Industrial Hydraulics Mobile Hydraulics Industrial Compressed Air ...

Industrial Hydraulics Mobile Hydraulics Industrial Compressed Air ...

Industrial Hydraulics Mobile Hydraulics Industrial Compressed Air ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

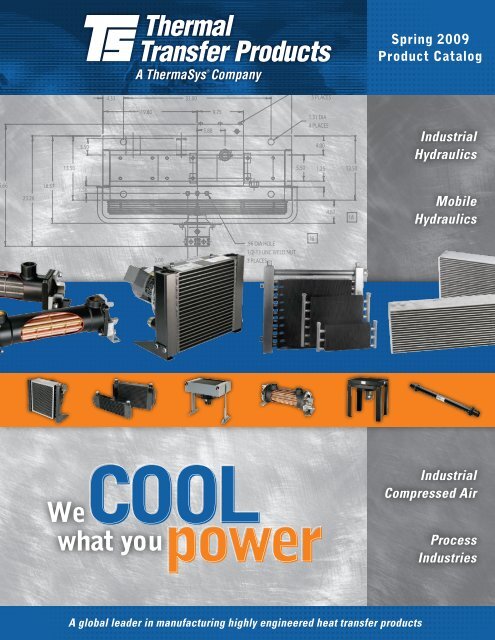

Spring 2009Product Catalog<strong>Industrial</strong><strong>Hydraulics</strong><strong>Mobile</strong><strong>Hydraulics</strong><strong>Industrial</strong><strong>Compressed</strong> <strong>Air</strong>ProcessIndustriesA global leader in manufacturing highly engineered heat transfer products

As a global leaderin manufacturing highlyengineered heat transferproducts, we provideapplication solutions in themobile, industrial, processand compressor markets.Our mission is to be the bestsupplier of highly engineeredcopper, brass and aluminumheat exchanger componentsand assemblies.Utilizing broad applicationsof lean manufacturingtechniques that enhanceour operational excellence,we provide responsiveon-time delivery at shortcatalog lead times.WeCOOL what youPOWERChoose Thermal Transfer Products for supreme performance.nCompetitive pricingnPrompt deliverynHighest quality materials and workmanshipnResponsive engineering assistancenStringent quality controlnCustom product capabilityEvery water cooled and air coolednASME code construction availableunit is leak-testednHighest integrity and honest business style

PRODUCT CATALOGContents1FLUID COOLING2 <strong>Air</strong> Cooled ProductsCopper Tube Construction<strong>Industrial</strong> Application4 AOC Series8 AO Series12 AOVH Series16 AOF Series20 RM Series<strong>Mobile</strong> Application24 AOC Series28 DH Series32 DF Series36 M Series40 MF Series44 AOHM & AOVHM Series3COMPRESSEDAIR COOLING134 <strong>Air</strong> Cooled & Water Cooled Products<strong>Compressed</strong> <strong>Air</strong> Aftercoolers& Oil Cooler Products<strong>Air</strong> Cooled ProductsCopper Tube Construction136 UPA Series138 AA Series140 Belt Guard AftercoolersBrazed Aluminum ConstructionAOL - <strong>Industrial</strong> Oil Cooler (see page 50)142 AHP Series146 ACOC SeriesWater Cooled Products2Brazed Aluminum Construction<strong>Industrial</strong> Application50 AOL54 BOL Series<strong>Mobile</strong> Application60 MA Series<strong>Industrial</strong> & <strong>Mobile</strong> Applications64 OCA SeriesFLUID COOLING70 Water Cooled ProductsCopper/Steel orStainless Steel Construction<strong>Industrial</strong> Application4Copper Tube Construction150 AB SeriesC Series Oil Cooler (see page 90)152 ACCESSORIES154 Modulating Water Valves and Bulb Wells156 Water Strainers157 Three-Way Thermostatic Valves160 Thermal Bypass Assembly162 Electronic Temperature Control& Bulb Well Assembly (AC)163 Thermostatic Temperature Controller (DC)164 Temperature Sensors165 <strong>Compressed</strong> <strong>Air</strong> Separators167 Automatic Float Drain168 Flexible Metal HoseShell & Tube72 EK Series80 K Series84 EC Series90 EKT Series92 C & SSC Series98 CA 2000 Series102 B Series108 A Series114 SSA Series118 UC/UCV Series5169 CROSS, TECHNICAL& MISCELLANEOUSREFERENCES170 Cross Reference199 Installation/Service218 Application/Sizing221 Policies229 Technical Reference232 Quick ReferenceBrazed Plate124 BPS Series128 BP Series130 BPCH SeriesSpecialty132 Fail Safe

FLUID COOLINGAIR COOLEDThermal Transfer Products manufactures an array of highly engineered air cooledproducts of copper tube and brazed aluminum construction for optimum performancein mobile and industrial applications.For the most challenging system requirements and refined cooling technology on the markettoday, TTP offers heat transfer coolers unrivaled in strength and rigidity that ensure durableperformance, such as the OCA series with our patented T-Bar brazed aluminum extruded tubecore geometry.

