insulator into the smokecharge cavity until it is seated against the forward endof the cavity.1-3. Fig.-2: Apply a liberal amount of grease to one end ofthe smoke charge element. Insert the greased end ofthe smoke charge element into the smoke chargeinsulator until it is seated against the forward end of thesmoke charge cavity. Set the completed forward closureassembly aside.2-1. Fig.-3: Using a hobby knife or similar tool, carefullydeburr (chamfer) both inside edges of the liner tube (3-5/8” O.D. black plastic tube).DO NOT OPEN RELOAD KIT UNTIL READY TO USE.PARTS:RMS-<strong>98</strong> HARDWARE<strong>98</strong>mm standard or enlarged aft closure 1<strong>98</strong>/7680 case 1<strong>98</strong>mm plugged forward closure 1<strong>98</strong>mm forward seal disk 1RELOAD KITNozzle (black plastic part) 1Liner (3-5/8" O.D. black plastic tube) 1Propellant grains (1-1/8” dia. core) 3Fwd & aft o-rings (3/16" thick X 3-5/8" O.D.) 2Grain spacer o-rings (1/16” thick X 3-3/8” O.D.) 2Smoke charge grain (2.0” long short solid part) 1Smoke charge insulator (1-1/2" O.D. tube) 1Forward seal disk o-ring (3/32” thick X 3-3/8” O.D.) 1ITEMS NEEDED FOR USE:Chapter 1. Forward Closure Assembly• Synco Super Lube or other grease• Hobby knife• Electric match w/thermalite, Firestar or other igniter• Masking tape• Wet wipes or damp paper towelsSAVE THE RELOAD KIT PLASTIC BAG FOR THE USED RE-LOAD PARTS. DISPOSE OF BAG AND PARTS PROPERLY.SmokeChargeCavitySmoke ChargeElementChapter 2. Case AssemblyDeburr (Chamfer)Both inner EdgesFig.-3LinerFig.-1<strong>98</strong>mm PluggedForward ClosureFig.-2Smoke ChargeInsulatorApply Grease toForward End ofSmoke Charge2-2. Fig.-4: Place the greased forward seal disk (3/32" thickX 3-3/8" O.D.) o-ring into the groove in the forward sealdisk.2-3. Fig.-5: Insert the smaller (o-ring) end of the seal diskinto the open end of the liner tube until the seal diskflange is seated against the end of the liner.2-4. Fig.-6: Install the propellant grains into the liner, placingthe two (2) grain spacer o-rings (1/16” thick x 3-3/8”O.D.) between each propellant grain. The forwardpropellant grain should be seated against the forwardseal disk.2-5. Fig.-7: Push the liner assembly into the motor case aft(nozzle) end first until it is equally recessed from bothends of the case. NOTE: A coating of grease on theoutside surface of the liner will facilitate installation andcasing cleanup after motor firing.2-6. Fig.-8: Place the greased forward (3/16" thick X 3-5/8"O.D.) o-ring into the forward (bulkhead) end of the caseuntil it is seated against the forward seal disk.2-7. Fig.-9: Thread the forward closure assembly into theforward end of the motor case by hand until it is seatedagainst the case.2-8. Fig.-10: Insert the nozzle into the aft end of the motorcase, with the nozzle flange seated against the linerassembly.2-9. Fig.-11: Place the greased aft (3/16" thick X 3-5/8"O.D.) o-ring into the groove in the nozzle.2-10. Fig.-12: Thread the aft closure into the aft end of themotor case by hand until it is seated against the case.NOTE: There will be considerable resistance to threadingin the closure during the last 1/8" to 3/16" of travel.It is normal if a slight (1/16” to 3/32”) gap remainsbetween the closure and the case and the grains rattleslightly in the liner after tightening.Chapter 2. Case Assembly (Cont’d)LinerCaseForward O-RingFig.-8Nozzle FlangeFig.-10Aft ClosureGreased ForwardSeal Disk O-ringFig.-4Fig.-6Forward SealDisk (AluminumWasher)Grain SpacerO-ringsFig.-7CaseForward(Bulkhead)End ViewsForwardSeal DiskLinerLinerAssemblyAft(Nozzle)End ViewsSeal DiskForward SealDisk AssemblyFig.-5PropellantGrainsLiner AssemblyForward Closure Ass'yFig.-9Fig.-12Fig.-11CaseAft O-Ring

