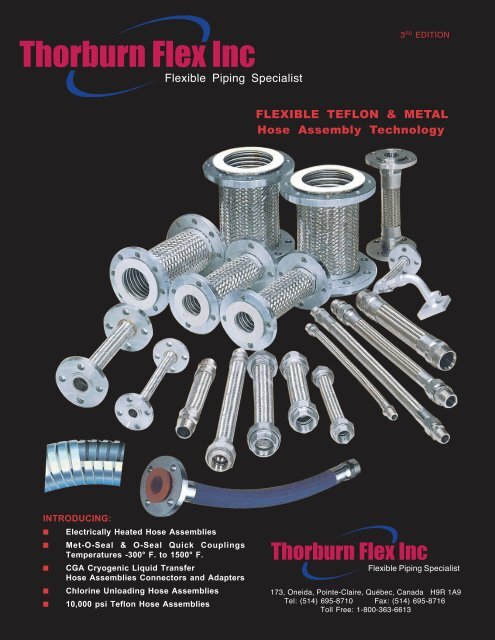

Metallic Hose Assemblies - Thorburn Flex Inc

Metallic Hose Assemblies - Thorburn Flex Inc

Metallic Hose Assemblies - Thorburn Flex Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Metal <strong>Hose</strong>CorrugatedCUSTOM METAL HOSE ASSEMBLIESPurposeCollarFlange<strong>Thorburn</strong>'s annular corrugated metal hose assemblies are made upof three major parts: metal hose, overbraid and end fittings. <strong>Assemblies</strong>achieve several objectives in pipework design: absorb vibration,supress rigid pipe transmitted noise, accommodate reciprocatingand flexing movement and adjust or correct for minor misalignment.Custom Designs<strong>Thorburn</strong> is geared to provide enduserdesigned hose assemblies. Youspecify the operating conditions andwe will produce a hose. The hosemay be exceptionally flexible or youmay need several hoses encapsulatedin outer hose: a jacketed hosefor heat exchange; an armoured hose;a hose to carry sensitive cables; anarticulated robotic cover; an insulatedhose; a colour coded hose. Our "cando"design specialists are only a phonecall away.UnbraidedhoseBraidCHARACTERISTICS<strong>Hose</strong><strong>Thorburn</strong>'s stainless steel annular corrugatedhose body provides the flexibleand pressure tight core of the assembly.<strong>Thorburn</strong>'s manufactured annularcorrugated hose tends to be more flexible andlower stressed than a helical product. The pitch of thehose can be varied to achieve performance requirements inboth flexibility and pressure rating.End FittingsThis is the means by which the custom-designed assembly is attachedinto the pipework system.Braided hoses accept lateralmotion onlyBraidWhen pressure is introduced into corrugated hose, it tends to openaxially. The pressure acts upon each corrugation at the rate of theeffective diameter of the corrugation, multiplied by the line pressure.The job of <strong>Thorburn</strong>'s tight weave braid is to prevent elongation.Fitting the braid to the corrugated tube also increases the hoopstrength, stabilizes movement and offers a form of abrasion protection. The core hose, a braid collar and the tight weavebraid are welded together to give the "live length" of assembly. Braid is made of stainless steel, Monel or bronze wire, wovenin such a way that line pressure produces braid tension which is dissipated into inward radial pressure. <strong>Thorburn</strong>'s multiplebraided assemblies accommodate higher pressures. As the braid is stretched in an operating assembly, it will not acceptaxial motion.2

Metal <strong>Hose</strong>Corrugated<strong>Thorburn</strong>'s standard annular flexible core starts its lifeas a coil of stainless steel strip which is mechanicallyformed into a tube and then longitudinally butt welded.Considerable care is taken to ensure that the strength ofthe butt weld is greater than that of the parent material.This rigid tube is then transferred to the corrugating machinewhere the corrugations are formed. After the tubehas been corrugated, it is pressure tested to ensure thatthere are no leaks.<strong>Thorburn</strong>'s "Tight weave" braid design is carefully calculatedto ensure that the number of wire gauge and theangle of lay give optimum performance. After the attachmentof the end fittings, the hose is pressure tested to1-1/2 times the working or design pressure and test certificatescan be supplied if required.Why Buy <strong>Thorburn</strong> Annular formed Corrugated Metal <strong>Hose</strong> <strong>Assemblies</strong>Annular (parallel) CorrugationsHelical (spiral) CorrugationsVSSeparate corrugations form acircle or ring in itselfSpiral path with one continuous corrugationrunning the length of the hose<strong>Thorburn</strong>'s standard metal hose core is corrugated intoa close pitch annular profile. These annular corrugationspermit the hose to be bent or isolate lateral deflectionwhile remaining liquid and gas tight.<strong>Thorburn</strong>'s annular corrugations permit the hose assemblyto absorb its thermal activated extension and compressionmovements.VSVSHelical corrugations tend to be less flexible and yieldhigher stress under flexural movement. In other words1) helical assembly takes more force to bend and requireslonger lengths to make a bend; 2) helical assemblylife is more adversely affected by flexure movementresulting in a shorter life.Helical corrugations have a tendency to twist whensubjected to extension and compression movement. Inother words, if your flexible hose component is subjectedto a change in temperature, the hose could failprematurally.3

Metal <strong>Hose</strong>CorrugatedExtra <strong>Flex</strong>ible Constructionsee page 9Higher Pressures AvailableOur Standard <strong>Hose</strong> is Type 321 - Stainless Steel (Braided Type 304)<strong>Thorburn</strong>#CodeS95 - Unbraided innercore 0S96 - Braided hose 1S96Z - Double braided hose 2Construction■ Medium wall butt welded tubing■ Closed pitch annular corrugations■ Size range 1/4" through 30"■ Working pressure - full vacuum to 2410 psi(depending on the size)Also Available Type 316L - <strong>Hose</strong> With 304 Braid<strong>Thorburn</strong>#CodeS91 - Unbraided innercore 0S92 - Braided hose 1S92Z - Double braided hose 2Construction■ Butt welded tubing■ Annular corrugations■ Size range 1/4" through 30"■ Working pressure - full vacuum to 2410 psi(depending on the size)Nominal I.D. <strong>Hose</strong> type <strong>Hose</strong> O.D. Minimum Bend radius (in.) Live length Working Weightfor vibration pressure lbs/ft(in.) (in.) Static Dynamic (in.) PSI @ 70°F0 .413 145 .081/4 1 .465 1 3.9 4 2233 .142 .512 3568 .20 .583 80 .103/8 1 .630 1.6 5.9 6 1523 .192 .677 2437 .290 .717 80 .131/2 1 .764 2.0 7.9 6 1276 .252 .811 2030 .370 .886 70 .165/8 1 .933 2.0 7.9 7 1059 .302 .984 1682 .430 1.063 60 .203/4 1 1.122 2.8 7.9 7 928 .362 1.169 1479 .514Continued on next page

Metal <strong>Hose</strong>CorrugatedNominal I.D. <strong>Hose</strong> type <strong>Hose</strong> O.D. Minimum Bend radius (in.) Live length Working Weightfor vibration pressure lbs/ft(in.) (in.) Static Dynamic (in.) PSI @ 70°F0 1.378 45 0.271 1 1.425 3.50 7.90 7 725 0.502 1.476 1160 0.730 1.654 35 0.381-1/4 1 1.713 4.30 9.80 8 609 0.632 1.772 972 0.880 2.047 35 0.461-1/2 1 2.106 5.10 9.80 8 464 0.832 2.165 740 1.210 2.559 15 0.602 1 2.638 6.90 13.80 9 450 1.182 2.717 711 1.750 3.189 15 0.732-1/2 1 3.268 7.90 16.10 10 377 1.472 3.346 595 2.220 3.740 15 0.813 1 3.819 8.10 17.70 11 261 1.682 3.898 406 2.550 4.520 11 1.703-1/2 1 4.620 8.50 20.00 11 300 2.802 4.720 390 3.900 4.606 10 1.184 1 4.685 9.10 22.00 12 232 2.252 4.764 377 3.330 5.709 10 1.715 1 5.827 11.00 26.00 16 232 3.422 5.945 363 5.130 6.772 2.5 2.306 1 6.890 12.60 32.10 17 174 4.422 7.008 290 6.550 8.976 2.0 4.208 1 9.094 17.10 40.00 19 145 7.082 9.213 232 9.960 11.18 5.0 6.8010 1 11.32 33.50 37.50 21 230 12.902 11.45 367 19.000 13.23 3.0 9.0212 1 13.37 47.50 55.00 23 165 14.832 13.50 257 20.640 15.40 1.7 11.1414 1 15.65 37 74 25 130 17.1823.220 17.45 1.5 12.8616 1 17.65 42 84 27 100 19.227.15 25.580 19.40 1.0 14.5018 1 19.65 47 94 29 85 20.1025.700 21.70 1.0 20.4020 1 21.95 53 106 32 70 26.4432.480 25.70 1.0 24.5024 1 25.95 62 125 35 40 31.3238.145

Metal <strong>Hose</strong>CorrugatedHeavy Duty Construction■ Heavy wall butt welded tubing■ Closed pitch annular corrugations■ Size range 1/2" through 6"■ Working pressure - full vacuum to 3783 psi(depending on the size)Higher Pressures AvailableOur Standard <strong>Hose</strong> is Type 321 - Stainless Steel (Braided Type 304)<strong>Thorburn</strong>#Code<strong>Thorburn</strong>#CodeS81 - Unbraided innercore 0S82 - Braided hose 1S82Z - Double braided hose 2S85 - Unbraided innercore 0S86 - Braided hose 1S86Z - Double braided hose 2Nominal I.D. <strong>Hose</strong> type <strong>Hose</strong> O.D. Bend radius (in.) Live length Working Weightfor vibration pressure lbs/ft(in.) (in.) Static Dynamic (in.) PSI0 0.82 80 0.391/2 1 0.92 1.50 8.00 6 2365 0.632 1.02 3783 0.870 1.21 70 0.483/4 1 1.31 2.00 8.00 6 1379 0.792 1.41 2206 1.100 1.50 40 0.791 1 1.60 3.00 9.00 8 1130 1.202 1.70 1808 1.610 1.85 33 1.021-1/4 1 1.97 3.25 10.00 8 1110 1.622 2.10 1776 2.220 2.17 20 1.361-1/2 1 2.30 3.25 10.00 9 955 2.112 2.43 1529 2.860 2.51 15 1.602 1 2.64 5.38 11.50 10 810 2.462 2.76 1017 3.320 3.23 10 2.002-1/2 1 3.36 7.00 24.00 10 504 2.652 3.49 806 3.300 3.78 10 2.973 1 3.91 7.50 28.00 11 540 4.362 4.03 650 5.750 4.81 8 3.514 1 4.93 20.00 40.00 11 286 4.922 5.05 458 6.330 6.87 5 3.476 1 7.10 24.00 95.00 11 266 6.372 7.33 425 8.976

Metal <strong>Hose</strong>Corrugated<strong>Thorburn</strong>Code#MONEL TYPE 400 HOSE & MONEL BRAIDM95 Unbraided innercore 0M96 Braided hose 1M96 Z Double braided hose 2INCONEL TYPE 625 INCONEL BRAIDI95 Unbraided innercore 0I96 Braided hose 1I96Z Double braided hose 2INCONEL TYPE 625 SS304 BRAIDIS95 Unbraided innercore 0IS96 Braided hose 1IS96Z Double braided hose 2Construction■■■■Higher Pressures AvailableMedium wall butt welded tubingClosed pitch annular corrugationsSize range 1/4" through 30" availableWorking pressure - full vacuum to 3190 psi(depending on the size)Nominal I.D. <strong>Hose</strong> type <strong>Hose</strong> O.D. Minimum Bend radius (in.) Live length Working Weightfor vibration pressure lbs/ft(in.) (in.) Static bend Constant flexing (in.) PSI @ 70°F0 .395 145 .0591/4 1 .449 1 4 4 2420 .112 .504 3190 .170 .335 145 .0885/16 1 .528 1.5 5.5 5 1970 .162 .579 3045 .220 .595 80 .113/8 1 .642 1.6 6 6 1450 .182 .693 2580 .260 .840 120 .401/2 1 .900 2.0 7 6 835 .512 .960 1500 .640 .864 70 .185/8 1 .917 2.0 8 7 1015 .292 .101 1810 .400 1.21 90 .793/4 1 1.27 3.0 9 6 600 .962 1.33 1080 1.150 1.53 56 1.021 1 1.59 3.0 10 8 500 1.222 1.65 755 1.440 1.86 53 1.611-1/4 1 1.92 4.0 12 8 460 1.842 1.98 570 2.080 2.19 37 1.971-1/2 1 2.29 4.0 13 9 410 2.552 2.39 550 3.160 2.83 20 2.632 1 2.93 5.0 16 10 375 3.372 3.03 500 4.110 3.00 12 2.042-1/2 1 3.12 7.0 17 10 375 2.882 3.24 500 3.750 3.57 8 2.503 1 3.69 9.0 21 11 295 3.452 3.81 500 4.427

