Specalog for 914G/IT14G Wheel Loader/Integrated ... - Teknoxgroup

Specalog for 914G/IT14G Wheel Loader/Integrated ... - Teknoxgroup

Specalog for 914G/IT14G Wheel Loader/Integrated ... - Teknoxgroup

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

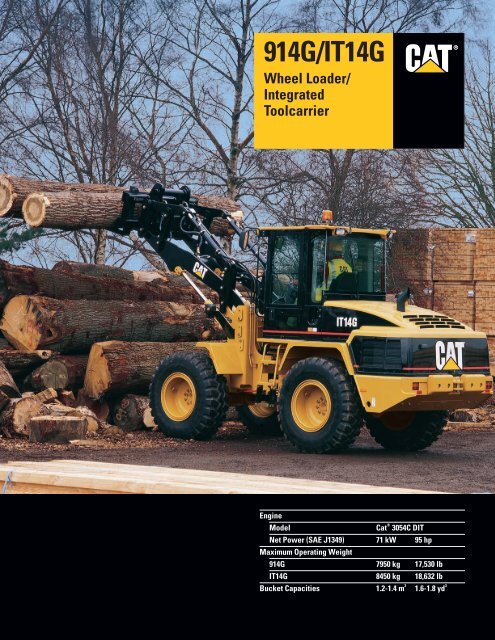

<strong>914G</strong>/<strong>IT14G</strong><strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong>Toolcarrier®EngineModelCat ® 3054C DITNet Power (SAE J1349) 71 kW 95 hpMaximum Operating Weight<strong>914G</strong> 7950 kg 17,530 lb<strong>IT14G</strong> 8450 kg 18,632 lbBucket Capacities 1.2-1.4 m 3 1.6-1.8 yd 3

<strong>914G</strong>/<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> ToolcarrierThe <strong>914G</strong>/<strong>IT14G</strong> defines world-class per<strong>for</strong>mance, value and reliability.Per<strong>for</strong>mance✔ The Cat ® 3054C DIT engine meetsthe latest emissions criteria and isper<strong>for</strong>mance matched with a Cat hystattransmission <strong>for</strong> smoothness andoperator com<strong>for</strong>t. pg. 4Operator StationErgonomically designed <strong>for</strong> totalmachine control in a com<strong>for</strong>table,spacious environment. All controls,levers, switches, and gauges arepositioned to maximize productivity.pg. 6Work ToolsCaterpillar’s selection of generalpurpose and multi purpose bucketsare designed to optimize per<strong>for</strong>mance.A quick coupler (optional on the <strong>914G</strong>)maximizes productivity. pg. 8Environmentally Responsible DesignCaterpillar ® machines not only help youbuild a better world, they help maintainand preserve our fragile environment.pg. 12The <strong>914G</strong>/<strong>IT14G</strong> sets the standard in itsclass <strong>for</strong> rugged, reliable per<strong>for</strong>mance,responsiveness and operating com<strong>for</strong>t.2

Per<strong>for</strong>manceExceptionally tough, the rugged per<strong>for</strong>mance and improved gradeability of the <strong>914G</strong>/<strong>IT14G</strong>helps increase productivity.Caterpillar ® Engine. The Caterpillar3054C DIT (Direct InjectionTurbocharged) engine has a provenreputation <strong>for</strong> rugged, reliable operationwhile providing peak per<strong>for</strong>mance ina wide range of operating conditions.Low Emission, Tier 2 Engine.The standard 3054C DIT is a verylow emission engine designed to meetU.S. EPA Tier 2 and EU Stage IIenvironmental emission standards.Cylinder Block. The 3054C cylinderblock features a deep skirted, internallystiffened cast iron block. Extra stock isused in the main bearing bulkheads <strong>for</strong>added rigidity.Steel Crankshaft. The 3054C featuresa large diameter, hardened <strong>for</strong>gedchrome-molybdenum steel crankshaftwith wide main and rod bearings <strong>for</strong>long service life.Pistons. The pistons are three-ring,controlled-expansion design.Oil Pump. The 3054C uses a gear-drivenoil pump located in the oil pan. Beingmounted below the crankshaft centerlineallows the pump to prime quicker andget up to pressure faster to help reducewear and extend engine service life.Fuel Pump and Fuel Filter. The 3054Cuses a highly dependable rotarydistributor-type fuel pump. The fuelfilter is integrated with an electric liftpump located on the hystat cover <strong>for</strong>easy serviceability. The electric liftpump provides exceptional cold startper<strong>for</strong>mance and automatic primingduring filter changes.Water Pump. The gear-driven waterpump provides reliable per<strong>for</strong>mancecompared with belts that can breakand disable the engine.Starting System. The starting system<strong>for</strong> the 3054C is a 24V, 4.5 kW gearreduction starter that incorporatesinternal shielding to preventinadvertent starts. A glow plug startingaid is standard <strong>for</strong> improved startingin extremely cold temperatures.Hystat Power Train. The hystat powertrain delivers a broader range of powerand per<strong>for</strong>mance with less operatorinput than converter-driventransmissions.4

