Good Laboratory Practice - UKM Medical Centre

Good Laboratory Practice - UKM Medical Centre

Good Laboratory Practice - UKM Medical Centre

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Role of Laboratories in Medicine <strong>Medical</strong> Testing <strong>Laboratory</strong>patient careclinical drug trial Research <strong>Laboratory</strong>discovery & development of newdrugs/therapyfundamental research/mechanisms of diseases Manufacturingpost clinical trials, bulkdrugs, cell-based therapy, plasma products, medicaldevice

Drug Development Process Stage I Stage 2 Stage 3 Stage 4Discovery Non-clinical Clinical Post-approvalTime line approximately 10 yrsManufacturing

Role of laboratories in drugdevelopment Stage I : discovery of active substance Stage II : non-clinical study on SAFETYtesting of drugs , Stage III : Studies in human/CLINICALTRIALS Stage IV : Post approval Clinical trials

Role of laboratories in non-clinicalsafety studysafety testing of drugs ,toxicology,mutagenicity,safety pharmacologybioavailability

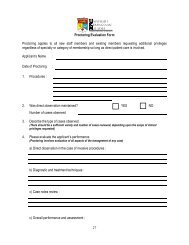

Role of laboratories in Clinical Trials-<strong>Medical</strong> Testing Laboratories Pre StudyScreeningEnrolment : inclusioncriteria exclusion During StudyVerify effects of drugsclinical efficacy End of Study Monitoring of adverseeffects safety Clinical efficacy Data analysis verification

The Term : <strong>Good</strong> <strong>Laboratory</strong><strong>Practice</strong>Numerous meanings depending on : Research <strong>Laboratory</strong> Sponsor Regulatory body Clients of <strong>Laboratory</strong>

Regulatory Authorities responsible for registering andcontrolling pharmaceuticals :- request laboratory to demonstrate data in registrationpackage for a new chemical/drugs has been gathered using'good laboratory practice'- require organisation be certified (or accredited) by a thirdparty for 'GLP' Organisations (researchers and medical laboratories) oftenclaimed that they are working under 'glp' Clients (clinicians & sponsors) of laboratories oftenrequest that their work be done using 'good laboratorypractice'

<strong>Good</strong> <strong>Laboratory</strong> <strong>Practice</strong><strong>Medical</strong> Testing laboratories must ensure resultsproduced are valid, reliable, accurate and reproducible Research Laboratories especially for non-clinical safetystudies must be concern with quality, reliability andintegrity of studies, reporting of verifiable conclusions andthe tracebility of data to ensure product safety and efficacy Manufacturing laboratory must ensure products areproduced under strict conditions and safe for use

<strong>Good</strong> <strong>Laboratory</strong> <strong>Practice</strong>Requires laboratory Accredited or Compliant to a set of defined STANDARDS Standards are documented agreements containingtechnical specifications or other precise criteria usedconsistently as rules, guidelines and definitions ofcharacteristics to ensure that material, products, processand services are fit for purpose

<strong>Good</strong> Clinical <strong>Practice</strong> (ICH-GCP) Standards must be adhered during Clinical Drugs Trialfor design, conduct, performance, monitoring, auditing,recording, analysis and reporting in order to provideassurance that data and reported results are credible andaccurate and integrity and confidentiality of trial subjectsare protectedSection 2.13 Systems with procedure that assure the quality of everyaspect of the trial should be implemented

ISO<strong>Good</strong> <strong>Laboratory</strong> <strong>Practice</strong>- Standards OECD Principle of <strong>Good</strong> <strong>Laboratory</strong><strong>Practice</strong> (OECD GLP)

ISO ISO (International Organisation of Standardisation) is aworldwide federation of national standards from 130countries NGO established in 1947 with a mission to promotedevelopment of standardisation and related activities in theworld with a view to :- facilitate international exchange of goods- develop coorperation in spheres of intellectual,scientific, technological and economic activity

ISO Standards for Accreditation of LaboratoriesFor Competence of Testing and Calibration Laboratories ISO/IEC Guide 25 (1990) ISO/IEC 17025 (1999) new standards which meets those ofISO 9001 and 9002 covering both technical and managerialrequirements ISO/IEC 15189 (2002)- expanded to include requirements for quality andcompetence of <strong>Medical</strong> Laboratories

Standards for <strong>Laboratory</strong> involved inClinical Studies Accreditation to ISO 17025- requirements for the competence of testing andcalibration laboratories Accreditation to ISO/IEC 15189 (2002)- requirements for quality and competence of <strong>Medical</strong>Testing Laboratories

Standards for Laboratories involved inNon-clinical Safety Testing 'Principle of GLP' : a set of standard applied tonon-clinical environmental health and safetystudies. The 'Principle of GLP' is a formal term Regulatory document

Formal concept of GLP The term '<strong>Good</strong> <strong>Laboratory</strong> <strong>Practice</strong>' has a SPECIFICmeaning when applied to non-clinical environmental healthand safety studies.