Metal <strong>Hose</strong>CorrugatedCompressedcorrugationsApplication<strong>Thorburn</strong>’s high pressure NS99Z metallic high pressure hoseassemblies were specifically designed to transfer heavy waterin a fuel handling system found in a CANDU 6 nuclearpower generating station. This hose can be manufactured tomeet the design requirements of ASME Section III and CSAN285.0 components in CANDU nuclear power plants. Anotherideal application is to transfer gaseous hydrogen toand from the bulk transport truck to the customer facility.Closed Pitch Compressed Corrugationsfor High Pressure ServiceConstruction■■Ultra-high pressure annular closed pitch corrugatedcompressed hose core SA240 type 321 c/w, multiplelayered braid A580 type SS304 or SS321Size range 1/4" through 2" standard: assembly lengthsup to 50' with one splice<strong>Hose</strong> part Nominal inches Bend radius (in.) Design pressure Minimum Approximateburst pressure weightnumber I.D. O.D. Static bend Constant flexing PSI at 70° F. PSI at 70° F. per ft.NS99Z-04* 1/4 . 0.64 6.00 12.00 4600 18000 0.36NS99Z-06* 3/8 0.93 6.00 12.00 3500 17000 0.55NS99Z-08 1/2 1.02 7.00 14.00 3500 14000 0.76NS99Z-12 3/4 1.46 7.50 15.00 2700 12000 1.19NS99Z-16 1 1.77 8.00 16.00 2595 12000 1.99NS99Z-20* 1 1/4 2.09 9.00 18.00 2400 8000 2.48NS99Z-24* 2 1/2 2.43 9.50 19.00 1688 6800 3.30NS99Z-32* 2 2.77 12.00 24.00 1300 530 3.90*Available on special order onlyUltra high pressures to 10,000 PSI available. Call <strong>Thorburn</strong> for details.Pressures shown are reduced to account for weld efficiency.Construction■■Ultra Heavy Duty High Pressure annular closed pitchcorrugated compressed hose core SA240 TYPE 321c/w multiple layered braided braid A580 type 321Size range 1/4" through 2" standard: assembly lengthsup to 50' with one spliceClosed Pitch, Fully Compressed Corrugationsfor Ultra High Pressure Service<strong>Hose</strong> part Nominal inches Bend radius (in.) Design pressure Minimum Approximateburst pressure weightnumber I.D. O.D. Static bend Constant flexing PSI at 70° F. PSI at 70° F. per ft.S50HD-04 1/4 . 0.69 2.50 11.50 10000 40000 0.65S50HD-06 3/8 0.92 3.75 15.00 8000 32000 1.00S50HD-08 1/2 1.06 4.50 16.50 7000 28000 1.43S50HD-12 3/4 1.55 6.50 30.50 6000 24000 2.65S50HD-16 1 1.95 9.00 35.00 5500 22000 3.90S50HD-20 1 1/4 2.19 10.00 38.00 4000 16000 8.12S50HD-24 1 1/2 2.62 12.00 41.00 4500 18000 6.72S50HD-32 2 3.15 15.00 48.00 4000 16000 8.36*Available on special order onlyUltra high pressures to 10,000 PSI available. Call <strong>Thorburn</strong> for details.Pressures shown are reduced to account for weld efficiency.8

Metal <strong>Hose</strong>CorrugatedEXTRAFLEX is a spirally-welded corrugatedhose specifically designed toachieve extreme flexibility and excellent pressure ratings.This unique hose features self-draining and minimal lineturbulence characteristics. EXTRAFLEX is available in T321and T316L stainless steel and is stocked in lengths of up to80 feet.EXTRAFLEX is used when temperature extremes, corrosivemedia, or permeation preclude the use of rubber, PTFE, orplastic hose.Typical applications for EXTRAFLEX are found in the compressedgas, food processing, and steel making industries.These applications include clean-in-place, automatic lubricationand self-draining fluid lines.Our Standard <strong>Hose</strong> is Type 321 - Stainless Steel (Braided Type 304)<strong>Thorburn</strong> #CodeS65 - Unbraided innercore 0S66 - Braided hose 1S66Z - Double braided hose 2Construction■ Heavywall butt welded tubing■ Spiral wound helical corrugations■ Size range 1/4" through 2"■ Working pressure - full vacuum to 2485 psi(depending on the size)Also Available Type 316L <strong>Hose</strong> With 304 Braid<strong>Thorburn</strong>#CodeS62Z & S66ZS61 - Unbraided innercore 0S62 - Braided hose 1S62Z - Double braided hose 2S62 & S66S61 & S65Inside Outside Static Min. Dynamic Min. Working Burst WeightDiameter Number Diameter Bend Radius Bend Radius Pressure Pressure per Foot(in.) of Braids (in.) (in.) (in.) (PSI) (PSI) (lbs.)0 0.50 180 0.091/4 1 0.57 1.0 3.0 2562 10,250 0.182 0.64 4100 16,400 0.260 0.67 100 0.143/8 1 0.74 1.25 3.5 1848 7,392 0.242 0.81 2957 11,827 0.360 0.82 80 0.231/2 1 0.89 1.50 4.0 1075 4,301 0.342 0.96 1720 6,881 0.460 1.21 70 0.343/4 1 1.28 2.25 6.0 792 3,168 0.542 1.35 1267 5,069 0.740 1.48 40 0.371 1 1.55 2.75 7.0 571 2,285 0.572 1.63 914 3,656 0.770 1.86 25 0.761 1/4 1 1.93 3.0 8.0 531 2,125 1.062 2.02 850 3,400 1.370 2.19 20 0.841 1/2 1 2.28 3.5 9.0 472 1,887 1.232 2.37 755 3,020 1.630 2.51 15 1.002 1 2.61 4.0 10.25 505 2,022 1.652 2.71 809 3,235 2.309

Metal <strong>Hose</strong>Corrugated <strong>Hose</strong> Thread Overall Cut-offsize size NPT DIM "B" DIM "A"1/4 1/4 1-7/8 1-1/23/8 3/8 1-7/8 1-1/21/2 1/2 2-3/8 1-3/43/4 3/4 2-5/8 21 1 2-5/8 21-1/4 1-1/4 3-1/4 2-1/21-1/2 1-1/2 3-1/4 2-1/22 2 3-1/2 2-1/22-1/2 2-1/2 4 33 3 4 34 4 5 4<strong>Hose</strong> Overall Cut-offsize DIM "B" DIM "A"1/4 1-7/8 1-1/23/8 1-7/8 1-1/21/2 2-3/8 1-3/43/4 2-3/8 1-3/41 2-3/8 1-3/41-1/4 2-1/2 1-3/41-1/2 2-1/2 1-3/42 3-1/8 2-1/82-1/2 3-1/8 2-1/83 3-1/8 2-1/84 3-1/2 2-1/25 3-1/2 2-1/26 4 38 4 3<strong>Hose</strong> Thread Overall Cut-offsize size NPT DIM "B" DIM "A"1/4 1/4 1-9/16 1-3/163/8 3/8 1-5/8 1-1/41/2 1/2 2-1/16 1-7/163/4 3/4 2-1/8 1-1/21 1 2-5/16 1-11/161-1/4 1-1/4 2-11/16 1-15/161-1/2 1-1/2 2-7/16 2-1/82 2 3-3/16 2-1/22-1/2 2-1/2 4 33 3 4 34 4 5 4<strong>Hose</strong> Thread Overall Cut-offsize size NPT DIM "B" DIM "A"1/4 1/4 1-1/16 11/163/8 3/8 1-1/8 3/41/2 1/2 1-7/16 13/163/4 3/4 1-7/16 13/161 1 1-5/8 11-1/4 1-1/4 1-3/4 11-1/2 1-1/2 1-13/16 1-1/162 2 2-1/4 1-1/42-1/2 2-1/2 2-7/16 1-7/163 3 2-5/8 1-5/84 4 2-7/8 1-7/8<strong>Hose</strong> Overall Cut-off Sanitarysize DIM "B" DIM "A" Flange OD1/2 3 2 1.983/4 3 2 1.981 3 2 1.981 1/2 3 1/2 2 1/2 1.982 4 1/2 3 1/2 2.522 1/2 4 1/2 3 1/2 3.053 4 1/2 3 1/2 3.58<strong>Hose</strong> Thread Overall Cut-offsize size NPT DIM "B" DIM "A"1/4 1/4 2-1/16 1-11/163/8 3/8 2-3/16 1-3/161/2 1/2 2-9/16 1-15/163/4 3/4 2-9/16 1-15/161 1 2-7/8 2-1/41-1/4 1-1/4 3-1/8 2-3/81-1/2 1-1/2 3-3/8 2-5/82 2 4 32-1/2 2-1/2 4-1/2 3-1/23 3 5-1/8 4-1/8All dimensions are in inches10

Metal <strong>Hose</strong>Corrugated<strong>Hose</strong> Overall Cut-offsize DIM "B" DIM "A"1/4 2-5/8 2-1/43/8 3-1/8 2-1/21/2 3-5/16 2-11/163/4 3-3/4 3-1/81 4 3-3/81-1/4 4-1/2 3-3/41-1/2 4 3-5/162 5-5/16 4-5/162-1/2 6-1/16 5-1/163 6-1/2 5-1/2<strong>Hose</strong>/ Overall Cut-off Boltflange DIM "B" DIM "A" holesizedia.1/2 2-5/8 2 5/83/4 2-5/8 2 5/81 2-5/8 2 5/81-1/4 2-3/4 2 5/81-1/2 2-3/4 2 5/82 3-1/2 2-1/2 3/42-1/2 3-1/2 2-1/2 3/43 3-1/2 2-1/2 3/44 4 3 3/45 4 3 7/86 4-1/2 3-1/2 7/88 5 4 7/8 <strong>Hose</strong> Thread Overall Cut-offsize size DIM "B" DIM "A"1/4 7/16 - 20 1-5/8 1-1/43/8 9/16 - 18 1-25/32 1-7/161/2 3/4 - 16 1-31/32 1-7/163/4 1-1/16 - 12 2-13/32 1-25/321 1-5/16 - 12 2-1/2 1-7/81-1/4 1-5/8 - 12 2-7/8 2-1/81-1/2 1-7/8 - 12 3-3/32 2-11/322 1-1/2 - 20 3-13/32 2-13/32<strong>Hose</strong>/ Overall Cut-offflange DIM "B" DIM "A"size1/2 2-5/8 23/4 2-5/8 21 2-5/8 21-1/4 2-3/4 21-1/2 2-3/4 22 3-3/8 2-3/82-1/2 3-3/8 2-3/83 3-3/8 2-3/84 3-3/4 2-3/45 3-3/4 2-3/46 4-1/2 3-1/28 4-3/8 3-3/8<strong>Hose</strong> Overall Cut-offsize DIM "B" DIM "A"1/4 2-5/16 2-9/163/8 3-3/32 2-3/41/2 3-17/32 33/4 4-9/32 3-21/321 4-9/16 3-15/161-1/4 5-1/16 4-5/161-1/2 5-11/32 4-21/32<strong>Hose</strong>/ Overall Cut-offflange DIM "B" DIM "A"size1/2 2-3/8 1-7/83/4 2-11/16 2-1/161 2-15/16 2-3/161-1/4 3-1/4 2-1/41-1/2 3-7/16 2-7/162 3-1/2 2-1/22-1/2 3-3/4 2-3/43 3-3/4 2-3/44 4 35 4-15/16 3-1/26 4-15/16 3-1/2All dimensions are in inches* Also available lightweight economical plate flanges withvarious plate thicknesses11