Hydrostatic Transmission. The highpressureclosed-loop hydrostatictransmission delivers high per<strong>for</strong>mancewith a broader range of power andper<strong>for</strong>mance to the ground.Axles. Heavy-duty design featuresstrong gears and bearings <strong>for</strong> durableper<strong>for</strong>mance. Oscillating rear axle helpsassure four-wheel ground contact <strong>for</strong>optimum traction and stability.Duo-Cone Seals on Axles.Patented Duo-Cone Seals on theaxle and housing keep oil in andlock contaminants out.Differentials. A choice of standardconventional or Limited Slip Differentialsadapts the machine to a wide range ofoperating conditions.Final Drives. Planetary final drivesconsist of ring gears and planetarycarrier assemblies.Fixed Front, Oscillating Rear Axle.The fixed front, oscillating rear axle(±11 degrees) ensures four-wheelground contact <strong>for</strong> optimum tractionand stability.Disc Brakes. Hydraulically-actuateddisc brakes are standard on both frontand rear axles which provide improvedper<strong>for</strong>mance and low-ef<strong>for</strong>t operation.Parking Brake. Parking brake featuresinclude the following:• Mechanical, shoe-type brake• Mounted on drive line <strong>for</strong> positivemanual operation• Transmission is automaticallyneutralized when parking brakeis appliedService Intervals. The recommendedengine oil change requirement is every500 hours of operation.5

Operator StationErgonomic design emphasizes com<strong>for</strong>t, visibility and easy operation.Cab. The ergonomic cab provides acom<strong>for</strong>table work environment withlarge windows, spacious interior room,generous storage areas and low interiorsound levels.Low-Ef<strong>for</strong>t Operation. Hydraulic pilotcontrols give the <strong>914G</strong>/<strong>IT14G</strong>uncompromised ease of operation of liftand tilt functions. A remote transmissioncontrol option adds a <strong>for</strong>ward/neutral/reverse control switch on the implementlever <strong>for</strong> easier operation and enhancedproductivity. Third and fourth functioncontrols are also available <strong>for</strong> use withspecial work tools. Hydrostatic, closedcentersteering system with flowamplification provides fast or slowsteering response, depending on theoperational requirement.6

Steering System. The adjustablesteering console lifts easily out of theway. Dual suspended brake pedalsfunction as a brake and a transmissionneutralizer so the operator can maintainhigh engine RPM <strong>for</strong> full hydraulicflow and fast cycle times.Right Side ConsoleOptional Engine Speed Control (ESC).A specific engine RPM can be set andmaintained with a switch in the cab.Optional Creeper Control. The creepercontrol option allows variable functionof travel speeds with full engine RPM.Seating Options. The Com<strong>for</strong>t SeriesSeat option is designed <strong>for</strong> maximumcom<strong>for</strong>t and fully-adjustable support.Seat Belt. All seats include acom<strong>for</strong>table 75 mm (3 inch) wideretractable seat belt.Visibility. Visibility to critical areassuch as the bucket is optimized.Lift arm spacing is wide and lineagegeometry maximizes visibilitythroughout the production cycle.Windows. Large windows with fulllengthglass windshield featuringbonded, tinted glass with silicon jointsand fewer obstructions allowsexpansive peripheral visibility.Wipers. Front and rear wipers withwashers are standard on the G-SeriesCab. The front wiper is intermittent.Storage. Generous storage spaceincludes a lockable compartment, coathook and special molded compartmentsdesigned to hold a lunchbox/cooler,cup or can. A tool box is also provided.Access/Egress. A two-door designallows easy access/egress. Both doorsopen fully and lock flush against thecab. Steps leading up to the cab arewide and angled out <strong>for</strong> secure footing.Customize the Cab. The cab can becustomized with:• 12V converter <strong>for</strong> poweringelectronics such as cellular phones,two-way radios and music systems• Radio installation package• Sun visor <strong>for</strong> windshield• Roll-down sun screen <strong>for</strong> rearwindow• External mirror package• Auxiliary lighting packages7

