oxyflex - mf 650 ® membran-plate-diffuser - Supratec

oxyflex - mf 650 ® membran-plate-diffuser - Supratec

oxyflex - mf 650 ® membran-plate-diffuser - Supratec

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

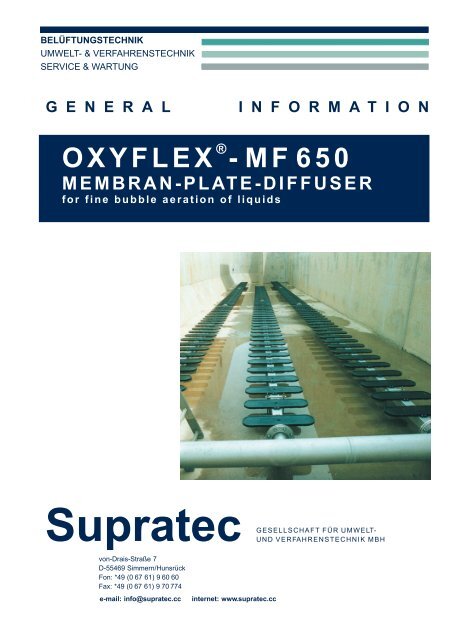

BELÜFTUNGSTECHNIKUMWELT- & VERFAHRENSTECHNIKSERVICE & WARTUNGG E N E R A LI N F O R M A T I O NOXYFLEX®- MF <strong>650</strong>MEMBRAN-PLATE-DIFFUSERfor fine bubble aeration of liquids<strong>Supratec</strong>GESELLSCHAFT FÜR UMWELT-UND VERFAHRENSTECHNIK MBHvon-Drais-Straße 7D-55469 Simmern/HunsrückFon: *49 (0 67 61) 9 60 60Fax: *49 (0 67 61) 9 70 774e-mail: info@supratec.ccinternet: www.supratec.cc

<strong>Supratec</strong>Gesellschaft für UmweltundVerfahrenstechnik mbHG E N E R A L I N F O R M A T I O N®O X Y F L E X - M F M E M B R A N - P L AT E - D I F F U S E Rf o r f i n e b u b b l e a e r a t i o n o f l i q u i d sGENERALINFORMATION®<strong>Supratec</strong> Gesellschaft für Umwelt- und Verfahrenstechnik mbH produces modern high efficientaeration systems, which are mainly used for oxygen transfer into biological waste water treatment.These products can also be used for any kind of transfer of gases into liquids.®OXYFLEX is the brand of <strong>membran</strong>e <strong>diffuser</strong>s (<strong>plate</strong>, tubes and discs) with a plastic body.®The extra ordinary charachteristics of OXYLFEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s are given by itsshape and the materials used.DESIGNMEMBRANE®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s are available in two sizes:®• OXYFLEX -MF <strong>650</strong> (width • length) <strong>650</strong> mm • 150 mm and®• OXYFLEX -MF 1100 (width • length) 1100 mm • 200 mm.The body is a oval <strong>plate</strong>, made of glass reinforced made of Polypropylene. The <strong>membran</strong>e is fixed tothis body with a plastic frame also made of glass reinforced Polypropylene.®Standard <strong>membran</strong>es are made of SUPRAFORM (EPDM).® ®Membranes made of SUPRASIL (Silicone) and SUPRADUR (Polyurethane) are also available.The <strong>membran</strong>es have a unique slot-arrangment. The size and arrangement of those slots isoptimized to archieve maximum oxygen transfer efficiency.CHARACTERISTICS®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s have low pressure loss.®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s are highly resitant against soiling.®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s produce fine bubbles of a medium diameter < 2 mm.Unlike tube <strong>diffuser</strong>s, the whole active <strong>diffuser</strong> surface is at the same hydraulic level, therefore the<strong>membran</strong>es operate evenly across the full range from minimal to maximal air flow. The featureresults in optimum lifetime and efficiency.®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s can be operated intermittently.®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s can be installed with plastic- and/or stainless steel pipesand are used for all geometric forms of tanks, but they are extraordinarily good for medium and hugesized tanks.PERFORMANCE®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s are well established and are working to the clientssatisfaction world-wide.® ® 3OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s have a very wide range, OXYFLEX -MF <strong>650</strong>: 0-13Nm /h.® 3The design air flow should be approximately, OXYFLEX -MF <strong>650</strong>: 7 ± 2 Nm /h®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s can reach specific oxygen transfer efficiency up to 253gO /Nm xm , if coverage and water depth is favourable.2 supCOMBINATIONVARIATIONS®For plants with partly intermittent operated tanks, OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s can be®combined with BRANDOL ceramic tube <strong>diffuser</strong>s. However, different pressure losses have to beconsidered.®Modifed OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s are also available for drinking water purposes.®OXYFLEX -MF <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s are also available as coarse bubble <strong>diffuser</strong>s.<strong>Supratec</strong> ® von-Drais-Straße 7 • D-55469 Simmern • Fon: +49 (0 67 61) 9 60 60 • Fax: +49 (0 67 61) 970 774 • info@supratec.cc