Metal <strong>Hose</strong>CorrugatedType of hose 1st end 2nd end <strong>Hose</strong> size Length in inches* FractionsCoverXXX XX XX XX XXX XXType of hoseS61S62S62ZS65S66S66ZS95S96S96ZS91S92S92ZM95M96M96ZMDF150**MDF225**2S962S96Z2S922S92ZNS99Z<strong>Thorburn</strong>EngineExhaust<strong>Assemblies</strong>Order by: Partnumber; Endconnection;Pipe size, Boltpattern; Bolthole diameterFitting code numbers01- Male nipple carbon steel02- Male nipple 304SS<strong>Hose</strong> size in1/16 of an inchExamples:Assemblylength ininches03- Male niple 316SS01=1/1602=1/8* For metric04- Hex male carbon steel04=1/4length, put05- Hex male 304SS06- Hex male 316SS06=3/8metric number08=1/2with the measurementtype.07- Female union carbon steel 150#12=3/408- Female union 304SS 150#64=4i.e. MM=09- Female union 316SS 150#etc.millimeters;10- Female 37 o 304SSM- meters, etc.11- Solid female pipe carbon steel12- Solid female pipe 304SSSpecial Monel fitting code13- Solid female pipe 316SSnumbers14- Weld nipple carbon steel15- Weld nipple 304SSM1- Monel male nipple16- Weld nipple 316SSM2- Monel hex male nipple17- Fixed flange carbon steel 150# M3- Monel female union18- Fixed flange 304SS 150#M4- Monel class 150 fixed flange19- Fixed flange 316SS 150#M5- Monel class 150 weld neck20- Weld neck flange carbon steel 150#flange21- Weld neck flange 304SS 150# M6- Lap joint flange class 150 steel22- Weld neck flange 316SS 150#with a Monel stub end23- Lap joint flange carbon steelM7- Lap joint flange class 15024- Lap joint flange and stub end 304SS316SS with a Monel stub end25- Lap joint flange and stub end 316SS M8- Lap joint flange class 15026- Lap joint flange carbon steelMoneland stub end 304SSwith Monel stub end27- Lap joint flange carbon steeland stub end 316SS28- 3000# male union - carbon steel29- 3000# male union - 304SS30- 3000# male union - 316SSORDERING FLANGES31- Male union - 316SS JIC w/adapter■ To order 300# flange, 600#32- Female union carbon steel 3000# flange, etc., use 150# assemblypart number and specify33- Female union 304SS 3000#34- Female union 316SS 3000#class 300# or 600# flange35- 150# CS male unionbelow part number.36- Female 37 o carbon steel37- Female JIC 37 o 316 stainless steel■ To order forged raised face38- Victaulic carbon steel39- Victaulic 304SSflanges A105 or A182 ANSI40- Victaulic grooveB16.5 Class 150, 300, 600,41- Sanitary Flange 316SSetc., please add "A" after theflange code ie: 17A, 19A, 20A.42- Male union - CS JIC w/adapter50- CGA 29550- CGA 295Quick couplings for <strong>Thorburn</strong> metal hose assemblies60- Met-O-Seal female*61- Met-O-Seal male*62- Met-O-Seal socket weld*63- Cam and Groove male shank E*64- Cam and Groove female coupler C*65- Cam and Groove elbow*66- Cam and Groove male elbow*67- Tank truck adapter*68- Vitaulic*69- Tube end*70- Pre swage bilok nut and sleeve*71- Pre-welded "O" seal gland and nut** Please specify materialFractions ofan inch in 1/8inchesExamples:01=1/802=1/404=1/206=3/407=7/8Cover CodesBlank if N/AInsulationFJ = Fry-SilJacketTS = Thor-SilSFS = SaturatedFibreGlassSleevingUCS = UnsaturatedCeramicSleevingSP = Sil-PonProtectionAF = Armour<strong>Flex</strong>UnpackedAFP = Armour-<strong>Flex</strong>PackedLS12 =LockSection (x)LS16 =LockSection (x)LS20 =LockSection (x)LS24 =LockSection (x)LS32 =LockSection (x)(x) = Add suffixS4 = 304SSS5 = 321SSS6 = 316SSCarbon steelleave blankHow to Order Special Ends■ To order plate flanges orspecial ends, simply insertXX for 1st end, YY for 2ndend and specify.■ To specify Hex on unions,use union number and specifyHex below.12

Metal <strong>Hose</strong>Technical DataMAXIMUMOFFSETA. Locate the minimum bend radius for intermittent flexureby referring to that column on the product specificationpage for that hose.Ambient temp.B. Locate this bend radius number in the left column of thetable below (if the radius falls between numbers on thetable, use next highest number).C. Locate the required offset for your applications.D. The minimum live length required is the intersecting boxof the two columns.E. To determine static bend minimum lengths, simply substitutestatic bend radius shown in step B and continuein the same manner.F. To determine O.A.L. of assembly, add the fitting lengthsto the live lengths shown below.OALLIVE LENGTHMin. Bend RadiusOffset Motion (maximum distance from center line)1/8" 1/4" 3/8" 1/2" 3/4" 1" 1 1/2" 2" 3" 4" 5" 6" 8" 10" 20" 30" 40" 50" 60"Minimum Live Length Required For Offset Motion2 1-1/4 1-3/4 2-1/4 2-1/2 3-1/4 3-3/4 4-1/2 5-1/4 6-3/4 8 9-1/4 10-1/2 12-3/4 154 1-3/4 2-1/2 3 3-1/2 4-1/2 5 6-1/4 7-1/4 9 11-3/4 12 13-1/2 16 18-1/26 2-1/4 3-1/4 3-3/4 4-1/4 5-1/4 6-1/4 7-1/2 8-3/4 10-3/4 12-3/4 14-1/4 16 19 21-1/28 2-1/2 3-1/2 4-1/4 5 6 7 8-3/4 10 12-1/2 14-1/2 16-1/4 18 21-1/4 24-1/410 2-3/4 4 4-3/4 5-1/2 6-3/4 8 9-3/4 11-1/4 13-3/4 16 18 20 23-1/2 26-1/2 34-1/212 3 4-1/4 5-1/4 6 7-1/2 8-1/2 10-1/2 12-1/4 15 17-1/2 19-1/2 21-1/2 25-1/2 28-3/4 3914 3-1/4 4-3/4 5-3/4 6-1/2 8 9-1/4 11-1/4 13-1/4 16-1/4 18-3/4 21 23-1/2 27-1/4 30-3/4 4316 3-1/2 5 6 7 8-1/2 10 12-1/4 14 17-1/4 20 22-1/2 25 29 32-3/4 4418 3-3/4 5-1/4 6-1/2 7-1/2 9 10-1/2 13 14-3/4 18-1/4 21-1/4 24 26 30-1/2 34 48 5720 4 5-1/2 6-3/4 7-3/4 9-1/2 11 13-1/2 15-3/4 19-1/4 22-1/2 25 27-1/2 32-1/4 36-1/4 53 6225 4-1/2 6-1/4 7-1/2 8-3/4 10-3/4 12-1/4 15 17-1/2 21-1/2 25 28 30-1/2 35-3/4 40 60 7130 4-3/4 6-3/4 8-1/4 9-1/2 11-3/4 13-1/2 16-1/2 19 23-1/2 27-1/4 30-1/2 33-1/2 40 43-3/4 66 79 8935 5-1/4 7-1/4 9 10-1/4 12-1/2 14-1/4 17-3/4 20-1/4 26-1/4 29-1/2 32-3/4 36 42 47 72 87 9840 5-1/2 8 9-1/2 11 13-1/2 15-1/2 19 22 27 31-1/4 35 38-1/2 44-3/4 50 77 93 10645 6 8-1/4 10 11-3/4 14-1/4 16-1/2 20-1/4 23-1/2 28-1/2 33 37 41 47-1/2 53 82 99 11350 6-1/4 8-3/4 10-3/4 12-1/4 15 17-1/2 21-1/2 24-1/2 30 35 39 43 50 56 87 105 120 13260 6-3/4 9-1/2 11-3/4 13-1/2 16-1/2 19 23-1/4 27 33 38 43 47 54-1/2 61 96 116 132 14670 7-1/4 10-1/4 12-3/4 14-3/4 17-3/4 20-1/2 25 29 35-1/2 41-1/2 46 51 58-3/4 65-3/4 104 126 143 159 17380 7-3/4 11 13-1/2 15-1/2 19 22 27 31 38 44 49-1/2 54 62-3/4 70 113 135 154 171 18690 8-1/4 11-3/4 14-1/4 16-1/2 20-1/4 23-1/2 28-1/2 33 40-1/2 46-3/4 52 57 66-1/2 74-1/2 118 143 164 183 199100 8-3/4 12-1/4 15 17-1/2 21-1/4 24-1/2 30 35 42-1/2 49 55 60 70 78-1/4110 9-1/4 13 15-3/4 18-1/4 22-1/2 26 31-3/4 36-1/2 44-3/4 51-1/2 58 63-1/2 73-1/4 82120 9-1/2 13-1/2 16-1/2 19 23-1/4 27 33 38-1/4 46-3/4 54 60-1/2 66-1/4 76-1/2 85-1/2130 10 14 17-1/4 20 24-1/4 28 34-3/4 39-3/4 48-1/2 56 62-3/4 69 79-3/4 89Applicable for static bend only13

Metal <strong>Hose</strong>Technical Data Minimum Live LengthDetermine the centerline bend radius required for yourapplication. Under the column headed "Centerline bendradius in inches", find your radius and read horizontallyto the desired degree of bend (45 o , 90 o or 180 o ).The number in that column will be the minimum livelength required to make that degree of bend along thedesired centerline radius.Note: Add fitting length dimension "A" plus the minimumlive length to calculate OAL.Centerline Minimum Live Length in inchesbend radiusin inches 45 o 90 o 180 o1 1 2 42 2 3-1/2 73 2-1/2 5 104 3-1/2 6-1/2 135 4 8 166 5 10 207 5-1/2 11 228 6-1/2 13 269 7-1/2 14-1/2 2910 8 16 3211 9 18 3612 10 19-1/2 3913 10-1/2 21 4214 11-1/2 22-1/2 4515 12 24 4816 13 26 5217 13-1/2 27 5418 14-1/2 29 5819 15-1/2 30-1/2 6120 16 32 6421 17 33-1/2 6722 17-1/2 35 7023 18-1/2 36-1/2 7324 19 38 7625 20 40 80Centerline Minimum Live Length in inchesbend radiusin inches 45 o 90 o 180 o26 21 42 8327 21-1/2 43 8628 22-1/2 44-1/2 8929 23 46 9230 24 48 9531 24-1/2 49 9832 25-1/2 51 10134 27 54 10836 28-1/2 57 11438 30 60 12040 32 63 12645 36 72 14450 40 80 16055 45 90 18060 49 97 19465 53 105 21070 56 112 22480 65 130 26090 73 145 290100 80 160 320120 95 190 380140 112 225 450160 128 255 510180 143 285 570200 160 320 64014

Metal <strong>Hose</strong>Technical Data<strong>Thorburn</strong> flexible metal hose assemblies are manufacturedto the highest quality levels to assure maximumservice life. The following precautions shouldbe adhered to when installing a flexible metal hoseassembly.CORRECTTRAVELINCORRECTTRAVELAvoid Improper Handling<strong>Thorburn</strong> metal hose can be damaged by draggingor when subjected to external abrasive or corrosiveconditions. Avoid installing hose in areas where itmay be subjected to corrosive sprays, spills, etc.CORRECTINCORRECTTRAVELRIGHTSUPPORTTRAVELDROOPINGWRONGTRAVELTRAVELTRAVELRIGHTWRONGMOTIONMOTIONTRAVELTRAVELRIGHTTRAVELWRONGTRAVELAvoid OverbendingOverbending <strong>Thorburn</strong> metal hose can result in prematurefailure. This often occurs at the end connections and maybe avoided by installing an elbow or interlock guard.Avoid TorqueTorquing or twisting <strong>Thorburn</strong> metal hose reduces servicelife substantially. When installing metal hose, it is importantthat all movement originates in the same plane as the centerline. Another precaution against torque is the use of a floatingflange or union on one end of the assembly.Calculations for minimum live length excluding end fittings<strong>Thorburn</strong> flexible metallic hose assemblies are usuallyflexed in accordance with one or a combination of themodes of motion shown below. To obtain maximumreliability it is essential to calculate the length of anassembly that will not be flexed beyond the minimumbend radius. The following formulae give a guide indetermining the lenght of tube required. They are basedon standard applications using our current prodluct range.Variations should be discussed with our technical dept.L = Minimum Live Length excluding end fittingR = Minimum Bend RadiusM = Movement π= 3.142VERTICAL LOOP –VERTICAL TRAVELL =π (R+M) ( )L = π R+ M 2C = π M +R4VERTICAL LOOP —HORIZONTAL TRAVELOFFSET OR LATERAL MOVEMENT(ONLY SUITABLE FOR SMALLMOVEMENTS OR STATICINSTALLATIONS)L = √20 x R x M15