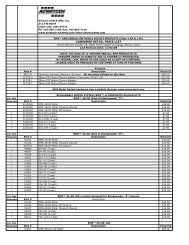

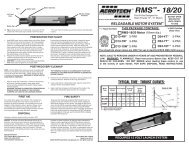

Nozzle Throat3-1. Fig.-13: Insert the coated end of a Firestar or otherigniter through the nozzle throat until it stops against thesmoke charge element.3-2. Secure the igniter to the nozzle with a piece of maskingtape.3-3. Install the motor into the rocket's motor mount tube.Ensure that the motor is securely retained in the rocketby using positive mechanical means to prevent it frombeing ejected during recovery system deployment.3-4. Prepare the rocket's recovery system and then launchthe rocket in accordance with the Tripoli RocketryAssociation (TRA) Safety Code and National Fire ProtectionAssociation (NFPA) Code 1127.Chapter 4. Post-Recovery CleanupNOTE: Perform motor clean-up as soon as possible after motorfiring. Propellant and delay residues become difficult to removeafter 24 hours and can lead to corrosion of the metal parts. Placethe spent motor components in the reload kit plastic bags andboxes and dispose of properly.4-1. After the motor has cooled down, unthread and removethe forward and aft closures.4-2. Remove the smoke charge insulator from the forwardclosure and discard. Using wet wipes or damp papertowels, remove all delay and propellant residue from theclosures.4-3. Remove and discard the forward and aft o-rings fromthe motor case. Remove the liner, forward seal disk andnozzle from the casing by pushing on the seal disk end.Remove the forward seal disk from the liner, andremove and discard the forward seal disk o-ring. DONOT DISCARD THE FORWARD SEAL DISK! Discardthe nozzle and liner. Using wet wipes or damp papertowels, wipe the inside of the casing and forward sealdisk to remove all propellant residue.4-4. Apply a light coat of grease to all threads and the insideof the motor case. Reassemble metal parts and storemotor in a dry place.<strong>AeroTech</strong> DivisionRCS Rocket Motor Components, Inc.Cedar City, UT 84721www.aerotech-rocketry.comChapter 3. Preparation For FlightInstall Igniter Against Smoke ChargeFig.-13Chapter 5. First AidFor a minor burn, apply a burn ointment. For a severe burn,immerse the burned area in ice water at once and see aphysician as quickly as possible. In the unlikely event of oralingestion of the propellant, induce vomiting and see a physicianas quickly as possible. <strong>AeroTech</strong> composite propellant consistsprimarily of Ammonium Perchlorate and a rubber-like plasticelastomer.Chapter 6. DisposalDamaged or defective reload kits should be returned to RCS.Chapter 7. Fire SafetyTests show that the pyrotechnic components of RMS reloadkits will not explode in fires and normally will not ignite unlesssubjected to direct flame and then will burn slowly. Use water tofight any fires in which <strong>AeroTech</strong>/RCS RMS reload kit pyrotechniccomponents may become involved: Direct the water atthe <strong>AeroTech</strong>/RCS RMS reload kit pyrotechnic componentsto keep them below their 550 deg. F autoignition temperature.Foam and carbon dioxide fire extinguishers will NOT extinguishburning propellants of the type used in RMS reload kit pyrotechniccomponents. Keep reload kit pyrotechnic componentsaway from flames, sources of heat and flammable materials.Disclaimer and WarrantyNOTICE: As we cannot control the storage and use of ourproducts, once sold we cannot assume any responsibility forproduct storage, transportation or usage. RCS shall not be heldresponsible for any personal injury or property damage resultingfrom the handling, storage or use of our product. The buyerassumes all risks and liabilities therefrom and accepts and uses<strong>AeroTech</strong>/RCS products on these conditions. No warranty eitherexpressed or implied is made regarding <strong>AeroTech</strong>/RCS products,except for replacement or repair, at RCS's option, of thoseproducts which are proven to be defective in manufacture withinone year from the date of original purchase. For repair orreplacement under this warranty, please contact RCS. Proof ofpurchase will be required. Note: Your state may provide additionalrights not covered by this warranty.P/N 20101 Rev. 11/16/09Made in U.S.A.©2009 RCS Rocket Motor Components, Inc., All rights reservedDivision of RCS Rocket Motor Components, Inc.RMS-<strong>98</strong>/7680HIGH-PERFORMANCENEW BLUE THUNDER PROPELLANTSERIESThrust in Pounds600500400300200100This Package Contains One Reload Kit:<strong>M1845NT</strong>-P (<strong>98</strong>/7680)NOTE: This reload kit MUST be used with separately packaged New Blue Thunder propellantgrains (P/N 03618-10) and motor liner tube (P/N 03040-3). RMS-<strong>98</strong> reload kits do notinclude an ejection charge. RMS-<strong>98</strong> motors must be used in conjunction with a timer,altimeter or radio-actuated recovery system.NOTE: This reload kit is ONLY for use in <strong>AeroTech</strong>/RCS, Dr. Rocket or Rouse-TechRMS <strong>98</strong>mm high-power motors.Certified by the Tripoli Rocketry Association (TRA).DO NOT OPEN RELOAD KIT UNTIL READY TO USETypical Time-Thrust Curve:00.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0Time in SecondsRMS <strong>98</strong>/7680 NEW BLUE THUNDER RELOAD KIT DATAHardware DesignationRMS-<strong>98</strong>/7680HardwareDesignationPerformanceDesignation<strong>M1845NT</strong>-PTotal Impulse(Typical)PropellantWeightRMS <strong>98</strong>MM HARDWARE DATAMotorDiameterNOTE: Motor lengths are measured from end of aft closure to end of forward closure.NT = New Blue ThunderLoaded Motor Weight8 ,122 N-sec3 ,718 g (8.19 lb)6,682 g (14.72 lb)MotorLengthKarl E. BaumannSignature LineHardwareWeightReload(s) UsedR MS-<strong>98</strong>/76803 .875" (<strong>98</strong>mm)23.51"1,926g (4.24 lb)<strong>M1845NT</strong>-PNOTE: SALE TO PERSONS UNDER 18 YEARS OF AGE PROHIBITED BY FEDERALLAW. WARNING-FLAMMABLE: Read Instructions Before Use. KEEP OUTOF REACH OF CHILDREN. FOR USE ONLY BY CERTIFIED HIGH-POWER USERS18 YEARS OF AGE OR OLDER. DO NOT SMOKE when loading these motors or usein the vicinity of open flames.