<strong>Supratec</strong>Gesellschaft für UmweltundVerfahrenstechnik mbH®D R A W I N G O X Y F L E X - M F 6 5 0 ‘ B ’Membrane Plate Diffuser®OXYFLEX -MF <strong>650</strong> Type ‘B’ will be installed to arectangular pipe by 4 welded thread bolts, those arewelded to the pipe.Materials:Body:Polypropylen (PP-GF)Frame:Polypropylen (PP-GF)Gasket: EPDM®Membrane: SUPRASIL (Silikon)®SUPRAFORM (EPDM)Membrane area: 0,1 m²MembraneBody <strong>plate</strong>FrameDistributor PipeGasketAir-SocketHole Ø 32mmFrame 2 PiecesThreat bolts M6Hole in PipeØ 32mmDistributor PipeFrame2 PiecesMembraneStand Juni 2009<strong>Supratec</strong> ® von-Drais-Straße 7 • D-55469 Simmern • Fon: +49 (0 67 61) 9 60 60 • Fax: +49 (0 67 61) 970 774 • info@supratec.cc

<strong>Supratec</strong>Gesellschaft für UmweltundVerfahrenstechnik mbHC U R V E S P R E S S U R E - O X Y G E N®O X Y F L E X - M F M E M B R A N - P L AT E - D I F F U S E Rf o r f i n e b u b b l e a e r a t i o n o f l i q u i d s®OXYFLEX -MF<strong>650</strong> <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong> are high efficient <strong>diffuser</strong>s and are mainly used for oxygen supply to biological waste watertreatment plants.Beside procedural necessities, important criterions are used to select the matching fine-bubble aeration-technology to the features of atreatment plant.® 3Systems using OXYFLEX -MF<strong>650</strong> <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s are typically designed at a specific air-flow of 7 Nm /h per unit.This gives a good compromise between capital in investment and efficiency.The following table shows figures taken from an actual oxygen efficiency test.The values have been reached in a circular basin with water depth of 4,35m, submergence of <strong>diffuser</strong>s of 4,15m and coverage of 11,27%.These are typical values particular to the test basin. The figures can deviation ± 25% in tanks of different sizes and <strong>diffuser</strong> density andloading.®SUPRATEC GmbH would be pleased to produce a data-sheet for any individual application on request. No guarantee-claims can be derived from the diagram!30specific O2-entrainment standard conditions andpressure loss®OXYFLEX -Mf<strong>650</strong>50∆pOCOCL,h [gO2/(Nm³ x mET)]25204030p [mbar]1520100 1 2 3 4 5 6 7 8 9specific load [Nm³/m]10<strong>Supratec</strong> ® von-Drais-Straße 7 • D-55469 Simmern • Fon: +49 (0 67 61) 9 60 60 • Fax: +49 (0 67 61) 970 774 • info@supratec.cc