GLP It is important to clearly differentiate between theformal, regulatory use of term 'good laboratorypractice' as opposed to the general application ofgood practices in scientific investigations

OriginFormal concept of GLP1 st evolved in USA, 1970s as a result of concerns aboutvalidity of preclinical safety data submitted to FDA fornew drug applications1950s -1 970s : 40% toxicology testing were carried out byIndustrial Biotest Laboratories (IBT)1961-1976, FDA imposed requirements for manufacturersto prove drug effectiveness and responsible in determiningif benefits outweigh risks

867 audits of IBT performed by FDA (1962 Law of DrugAmendments) : 518 were found to be invalid due tonumerous discrepancies between study and data FDA found 4 IBT managers guilty of frauds

GLP regulations (US) Deficiencies made public in the Kennedy Hearings of theUS Congress. FDA decide to regulate laboratory testing. Political outcome led to the publication by FDA ofProposed Regulations on <strong>Good</strong> <strong>Laboratory</strong> <strong>Practice</strong> in 1976,Final Rule , June 1979 This forms the regulatory basis for assurance that reportson studies submitted to FDA would reflect faithfully andcompletely the experimental work carried out.

Establishment of Regulation of <strong>Laboratory</strong><strong>Practice</strong> for Non clinical Safety TestingNeed drivers Not all scientific work was good work Guidelines required to ensure the quality and integrity ofsafety data To allow correct construction of all experiments to-support the approval and manufacturing safetyregulated productsTo effect compliance to regulationsAuthorities must be given absolute power over testinglaboratoriesPenalties included steep fines and criminalprosecution

GLP regulations-Origin 1976 GLP guideline proposed 1978 GLP guideline finalised 1979 GLP guidelines effective 1987 additional changes ( Code of FederalRegulation 21, part 58) 2000 : International GLP

International Harmonisation-OECD Principle of GLP The Organisation for Economic Cooperation andDevelopment (OECD ) formulated the first worldwideOECD Principles of GLP 1981 ( revised in 1997)- to avoid non-tariff barriers to trade- to promote mutual acceptance of data to non-clinical safetytest- to eliminate unneccessary duplication of experiments

OECD Principle of GLP Adherence of member countries to these OECDstandards permits international acceptability of safetytesting from different countries (1981) International harmonisation of tests

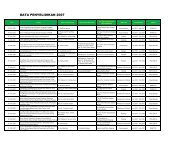

OECD Principle of GLP 1981, Member countries(31 member countries) Mutual Acceptance of data1997, Non-membercountries, full adherence (4)Compliance programmeNon-member countries/ProvisionalGLP Complianceprogramme (GLP CP) waslaunched in Malaysia in 2009if full adherence GLP safety data willbe accepted by members (31) &non-members (4)

The principle of <strong>Good</strong> <strong>Laboratory</strong><strong>Practice</strong> in general is concerned with how we organise our laboratories andhow we organise our studies. addresses responsibilities for managing people, facilitiesand equipment for good science concerned with how we plan, perform and report ourexperiments and studies importantly it does not interfere with the ability of scientiststo make scientific decision

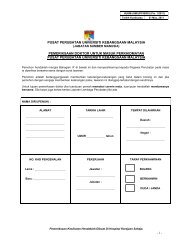

<strong>Good</strong> <strong>Laboratory</strong> <strong>Practice</strong> for Laboratoriesinvolved in Clinical Studies <strong>Medical</strong> laboratory services must meet the needs of allpatients and the clinical personnel responsible for thecare of those patients. Such services include arrangements for requisition,patient preparation, patient identification, collection ofsamples, transportation, storage , processing andexamination of clinical samples together withsubsequent validation interpretation reporting andadvice, in addition to safety and ethics in medicallaboratory work.