Work ToolsCaterpillar offers a wide range of work tools to match the <strong>914G</strong>/<strong>IT14G</strong> to the job and yourspecific application.Special Applications. Some of thenumerous specialty tools availableinclude:• Snow plows• Hydraulic brooms• Asphalt cutter• <strong>Loader</strong> rakesVersatility. With a variety of work toolsoffered by Caterpillar, the <strong>914G</strong>/<strong>IT14G</strong>is ideal <strong>for</strong> a wide range of applications.Quick Coupler. Work tools can bechanged quickly and easily with theintegral quick coupler system, standardon the <strong>IT14G</strong> and optional on the <strong>914G</strong>.A switch in the <strong>IT14G</strong> cab activates ahydraulic cylinder <strong>for</strong> positive toolengagement or disengagement.Buckets. With exceptional rimpulland high breakout and lift <strong>for</strong>ces,the <strong>914G</strong>/<strong>IT14G</strong> demonstrates strongper<strong>for</strong>mance as a bucket loadingmachine. A wide range of Caterpillarbuckets are available including:• General purpose• Multi purpose• Light material• Side dump• High dump• Material handlingBuckets resist high load twisting anddistortion and feature integral spill platesto help reduce spillage. Choice of groundengaging tools includes:• Bolt-on cutting edges• Bolt-on teeth• Bolt-on segments• Weld-on flush-mounted teethMaterial Handling. Exceptional visibilityand heavy-lift capabilities enable you towork quickly and efficiently in materialhandling applications. A wide range oftools are available such as:• Pallet, lumber and log <strong>for</strong>ks(<strong>for</strong>ks available <strong>for</strong> <strong>IT14G</strong> only)• Material handling arm• Tire loaders• Specialty clampsAuxiliary Hydraulics. Optional 3rd(standard on <strong>IT14G</strong>) and 4th functionhydraulics are available <strong>for</strong> use withwork tools that require hydraulic power,such as rotary brooms, augers, high dumpand side dump buckets.Work Tool Controls. Work tool controlsfeature pilot operated lift and tilt circuitswith low ef<strong>for</strong>t single-lever control.Controls can be locked <strong>for</strong> roading.<strong>IT14G</strong> 8-bar Parallel Linkage. 8-barparallel linkage on the <strong>IT14G</strong> simplifieskeeping <strong>for</strong>ks level throughout therange of lift, without adjustment.Longer lift arms, taller front towerand higher pivot points offer more lift,height and reach than conventionalloaders. Having more tilt capacity thanlift in almost every position providessuperior load control.8

BrushcutterThe <strong>IT14G</strong> is the plat<strong>for</strong>m <strong>for</strong> the T-121C Little & Company Brushcutter offering maximumvisibility to the mower, superior machine balance, hystat transmission and versatility toprovide greater operator confidence and higher productivity.Quick Attach Frame. The fully weldedquick-attach box frame incorporatestop and bottom cross bracing and allcomponents are installed with grade 8hardware or better. All componentsare plated or fully primed and painted.The frame:• Creates a rigid structure to protectloader and hydraulic components• Provides built-in parking stands <strong>for</strong>a stable storage plat<strong>for</strong>m• Designed <strong>for</strong> one-person attachment,installed without modification ofwheel loader, enabling easy assembly• Eliminates need <strong>for</strong> front-sidehydraulic reservoir and over-thehoodframework, allowing optimumvisibility and safety• Enables easy access <strong>for</strong> maintenanceDynamX Booms. DynamX booms arefabricated from T1 steel. External andinternal rein<strong>for</strong>cement plates addadditional stability. High-strength pivotpins are machined <strong>for</strong> trueness and heattreated<strong>for</strong> long life.Hydraulics. PowerAxe cutting heads,cutting shafts and rotary cutting discsare fabricated with T1 steel <strong>for</strong> severedutyreliability and per<strong>for</strong>mance, longlife and safety. Drop-<strong>for</strong>ged flail cuttingknives and flame-cut rotary blades areheat-treated <strong>for</strong> extra long life.9

ServiceabilityImproved access and fewer maintenance requirements provide unparalleled ease of service.Easy Access. One-piece engineenclosure hood with gas struts lift <strong>for</strong>exceptional access to filters and servicepoints. Radiator and oil coolers areeasily accessible <strong>for</strong> cleaning.Simplified Routine Service. All servicepoints are accessible from the groundlevel. Easily check radiator coolant andhydraulic oil levels with sight gauges.Swing-Out Oil Cooler. A swing-out oilcooler allows quick, easy cleaning andservice to the radiator.S•O•S SM Ports. Scheduled Oil Samplingports are factory installed <strong>for</strong> improvedaccess to engine, transmission andhydraulic oils. S•O•S ports make oilsampling quicker, cleaner and providethe best oil sample <strong>for</strong> analysis.Oil Filters. Spin-on filters <strong>for</strong> engine oiland hydraulic oil are vertically mounted<strong>for</strong> easier servicing.Extended Life Coolant/Antifreeze.Cat ® Extended Life Coolant/Antifreezeallows extended operation (up to6,000 hours) between changes.Other Service Features. Other servicefeatures include:• Maintenance free driveshaft• Stationary radiator and coolant hoses• Standard hydraulic oil cooler• Adjustment free brakes• Grouped grease fittings• Positive torque hose clamps• Braided, color coded andnumbered wiringElectrical System. The electrical systemis a 24-volt system. Standard machinesinclude two 12V (900 CCA) Caterpillarmaintenance-free batteries, easilyaccessible inside the engine enclosure,and a charging system equipped withan 80-amp alternator.10

