IPCX Chillers - Dunham-Bush Americas

IPCX Chillers - Dunham-Bush Americas

IPCX Chillers - Dunham-Bush Americas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

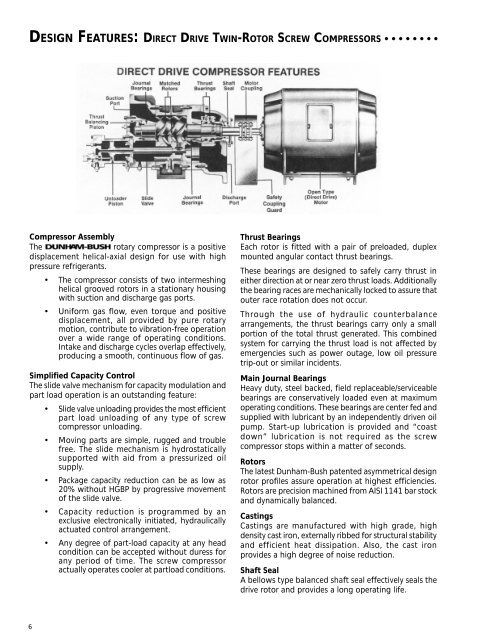

DESIGN FEATURES: DIRECT DRIVE TWIN-ROTOR SCREW COMPRESSORS○ ○ ○ ○ ○ ○ ○ ○Compressor AssemblyTherotary compressor is a positivedisplacement helical-axial design for use with highpressure refrigerants.• The compressor consists of two intermeshinghelical grooved rotors in a stationary housingwith suction and discharge gas ports.• Uniform gas flow, even torque and positivedisplacement, all provided by pure rotarymotion, contribute to vibration-free operationover a wide range of operating conditions.Intake and discharge cycles overlap effectively,producing a smooth, continuous flow of gas.Simplified Capacity ControlThe slide valve mechanism for capacity modulation andpart load operation is an outstanding feature:• Slide valve unloading provides the most efficientpart load unloading of any type of screwcompressor unloading.• Moving parts are simple, rugged and troublefree. The slide mechanism is hydrostaticallysupported with aid from a pressurized oilsupply.• Package capacity reduction can be as low as20% without HGBP by progressive movementof the slide valve.• Capacity reduction is programmed by anexclusive electronically initiated, hydraulicallyactuated control arrangement.• Any degree of part-load capacity at any headcondition can be accepted without duress forany period of time. The screw compressoractually operates cooler at partload conditions.Thrust BearingsEach rotor is fitted with a pair of preloaded, duplexmounted angular contact thrust bearings.These bearings are designed to safely carry thrust ineither direction at or near zero thrust loads. Additionallythe bearing races are mechanically locked to assure thatouter race rotation does not occur.Through the use of hydraulic counterbalancearrangements, the thrust bearings carry only a smallportion of the total thrust generated. This combinedsystem for carrying the thrust load is not affected byemergencies such as power outage, low oil pressuretrip-out or similar incidents.Main Journal BearingsHeavy duty, steel backed, field replaceable/serviceablebearings are conservatively loaded even at maximumoperating conditions. These bearings are center fed andsupplied with lubricant by an independently driven oilpump. Start-up lubrication is provided and “coastdown” lubrication is not required as the screwcompressor stops within a matter of seconds.RotorsThe latest <strong>Dunham</strong>-<strong>Bush</strong> patented asymmetrical designrotor profiles assure operation at highest efficiencies.Rotors are precision machined from AISI 1141 bar stockand dynamically balanced.CastingsCastings are manufactured with high grade, highdensity cast iron, externally ribbed for structural stabilityand efficient heat dissipation. Also, the cast ironprovides a high degree of noise reduction.Shaft SealA bellows type balanced shaft seal effectively seals thedrive rotor and provides a long operating life.6