IPCX Chillers - Dunham-Bush Americas

IPCX Chillers - Dunham-Bush Americas

IPCX Chillers - Dunham-Bush Americas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

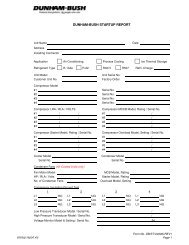

F. (Condenser Water Control provides analog output that can be used to control condenser water flow.The 0-5VDC or 0-10VDC signal increases as discharge pressure rises above a setpoint (TYP 160 psig).This should produce an increase in the condenser water flow.)G. (Shipping Less Refrigerant to enable shipping by means that do not allow shipping with refrigerantcharges installed in the unit. The chiller must be built and tested and the refrigerant removed aftertesting.)H. (Cooler Double Layer Insulation for factory installed two ¾ inch layers of closed cell cooler insulation).I. (Flow Switch shipped loose for field mounting and wiring).J. (Vibration Isolators shipped loose: spring or rubber-in-shear).K. (Alarm Bell shipped loose to be mounted remote of the chiller and wired to the common alarmcontacts by the contractor).L. (Remote Monitor Display Terminal to provide remote monitoring and enabling/disabling of the chillcontrol plus reading of all microcomputer screens).Part 3: Execution3.01 Installation Work By Mechanical ContractorA. Install on a flat surface level within 1/16 inch per foot and of sufficient strength to support concentratedloading. Place vibration isolators under the unit.B. Assemble and install all components furnished loose by manufacturer as recommended by themanufacturer's literature.C. Complete all fluid and electrical connections so unit fluid circuits and electrical circuits are serviceable.D. Provide and install valves in fluid piping upstream and downstream of the cooler fluid connections toprovide means of isolating cooler for maintenance and to balance and trim system.E. Provide soft sound and vibration eliminator connections to the cooler and condenser water inlet andoutlet as well as electrical connections to the unit.F. Interlock chillers through a flow switch in the chilled water line to the chilled water pump to ensurethe unit can operate only when fluid flow is established.G. Furnish and install taps for thermometers and pressure gauges in fluid piping adjacent to inlet andoutlet connections of the evaporator.H. Provide and install drain valves with capped hose ends to each cooler and condenser head drainfitting.I. Install vent cocks to each cooler and condenser head vent fitting.3.02 Work By Temperature Control ContractorA. Furnish interlock wiring per manufacturer's recommendations and install loose control componentsfurnished by chiller manufacturer.3.03 Work By Electrical ContractorA. Furnish power wiring to chiller control panel and obtain required code approval.B. Furnish and install approved disconnect switch.END OF SECTIONSpecification subject to change without notice.101 Burgess Road, Harrisonburg, VA 22801Phone: (540) 434-0711 FAX (540) 432-6690March 2000www.dunham-bush.comForm No. 6061-1A