Metal <strong>Hose</strong>Technical DataA piping system which utilizes <strong>Thorburn</strong> flexible metal hose assemblies to absorb pipe movement must beproperly anchored and guided to assure correct functionning and maximum service life of the metal hose. Thebasic principles to be observed are:1) The direction of pipe motion must be perpendicular to the center line (axis) of the hose.2) The pipe must be anchored at each change of direction where a flexible metal hose is employed to preventtorsional stress.Typical examples of correct and incorrect guiding are shown below.RIGHTAnchor (1)WRONGThermal expansion<strong>Hose</strong> assemblyGuideWrong... Pipe notguided or supported,allowing pipe to sagValve (if used)Anchor (1)Inlet<strong>Hose</strong> assemblyGuide1-1/2 times pipe size (2)InletWrong... Weight of piping on hosecompresses hose axially, causingbraid to bow-out, allowing thecorrugated hose to squirm orbuckleThermalexpansion(1) Anchors are to be used at the end of hose opposite from the source ofmotion(2) Approximate length to straighten flow before entering corrugated metalhoseWrong... If valve betweenequipement and hose is quickactingtypeWrong... Pipe not guided, allowingpipe to sagRIGHTPipe HangerWRONGAnchorThermal expansion (1)GuideWrong... Direction of motion not perpendicularto hose centerline (axis)<strong>Hose</strong> assemblyWrong... Braid on hose bowed-outdue to axial compression componentof applied motion resulting inrelaxing of braid tension, thus permittingthe corrugated hose to buckleEquipementEquipement(1) Direction of motion must be applied perpendicular to hose centerline(axis)16

Metal <strong>Hose</strong>Technical DataTEMPERATURE CORRECTION FACTORSFOR REDUCING PRESSURETemperatureMaterialF o St. steel Steel Monel Bronze70 1.00 1.00 1.00 1.00150 .97 .99 .93 .92200 .94 .97 .90 .89250 .92 .96 .87 .86300 .88 .93 .83 .83350 .86 .91 .82 .81400 .83 .87 .79 .78450 .81 .86 .77 .75500 .78 .81 .73600 .74 .74 .72700 .70 .66 .71800 .66 .52 .70900 .62 .501000 .601100 .581200 .551300 .501400 .441500 .40MAXIMUM SERVICE TEMPERATUREAlloy Maximum Alloy Maximumtemp. F otemp. F oANSI stainless steeltype:321 1500316 ELC 1500304L 1500304 & 316 850302 850Mild steel 850Malleable iron 800Monel 800Bronze 450Brass 450Copper 400Brazing (RCuZn-Cor BCuP-2):Bronze hose 450Steel <strong>Hose</strong> 850Silver brazing(AWS-BAg-2) 600Asbestos packinggrade:Commercial 450Underwriters 450Aluminum 52S-0(5052-0) 600Galvanizing 450Soft solder:(Pb: 60, Sn: 40) 250(Pb: 95, Sn: 5) 350COEFFICIENTS FOR INCREASINGBEND RADIUS AT ELEVATED TEMPERATURESTemperature F oBend radius70 1.00210 1.10300 1.25400 1.30570 1.40750 1.50930 1.601110 1.80Shock PressureWhen pulsating, surge or shock pressures exist, these havea marked effect on the service life of metal hoses. If thissituation is encountered, the peak pressure must not exceed50% of the maximum working pressure.Flow VelocityHigh velocities in corrugated hose should be avoided as thecorrugations could be forced into resonant vibrations resultingin premature fatigue failure. Where the flow velocityexceeds 100 ft/sec for gas or 50 ft/sec for liquid in unbraidedhose and 150 ft/sec for gas or 75 ft/sec for liquid in braidedhose, an interlock hose should be used as a liner. When thehose is installed in a bent condition, these flow values shouldbe reduced by 50% for a 90 o bend, 25% for a 45 o bend andso on, proportionally to the angle of bend. Where velocityexceeds the above values, the next lager size of hose withliner should be used.Pressure LossAs a rough estimate, it can be assumed that the pressureloss in corrugated hoses is 100% higher than in new weldedsteel pipes, and in stripwound hoses it is 20% higher. Thismeans that in the case of corrugated hoses an increase indiameter of 15% and in the case of stripwound hoses of only4% is sufficient to reduce the pressure loss to the value ofthe pressure loss in steel pipes. For more accurate calculations,consult <strong>Thorburn</strong> engineering with application details.SATURATED STEAM PRESSURE - TEMPERATURESaturated steam Saturated steam Saturated steam Saturated steampressure PSIG Temp. F o pressure PSIG Temp. F o pressure PSIG Temp. F o pressure PSIG Temp. F oVACUUM HG-- 0 0 212 150 366 450 46029.84 20 10 238 175 377 475 46529.74 32 20 259 200 388 500 47029.67 40 30 274 225 397 550 48029.39 60 40 287 250 406 600 48928.89 80 50 298 275 414 700 50527.99 100 60 307 300 422 800 52026.48 120 75 320 325 429 900 53424.04 140 80 324 350 436 1000 54620.27 160 90 331 375 442 1250 57414.63 180 100 338 400 448 1500 6066.46 200 125 353 425 454 2500 66917

Metal <strong>Hose</strong>Technical DataExamples:A 3" steel pipe line is 138 feet long.Maximum temperature the line willencounter is 400 o F. Lowest temperatureis 20 o F.Calculation:From the chart, the expansion ofsteel pipe at:440 o F 3.595 inches per100 feet ofpipe20 o F 0.148 inches per100 feet ofpipeDifference3.447 inches per100 feet ofpipe138 x 3.447 = 4.75" or100 approximately4-3/4" totaltraverseA 4" stainless steel line is 50 feetlong. Maximum temperature theline will encounter is approximately580 o F. Lowest temperatureis approximately -180 o F.Calculation from the chart:– the expansion of stainless steelpipe at:580 o F 6.835 inches per100 feet ofpipe– the contraction of stainless steelpipe at:-180 o F -1.850 inches per100 feet ofpipeTotalMovement 8.685 inches per 100feet of pipe50 x 8.685 = 4.342 or100 approximately4-11/32" totaltraverseFrom the "Piping Handbook" bySabin Crocker, McGraw-HillPublishing Co.* Monel is a registered trademarkof International Nickel Co.Note: This data is for informationand does not suggest that thematerials are suitable for alltemperatures shown and shouldonly be used as a guide.Saturatedsteam vacuumin. Hg below212 o F,Pressure psigauge above212 o FVacuum<strong>Inc</strong>hes of HgPressure PSI Gauge29.3928.8927.9926.4824.0420.2714.636.452.510.320.734.552.374.9103.3138.3180.9232.4293.7366.1451.3550.3664.3795.3945.31,1151,3081,5251,7682,0412,3462,7053,080-320-300-280-260-240-220-200-180-160-140-120-100-80-60-40-20020324060801001201401601802002122202402602803003203403603804004204404604805005205405605806006206406606807007207407607808008208408608809009209409609801000THERMAL EXPANSION OF PIPE (in inches per 100 feet)TemperatureDegrees FahrenheitCast iron-1.058-0.982-0.891-0.797-0.697-0.593-0.481-0.368-0.248-0.12700.1280.2090.2630.3910.5220.6600.7990.9241.0731.2181.3681.4511.5071.6531.8041.9582.1062.2682.4162.5732.7322.8813.0553.2183.3843.5563.7203.8934.0634.2384.4144.5984.7694.9555.1335.3155.5025.6815.8796.0736.2626.4606.6526.8437.0497.2487.4527.6687.8628.0738.2798.490-1.282-1.176-1.066-0.948-0.826-0.698-0.563-0.428-0.288-0.14500.1480.2300.2850.4480.5800.7530.9101.0641.2231.3831.5461.6431.7071.8752.0382.2052.3742.5452.7172.8843.0663.2303.4213.5953.7843.9554.1514.3424.5254.7154.9065.1025.2925.4825.6865.8756.0846.2806.4906.6886.9017.1057.3197.5177.7437.9538.1688.4008.6108.8309.0519.27618Carbon and Carbonmolybdenum steelWrought iron-1.289-1.183-1.073-0.955-0.833-0.705-0.570-0.435-0.295-0.15200.1540.2490.3130.4680.6280.7870.9581.1131.2751.4451.6261.7211.7841.9582.1272.3132.4782.6482.8363.0233.1983.3693.5683.7483.9444.1284.3254.5254.7144.9055.1165.3035.5085.6985.9156.1086.3296.5216.7476.9487.1627.3567.6057.8008.0438.2488.4878.7158.9379.1489.3959.6244-6% CrAlloy steel-1.250-1.150-1.030-0.970-0.800-0.700-0.550-0.430-0.290-0.14500.1400.2340.2800.4300.6000.7500.9001.0501.2201.3701.5201.6001.6751.8252.0002.1502.3202.4702.6252.8202.9803.1403.3003.4703.6503.8004.0004.1504.3504.5404.7404.9205.1105.2805.4705.6705.8506.0506.2206.4306.6006.8007.0007.2007.4007.5807.7707.9708.1708.3608.5608.76012% CrStainless steel-1.770-1.670-1.570-1.470-1.370-1.270-1.170-1.070-0.970-0.870-0.750-0.630-0.520-0.400-0.270-0.13000.1400.2340.2800.4300.6000.7500.9001.0501.2201.3701.5201.6001.6751.8252.0002.1502.3202.4702.6252.7802.9803.1303.3003.4703.6503.8004.0004.1504.3404.5004.6404.8505.0205.1805.3505.5505.7005.9006.0406.2806.4806.6806.8907.0907.3007.5007.7207.9508.1408.3508.5508.75018 Cr-8 NiStainless steel-3.110-2.930-2.750-2.570-2.390-2.210-2.030-1.850-1.670-1.480-1.300-1.090-0.880-0.670-0.450-0.22500.2230.3560.4460.6690.8921.1151.3381.5451.7842.0002.2302.3612.4602.6802.9203.1303.3753.6153.8404.0754.3464.5604.8005.0455.3355.5405.8006.0506.3206.5726.8357.1007.3707.6307.9008.1708.4258.6708.9329.2209.4809.75010.02010.27010.54010.82011.07511.35011.62011.90012.15012.432Copper-2.975-2.805-2.635-2.465-2.295-2.125-1.955-1.782-1.612-1.428-1.235-1.040-0.835-0.630-0.421-0.21000.2380.3660.4510.6840.8961.1341.3661.5901.8042.0512.2962.4282.5162.7562.9853.2183.4613.6963.9414.1764.4244.6664.9145.1545.4085.6515.9066.1486.4106.6406.9197.1847.4327.6987.9498.1968.4728.7088.9999.2569.5329.78810.06810.30810.61010.97111.15611.42111.70711.97612.26912.543Brass-2.065-1.890-1.705-1.508-1.308-1.098-0.888-0.673-0.452-0.22700.2330.3730.4660.6900.9201.1501.3901.6251.8652.1002.3402.4672.5802.8303.0703.3153.5653.8204.0654.3204.5604.8255.0805.3405.6005.9256.1206.3806.6506.9207.1707.4407.7157.9808.2408.5158.7809.0509.3249.6009.87010.15010.42510.69010.97511.25011.54511.81512.12012.42012.72013.080Aluminum6061 Alloy-3.96-3.71-3.46-3.21-2.96-2.71-2.46-2.22-1.97-1.73-1.47-1.22-0.98-0.74-0.49-0.2500.340.540.681.011.351.692.022.362.683.033.383.593.724.054.394.725.075.415.746.086.426.777.107.447.778.118.448.789.139.469.8010.1410.4910.82Monel Alloy 400-2.60-2.44-2.28-2.12-1.96-1.80-1.64-1.48-1.32-1.15-0.98-0.82-0.66-0.49-0.32-0.1700.1970.3150.3940.5910.7900.9851.181.381.581.771.972.092.172.362.562.762.953.153.353.553.743.944.144.344.534.734.925.125.325.525.715.916.116.306.506.706.897.097.297.497.687.888.088.288.478.678.869.099.269.469.659.85

Metal <strong>Hose</strong>Lock Section A single interlocking strip of metal is spirally wound toform a durable, standard bore flexible hose. Dependingupon the material used, packing, and strip thickness,a standard bore metal hose can operate in avariety of temperatures ranging from -100 o F to +1200 o F.Standard bore metal hose can be manufactured fromvarious grades of most stainless steel alloys, aluminum,bronze, brass, aluminized, galvanized and tin plate.APPLICATIONS■ Engine exhaust ■ Dust collecting■ Auto heating tubing ■ Ventilation ducts ■ Hot air ducting■ Conveying grain or sawdust ■ Protective casing ■ Fume extracting"LS" Series(Unpacked)"LS" Series(Packed)<strong>Thorburn</strong>'s "LS" series is an "S" lock section hose thatis primarily designed for conveying air, exhaust anddry bulk products. <strong>Thorburn</strong>'s "LS" series hose is availablepacked or unpacked.For additional leak proofing, a continuous strand isinserted into the groove of the <strong>Thorburn</strong> "LS" serieshose during manufacturing. The strand is sealed insidethe hose, and will not contaminate the productduring transference.PackingTemperatureType Benefits Ability Cotton Lowest cost 180 o FPyro-pak Coated high 1000 o FtemperaturefilamentHard Packing For extreme 1200 o F(copper, high temperaturesstainless steel)Elastomeric Maximum 180 o Fpressure/vacuumresistance19