Owning & Operating CostsCost saving features help improve your bottom line.Low Fuel Consumption. The 3054C DITengine features low fuel consumption<strong>for</strong> more economical operation.Increased Power, Faster Cycle Times.Higher horsepower and increased torquerise results in more power and fasterspeed-on-a-grade, allowing the operatorto get more work done in a day.Extended Service Intervals. Serviceintervals have been extended to reducemachine service time and increasemachine availability:• 4,000 hour hydraulic oil change(S•O•S sampling required)• 1,000 hour hydraulic filter change• 500 hour engine oil changeMachine Security System Option.The Machine Security System (MSS)option inhibits unauthorized machine useby immobilizing vital electrical circuits.11

Environmentally Responsible DesignCaterpillar machines not only help you build a better world, they help maintain and preserveour fragile environment.Ozone Protection. To help protect theearth’s ozone layer, the air conditioningunit uses only R-134a refrigerantwhich does not contain harmfulchlorofluorocarbons (CFC’s).Fewer Leaks and Spills. Engine oiland hydraulic filters are positionedvertically and are easily removedwithout spillage. Cat O-ring face seals,XT hose and hydraulic cylinders areall designed to help prevent fluid leaksthat can weaken machine per<strong>for</strong>manceand cause harm to the environment.Rebuildable Components. All majorcomponents are designed <strong>for</strong>rebuildability.Biodegradable Hydraulic Oil.Caterpillar biodegradable hydraulicoil can be used in the <strong>914G</strong>/<strong>IT14G</strong>,providing an environmentally-soundalternative to mineral-based oils.Low Fuel Consumption. The <strong>914G</strong>/<strong>IT14G</strong>gets more work done in a day resultingin less fuel consumed and minimalimpact on the environment.Low Exhaust Emissions. The Cat 3054CDIT is a low emission engine designedto meet current emission regulationsand is U.S. EPA Tier 2 and EU Stage IIcompliant.12

Complete Customer SupportCaterpillar dealer services ensure a longer machine operating life with lower costs.Selection. Make detailed comparisons ofmachines be<strong>for</strong>e purchasing. What arethe job requirements? What productionis necessary? What is the true cost oflost production? Your Cat dealer cangive you precise answers to these andmany more questions.Purchase. Look at the value the<strong>914G</strong>/<strong>IT14G</strong> offers. Consider thefinancing options your Cat dealer offersas well as day-to-day operating costs.Dealer support services can be includedin the cost of the machine to yield lowerequipment owning and operating costsover the life of the machine.Operation. For the best operatingtechniques to increase productivityand your profit, turn to your Cat dealer<strong>for</strong> the latest training literature andtrained staff.Maintenance. Choose from a wide rangeof maintenance services at the timeof machine purchase. Repair optionprograms guarantee the cost of repairsup front. Diagnostic programs such asS•O•S SM Oil Analysis and TechnicalAnalysis help avoid unscheduledrepairs that can cost unnecessarytime and money.Replacement. Repair, rebuild or replace?Your Cat dealer can help you evaluate thecost involved to make the right choice.Product Support. You will find nearlyall parts at our dealer parts counter.Cat dealers utilize a worldwide computernetwork to find in-stock parts to minimizemachine downtime. Additionally,Caterpillar offers a line of genuineremanufactured components whichcan help lower repair costs.www.cat.com. For more completein<strong>for</strong>mation on Cat products, dealerservices and industry solutions, visitus on the web at www.cat.com.Specializing in fast, accurate andup-to-date in<strong>for</strong>mation, the Cat website delivers the in<strong>for</strong>mation you needto operate your business, 24-hours a day.13