<strong>Supratec</strong>Gesellschaft für UmweltundVerfahrenstechnik mbHI N S T A L L A T I O N M A N U A L®O X Y F L E X - M F M E M B R A N - P L AT E - D I F F U S E Rf o r f i n e b u b b l e a e r a t i o n o f l i q u i d sDESCRIPTION®OXYFLEX -MF<strong>650</strong> - <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong> Type ‘AS’ has a solid, strong, horizontal body, made ofglass-reinforced Polypropylene and a slipped over <strong>membran</strong>e (e.g. EPDM).The two-piece-frame, made of glass-reinforced Polypropylene ensures the proper location of the<strong>membran</strong>e.The body has a connecting-thread (standard 1”BSPmale) that is welded into a Polypropylene clamp.This clamp can be fastened by screws or wedges.The integral gasket of the clamp seals the system.MEASUREMENTSWidth: 189 mm, Length: 680 mm, Height: 21 mm- with rounded edges (not including clamp)2Free <strong>membran</strong>e area: Length: <strong>650</strong> mm, Width: 150 mm (0,1 m )STORAGEPREPARATIONThe <strong>diffuser</strong>s should be stored in their packing inside a dry and aerated building. DIN 7716 has to beconsidered.®Before installation of the OXYFLEX -MF <strong>650</strong> - <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong> Type ‘AS’ it has to bechecked that the piping system is clean.Drilling chips, dirt etc. have to be removed, as those will be transported into the <strong>diffuser</strong>s as soon asblowers are set into operation causing serious damage to the <strong>diffuser</strong> <strong>membran</strong>es.LEVELLINGINSTALLATION®OXYFLEX -MF <strong>650</strong> - <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong> Type ‘AS’ normallyinstalled onto round pipes. The piping system has to be levelled to maximum ± 10 mm.®OXYFLEX -MF <strong>650</strong> - <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong> Type ‘AS’ can be fixed to round pipes made ofstainless steel or plastic, with a minimum diameter of 50 mm. On the upper side of those pipes,centred holes of diameter Ø 14 mm must be made.The clamp will be installed in such a way, that the hole of Ø 14 mm and the opening of the clamp arealigned.Care must be taken of the horizontal seat of the <strong>diffuser</strong>s. The O-Ring seal, made of EPDM must beclean and undamaged and should sit between <strong>diffuser</strong> and pipe.<strong>Supratec</strong> ® von-Drais-Straße 7 • D-55469 Simmern • Fon: +49 (0 67 61) 9 60 60 • Fax: +49 (0 67 61) 970 774 • info@supratec.cc

<strong>Supratec</strong>Gesellschaft für UmweltundVerfahrenstechnik mbHO P E R A T I O N M A N U A L®O X Y F L E X - M F M E M B R A N - P L AT E - D I F F U S E Rf o r f i n e b u b b l e a e r a t i o n o f l i q u i d sFUNCTIONANDLEAKAGE CHECKFIRST RUN OFDIFFUSERSVISUAL BUBBLECHECKOXYGEN-TRANSFER-EFFICIENCY TESTSTART UP®After installation of OXYFLEX -MF <strong>650</strong> <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s a function and leakage test shouldbe carried out.The tank should be filled with clean water up to maximum 10 cm above <strong>diffuser</strong>s’ surface and the3<strong>diffuser</strong>s set in operation (specific air flow: 6 Nm /h per unit).Then function and installation can be checked and confirmed by report.®After function and installation has been checked and confirmed OXYFLEX -MF <strong>650</strong> <strong>membran</strong>e <strong>plate</strong><strong>diffuser</strong>s have to be operated at least another 60 hours continuously, at a specific air flow of minimum310 Nm /h per unit.Water level shall be as quickly as possible raised up to minimum 100 cm above <strong>diffuser</strong>s’ surface.IMPORTANT: • Diffusers should not stand still3• Specific air flow should not exceed 13 Nm /h per unit.The visual judgement of the bubble distribution should not be taken before the above specific first runof <strong>diffuser</strong>s.To do the visual check, the <strong>diffuser</strong>s shall operate at maximum capacity and shall be turned to theminimum.• Test of even aeration (visual bubble check) must take place when the water level is at least 60-1003cm above <strong>diffuser</strong>s’ surface and a specific air flow of at least 6 Nm /h per unit.• Test of even aeration (visual bubble check) at minimum air flow can only take place if the watertemperature is above 10°C.®Before the stated oxygen transfer efficiency figures of the OXYFELX - MF <strong>650</strong> <strong>membran</strong>e <strong>plate</strong><strong>diffuser</strong>s are proved with an oxygen transfer efficiency test, the above mentioned steps have to beconsidered.The oxygen transfer efficiency test must be done accordingly to accepted rules (e.g. ATV-M 209) inclean or waste water.Guarantee figures have to be controlled exactly. It is necessary to have a precise air-flowmeasurement system.®After successful oxygen transfer efficiency test, start up of the OXYFLEX -MF <strong>650</strong> <strong>membran</strong>e <strong>plate</strong><strong>diffuser</strong>s may follow immediately. If there is a postponement of the start up, care should be taken that®the water level stays at least 100 cm above <strong>diffuser</strong>s’ surface to protect OXYFLEX -MF <strong>650</strong><strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s from sunlight and / or freezing.<strong>Supratec</strong> ® von-Drais-Straße 7 • D-55469 Simmern • Fon: +49 (0 67 61) 9 60 60 • Fax: +49 (0 67 61) 970 774 • info@supratec.cc