Metal <strong>Hose</strong>Lock SectionSize I.D. O.D. (<strong>Inc</strong>hes) Min. inside bend Approx weight percode (inches) diameter (inches) foot (pounds)LS12 LS16 LS20 LS12 LS16 LS20 LS12 LS16 LS2008 1/2 5/8 11/16 -- 3.5 4.0 -- 0.14 0.18 --10 5/8 3/4 13/16 -- 4.0 4.5 -- 0.17 0.22 --12 3/4 7/8 15/16 -- 4.5 5.0 -- 0.20 0.26 --14 7/8 1 1-1/16 -- 5.5 6.0 -- 0.25 0.33 --16 1 1-1/8 1-3/16 1-1/4 6.5 7.0 7.5 0.26 0.35 0.5018 1-1/8 1-1/4 1-5/16 1-3/8 7.0 7.5 8.0 0.30 0.39 0.6020 1-1/4 1-3/8 1-7/16 1-1/2 7.5 8.5 9.0 0.32 0.42 0.6422 1-3/8 1-1/2 1-9/16 1-5/8 8.0 9.0 10.0 0.36 0.47 0.7024 1-1/2 1-5/8 1-11/16 1-3/4 8.5 10.0 11.0 0.40 0.52 0.8528 1-3/4 1-7/8 1-15/16 2 10.0 11.0 11.5 0.45 0.65 0.9532 2 2-1/8 2-3/16 2-1/4 11.5 12.5 13.0 0.60 0.78 1.1536 2-1/4 2-3/8 2-7/16 2-1/2 13.0 14.0 15.0 0.70 0.91 1.2940 2-1/2 2-5/8 2-11/16 2-3/4 15.0 16.0 17.0 0.80 1.04 1.4444 2-3/4 2-7/8 2-15/16 3 17.0 18.0 19.0 0.92 1.12 1.5848 3 3-1/8 3-3/16 3-1/4 19.0 19.5 21.0 1.02 1.33 1.7356 3-1/2 3-5/8 3-11/16 3-3/4 22.0 23.5 25.0 1.26 1.64 2.0164 4 4-1/8 4-3/16 4-1/4 24.0 25.5 27.0 1.38 1.80 2.3072 4-1/2 4-5/8 4-11/16 4-3/4 27.0 28.5 30.0 1.55 2.02 2.5980 5 5-1/8 5-3/16 5-1/4 29.0 31.0 33.0 1.70 2.21 2.8696 6 6-1/8 6-3/16 6-1/4 38.0 40.5 43.0 2.00 2.60 3.45112 7 7-1/8 7-3/16 7-1/4 43.0 46.0 48.0 2.30 3.00 4.03128 8 8-1/8 8-3/16 8-1/4 48.0 51.0 55.0 2.60 3.38 4.60144 9 9-1/8 9-3/16 9-1/4 52.0 56.0 59.0 3.10 4.03 5.18160 10 10-1/8 10-3/16 10-1/4 56.0 60.0 63.0 3.50 4.55 5.75192 12 -- 12-3/16 12-1/4 -- 70.0 76.0 -- 5.46 6.90224 14 -- -- 14-1/4 -- -- 85.0 -- -- 8.05Size I.D. O.D. (<strong>Inc</strong>hes) Min. inside bend Approx. weightcode (inches) diameter (inches) per foot (pounds)LS24 LS32 LS24 LS32 LS24 LS3232 2 2-9/32 2-5/16 15.0 17.0 1.45 1.7136 2-1/4 2-17/32 2-9/16 17.0 18.0 1.63 1.9240 2-1/2 2-25/32 2-13/16 19.5 20.0 1.81 2.1444 2-3/4 3-1/32 3-1/16 22.0 23.0 1.99 2.3548 3 3-9/32 3-5/16 24.0 26.0 2.18 2.5656 3-1/2 3-25/32 3-13/16 26.0 27.0 2.54 2.9964 4 4-9/32 4-5/16 28.5 30.0 2.90 3.4272 4-1/2 4-25/32 4-13/16 31.0 33.0 3.26 3.8580 5 5-9/32 5-5/16 34.0 36.0 3.63 4.2896 6 6-9/32 6-5/16 45.0 47.0 5.35 5.13112 7 6-9/32 7-5/16 50.0 52.0 5.08 5.99128 8 8-9/32 8-5/16 57.0 59.0 5.80 6.84144 9 9-9/32 9-5/16 61.0 63.0 6.53 7.70160 10 10-9/32 10-5/16 66.0 69.0 7.25 8.55192 12 12-9/32 12-5/16 78.0 80.0 8.70 10.25224 14 14-9/32 14-5/16 88.0 95.0 10.15 11.95For ordering details, pleasesee page 2020

Metal <strong>Hose</strong>Lock Section<strong>Thorburn</strong> "LS" Series Part NumbersThickness Unpacked Elastomeric Pyro-pak Cotton Copper wire stainlesspacked packed packed packed wire packedLight weight (.010" - 012") LS-12 LS-12E LS-12A LS-12B LS-12C LS-12SMed. weight (0.13" - 016") LS-16 LS-16E LS-16A LS-16B LS-16C LS-16SMed.-heavy wt (0.17" - 020") LS-20 LS-20E LS-20A LS-20B LS-20C LS-20SHeavy weight (0.17" - 020") LS-24 LS-24E LS-24A LS-24B LS-24C LS-24SEx. heavy wt (0.23" - 030") LS-32 LS-32E LS-32A LS-32B LS-32C LS-32SFor technical specifications, please see page 20.<strong>Thorburn</strong>part number<strong>Hose</strong> material<strong>Hose</strong> sizeExampleCoupling ends1st end 2nd endEnd materials1st end 2nd end<strong>Hose</strong> length ininchesLS20E - SS - 064 - 05 08 - S S - 0250 - XSpecialCodes<strong>Hose</strong> material<strong>Hose</strong> size in1/16 of an inchEnd stylesEnd materialsSpecialPlease seeabove for<strong>Thorburn</strong> hosepart numberdetailsSS -SC -AA -BB -S6 -S1 -6L -4L -S4 -TT -XX -304SSGalvanizedsteelAluminumBronze316SS321SS316SSL304SSL430SSTin plateSpecial,specify001 - 1/16"002 - 1/8"004 - 1/4"016 - 1"032 - 2"064 - 4"XXX- Special,specifyetc.01 - Male NPT02 - Female NPT union03 - 150 lbs flange fixed04 - 300 lbs flange fixed05 - 150 lbs flange floating06 - 300 lbs flange floating07 - Male camlok coupling08 - Female camlok couplingXX - Special (specify)A - AluminumB - BronzeS - 304SSZ - 316SSC - Carbon steelX - SpecialSpecify21

Metal <strong>Hose</strong>Lock SectionStripwound hose fixed on exhaust systemsin the automotive industryStripwound flexible metal hose with onewire braid. Conveyance of pure oxygen,oxygen and feeding of cooling waterin convertor lances.Recovery of rain water on diesellocomotiveSmooth connection between tanksystemsStripwound hose for the suction of wood chips on a wood machineConnection on generator set forexhaust system22

Metal <strong>Hose</strong>Lock Section<strong>Thorburn</strong>'s Tar-<strong>Flex</strong> hose has uniform flexibility for easeof handling and excellent resistance to deterioration byheat. This, added to the ruggedness and dependabilityof a fully interlocked and packed construction, makes<strong>Thorburn</strong>'s Tar-<strong>Flex</strong> the ideal hose for road surfacingservice, asphalt carrying truck use, road patching units,hot tar pots and kettles and hand held patching hoses.Packed interlock hoseTypical Applications■■■Tank car loadingHigh pressure steamEngine exhaust■■Oil and liquid transferAsphalt tanksSpecificationsTFS - Galvanized steel (.020" to .060" metal)TFS4 - 304SS (.017" to .040" metal)Standard End StylesTar-<strong>Flex</strong> rugged interlocked designCode: 01Solid male couplingCarbon steelCode: 02Female unionCarbon steelCode: 03Welded male NPTHex adapterCarbon steelCode: 04Welded flange 150Carbon steel<strong>Thorburn</strong> I.D. Nominal O.D. Nom. inside Weightnumber (in.) (in.) bend dia. (in.) per foot(lbs)TFS4 / TFS-12 3/4 31/32 11 .59TFS4 / TFS-16 1 1-1/4 13 .79TFS4 / TFS-20 1-1/4 1-1/2 15 .93TFS4 / TFS-24 1-1/2 1-3/4 17 1.2TFS4 / TFS-32 2 2-1/4 24 2.00TFS4 / TFS-40 2-1/2 2-13/16 32 2.67TFS4 / TFS-48 3 3-3/8 39 3.72TFS4 / TFS-64 4 4-7/16 52 5.58TFS4 / TFS-80 5 5-7/16 63 6.75TFS4 / TFS-96 6 6-1/2 68 9.75TFS4 / TFS-128 8 8-9/16 90 16.00:NOT FORPRESSURESERVICE <strong>Thorburn</strong> 1st end 2nd end Assembly---part no. code code length in inchesTFS-48 - 03 - 04 - 14423

Metal <strong>Hose</strong>Lock SectionAF (unpacked) AFP (packed)<strong>Thorburn</strong>'s Armour-<strong>Flex</strong> has a "square-locked"profile, and is available either with or withoutpacking. Extremely flexible, not pressure tight,but with packing can be considered moisturetight. As protective conduit, it is used widely onsuch products as electrical appliances, electronicequipement, instruments, etc.Galvanized steel / Stainless steelTYPICAL APPLICATIONS ■■■Capillary tube armourThermo couple casingShowcase wire protectori.e.StyleAFSize32MaterialC■■Fire proof conductSpout tubingUnpacked style2"Galvanized steelSTYLES AF= UnpackedAFP= PackedTHORBURN ARMOR-FLEX SPECIFICATIONS<strong>Thorburn</strong> # I.D. (in.) O.D. (in.) Bend radius (in.) Weight per foot (lbs.)AF/AFP 03* 3/16 9/32 7/8 .03AF/AFP 04* 1/4 21/64 7/8 .04AF/AFP 05* 5/16 13/32 1 .06AF/AFP 06* 3/8 31/64 1-1/4 .09AF/AFP 07* 7/16 37/64 1-3/8 .14AF/AFP 08* 1/2 41/64 1-5/8 .16AF/AFP 10* 5/8 25/32 1-3/4 .19AF/AFP 12* 3/4 29/32 2-1/2 .22AF/AFP 14* 7/8 1-5/64 3 .26AF/AFP 16* 1 1-3/16 3 .36AF/AFP 20* 1-1/4 1-29/64 3 .42AF/AFP 24* 1-1/2 1-49/64 3-1/2 .51AF/AFP 28* 1-3/4 2-1/64 3-1/2 .80AF/AFP 32* 2 2-17/64 4 .90* Insert <strong>Thorburn</strong> Armor-<strong>Flex</strong> material code (C: Steel; S: Stainless) i.e. AP08S24

Metal <strong>Hose</strong>Lock SectionTYPICAL APPLICATIONS■ Lathes■ Milling machines■ Various machine tools<strong>Thorburn</strong>'s Cool-<strong>Flex</strong> metal coolant hose assemblies areprecision manufactured of high quality oil-tempered steel forfunctional dependability. They are easily hand bendable, yet willhold their shape despite machine vibration or high rate of flow.THORBURN COOL-FLEX SPECIFICATIONS<strong>Thorburn</strong> # I.D. (in.) Centerline radius for O.D. (in.) Fittings and nozzlespermanent bends min.(same as I.D.)(in.)CH02 1/8 4-1/2 .350 .1/8CH04 1/4 5-1/4 525 1/4CH06 3/8 5-1/2 .600 3/8CH08 1/2 6-1/4 .840 1/2CH12 3/4 7-1/2 1.100 3/4Any assembly available with stopcock or union if required.Standard lengths: 6", 9", 12", 15", 18", 21", 24", 30" and 36".<strong>Thorburn</strong> # 1st end 2nd end Length (in.) Adapterand size codeCH08 01 02 12 Ui.e.: 1/2" I.D. male nozzle 12" long C/W unioncoolant hose 00 01 02 UN STFemale Male Nozzle Union Stopcock25