EngineModelCat 3054C DITGross Power (SAE J1995) 75 kW 101 hpNet Power (SAE J1349) 71 kW 95 hpGross Power (ISO 14396) 75 kW 100 hpNet Power (ISO 9249) 72 kW 96 hpNet Power (EEC 80/1269) 72 kW 96 hpBore 105 mm 4.13 inStroke 127 mm 5 inDisplacement 4.4 L 268 in 3• Caterpillar four-stroke cycle, four cylinder 3054C DITdiesel engine.• Ratings at 2300 RPM.• Net power shown is the power available at the flywheelwhen the engine is equipped with alternator, air cleaner,muffler and fan at minimum speed.• Power rating conditions based on standard air conditionsof 25° C (77° F) and 99 kPa (29.32 Hg) dry barometer.• No derating required up to 2268 m (7500 ft) altitude.• Direct injection rotary fuel pump with individual adjustmentfreeinjection valves.• Cast iron block with internally stiffened deep skirt design.• Field replaceable dry cylinder liners.• Replaceable valve guides and seats.• Large diameter, hardened chrome-molybdenum steelcrankshaft.• Three-ring controlled-expansion pistons lubricated fromoil jets.• Helical steel front gear train.• Fuel priming pump and fuel/water separator are standard.Electronic fuel priming pump eliminates the need <strong>for</strong>manual priming.• Gear-driven oil pump located in oil pan.• Gear-driven water pump.• Direct electric 24V starting and charging system withtwo 12V 900 CCA Caterpillar maintenance free batteriesand 80A alternator.• Glow plug starting aid is standard <strong>for</strong> improved startingin extremely cold temperatures.WeightsMax Operating Weight — <strong>914G</strong> 7950 kg 17,530 lbMax Operating Weight — <strong>IT14G</strong> 8450 kg 18,632 lbOptional Counterweight* 150 kg 330 lb* Optional on <strong>914G</strong>. Standard on <strong>IT14G</strong>.• <strong>914G</strong> with 1.4 m 3 (1.8 yd 3 ) bucket with bolt-on cutting edgeand optional 150 kg (330 lb) counterweight.• <strong>IT14G</strong> with 1.4 m 3 (1.8 yd 3 ) bucket with bolt-on cutting edgeand standard 150 kg (330 lb) counterweight.SteeringSteering Articulation 40ºSteering Angle, each direction 40ºSteering Cylinders, two, bore 63.5 mm 2.5 inHydraulic Output at 57 L/min 15.1 gal/min2300 engine rpm and6900 kPa (1,000 psi)• Fully hydraulic power steering features center-point framearticulation, front/rear wheel track and dedicated fixeddisplacement steering pump to provide flow at all engineand ground speeds.• Adjustable steering column <strong>for</strong> operator com<strong>for</strong>t.• High impact rubber steering stops.• Optional secondary steering system available.<strong>Loader</strong> Hydraulic System<strong>914G</strong>Output at 2300 engine rpm and 90 L/min 23.8 gal/min6900 kPa (1,000 psi) withSAE 10W oil at 65° C (150° F)Hydraulic Cycle Time10.9 SecondsPump Flow — Implement pump 90 L/min 23.8 gal/minRelief Pressure — 245.5 bar 3,560 psiImplement pumpHydraulic Cycle Time:10.9 SecondsRaise5.6 SecondsDump2.1 SecondsLower, empty, float down 3.2 SecondsTotal10.9 SecondsRelief Valve Setting 245.5 bar 3,560 psiLift Cylinders, double acting: 89 672 mm 3.5 26.5 inTilt Cylinder, double acting: 102 4.0 400 mm 15.8 in14 <strong>914G</strong>/<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications

Typical material densities — loosekg/m 3 lb/yd 3Basalt 1960 3305Bauxite, Kaolin 1420 2394Claynatural bed 1660 2799dry 1480 2495wet 1660 2799Clay and graveldry 1420 2394wet 1540 2596Decomposed rock75% rock, 25% earth 1960 330550% rock, 50% earth 1720 290025% rock, 75% earth 1570 2647Earthdry, packed 1510 2546wet, excavated 1600 2698Granitebroken 1660 2799Gravelpitrun 1930 3254dry 1510 2546dry, 6-50 mm (0.2-2") 1690 2849wet, 6-50 mm (0.2-2") 2020 3406kg/m 3 lb/yd 3Gypsumbroken 1810 3052crushed 1600 2698Limestonebroken 1540 2596crushed 1540 2596Sanddry, loose 1420 2394damp 1690 2849wet 1840 3102Sand and clayloose 1600 2698Sand and graveldry 1720 2900wet 2020 3416Sandstone 1510 2546Shale 1250 2107Slagbroken 1750 2950Stonecrushed 1600 2698<strong>914G</strong> Bucket Size Selectorkg/m 3Bucket Capacity1400 1600 1800 2000 2200 2400 2600m 3 yd 31.2 1.6Material Density1.3 1.71.4 1.8115% 100% 95%% = Bucket Fill Factor2400 2700 3000 3300 3600 3900 4200 lb/yd 3<strong>914G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications19

