Quick Coupling Products - LSR Distribuidor

Quick Coupling Products - LSR Distribuidor Quick Coupling Products - LSR Distribuidor

A PneumaticsPneumaticQuickCouplingsA-1Quick Coupling Division8145 Lewis Road • Minneapolis, MN 55427www.parker.com/quickcouplings

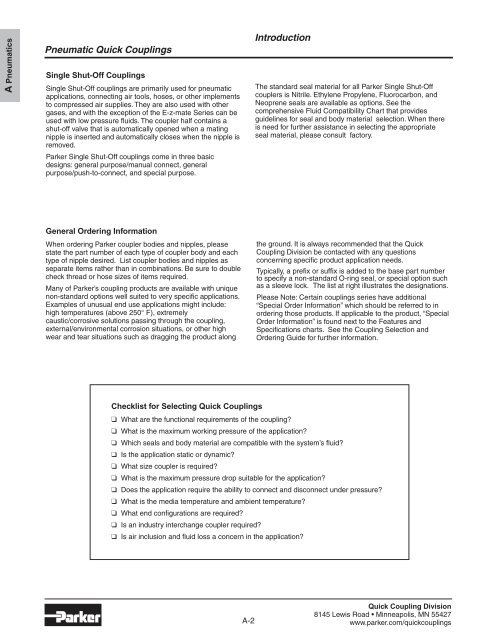

A PneumaticsPneumatic Quick CouplingsSingle Shut-Off CouplingsSingle Shut-Off couplings are primarily used for pneumaticapplications, connecting air tools, hoses, or other implementsto compressed air supplies. They are also used with othergases, and with the exception of the E-z-mate Series can beused with low pressure fluids. The coupler half contains ashut-off valve that is automatically opened when a matingnipple is inserted and automatically closes when the nipple isremoved.Parker Single Shut-Off couplings come in three basicdesigns: general purpose/manual connect, generalpurpose/push-to-connect, and special purpose.IntroductionThe standard seal material for all Parker Single Shut-Offcouplers is Nitrile. Ethylene Propylene, Fluorocarbon, andNeoprene seals are available as options. See thecomprehensive Fluid Compatibility Chart that providesguidelines for seal and body material selection. When thereis need for further assistance in selecting the appropriateseal material, please consult factory.General Ordering InformationWhen ordering Parker coupler bodies and nipples, pleasestate the part number of each type of coupler body and eachtype of nipple desired. List coupler bodies and nipples asseparate items rather than in combinations. Be sure to doublecheck thread or hose sizes of items required.Many of Parker’s coupling products are available with uniquenon-standard options well suited to very specific applications.Examples of unusual end use applications might include:high temperatures (above 250° F), extremelycaustic/corrosive solutions passing through the coupling,external/environmental corrosion situations, or other highwear and tear situations such as dragging the product alongthe ground. It is always recommended that the QuickCoupling Division be contacted with any questionsconcerning specific product application needs.Typically, a prefix or suffix is added to the base part numberto specify a non-standard O-ring seal, or special option suchas a sleeve lock. The list at right illustrates the designations.Please Note: Certain couplings series have additional“Special Order Information” which should be referred to inordering those products. If applicable to the product, “SpecialOrder Information” is found next to the Features andSpecifications charts. See the Coupling Selection andOrdering Guide for further information.Checklist for Selecting Quick Couplings❑ What are the functional requirements of the coupling?❑ What is the maximum working pressure of the application?❑ Which seals and body material are compatible with the system’s fluid?❑ Is the application static or dynamic?❑ What size coupler is required?❑ What is the maximum pressure drop suitable for the application?❑ Does the application require the ability to connect and disconnect under pressure?❑ What is the media temperature and ambient temperature?❑ What end configurations are required?❑ Is an industry interchange coupler required?❑ Is air inclusion and fluid loss a concern in the application?A-2Quick Coupling Division8145 Lewis Road • Minneapolis, MN 55427www.parker.com/quickcouplings

