USER'S, MAINTENANCE and SERVICE ... - Upgnet.com

USER'S, MAINTENANCE and SERVICE ... - Upgnet.com

USER'S, MAINTENANCE and SERVICE ... - Upgnet.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

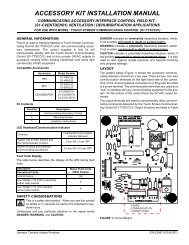

66441-YUM-C-071115 TON(2) 18" X 24"FILTERS20 TON15,20,25 TON REHEAT(4) 16" X 20"FILTERS15 TON(3) 18" X 24"FILTERS20 TON15,20,25 TON REHEAT(4) 16" X 25"FILTERS(6) 12" X 24"FILTERS(6) 12" X 24"FILTERSINDOOR COILCONDENSATEDRAINCONNECTION15, 20, 25 TON REHEAT UNITS15 & 20 TON STANDARD & HIGH EFFICIENCY UNITSINDOOR COILCONDENSATEDRAINCONNECTIONExcessive lubrication may accelerate the accumulationof dust.BLOWER ASSEMBLYEven with good filters properly in place, blower wheels <strong>and</strong>motors will be<strong>com</strong>e dust laden after many months of operation.The entire blower assembly should be inspected annually.If the motor <strong>and</strong> wheel are heavily coated with dust, theycan be brushed <strong>and</strong> cleaned with a vacuum cleaner.BLOWER SHAFT BEARINGBlower shaft bearings should be inspected on a monthlybasis. At a minimum, the bearings should be relubricatedevery 6 months using a lithium-based grease (NLGI grade 2)re<strong>com</strong>mended for ball bearing service.25 TON STANDARD EFFICIENCY15, 17.5, 20, 25 TON ULTRA-HIGH EFFICIENCY UNITSFIGURE 5 - END VIEW LESS FILTER ACCESSPANELPerform all maintenance operations on the blowermotor with electric power disconnected from theunit. Do not attempt to lubricate bearings with theunit in operation.ECONOMIZEREven with good filters properly in place, the economizerassembly will be<strong>com</strong>e dust laden after many months of use.The entire assembly should be inspected annually. If theassembly is heavily coated with dust, it can be brushed <strong>and</strong>cleaned with a vacuum. A <strong>com</strong>mon aerosol contact cleanerwill help remove excess accumulation.After the dust <strong>and</strong> debris is removed, a silicon based spraylubricant should be applied to each of the gears used to connect<strong>and</strong> ensure proper alignment of the damper blades.Perform all maintenance operations on thedamper assembly with power disconnected. Donot clean or lubricate with the unit in operation.Damage can occur if the bearings are overlubricated.Use grease sparingly.MOTORSOutdoor fan motors are permanently lubricated <strong>and</strong> requireno maintenance.Ventor motor is factory lubricated for an estimated 10 yearlife.Indoor Blower Motor <strong>and</strong> Drive - The indoor blower motor featuresball bearings that do not require periodic lubrication.Periodic lubrication of the motor <strong>and</strong> bearings can extend thelife of <strong>com</strong>ponents but is optional.If desired, every three years, using a low pressure greasegun, pump grease into the bearing grease fitting until greasejust begins to show at the seals. Do not over lubricate. Useany lithium base grease re<strong>com</strong>mended for ball bearing service.6 Johnson Controls Unitary Products