Life-Cycle Management - Army Logistics University - U.S. Army

Life-Cycle Management - Army Logistics University - U.S. Army

Life-Cycle Management - Army Logistics University - U.S. Army

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The Reality of the Single-Fuel Concept<br />

To simplify fuel operations, the Department of<br />

Defense (DOD) has adopted a single-fuel concept<br />

(SFC) that requires U.S. forces to use only one<br />

fuel while deployed. Although the concept has merits,<br />

it also has shortcomings. The challenge is to develop a<br />

policy that will best meet all military fuel needs.<br />

Evolution of the SFC<br />

Waxing and fuel filterability problems with the<br />

North Atlantic Treaty Organization’s (NATO’s) standard<br />

diesel fuel, F54, during cold weather created<br />

severe problems for the engines of M1 Abrams main<br />

battle tanks and other gasoline turbine-powered equipment<br />

when they were introduced to U.S. forces in Germany<br />

in 1981. [Diesel fuel typically has a high paraffin<br />

hydrocarbon content, which prevents it from flowing at<br />

low temperatures. Waxing refers to this situation, in<br />

which the paraffin hydrocarbons in the fuel congeal<br />

and wax-like particles are formed that can either coat<br />

the surfaces they contact or plug fuel filters.]<br />

The interim fix for these problems involved blending<br />

the F54 diesel fuel with aviation kerosene turbine<br />

fuel (either JP5 or JP8) to lower both the waxing tendency<br />

and the viscosity of the diesel fuel. This blended<br />

fuel, known as the “M1 fuel mix,” was used for all<br />

diesel-fueled equipment in forward areas from<br />

November through April annually. Other NATO<br />

countries soon adopted the blend (50 percent F54 and<br />

50 percent JP8 or JP5), which subsequently was<br />

given the NATO code number F65. These fixes for<br />

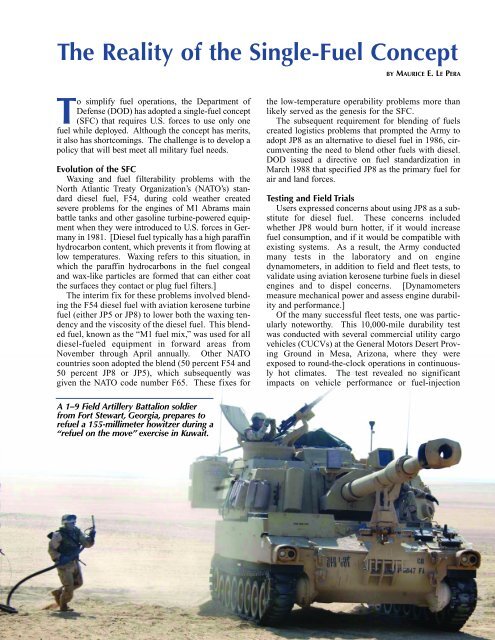

A 1–9 Field Artillery Battalion soldier<br />

from Fort Stewart, Georgia, prepares to<br />

refuel a 155-millimeter howitzer during a<br />

“refuel on the move” exercise in Kuwait.<br />

BY MAURICE E. LE PERA<br />

the low-temperature operability problems more than<br />

likely served as the genesis for the SFC.<br />

The subsequent requirement for blending of fuels<br />

created logistics problems that prompted the <strong>Army</strong> to<br />

adopt JP8 as an alternative to diesel fuel in 1986, circumventing<br />

the need to blend other fuels with diesel.<br />

DOD issued a directive on fuel standardization in<br />

March 1988 that specified JP8 as the primary fuel for<br />

air and land forces.<br />

Testing and Field Trials<br />

Users expressed concerns about using JP8 as a substitute<br />

for diesel fuel. These concerns included<br />

whether JP8 would burn hotter, if it would increase<br />

fuel consumption, and if it would be compatible with<br />

existing systems. As a result, the <strong>Army</strong> conducted<br />

many tests in the laboratory and on engine<br />

dynamometers, in addition to field and fleet tests, to<br />

validate using aviation kerosene turbine fuels in diesel<br />

engines and to dispel concerns. [Dynamometers<br />

measure mechanical power and assess engine durability<br />

and performance.]<br />

Of the many successful fleet tests, one was particularly<br />

noteworthy. This 10,000-mile durability test<br />

was conducted with several commercial utility cargo<br />

vehicles (CUCVs) at the General Motors Desert Proving<br />

Ground in Mesa, Arizona, where they were<br />

exposed to round-the-clock operations in continuously<br />

hot climates. The test revealed no significant<br />

impacts on vehicle performance or fuel-injection<br />

40 JANUARY–FEBRUARY 2005