- Page 1: Quick CouplingProductsCatalog 3800

- Page 11 and 12: A PneumaticsPneumatic Quick Couplin

- Page 13 and 14: A PneumaticsPneumatic Quick Couplin

- Page 15 and 16: A PneumaticsPneumatic Quick Couplin

- Page 17 and 18: A PneumaticsPneumatic Quick Couplin

- Page 20 and 21: Pneumatic Quick Couplings3General P

- Page 22 and 23: Pneumatic Quick CouplingsCouplersFe

- Page 24 and 25: Pneumatic Quick CouplingsGeneral Pu

- Page 26 and 27: Pneumatic Quick Couplings1/4" and 3

- Page 28 and 29: Pneumatic Quick CouplingsGeneral Pu

- Page 30 and 31: Pneumatic Quick Couplings7General P

- Page 32 and 33: Pneumatic Quick CouplingsCouplersFe

- Page 34 and 35: Pneumatic Quick CouplingsGeneral Pu

- Page 36 and 37: Pneumatic Quick CouplingsSpecial Pu

- Page 38 and 39: Pneumatic Quick CouplingsSpecial Pu

- Page 40 and 41: Pneumatic Quick CouplingsOperationP

- Page 42 and 43: Pneumatic Quick CouplingsSpecial Pu

- Page 44 and 45: Pneumatic Quick CouplingsMale Reusa

- Page 46 and 47: Pneumatic Quick CouplingsPartMeets

- Page 48 and 49: HydraulicB HydraulicsQuickCouplings

- Page 50 and 51: Hydraulic Quick CouplingsTable of C

A PneumaticsPneumatic <strong>Quick</strong> <strong>Coupling</strong>sSingle Shut-Off <strong>Coupling</strong>sSingle Shut-Off couplings are primarily used for pneumaticapplications, connecting air tools, hoses, or other implementsto compressed air supplies. They are also used with othergases, and with the exception of the E-z-mate Series can beused with low pressure fluids. The coupler half contains ashut-off valve that is automatically opened when a matingnipple is inserted and automatically closes when the nipple isremoved.Parker Single Shut-Off couplings come in three basicdesigns: general purpose/manual connect, generalpurpose/push-to-connect, and special purpose.IntroductionThe standard seal material for all Parker Single Shut-Offcouplers is Nitrile. Ethylene Propylene, Fluorocarbon, andNeoprene seals are available as options. See thecomprehensive Fluid Compatibility Chart that providesguidelines for seal and body material selection. When thereis need for further assistance in selecting the appropriateseal material, please consult factory.General Ordering InformationWhen ordering Parker coupler bodies and nipples, pleasestate the part number of each type of coupler body and eachtype of nipple desired. List coupler bodies and nipples asseparate items rather than in combinations. Be sure to doublecheck thread or hose sizes of items required.Many of Parker’s coupling products are available with uniquenon-standard options well suited to very specific applications.Examples of unusual end use applications might include:high temperatures (above 250° F), extremelycaustic/corrosive solutions passing through the coupling,external/environmental corrosion situations, or other highwear and tear situations such as dragging the product alongthe ground. It is always recommended that the <strong>Quick</strong><strong>Coupling</strong> Division be contacted with any questionsconcerning specific product application needs.Typically, a prefix or suffix is added to the base part numberto specify a non-standard O-ring seal, or special option suchas a sleeve lock. The list at right illustrates the designations.Please Note: Certain couplings series have additional“Special Order Information” which should be referred to inordering those products. If applicable to the product, “SpecialOrder Information” is found next to the Features andSpecifications charts. See the <strong>Coupling</strong> Selection andOrdering Guide for further information.Checklist for Selecting <strong>Quick</strong> <strong>Coupling</strong>s❑ What are the functional requirements of the coupling?❑ What is the maximum working pressure of the application?❑ Which seals and body material are compatible with the system’s fluid?❑ Is the application static or dynamic?❑ What size coupler is required?❑ What is the maximum pressure drop suitable for the application?❑ Does the application require the ability to connect and disconnect under pressure?❑ What is the media temperature and ambient temperature?❑ What end configurations are required?❑ Is an industry interchange coupler required?❑ Is air inclusion and fluid loss a concern in the application?A-2<strong>Quick</strong> <strong>Coupling</strong> Division8145 Lewis Road • Minneapolis, MN 55427www.parker.com/quickcouplings