<strong>Supratec</strong>Gesellschaft für UmweltundVerfahrenstechnik mbHM A I N T E N A N C E M A N U A L®O X Y F L E X - M F M E M B R A N - P L AT E - D I F F U S E Rf o r f i n e b u b b l e a e r a t i o n o f l i q u i d sMAINTENANCE®OXYFLEX -MF <strong>650</strong> <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s do not need a lot of maintenance. Usually it is enoughto have one run of 10 to 15 minutes operation at minimum air-flow per day, where each single® 3OXYFLEX -MF <strong>650</strong> <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong> shall operate at a specific air-flow of at least 10 Nm /hper unit.To do so, it may help to shut down the system partially, by closing the corresponding valves.This removes layers of sludge which may have occurred after long times of in operation of thesystem or long times of low specific air flow.®At least once per year OXYFLEX - MF <strong>650</strong> <strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s should be checked visually,particulary they should be checked for layers of sludge or similar. If so, those layers should beremoved carefully.A seperate maintenance-contract is available.SUPERVISIONA Visual bubble check should be carried out daily. The pressure loss of the system should bemonitored and reported monthly.Apparent changes of the bubble distribution and/or of the pressure loss should be promptly reported®to SUPRATEC GmbH, especially at installations with intermittent operation where there is a risk that®activated sludge could penetrate the entire piping through a damaged OXYFLEX -MF <strong>650</strong>®<strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong> which would affect function and lifetime of all OXYFLEX -MF <strong>650</strong><strong>membran</strong>e <strong>plate</strong> <strong>diffuser</strong>s in the system.® ®The maximum of SUPRATEC GmbH’s warranty for OXYFLEX -MF <strong>650</strong> <strong>membran</strong>e is 24 months.Longer warranty can be arranged only with conclusion of a maintenance contract between the®operator and SUPRATEC GmbH.Damage and/or other influences are specifically excluded from the warranty promise.WARRANTYThe warranty ends if it is known, that sewage is partially or mainly of industrial origin and/or the®sewage has a damaging influence on <strong>membran</strong>e <strong>diffuser</strong>s and SUPRATEC GmbH was not informedaccordingly.®In such a case, a confirmation of the warranty is to be ordered through SUPRATEC GmbH.®The general sales and warranty conditions of SUPRATEC GmbH apply.<strong>Supratec</strong> ® von-Drais-Straße 7 • D-55469 Simmern • Fon: +49 (0 67 61) 9 60 60 • Fax: +49 (0 67 61) 970 774 • info@supratec.cc