Metal <strong>Hose</strong>Smooth Lock Section BoreSizes 1-1/2" to 16" dia.1) All stainless "SS": For longevity andcorrosive environments2) Galvanized "CC": For economy andless corrosive environments3) Galvanized Stainless Lined "CS": Foreconomy in corrosive internal environmentNote:Smooth Bore is a unidirectionalhose. Flow must be indirection of arrows on O.D.FLOW<strong>Thorburn</strong> Smooth-<strong>Flex</strong>Loads – Unloads30 to 50% faster■ Ships ■ Trucks■ Barges ■ Rail cars■ Elevators ■ Tanks■ Silos ■ In-plant■ Great for portable applications■■■■■■<strong>Thorburn</strong> Smooth-<strong>Flex</strong>was designed for pneumatic andgravity feeding or bulk materialsGrainsPlastic pelletsPowdersDry food stuffsAluminum chipsCharcoal■■■■■Wood chipsSaw dustFlue ductsSuction linesAshesFittings <strong>Hose</strong>Tubing, etc.<strong>Flex</strong>iblemetal hoseCompensatorWeightor force■■■The compensator connects flexible metal hose to fittings, rubber hose, pipe, etc. without cementing orwelding. This keeps the compensator and fitting usable if the metal hose fails. Welding in most cases willlocally "burn out" the metal hose packing and cause air leaks.The compensator absorbs vibration and stress at the solid connection. This protects the flexible hose frompremature failure caused by over stressing.The compensator can be used for "on-sight" repairs in remote operations where welding and cementing arenot feasable. Installs in 5 to 15 minutes with just a screw driver if screw type band clamps are used to mountthe compensator.■ Temperature range -65 o to 285 o F.■ Used indoors or outdoors.26

Metal <strong>Hose</strong>Smooth Lock Section BoreA stainless steel insert may be mountedon the I.D. of the compensator to coverthe exposed urethane for applicationsthat cannot tolerate any internal contaminationexposed to their products.Type "E"Type "C"Smooth-<strong>Flex</strong> TypeAll StainlessSSSteel/SSCSSteel/SteelCC<strong>Hose</strong> Style & CodeHeavyDutySF500MediumDutySF400LightDutySF300HeavyDutySF350SMediumDutySF250SLightDutySF150SHeavyDutySF350CMediumDutySF250CLightDutySF150CArmour Material Type 301 Stainless Steel Hot Dip Galvanized Coated Carbon SteelArmour Thickness .018" .018" .015" .018" .018" .015" .018" .018" .015"Liner Material Type 301 Stainless Steel Type 301 Stainless Steel Hi-Carbon SteelLiner Thickness .018" .015" .015" .018" .015" .015" .018" .015" .015"Extension-CompressionPercent of Length± 1% ± 1-1/2% ± 2% ± 1% ± 1-1/2% ± 2% ± 1% ± 1-1/2% ± 2%GT Packing–20º-180ºF (neg. 5ºHg)(pos. 20 psi)–20º-180ºF (neg. 5ºHg) (pos. 20 psi)TemperatureandPressureRatingsAP PackingCC PackingSS Packing–40º-400ºF (neg. 5ºHg)(pos. 5 psi)–60º-300ºF (neg. 15ºHg)(pos. 15 psi)–60º-2100ºF (neg. 15ºHg)(pos. 15 psi)–40º-400ºF (neg. 20ºHg) (pos. 20 psi)–60º-300ºF (neg. 15ºHg) (pos. 15 psi)–60º-400ºF (neg. 15ºHg) (pos. 15 psi)Unpacked–60º-2700ºF(No Pressure Rating)–60º-400ºF (No Pressure Rating)<strong>Hose</strong> Code <strong>Hose</strong> Size 1/16" First End Code Second EndCode<strong>Hose</strong> Length<strong>Inc</strong>hesSF500 - 64 - E - C - 144Description: All stainless heavy-duty Smooth-<strong>Flex</strong> hose 4" I.D. C/W hose shank 1st end, 2nd end femalecoupler, 144" long. Special note: Other fitting types are available. Call <strong>Thorburn</strong> for details.27

Teflon Lined <strong>Hose</strong>■ Chemical Inertness: Teflon won't decompose or break down in the mostcorrosive environments and it is inert to practically all commercial chemicals,acids, alcohols, coolants, elastomers, petroleum compounds, solvents, vinyls,synthetic lubricants and hydraulic fluids.■ Temperature Resistant: Operating range of -100 o F to 500 o F means hosestays flexible at low temperatures, strong at high temperatures.<strong>Flex</strong>ibilitywhen youneed it!■ <strong>Flex</strong> and Shock Resistance: <strong>Thorburn</strong> T-<strong>Flex</strong> is not affected by continuousflexing, vibration or impulse –withstands alternating cold and heatcycling.■ Low Friction: Liquids maintain a steady flowwithout clogging. Constant low pressure drop meansdeposits can't accumulate on inside walls.■ Moisture Resistant: Ideal for pneumatic systemsrequiring low dew point. No possibility of saturationor leakage.POSITIVEBRAID LOCK■ Non-Contaminating: Will not contaminate thematerial, fluid or gas conducted –Teflon is FDA approvedfor food products, pharmaceuticals, etc.■ Steam Compatibility: Absorbs no moisture hot or cold–rated for steam to 250 psi (400 o F)– has low volumetricexpansion characteristics, is easy to clean and sterilize.Compare ifyou dare!■ Light Weight: Easier to move, handle, install thanrubber hose with a comparable burst pressurerating. Ideal as pigtail in gas handling and pneumaticsystems where dew point must be low.■ Resists Deterioration: Impervious to weatherand can be stored for long periods without aging.Will not age during service.■ Unlimited Life: Unmeasurable life expectancy when appliedwithin its temperature and pressure ratings. Will not tear-up, eat-out,burn-up or wear-out.The ultimatehose!■ Non-Adhesive: Handles substances such as adhesives, asphalt, dyes,grease, glue, latex, lacquers and paints. No carbon build up when used as acompressor discharge line.■ Non-Conductive: Excellent dielectric properties. Ideal hose core for applicationsrequiring electrical isolation.28

Teflon Lined <strong>Hose</strong> Summary of Properties TFE, FEP, PFAProperties TFE FEP PFAColor Milky white Clear blue Clear bluetinttintContinuous service -250 o - +260 o C -200 o - +204 o C -200 o - +260 o Ctemperature -420 o - +500 o F -300 o - +400 o F -300 o - +500 o FMelting point 327 o C -268 o - +271 o C -302 o - +310 o C621 o F -487 o - +540 o F -575 o - +590 o FDielectric strength(ASTM D149)Short term 125 mil 500 500 500Volts/Mil 10 mil 1400 1400 2000Dielectric constant(ASTM D140) 20 21 2.0610 2 to 10 6 HzSpecific gravity(ASTM D792) 2.10-2.20 2.10-2.10 2.10-2.20Summary of Properties TFE, FEP, PFA ... ctndProperties TFE FEP PFACoefficient offriction dynamic 10 0.25 0.20Tensile strengthPSI 2000-6000 2000 Min 4000 MinD638 elongationMin. (D638) 200 250 250<strong>Flex</strong> modulusPSI x 10 3 (D790) 40-90 95 200Impact strength(Charpy, notched) 4 -- --Ft-Lb/In 2Flammability Non-flamm. Non-flamm. Non-flamm.Water absorption %D570 < .01 < .01 < .03 Tensile strength as a function of temperature Extension as a function of temperature Deformation as a function of time under various pressureload applicationsDeformation under application of pressure at 70 kp,cm 2as a function of time at various temperaturesDeformation under alternating application and removal ofload (70 kp/cm 2 ) at a temperature of 25 o C Tensile strength and extension as a function of temperature29

Teflon Lined <strong>Hose</strong>Aerosol PackagingFor handling nitrous oxide, etc., as charging lines for pressurizingaerosol cans.Air ConditioningUsed to carry hot gases during dehydration of equipmentprior to charging with refrigerant.AutoclavesAs a combination steam-vacuum line; typically furnishedwith an internal flat support spring where full vacuum (28")at 400 o F is required.AutomotiveWindshield forming; automotive automatic paint spray systems;reaction injection molding.Bakery IndustryAs steam lines in various equipement such as on kettles formixing batter; used with freon systems in quick-freeze operations.Buses and TrucksUsed as a compressor discharge line; also oil, fuel, waterand air lines because the engine compartment temperaturescan cause premature failure of rubber and other typesof hoses.Can IndustryHandles hot adhesives for the sealing process during manufactureof beer cans; also conducts cooling water to supportracks to dispel heat from can body before it reaches solderingunit.CardboardSteam to the presses; also hot wax as it is applied to thecardboard/paper.Chemical IndustryAn all purpose hose to handle all chemicals with the onlyexceptions... the molten alkali metals including molten sulfur.Teflon hose needs to be specially reinforced for applicationssuch as bromine and chlorine. One hose handlesmany chemicals; suitable for tank truck as well as in plantuse. Also used in-plant as a piping substitute.DiesUsed to convey dies and pigments especially where a highdegree of purity is required; Teflon's cleanability is a featurein this application.ElectronicsCoolant lines for electronics gear, i.e. color televisioncameras, radar units.Food IndustryFor recirculating hot oils and grease in deep fry systems; forconveying glutamates in the manufacture of corn syrup; forsteam sealing small glassine containers such as individualportions of jelly; water supply to coffee urns. Teflon hose isan F.D.A. approved product.Gas Detection"Sniffer" lines to detect the presence of poisonous or corrosivegases.Gas TransferFor filling cylinders as a replacement for copper tubingpigtails; in high pressure applications especially where temperatureof a high degree of cleanliness is required.30

Teflon Lined <strong>Hose</strong>Glass Bottle IndustryUsed to supply the air cylinders on the stackers which putthe hot bottles in conveyer belts; also as gas lines to theburners and cooling water for the molds.Glue IndustryUsed to convey hot melt adhesives to the dispensing gunsor nozzles.HydraulicCarries hot oil and other lubricants without contamination;Teflon is especially good in applications where temperature,fluid viscosity or aging are factors.Laundry or Dry CleaningSteam lines on the laundry presses and hand irons.MarineSteam condensate lines; hydraulic hoses (catapults); fueland oil lines in the engine compartment; hydraulic steeringsystems.Paint SprayUsed in airless paint systems to convey paint, lacquers andstrong solvents.Paper/Cardboard/Fiberboard IndustriesSteam lines to the platens; wax coatings; steam hose on drycans; chlorine (special) in the bleaching operation; blackliquor lines; ideal rotary joint hose.Photo/Photo ChemicalIdeal for conveying light-sensitive chemicals especially wherebatch contamination is critical.Platen Presses<strong>Hose</strong> conducts steam alternately with cold water to themultiple platens for manufacturing such as: battery cases;styrene sheets; radio cases; records; plywood; fiberboard;tires; molded rubber; tire recapping; plastic toys; dinnerware;plastic helmets; tennis balls; golf balls; rubber mats.Plating IndustryConveying steam to centrifical dryers; acid transfer.Power HousesOn oil burners as oil feed lines.RailroadsSteam lines to tank car heaters.Shoe ManufacturingFor transferring hot adhesives to cement the shoe soles;steam to molding presses.Spray SystemsExtermination systems for handling such things as carbontetrachloride.Stationary Power PlantsFuel, oil, air and hydraulic lines on jet engines.Textile IndustrySteam hoses on dryers/rotary joint connectionsTire ManufacturingSteam lines to Bag-O-Matic type presses; also as steamlines used in recapping.Toy IndustryUsed to convey hot plastisols to the "slush" molds.Urethane Foam IndustryConveying synthetic foam material under heat and highpressure.31