<strong>IT14G</strong> Operating SpecificationsRated bucket capacity (§)Struck capacity (§)WidthDump clearance at fulllift and 45° discharge (§)Reach at full liftand 45° discharge (§)Reach at 45° discharge and2130 mm (7' 0") clearance (§)Reach with lift armshorizontal and bucket levelDigging depth (§)Overall lengthOverall height with bucketat full raise (§)<strong>Loader</strong> clearance circle withbucket in carry positionStatic tipping load straight* (§)Static tipping loadfull 40° turn* (§)Breakout <strong>for</strong>ce (§)Operating weight*m 3yd 3m 3yd 3mmft/inmmft/inmmft/inmmft/inmmft/inmminmmft/inmmft/inmft/inkglbkglbkglbkglbGeneralPurpose BucketsWith Bolt-OnCutting EdgeWith Bolt-OnTeethWith Bolt-OnTeeth, SegmentsPenetrationBucketsWith FlushMounted Teeth1.3 1.4 1.2 1.3 1.3 1.4 1.31.7 1.8 1.6 1.7 1.7 1.8 1.71.1 1.2 1.0 1.1 1.1 1.2 1.11.4 1.5 1.3 1.5 1.4 1.5 1.52401 2401 2424 2424 2424 2424 24347' 10.5" 7' 10.5" 7' 11.4" 7' 11.4" 7' 11.4" 7' 11.4" 7' 11.8"2921 2886 2977 2942 2930 2895 29429' 7" 9' 6" 9' 9" 9' 8" 9' 7" 9' 6" 9' 8"787 823 757 792 779 814 7922' 7" 2' 8" 2' 6" 2' 7" 2' 7" 2' 8" 2' 7"1426 1443 1351 1368 1375 1390 13804' 8" 4' 9" 4' 5" 4' 6" 4' 6" 4' 7" 4' 6"2151 2201 2090 2140 2139 2189 21407' 1" 7' 3" 6' 10" 7' 0" 7' 0" 7' 2" 7' 0"174 174 155 155 174 174 1556.9" 6.9" 6.1" 6.1" 6.9" 6.9" 6.1"6424 6474 6506 6556 6524 6574 655421' 1" 21' 3" 21' 4" 21' 6" 21' 5" 21' 7" 21' 6"4802 4855 4802 4855 4802 4855 485515' 9" 15' 11" 15' 9" 15' 11" 15' 9" 15' 11" 15' 11"10.40 10.42 10.47 10.50 10.47 10.50 10.4934' 1" 34' 2" 34' 4" 34' 5" 34' 4" 34' 5" 34' 5"5541 5495 5637 5589 5503 5456 560512,218 12,116 12,407 12,324 12,134 12,030 12,3594792 4750 4882 4840 4754 4712 485510,566 10,474 10,765 10,672 10,483 10,390 10,7057865 7435 8456 7965 7920 7481 797917,342 16,394 18,645 17,563 17,464 16,496 17,5948032 8044 7990 8003 8063 8076 799017,771 17,737 17,618 17,647 17,779 17,808 17,618* Static tipping and operating weights shown are <strong>for</strong> high-speedversion <strong>IT14G</strong> and include lubricants, full fuel tank, ROPS cab, 80 kg(176 lb) operator, standard 250 kg (550 lb) counterweight and17.5 - R25 (L2 equivalent) tires.Note: Specifications and ratings con<strong>for</strong>m to all applicable standardsrecommended by the Society of Automotive Engineers (SAE). SAEStandards J732 and J742 govern loader rating, denoted in the text by (§).20 <strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications

<strong>IT14G</strong> Dimensions with BucketAll dimensions are approximate.◆Dimensions vary withbucket. Refer to OperatingSpecifications chart on page 20.57 o◆3100 mm(10' 2")◆48 o3565 mm(11' 8")3798 mm(12' 6")2255 mm(7' 5")2080 mm(6' 10")54 o49 o◆620 mm(2' 0")374 mm(1' 3")30 o 1300 mm1658 mm(5' 5")2600 mm(8' 6")(4' 3")◆Tread width◆Width over tiresGroundclearanceChange inverticaldimensionsmm inches mm inches mm inches mm inches15.5 - 25, 12PR (L-2) 1800 70.9 2222 87.5 414 16.3 –42 –1.717.5 - R25 (L-2 equivalent) 1800 70.9 2298 90.5 456 18.0 — —<strong>IT14G</strong> Supplemental SpecificationsChange inOperating WeightChange in ArticulatedStatic Tipping Loadkg lb kg lbAir conditioner +55 +121 +62 +137Canopy, ROPS (less cab) –122 –269 –89 –196Ride control +28 +62 +5 +11Powertrain guard +17 +37 +15 +33Secondary steering +30 +66 +38 +84Tires & rims, 15.5 - 25, 12PR (L-2) –140 –309 –84 –185Tires & rims, 15.5 - 25, 12PR (L-3) –76 –168 –46 –101Tires & rims, 15.5 - 25, R25 (L-2 equivalent) –84 –185 –44 –97Tires & rims, 15.5 - 25, R25 (L-3 equivalent) –4 –9 –2 –4Tires & rims, 17.5 - 25, 12PR (L-2) –40 –88 –21 –46Tires & rims, 17.5 - 25, 12PR (L-3) +32 +71 +17 +37Tires & rims, 17.5 - 25, R25 (L-3 equivalent) +100 +220 +54 +119Tires & rims, 17.5 - 25, R25 (L-2/L-3 equivalent) +76 +168 +41 +90Static tipping load changes are <strong>for</strong> an <strong>IT14G</strong> with lubricants, full fuel tank, ROPS cab, 80 kg (176 lb) operator,standard 250 kg (550 lb) counterweight, 17.5 R25 L-2 equivalent tires and a 1.3 cu. m (1.7 cu. yd.) general purposebucket with bolt-on cutting edge.<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications21