Fundamental Points of ISO/IEC 17025and 15189 Management requirement Technical requirements

Management requirementOrganisation &management\qualitymanagement systemDocument controlReview of contractsExamination by referrallaboratoriesExternal services and supplyAdvisory servicesResolution of complaintsIdentification and control ofnon-conformitiesCorrective actionPreventive actionContinual improvementQuality and technical recordsInternal auditsManagement review

Technical requirementsPersonnelAccomodation andenvironmentalconditions<strong>Laboratory</strong> equipmentAssuring quality ofexamination proceduresPost-examinationproceduresReporting of resultsPre-examinationproceduresExamination procedures

OECD Principles of GLPfor Preclinical Safety Studies Define and describe a quality system concerned with theorganisational processes and conditions under which anon-clinical health and environmental safety study isconducted Non-clinical laboratory study means in vivo or in vitroexperiments in which test articles are studied prospectivelyin test systems under laboratory conditions to determinetheir safety

GLP in the OECD Principles 'a quality system concerned with the organisational processand the conditions under which non-clinical health andenvironmental studies are planned, performed, monitored,recorded, archived and reported.' It does not concern with the technical validity of the studies

Fundamental points of GLP<strong>Good</strong> <strong>Laboratory</strong> <strong>Practice</strong> applied in whatever industry targeted, stressesthe importance of the following main points Resources : Organisation, personnel, facilities,equipment Rules : Protocols, Standard Operating Procedures,concept of Study Director Characterisation : Test items, test systems Documentation : Raw data, final report, archives Quality Assurance : Independence from study conduct

Resources Organisation and personnel Facilities and equipment

Resources Organization & PersonnelStructure of orgn and Orgnchart must reflect realities andup-to dateresponsbilities of all personnelclearly defined; job description,qualifications & competencedefined in training andeducation records.Study Director Full responsibility of GLPcompliance of all activitieswithin study, signed compliancestatement Aware of all occurances, judgeimpact and institute correctiveaction

Facilities and Equipment Adequate and sufficient to perform the studies suitable size, construction and locationminimize disturbances that would interfere with validity ofstudy.Avoid problem of overcrowding, cross contamination,confusion between projects and cramped workingcondition. Utilities ( water, electricity etc) must beadequate and stable

Equipment : strict programme of validation, qualification,calibration and maintenance. Records of proceduresmaintained Reagents: labeled appropriately to indicate source,identity, concentration and stability information, earliestexpiratory date and specific storage instruction Separate facilities for handling and storage of test andreference material to prevent contamination and ensuresafe storage for hazardous substances

Handling and disposal of waste should be carried out insuch a manner so as not to influence the integrity of thestudy in progress and consistent with regulatoryrequirementsappropriate collection, storage, disposal facilities,decontamination, transportation and destructionprocedures Archive facilitites should be provided for storage andretrieval of raw data, samples and specimens. Access toarchive should be limited to personnel authorized bymanagement

RulesProtocols The principle steps of studies have to be described in aStudy Protocol or Study Plan The Protocol has to be adopted by the Study Directorthrough dated signature before study starts and alterationsto the study design cannot be made unless by formalamendment procedures.

RulesWritten Procedures Routine procedures described in Standard OperatingProcedures (SOP) Standardization of certain techniques to facilitatecomparisons of results Procedures must be reviewed regularly and modified ifnecessary to reflect the actual state of the art SOPs must be available at the work place and in currentversion

RulesStudy Director Concept of SD as the pivotal point of study control, singlemost important individual in a GLP study person fully responsible for adequacy of protocol and GLPcompliant conduct of the study. SD has to formally acceptresponsibility for GLP compliance by signing thecompliance statement.

Characterisation preclinical safety testing of pharmaceutical compundsrequires detail knowledge about the properties of the testitems and of the test system (often animal ) to which it isadministered. identity, purity, composition, stability, impurity profileshould be known for the test item, for the vehicle and forthe reference material. If the test system is an animal, it is essential to know suchdetails as its strain, health status and normal biologicalvalues

DocumentationRaw Data Results of investigations, documentation of procedures andcircumstances under which study was conducted Results and their intepretation must be a true reflection ofthe raw dataStudy Report Responsibility of Study Director Ensures contents of report describe the study accurately Study Director responsible for scientific intepretation of theresults

DocumentationArchives For reasons of reconstruction many years later Safekeeping of all records, kept in integer state and canneither be lost nor altered Restrict access to archives to a limited number of peopleand maintain records of log-in and log-out for bothdocuments and people

Quality AssuranceQA defined by GLP A team of persons charged with assuring the managementthat GLP compliance has been attained in a test facility as awhole as well as within each study. QA has to be independent of the operational conduct of thestudies and it functions as witness to the whole preclinicalresearch process