Teflon Lined <strong>Hose</strong><strong>Thorburn</strong> TS series is an ideal hose that solvesdemanding problems in diverse applications such aschemical transfer, steel processing, paint spraying,fuel and lubricant handling, hydraulic systems, plasticmolding machines, food processing, marine and transportationindustries.<strong>Hose</strong> ConstructionGeneral purpose assemblies<strong>Thorburn</strong> TS11 series has a smooth innercore ofextruded white Teflon resin with type 304 stainlesssteel wire braid reinforcement.Conductive assemblies<strong>Thorburn</strong> TS12 series has a precisely controlledamount of carbon black added to the inner 15% of theTeflon innercore. This homogeneous material providesa continuous conductive path to the metal endfittings, to bleed off static electricity in high flow applications.Temperature Range-65 o F to 450 o F (-54 o C to 232 o C) for continuousservice. -100 o F to 500 o F (-73 o C to 260 o C) for intermittentservice only.StandardsMeets requirements of SAE 100R14.Accepted by U.S. and Canadian Coast Guard.Rating PressureSizes through 5/8" I.D. Full vacuumLong LengthsUp to 2000 feet upon requestSpecial note: PTFE standard core, PFA, FEP tefloncore construction available upon request.<strong>Thorburn</strong>'s Nominal Average Average Operating Operating Min. burst Typ. max. Minimum <strong>Hose</strong>Number Size (in.) I.D. (in.) O.D. (in.) pressure pressure pressure continuous bend weightpsi at psi at psi at length (ft.) radius (in.) (lb./ft.)room temp. 400 o F room temp.TS11-3 3/16 .125 .234 3000 1500 15000 200 2 .050TS11/TS12-4 1/4 .187 .312 3000 1500 15000 200 2 .070TS11/TS12-5 5/16 .250 .375 3000 1500 14000 150 3 .099TS11/TS12-6 3/8 .312 .445 2500 1500 12000 150 4 .110TS11-6T* 3/8 .375 .503 2250 1500 10000 150 4.5 .124TS11/TS12-8 1/2 .406 .549 2000 1500 10000 100 5.2 .123TS11/TS12-10 5/8 .500 .648 1500 1000 8500 100 6.5 .154TS11/TS12-12 3/4 .625 .778 1200 1000 6000 75 7.7 .170TS11/TS12T* 3/4 .755 .886 1100 1000 4500 75 8.2 .198TS11/TS12-16 1 .875 1.030 1000 1000 4000 60 9 .273TS11-16T* 1 1.000 1.135 900 900 3800 60 10 .305TS11-16Z** 1 .875 1.065 1250 1250 8000 60 9 .409TS12-20 1-1/4 1.125 1.315 800 800 3200 40 16 .540TS12-24Z** 1-1/2 1.375 1.672 1000 1000 4250 20 14 .875* T: True bore (<strong>Thorburn</strong> true bore fittings are non stock. Check delivery before ordering.)** Z: Double braid32

Teflon Lined <strong>Hose</strong><strong>Thorburn</strong>'s exclusive "Sure Seal" coupling attachmentmethod is based upon extensive developmentengineering. The Teflon innercoreand over braid are firmly locked between thefitting collar and insert for a permanent, leakproofassembly. The positive braid lock assuresthat strain is absorbed by the braid, notthe Teflon hose.Materials The "sure seal" couplings are availablein stainless steel, brass, or a combinationof brass and carbon steel. The wetted surfacesof stainless steel fittings are type 303, otherparts are type 304, unless specified (othermaterials available upon request)."Sure-Seal"-swaged end fittingconnectionStainless steelwire braidTefloninnercore<strong>Thorburn</strong>'s exclusive swaged or crimp "Sure Seal" couplingattachment offers the industry the safest and mostreliable hose to coupling attachment method.All 316SS stainless steel couplings available uponrequest. Please specify S6 after part number.MALE PIPEFEMALE 37 O SWIVEL(universal)Stainlesssteel partnumberC115SSMP0302C115SSMP0402C115SSMP0404C115SSMP0504C115SSMP0604C115SSMP0606C115SSMP0806C115SSMP0808C115SSMP1008C115SSMP1212C115SSMP1616BrasspartnumberC115BMP0302C115BMP0402C115BMP0404C115BMP0504C115BMP0604C115BMP0606C115BMP0806C115BMP0808C115BMP1008C115BMP1212C115BMP1616<strong>Hose</strong> Size(in.)3/161/41/45/163/83/81/21/25/83/41MaleThread1/8 - 271/8 - 271/4 - 181/4 - 181/4 - 183/8 - 183/8 - 181/2 - 141/2 - 143/4 - 141 - 11-1/2Stainlesssteel partnumberC115SSFJ0302C115SSFJ0404C115SSFJ0505C115SSFJ0606C115SSFJ0808C115SSFJ1010C115SSFJ1212C115SSFJ1616BrasspartnumberC115SSBFJ0302C115SSBFJ0404C115SSBFJ0505C115SSBFJ0606C115SSBFJ0808C115SSBFJ1010C115SSBFJ1212C115SSBFJ1616<strong>Hose</strong> Size(in.)3/161/45/163/81/25/83/41FemaleThread3/8 - 247/16 - 201/2 - 209/16 - 183/4 - 167/8 - 141-1/16 - 121-5/16 - 12INVERTED FLARE - POWER TRIM - STEP-DOWNFor marine, automotive and other hydraulic applicationsStainlesssteel partnumber<strong>Hose</strong> Size(in.)ThreadOverallLength A(in.)DeductLength B(in.)NominalI.D.(in.)DropHeight(in.)StraightT106679-11/43/8 - 241.8571.369.156--45 o ElbowT106679-21/43/8 - 241.9871.499.156.75090 o ElbowT1066-79-31/43/8 - 241.6121.124.1561.31233

Teflon Lined <strong>Hose</strong>FEMALE PIPETUBE END*Tube fittingsStainlessSteel partnumberBrasspartnumber<strong>Hose</strong> Size(in.)MaleThread316Stainlessnumber<strong>Hose</strong> Size(in.)TubeSize O.D.(in.)C115SSFP0504C115SBFP05045/161/4 - 18C115SSTE0404C115SSTE0606C115SSTE08081/43/81/21/43/81/2Also available with pre-assembled Swagelok®compatible nuts and sleevesTWO-BOLT SWIVEL FLANGEBrasspartnumberC115BFL0606C115BFL1212C115BFL1616<strong>Hose</strong> Size(in.)3/83/41PAINT SPRAYFEMALECarbonSteel partnumberC115SPS0505<strong>Hose</strong> Size(in.)5/16FemaleThread1/4 - 18SANITARY FITTING316StainlessnumberC115SF08C115SF12C115SF16<strong>Hose</strong> Size(in.)1/23/41FaceDiameter(in.)1.9851.9851.985Many other styles and shapes available.Also available, field attachable reusablecouplings for the mass transit andtrucking industry. See pages 49-53 of thiscatalogue.Swagelok® is a registered trade mark of the CrawfordP[?]y Company34

Teflon Lined <strong>Hose</strong> MALE CONNECTORTube to male pipeStyle 348F90 O ELBOWTube to male pipeStyle 349F<strong>Thorburn</strong>NumberTubeO.D.StraightThreadPipeThreadLH<strong>Thorburn</strong>NumberTubeO.D.StraightThreadPipeThreadLH02X0203X0304X0204X0404X0605X0205X0405X0606X0206X0406X0606X0808X0408X0608X0808X1210X0610X0810X1212X0812X1212X1614X1216X1216X1616X2020X1620X2024X2432X321/83/161/41/41/45/165/165/163/83/83/83/81/21/21/21/25/85/85/83/43/43/47/81111-1/41-1/41-1/225/16 - 243/8 - 247/16 - 207/16 - 207/16 - 201/2 - 201/2 - 201/2 - 209/16 - 189/16 - 189/16 - 189/16 - 183/4 - 163/4 - 163/4 - 163/4 - 167/8 - 147/8 - 147/8 - 141-1/16 - 121-1/16 - 121-1/16 - 121-3/16 - 121-5/16 - 121-5/16 - 121-5/16 - 121-5/8 - 121-5/8 - 121-7/8 - 122-1/2 - 121/83/161/81/43/81/81/43/81/81/43/81/21/43/81/23/43/81/23/41/23/413/43/411-1/411-1/41-1/221-3/321-1/81-13/321-13/321-13/321-13/641-27/641-27/641-1/41-27/641-27/641-43/641-33/641-33/641-49/641-27/321-4/161-7/81-61/642-3/642-3/642-15/642-5/642-5/642-9/322-25/642-13/322-7/162-43/643-3/327/167/169/169/169/169/165/85/85/85/83/47/813/1613/167/81-1/815/1615/161-1/81-1/81-1/81-3/81-1/41-3/81-3/81-11/161-11/161-11/1622-5/802X0203X0204X0204X0404X0604X0805X0205X0405X0606X0406X0606X0808X0408X0608X0808X1210X0610X0810X1212X0812X1212X1614X1616X1216X1620X1620X2024X2024X2432X321/83/161/41/41/41/45/165/165/163/83/83/81/21/21/21/25/85/85/83/43/43/47/8111-1/41-1/41-1/21-1/225/16 - 243/8 - 247/16 - 207/16 - 207/16 - 207/16 - 201/2 - 201/2 - 201/2 - 209/16 - 189/16 - 189/16 - 183/4 - 163/4 - 163/4 - 163/4 - 167/8 - 147/8 - 147/8 - 141-1/16 - 121-1/16 - 121-1/16 - 121-3/16 - 121-5/16 - 121-5/16 - 121-5/8 - 121-5/8 - 121-7/8 - 121-7/8 - 122-1/2 - 121/81/81/81/43/81/21/81/43/81/43/81/21/43/81/23/43/81/23/41/23/4113/4111-1/41-1/41-1/2249/6453/6457/641-3/641-3/641-3/6461/641-1/161-1/161-1/161-5/321-5/161-1/41-1/41-11/321-29/641-1/41-29/641-29/641-21/321-21/321-21/321-23/321-13/161-13/162-1/161-1/162-21/642-21/643-1/1629/3223/3225/321-3/321-7/641-15/322-5/321-3/321-7/641-3/321-7/641-15/321-5/321-7/321-15/321-19/321-7/321-15/321-19/321-19/321-19/321-31/321-31/321-25/321-31/321-11/322-3/82-/382-5/83UNIONTube to tubeStyle 342F <strong>Thorburn</strong>Number020304050606X040808X061010X08121416202432TubeO.D.1/83/161/45/163/83/81/21/25/85/83/47/811-1/41-1/22TubeO.D.1/83/161/45/163/81/41/23/85/81/23/47/811-1/41-1/22StraightThread5/16 - 243/8 - 247/16 - 201/2 - 209/16 - 189/16 - 183/4 - 163/4 - 167/8 - 147/8 - 141-1/16 - 121-13/16 - 121-15/16 - 121-5/8 - 121-7/8 - 122-1/2 - 12StraightThread5/16 - 243/8 - 247/16 - 201/2 - 209/16 - 187/16 - 203/4 - 169/16 - 187/8 - 143/4 - 161-1/16 - 121-13/16 - 121-15/16 - 121-5/8 - 121-7/8 - 122-1/2 - 12L1-5/321-7/321-23/641-23/641-25/641-3/81-21/321-9/161-21/321-3/42-9/642-13/642-15/642-27/642-41/643-25/64Style of adapterTube O.D. in 1/16 of an inchPipe size in 1/16 of an inchMaterial "S"= Steel, "S6"= 316SS, "B"= BrassComplete with nuts & sleeves (Blank= body only)348F 02X02 SAMany more shapesand sizes available.Call <strong>Thorburn</strong> for detailsAll sizes not availablein all materials.35

Teflon Lined <strong>Hose</strong><strong>Thorburn</strong>'s TSX16 high pressure Teflon hose is nearly50% lighter than any other high pressure spiral wrappedTeflon hose without reduction in strength or reliability.Long life expectancy, high durability and proven performancemake this economical product the most costeffective high pressure hose ever offered industrialusers.TYPICAL APPLICATIONS■ Transfer of industrial gases■ Reaction injection molding (RIM)■ Hydraulic and pneumatic systemsSTANDARDSMeets requirements of SAE 100R8 and 100R9.HOSE CONSTRUCTIONSmooth conductive innercore of extruded Teflon incorporates<strong>Thorburn</strong> zero static construction. Reinforcedby combined plaits of small diameter, tiered,tension controlled type 304 stainless steel wire braid.TEMPERATURE RANGE-65 o F to 400 o F (-54 o C to 204 o C) stainless steel fittings.-25 o F to 300 o F (-32 o C to 149 o C) carbon steel fittings.<strong>Thorburn</strong>'s Nominal Average Average Operating High temp. Room temp. Typ. max. Minimum <strong>Hose</strong>Number Size (in.) I.D. (in.) O.D. (in.) pressure* min. burst burst continuous bend weightpsi at psi psi length (ft.) radius (in.) (lb./ft.)room temp.TSX16-4 1/4 .222 .390 4000 12000 16000 50 1.5 .100TSX16-6 3/8 .308 .490 4000 12000 16000 50 2.5 .163TSX16-8 1/2 .401 .615 4000 12000 16000 38 2.875 .232TSX16-10 5/8 .495 .730 4000 12000 16000 38 3.25 .325TSX16-12 3/4 .617 .990 4000 12000 16000 38 3.875 .660TSX16-16 1 .867 1.270 4000 9000 16000 38 5.0 1.020TSX16-20 1-1/4 1.118 1.660 4000 9000 16000 20 12.0 1.850TSX16-24 1-1/2 1.375 1.900 3000 9000 12000 20 14.0 1.910* Operating pressures shown are for non-impulse service. Reduce operating pressures by 1000 psi for impulseservice applications. For service at 400 o F, maximum operating pressure for all sizes is 3000 psi.This new ultra high pressure Teflon hose is designedfor extremely demanding high pressure service in hydraulicand pneumatic systems, and for high pressurecleaning.ALSO AVAILABLECALL NOW!10,000 psiworking pressureRECOMMENDED APPLICATIONS■ Ground test and ground support■ Pressure wash for industrial and marine applications■ Hydraulic and pneumatic systems<strong>Thorburn</strong>'s Nominal Nominal Minimum Maximum Min. burst <strong>Hose</strong>Number I.D. (in.) O.D. (in.) bend radius operating pressure weight(in.) pressure psi psi (lb./ft.)TSX17-4 1/4 0.495 3.0 6000 24000 0.24TSX17-6 3/8 0.617 5.0 6000 24000 0.40TSX17-8 1/2 0.738 5.75 6000 24000 0.49TSX17-10 5/8 0.875 6.5 4000 16000 0.70TSX17-12 3/4 1.11 7.75 4000 16000 1.14TSX17-16 1 1.42 9.62 4000 16000 1.86HOSE CONSTRUCTIONSmooth conductive innercore of extruded PTFE Teflonincorporating zero static construction for a continuousconductive path to the metalend fittings. TSX17 has multiplelayers of 304 stainlesssteel spiral wrap and braidedbraids for reinforcement.TEMPERATURE RANGE-65 o F to 400 o F (-54 o C to 204 o C)36