<strong>IT14G</strong> Dimensions with ForksAll dimensions are approximate.586 mm(1' 11")◆ Dimensions vary with<strong>for</strong>k length. Refer to operatingspecifications chart below.1490 mm(4' 11")3708 mm(12' 2")745 mm(2' 5")34 mm(1.3")1808 mm(5' 11")◆<strong>IT14G</strong> Operating Specifications with ForksFork Tine Length1050 mm(3' 5")1200 mm(3' 11")1350 mm(4' 5")Operating load:Per SAE J1197 FEB91(50% of full turn static tipping load) 1927 kg (4,249 lb) 1870 kg (4,123 lb) 1810 kg (3,991 lb)Per CEN 474-3, rough terrain(60% of full turn static tipping load) 2312 kg (5,098 lb) 2244 kg (4,948 lb) 2172 kg (4,789 lb)Per CEN 474-3, firm & level ground(80% of full turn static tipping load) 3082 kg (6,796 lb) 2992 kg (6,597 lb) 2896 kg (6,386 lb)Overall length 6723 mm (22' 1") 6873 mm (22' 7") 7023 mm (23' 1")Load center 525 mm (21") 600 mm (24") 675 mm (27")Static tipping load with level arms and <strong>for</strong>ks,600 mm (23.6") load center, straight* 4447 kg (9,806 lb) 4309 kg (9,501 lb) 4179 kg (9,215 lb)Static tipping load with level arms and <strong>for</strong>ks,600 mm (23.6") load center, full 40° turn* 3853 kg (8,496 lb) 3734 kg (8,233 lb) 3620 kg (7,982 lb)Operating weight* 7898 kg (17,415 lb) 7915 kg (17,453 lb) 7928 kg (17,481 lb)* Static tipping and operating weights shown are <strong>for</strong> an <strong>IT14G</strong> with lubricants, full fuel tank, ROPS cab,80 kg (176 lb) operator, standard 250 kg (550 lb) counterweight and 17.5 R25 (L2 equivalent) tires.Tipping load is defined by SAE J732.22 <strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications

<strong>IT14G</strong> Dimensions with Material Handling ArmAll dimensions are approximate.1962 mm(6' 5")1402 mm(4' 7")2522 mm(8' 3")6840 mm(22' 5")6012 mm(19' 9")5185 mm(17' 0")3179 mm(10' 5")4178 mm(13' 8")5178 mm(17' 0")1585 mm(5' 2")1874 mm(6' 2")1514 mm(4' 11")2670 mm(8' 9")3468 mm(11' 5")2116 mm(6' 11")2719 mm(8' 11")<strong>IT14G</strong> Operating Specifications with Material Handling ArmMaterial Handling Arm Position Retracted Mid-Position ExtendedOperating load at 40° full turn 1370 kg (3,021 lb) 1076 kg (2,373 lb) 888 kg (1,958 lb)Static tipping load, straight* 3158 kg (6,963 lb) 2484 kg (5,477 lb) 2051 kg (4,522 lb)Static tipping load, full 40° full turn* 2740 kg (6,042 lb) 2153 kg (4,747 lb) 1777 kg (3,918 lb)Operating weight* 7770 kg (17,133 lb) 7770 kg (17,133 lb) 7770 kg (17,133 lb)* Static tipping and operating weights shown include lubricants, full fuel tank, ROPS cab,80 kg (176 lb) operator, standard 250 kg (550 lb) counterweight and 17.5 - R25 (L2 equivalent) tires.Note: Machine stability and operating weights are affected by tire size, tire ballast and other attachments.<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications23

