"A" Ductable Liquid Chillers with Integrated Hydronic Module

"A" Ductable Liquid Chillers with Integrated Hydronic Module

"A" Ductable Liquid Chillers with Integrated Hydronic Module

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

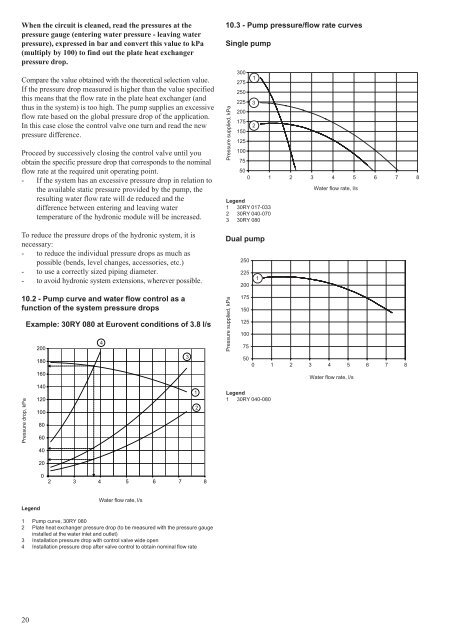

When the circuit is cleaned, read the pressures at thepressure gauge (entering water pressure - leaving waterpressure), expressed in bar and convert this value to kPa(multiply by 100) to find out the plate heat exchangerpressure drop.Compare the value obtained <strong>with</strong> the theoretical selection value.If the pressure drop measured is higher than the value specifiedthis means that the flow rate in the plate heat exchanger (andthus in the system) is too high. The pump supplies an excessiveflow rate based on the global pressure drop of the application.In this case close the control valve one turn and read the newpressure difference.Proceed by successively closing the control valve until youobtain the specific pressure drop that corresponds to the nominalflow rate at the required unit operating point.- If the system has an excessive pressure drop in relation tothe available static pressure provided by the pump, theresulting water flow rate will de reduced and thedifference between entering and leaving watertemperature of the hydronic module will be increased.To reduce the pressure drops of the hydronic system, it isnecessary:- to reduce the individual pressure drops as much aspossible (bends, level changes, accessories, etc.)- to use a correctly sized piping diameter.- to avoid hydronic system extensions, wherever possible.10.2 - Pump curve and water flow control as afunction of the system pressure dropsPressure drop, kPaExample: 30RY 080 at Eurovent conditions of 3.8 l/s2001801601401201008060431210.3 - Pump pressure/flow rate curvesSingle pumpPressure supplied, kPa30027525022520017515012510075132500 1 2 3 4 5 6 7 8Legend1 30RY 017-0332 30RY 040-0703 30RY 080Dual pumpPressure supplied, kPa250225200175150125100751Water flow rate, l/s500 1 2 3 4 5 6 7 8Legend1 30RY 040-080Water flow rate, l/s402002 3 4 5 6 7 8LegendWater flow rate, l/s1 Pump curve, 30RY 0802 Plate heat exchanger pressure drop (to be measured <strong>with</strong> the pressure gaugeinstalled at the water inlet and outlet)3 Installation pressure drop <strong>with</strong> control valve wide open4 Installation pressure drop after valve control to obtain nominal flow rate20