ISO Accreditation vs GLP Fundamental requirement of the GLP Principles notcovered in ISO/IEC : the use of study plans and StudyDirector as a concept More stringent under GLP- Recording and reporting of data- Management of data retained in archive toallow complete reconstruction of study- A program of independent QA includinginternal audits of every study

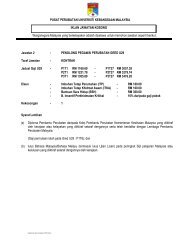

Compliance to Standards ISO Accreditation : assessment by AccreditingBody :e.g Australia -NATAMalaysia - Standards Malaysia (MOSTI) OECD GLP compliance : ComplianceMonitoring Authority:Australia - NATA,Malaysia- NPCB, Standards Malaysia

Accreditation Authorities for ISO Most trading nations establish systems for laboratoryaccreditation. The accreditation authorities are usually governmentownedor government-endorsed and operate free from anycommercial influence Countries established international network of MutualRecognition Arrangements

ISO Accreditation Authorities/Bodies European Coorperation for Accreditation inEurope which include UK Accreditation Services(UKAS) International <strong>Laboratory</strong> Accreditation Cooperation(ILAC) International Accreditation Forum Asia Pacific <strong>Laboratory</strong> AccreditationCoorperation

Malaysia Standards Malaysia, MoSTI responsible for :- ISO Accreditation of Testing and CalibrationLaboratories- Accreditation of <strong>Medical</strong> Laboratories (SAMM):' Skim Akreditasi Makmal Malaysia (MS ISO15189) launched in 2004Malaysia is a member of APLAC

GLP complianceOECD Principles of GLPbasic GLP documentEach country has anational GLP compliancemonitoring authorityRegistration Authoritieslooks for compliancefacility claim to becompliant with OECDPrinciple of GLP must beby NATA/NPCBe.g. Pharmaceuticals:Australia : Therapeutics<strong>Good</strong> Administration(TGA), Malaysia: DCA

OECD Principle of GLP 1981, Member countries(31 member countries) Mutual Acceptance of data1997, Non-membercountries, full adherence (4)Compliance programmeNon-member countries/ProvisionalGLP Complianceprogramme (GLP CP) waslaunched in Malaysia in 2009if full adherence GLP safety data willbe accepted by members (31) &non-members (4)

OECD GLP ComplianceMonitoring Authorities for MalaysiaNational PharmaceuticalControl Bureau (NPCB)MoHPharmaceutical productsCosmeticsFood additive productsVeterinarySTANDARDSMALAYSIA, MoSTIPesticidesIndustrial productsFeed Additive productsBiotechnology (nonpharmaceutical)products

Drug Development Process Stage I Stage 2 Stage 3 Stage 4Discovery Non-clinical Clinical Post-approvalTime line approximately 10 yrsManufacturing

Classical drug development process4 well-defined stages Stage I Discovery of potentialnew drug products Not covered by aregulatory standard

Stage II non-clinical, not inhuman Safety Testing GLP Principlesspecific for this stage :toxicologysafety pharmacologypharmacokineticsbioavialbility

Stage IIIClinical Studies, in humanGCP is the basis for qualitystandards, ethical conduct andregulatory compliance(Standard :ISO)Phase I ( tolerance of test drugs,define humanpharmacokinetics) to Phase II (dose-effect relationship) andPhase III (full-scale, oftenmulti-centre clinical efficacytrials in patients)

Stage IVPost-approval.Drug registered , availableon marketAny subsequent clinicaltrials (Phase IV) mustcomply with GCP(Standard :ISO)

From stage 3 of development and continuing throughoutthe rest of the drug's lifetime. GMP applies to allmanufacturing of bulk and formulated product. <strong>Good</strong> Manufacturing <strong>Practice</strong> (GMP)- WHO standards/document (Geneva, WHO 1999)

Figure 1 illustrates how so called <strong>Good</strong> <strong>Practice</strong>sregulations correlate to the life of a drug, startingfrom basic research and drug discovery on theleft side through preclinical development in themiddle and clinical trials and manufacturing atthe right Figure 1. GLP vs. GCP, GMP and 21 CFFRPart 11

<strong>Good</strong> <strong>Practice</strong>s regulations in drugdevelopmentillustrates how so called <strong>Good</strong> <strong>Practice</strong>s regulations correlate to the life of a drug, startingfrom basic research and drug discovery on the left side through preclinical development in themiddle and clinical trials and manufacturing at the right. GLP vs. GCP and GMP