Typical material densities — loosekg/m 3 lb/yd 3Basalt 1960 3305Bauxite, Kaolin 1420 2394Claynatural bed 1660 2799dry 1480 2495wet 1660 2799Clay and graveldry 1420 2394wet 1540 2596Decomposed rock75% rock, 25% earth 1960 330550% rock, 50% earth 1720 290025% rock, 75% earth 1570 2647Earthdry, packed 1510 2546wet, excavated 1600 2698Granitebroken 1660 2799Gravelpitrun 1930 3254dry 1510 2546dry, 6-50 mm (0.2-2") 1690 2849wet, 6-50 mm (0.2-2") 2020 3406kg/m 3 lb/yd 3Gypsumbroken 1810 3052crushed 1600 2698Limestonebroken 1540 2596crushed 1540 2596Sanddry, loose 1420 2394damp 1690 2849wet 1840 3102Sand and clayloose 1600 2698Sand and graveldry 1720 2900wet 2020 3416Sandstone 1510 2546Shale 1250 2107Slagbroken 1750 2950Stonecrushed 1600 2698<strong>IT14G</strong> Bucket Size Selectorkg/m 3Bucket Capacity1400 1600 1800 2000 2200 2400 2600m 3 yd 31.2 1.6Material Density1.3 1.71.4 1.8115% 100% 95%% = Bucket Fill Factor2400 2700 3000 3300 3600 3900 4200 lb/yd 324 <strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer <strong>for</strong> details.24V direct electric startingAir cleaner, radial sealAlarm, back-upAlternator, 80-ampereAntifreeze (protected to –36° C/–33° F)Extended life coolant antifreezeBatteries, two 900 CCA maintenance freeBattery disconnect switchBrakesEnclosed/sealedParking — mechanical on drive line, secondaryService — inboard, oil-immersed, enclosed, wet-discfull hydraulicBucket control, single lever, pilotBucket/<strong>for</strong>k positioner, automaticCab, ROPS (sound suppressed and pressurized)Adjustable steering columnCigar lighterCup holderGround level door releaseHeater/defrosterRearview mirrors, inside (2)Storage space, lockableSeat, adjustable fabric suspensionSeat belt, 75 mm (3 in), retractableTinted front safety glassTwo doors, fixed glassWiper and washer (front & rear), front intermittentCounterweight (150 kg/330 lb); optional on <strong>914G</strong>Defroster, rear window, wired glassDifferentials, conventional (front & rear)Driveshaft; lubed <strong>for</strong> lifeElectric fuel pumpEngine: Caterpillar 3054C DIT dieselLow emissionTurbochargedEngine enclosure, lockableFenders (front/rear)Glow plug starting aidHitch, drawbarHorn, front, warning (electrical)Hydraulic control, pilot-operated, single lever, 2 valveThird function hydraulics standard on <strong>IT14G</strong> onlyPilot control detentsFloatRackbackRaiseThird function hydraulicsHydraulic oil cooler, tiltableHydraulic diagnostic connectorsIgnition key start/stop switchIndicatorsAir cleanerAir filterBrake charge pressureEngine oil pressureElectrical system voltageHystat oil filter bypassParking brakePrimary steeringInstrumentationBattery voltage gaugeEngine coolant temperature gaugeFuel level gaugeHour meter, digitalHydraulic oil level sight gaugeHydraulic oil temperature gaugeLift kickout, automaticLift/tilt kickout neutralizerLighting systemBrake lightsInterior lightTurn signals (front and rear)Working lights, halogen (front and rear)LinkageSealed Z-bar design loader linkage (<strong>914G</strong> only)8 bar parallel lift linkage with sealed pins (<strong>IT14G</strong> only)MufflerPilot hydraulic implement controlsPower receptacles; internal and externalPressure test pointsRadiator, serviceable unit coreRadiator expansion bottleSingle lever transmission controlS•O•S SM portsEngine oilHydraulic oilStandard hydraulic oil coolerSteering, hydraulicSuction fanTransmission, hydrostaticVandalism protection-locked service points<strong>914G</strong>/<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications25

Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer <strong>for</strong> details.Air Conditioner, R-134a refrigerantBottom guard, hystatCanopy, ROPSCounterweight, 150 kg/330 lb (optional <strong>914G</strong> only)Creeper Control, transmissionDifferential, Limited Slip (front and/or rear axle)Drain valves, ecologicalEngine Speed Control (ESC)Electrical accessories package (12V converter, accessory plugoutlet, wiring)Fenders, roadingForward/Neutral/Reverse (FNR) remote transmission controlGuard, windshield (optional <strong>914G</strong> only)Ground engaging tools, bucketHydraulic third and fourth valves (Hydraulic third valvestandard on <strong>IT14G</strong>)- quick disconnects- hydraulic lines and controlLightingAuxiliary front: 2 cab-mounted halogen, workingBeacon, magnetic rotatingLow sound packageMachine Security SystemIncludes 2 preprogrammed keys, additional keys areavailable through parts distribution (206-5162)Requires Caterpillar Service Tool, Electronic Technician(ET) to activate and modify programming of keysMirrorsExternal (2)Quick Coupler (Standard on <strong>IT14G</strong>)Radio prep package (12V)- includes speakers, antenna, converter and mounts(Radio not included)Remote Forward/Neutral/Reverse transmission controlRide Control systemRotating beacon, magneticSeats:- heated, fabric, with parking brake alarm- Caterpillar Com<strong>for</strong>t Series, fabric, air suspensionSliding door windowSpeedometerStarting aidEngine block heater (120V or 240V)Steering, secondarySun screen, rear windowSun visorTires:- bias ply, 15.5 25 and 17.5 25- radial, 15.5 R25 and 17.5 R25Tire rims, 1- and 3-pieceTool box, lockableTool kit26<strong>914G</strong>/<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications

Notes<strong>914G</strong>/<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> Toolcarrier specifications 27

<strong>914G</strong>/<strong>IT14G</strong> <strong>Wheel</strong> <strong>Loader</strong>/<strong>Integrated</strong> ToolcarrierFor more complete in<strong>for</strong>mation on Cat products, dealer services,and industry solutions, visit us on the web at www.cat.com© 2006 CaterpillarAll Rights ReservedPrinted in U.S.A.Materials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.See your Caterpillar dealer <strong>for</strong> available options.AEHQ5560-01 (2-06)Replaces AEHQ5560CAT, CATERPILLAR, their respective logos and “Caterpillar Yellow,”as well as corporate and product identity used herein, aretrademarks of Caterpillar and may not be used without permission.R