Teflon Lined <strong>Hose</strong>This new lightweight high pressure Teflon hose is reinforcedwith super strong, super lightweight Kevlar aramidfiber. The lightweight design gives at least 50% weightsavings over conventional lightweight high pressure Teflonhoses. The non-metallic braid is ideal for applications whereelectrical continuity between end fittings is not allowed.■■■Ground test and ground supportIndustrial robotics for extreme pressure applicationsinvolving bonding materials or other high viscosity fluidsIndustrial gasesRECOMMENDED APPLICATIONS■ Electrically charged equipment needing electrical isolation■ Salt water or other corrosive environment■ Any installation where a high pressure hose must besuper lightweightHOSE CONSTRUCTIONThe smooth conductive liner is extruded Teflon PTFE, incorporating<strong>Thorburn</strong> zero static construction. TSX18 has achemical resistant barrier layer and chafe protecting overbraidof black polyester. End fittings are 304 stainless steel.TEMPERATURE RANGE-65 o F to 275 o F (-54 o C to 135 o C) stainless steel fittings.Maximum working pressure 4000 psi<strong>Thorburn</strong>'s Nominal Minimum 4000 psi 3000 psi Min. burst Min. burst <strong>Hose</strong>Number O.D. (in.) I.D. (in.) bend radius bend radius room temp. 275 o F weight(in.) (in.) (lb./ft.)TSX18-4 0.400 0.212 3.0 1.5 16000 12000 0.056TSX18-6 0.520 0.305 5.0 2.5 16000 12000 0.078TSX18-8 0.662 0.400 5.75 2.88 16000 12000 0.125TSX18-10 0.825 0.505 6.5 3.25 16000 12000 0.147TSX18-12 0.964 0.610 7.75 5.0 16000 12000 0.226JIC - FEMALE SWIVEL(37 o seat)FLAT FACE O-SEALO-ring assurespositive sealingCarbonsteel partnumberT50004-60T50006-60T50008-60T50010-60T50012-60T50016-60T50020-60T50024-60StainlesspartnumberTY40004-72TY40006-72TY40008-72TY40010-72TY40012-72TY40016-72TY40020-72TY40024-72<strong>Hose</strong> Size(in.)1/43/81/25/83/411-1/41-1/2FemaleThread7/16 - 209/16 - 183/4 - 167/8 - 141-1/16 - 121-5/16 - 121-5/8 - 121-7/8 - 12 Note: "O" Ring type should be specifiedStainlesspartnumberTFS-03TFS-04TFS-06TFS-08TFS-10TFS-12<strong>Hose</strong> Size(in.)3/161/43/81/25/83/4FittingThread3/8 - 247/16 - 209/16 - 183/4 - 167/8 - 141-1/16 - 1237

Teflon Lined <strong>Hose</strong>The drawback found in using large diameter smooth tubeTeflon lined stainless steel braided hose assemblies wasits inability to stand up to rugged handling. These traditionalassemblies would tend to kink when bent into tightradii and the braid would tend to separate during handling,exposing the operator to potentail dangerous failure.To address this problem, <strong>Thorburn</strong> developed its TR40which combines the traditional technology of a rubber chemicalpressure hose with the superior properties of teflon.The smooth teflon lined tube is reinforced with a combinationof high tensile calendared synthetic fabric braid andhelical wires which are then shielded with a tough abrasivechemical resistant cover. The hose is then vulcanized andbonded into an integral unit. The end result provides forgreater handling, flexibility and abrasion resistancy.TYPICAL HANDLING TRANSFER APPLICATIONS■■■■■■■Pharmaceutical– parentals, lotions, creams, aluminum chloridePhoto-chemical– ferricyanide bleach, ferric chlorideInks, dyes, glues– Hot melt adhesivesSolvents– from acetone to xylenePlating chemicals– Sodium cyanide, pickling liquorsCleaners– Alkali solvents, perchlorohydrate, trichloroethyleneBlack liquor, spill clean-up, spent caustic acid✓✓✓Full vacuum/500psi smooth boreNon-stick/non-contaminating teflontubePinpricked cover for effusiondissipationService temperratureContinuous: -40°F. to 225°F.Intermittent: -60°F. to 300°F.TR40... the ultimate refinement insmooth bore technology“Mighty Crimp” 316SSHigh pressure coupling technology✓ Greater safety✓ more reliability✓ Higher pressure containment<strong>Thorburn</strong> TR40 assemblies fitting to end joints are provided through a mighty crimp processwhich features a smooth low profile compression crimp fitting. The teflon innercore, braidreinforcements and outer cover are locked into tthe insert serrations and ferrule grooves,assuring 360° blow-off proof assemblies.<strong>Thorburn</strong>'s Size Size Recom. Min. burst Min. recom. Approx. VacuumNumber I.D. (in.) nominal working pressure bend radius weight ratingO.D. (in.) pressure (psi) (in.) (lb./ft.) (in. (Hg))(psi) 70°TR40-08 1/2 15/16 400 1000 3 0.35 30TR40-12 3/4 1-1/4 400 1000 6 0.62 30TR40-16 1 1-1/2 400 1000 9 0.75 30TR40-20 1-1/4 1-3/4 400 1000 11 0.98 30TR40-24 1-1/2 2-1/9 300 1200 12 1.20 30TR40-32 2 2-1/2 300 1200 16 1.50 30TR40-40 2-1/2 3-1/8 150 600 28 2.35 30TR40-48 3 3-5/8 150 600 30 2.50 30Special note: Somefitting ends might havea lower design pressure.Please contact<strong>Thorburn</strong> for details.38

Teflon Lined <strong>Hose</strong>MALE PIPE (N.P.T.) FITTING LAP-JOINT 150 FLANGE CAM-LOCK FEMALE COUPLER TR40MP TR40LF TR40FC<strong>Thorburn</strong> <strong>Hose</strong> NPT Length Cutpart size thread offnumberTR40MP 08-08 S6 1/2 1/2"x14 2.89 1.45TR40MP 12-12 S6 3/4 3/4"x14 3.22 1.63TR40MP 16-16 S6 1 1"x11 1/2 3.69 1.98TR40MP 20-20 S6 1 1/4 1 1/4"x111/2 4.39 2.09TR40MP 24-24 S6 1 1/2 1 1/2"x111/2 4.82 2.18TR40MP 32-32 S6 2 2"x11 1/2 5.86 2.33TR40MP 48-48 S6 3 3"x8 6.25 2.60<strong>Thorburn</strong> <strong>Hose</strong> Length Cutpart size offnumberTR40LF08 S6 1/2 2.90 1.40TR40LF12 S6 3/4 3.10 1.50TR40LF16 S6 1 3.40 1.65TR40LF20 S6 1 1/4 3.90 1.68TR40LF24 S6 1 1/2 4.00 1.85TR40LF32 S6 2 5.70 2.70TR40LF48 S6 3 6.00 2.90<strong>Thorburn</strong> <strong>Hose</strong> Length Cutpart size offnumber in. in.TR40FC12 S6 3/4 4.00 2.50TR40FC16 S6 1 4.50 3.00TR40FC20 S6 1 1/4 5.25 3.25TR40FC24 S6 1 1/2 5.75 3.50TR40FC32 S6 2 6.75 4.00TR40FC48 S6 3 7.25 4.00SANITARY, BEVELSEAT FITTINGFEMALE 37° SWIVELSANITARY, CLAMP STYLETR40SB<strong>Thorburn</strong> <strong>Hose</strong> Cutpart size offnumberTR40SB16 S6 1 1.75TR40SB24 S6 1 1/2 2.50TR40SB32 S6 2 2.75TR40SB48 S6 3 3.00TR40FJX<strong>Thorburn</strong> <strong>Hose</strong> NPT Length Cutpart size thread offnumberTR40FJX 08-08 S6 1/2 1/2"x14 2.89 1.68TR40FJX 12-12 S6 3/4 3/4"x14 3.22 1.99TR40FJX 16-16 S6 1 1"x11 1/2 3.69 2.43TR40FJX 20-20 S6 1 1/4 1 1/4"x111/2 4.39 2.78TR40FJX 24-24 S6 1 1/2 1 1/2"x111/2 4.82 2.93TR40FJX 32-32 S6 2 2"x11 1/2 5.86 3.47TR40SC<strong>Thorburn</strong> <strong>Hose</strong> Flange Cutpart size O.D. offnumber in. in.TR40SC08 S6 1/2 1.98 1.25TR40SC12 S6 3/4 1.98 1.30TR40SC16 S6 1 1.98 1.40TR40SC24 S6 1 1/2 1.98 1.40TR40SC32 S6 2 2.52 1.50TR40SC48 S6 3 3.58 1.50TR40 “Sanitary”Clamp-style Connectorallows quick interface withexisting systems.Also available:Teflon Encapsulated Coupling System(see page 47)✓ Ultimate corrosion or contaminationresistant coupling system✓ Ideal applied pharmaceutical preparations,deionized water transfer etching solutionhandling✓ Available for Cam-Lock female coupler sanitaryclamp-style and lap-joint flange insert39

Teflon Lined <strong>Hose</strong><strong>Thorburn</strong>'s TC72 and TC76 convolutedTeflon transfer hoses effectively combinesflexibility of application with corrosion resistance,long-term durability and chemicalinertness.TYPICAL APPLICATIONS<strong>Thorburn</strong>'s TC72 transfer hose is an idealhose for transferring chemicals, food handlingand various processing applicationsfrom waste water to hazardous waste.Typical uses include chemical loading andunloading of trucks, tank cars andprocess vehicles; batch bulk transfers anddecanting vessels and drums.POSITIVEBRAID LOCK<strong>Thorburn</strong>'s TC76 conductive transfer hose is extensively used in applications which have high flow ratesand require dissipation of a static charge, i.e. fuel handling, tire presses, laundry presses and other typesof steam service where on-off operating cycles cause wide temperature fluctuations inside the hose.HOSE CONSTRUCTIONConvoluted innercore of 100% pure Teflon, externally reinforced with Teflon-impregnated fiberglass and type304 stainless steel wire braid. <strong>Thorburn</strong>'s TC76 hose has precisely controlled amount of carbon black addedto the inner 15% of the Teflon innercore. This homogeneous material provides a continuous conductive pathto the metal end fittings.■ Temperature range -65 o F to 400 o F (-54 o C to 204 o C)■ Accepted by U.S. and Canadian Coast GuardSPECIFICATIONS<strong>Thorburn</strong>'s Nominal Average Average Operating Min. burst High temp. Typ. max. Minimum <strong>Hose</strong>Number Size (in.) I.D. (in.) O.D. (in.) pressure pressure min. burst continuous bend weightpsi psi at psi length (ft.) radius (in.) (lb./ft.)room temp.TC72/TC76-4 1/4 .290 .480 1000 4000 2800 75 1/2 .08TC72/TC76-6 3/8 .375 .590 1000 4000 2800 75 3/4 .12TC72/TC76-8 1/2 .512 .785 1000 4000 2800 75 1 .16TC72/TC76-12 3/4 .750 1.090 1000 4000 2500 50 2 .27TC72/TC76-16 1 .998 1.300 1000 4000 2500 50 3 .36TC72/TC76-20 1-1/4 1.239 1.560 1000 4000 2500 50 6-1/4 .48TC72/TC76-24 1-1/2 1.500 1.792 750 3000 2100 50 7-1/2 .61TC72/TC76-32 2 1.982 2.333 500 2000 1700 50 10 .97For vacuum rating, contact <strong>Thorburn</strong>'s sales department with application details.40