1COPPER TUBE CONSTRUCTION<strong>Industrial</strong> Application (AC Fan Driven)AOC Series Low cost, low flows (Perfect for off-linerecirculation loop), high heat removal, optional serviceablebypass valveAO Series Medium flows, moderate heat removal, optionalbypass valveAOVH Series High flows, moderate heat removal, optionalbypass valveAOF Series AO Series with filterRM Series Low cost, low flows (case drain applications)<strong>Mobile</strong> Application (DC or Hydraulic Fan Driven)AOC Series Low cost, low flows (Perfect for off-linerecirculation loop), high heat removal, optional serviceablebypass valveDH Series Low cost, moderate flows, high heat removal,optional bypass valveDF Series Steel fins, steel manifolds, and copper tubesM Series High flows, high heat removal, optionalbypass valveMF Series Aluminum fins, steel manifolds, and copper tubesAOHM & AOVHM Series High flows, moderate heatremoval, optional bypass valve removal, hydraulicmotor onlyBRAZED ALUMINUM CONSTRUCTION<strong>Industrial</strong> ApplicationAOL Series Bar & plate, industrial duty, very high flows,very high heat removalBOL Series Bar & plate, brazed aluminum core, rugged,lightweight, and compact, provides the best heat transferper given envelope size while minimizing pressure drop,with AC motor or hydraulic motor<strong>Industrial</strong> & <strong>Mobile</strong> ApplicationOCA Series Available in a wide range of sizes, anddesigned for a broad range of applications with theadvantage of providing ample cooling in areas wherewater is costly or unavailable<strong>Mobile</strong> ApplicationMA Series Bar & plate, brazed aluminum core, rugged,lightweight, and compact, provides the best heat transferper given envelope size while minimizing pressure drop,with DC motora global leaderin manufacturinghighly engineeredheat transfer products

FLUID COOLING | <strong>Industrial</strong> AOC SeriesFEATURESn AC Motorsn Core Filtern 3/4” Tubesn Low Costn <strong>Industrial</strong> Dutyn Quiet OperationAIR COOLED AOCnFor Low Flow RatesnOil Flows to 150 GPMnMounting Brackets IncludednSAE ConnectionsnSingle or Three-Phase 60/50 HzMotorsnFilter StandardOPTIONSBuilt-in Serviceable Bypass Valve;NPT or BSPP Oil ConnectionsRatingsOperating Pressure - 300 psiTest Pressure - 300 psiOperating Temperature - 350° FMaterialsTubes CopperFins AluminumTurbulators AluminumFan Blade Aluminum with steel hubFan Guard Steel with black baked enamel finishCabinet Steel with baked enamel finishManifolds Copper: Model AOC-08Steel: Models AOC-19 – AOC-70Connections Brass: Model AOC-08Steel: Models AOC-19 – AOC-70Nameplate AluminumFilter Stainless frame with washable mediaRelief Bypass Valve OptionMODELDESCRIPTIONAOC-08 Available in one pass (30 and 60psi), two pass (60 psi), designsonly. Valves are built into tubesand do not affect externaldimensions. All steel valves.Non-serviceable.AOC-19thruAOC-33AOC-37ThruAOC-70Available in 30 psi or 60 psisettings. 3/4”, external, all steelvalve. May be removed forservicing.Available in 30 psi or 60 psisettings. 1-1/2”, external, allsteel valve. May be removed forservicing.How to Order (AOC-08 models only)AOC – 0 8 – – –ModelSeriesAOC - StandardModel SizeSelectedNumber ofPasses1 - One Pass2 - Two Pass4 - Four PassConnectionType1 - NPT2 - SAE3 - BSPPRelief Bypass*Blank - No Bypass30 - 30 psi60 - 60 psiSpecify MotorRequired115/230V Single PhaseNo Motor*Bypass not available in Four Pass4AOCHow to Order (Models AOC-19 through AOC-70)AOCModelSeriesAOC - Standard– – – –Model SizeSelectedConnectionType1 - NPT2 - SAE3 - BSPPRelief BypassBlank - No Bypass30 - 30 psi60 - 60 psiTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.comSpecify MotorRequired115/230V Single Phase208-230/460V Three Phase575 VoltNo Motor

DimensionsModels AOC-19 Through AOC-33MODELS AOC-19 THROUGH AOC-331/2 NPTFOR OPTIONALTEMP. SENSORBEF (2 PLACES)*CGAAIR FLOWAIRFILTERDMODELS AOC-37 THROUGH AOC-70ELECTRICMOTORH.41 X 1.19 SLOT2 EACH BRACKETMPJModels AOC-37 Through AOC-701/2 NPTFOR OPTIONALTEMP. SENSORINBESERVICEABLEBYPASS VALVE30 OR 60 PSIF (2 PLACES)OUTCGCOOLED AOCADAIR FLOWAIRFILTERELECTRICMOTORH3/8 NPTDRAIN.53 DIA HOLE2 EACH BRACKETMPJMODELAOC-19AOC-22AOC-24AOC-33ANo Bypass Bypass13.62 16.0015.62 18.0019.62 22.0025.62 28.00BNo Bypass Bypass16.50 18.1622.00 23.6624.75 26.4130.25 31.91FC D ESAE NPT & BSPP13.08 10.31 15.00Unit Shown with Optional Bypass Valve12.19 12.31 20.50 #12 .7516.31 23.2513.1922.31 28.75 #16 1.00SAE3.05GNPT & BSPP4.124.34H J M P14.7518.6921.4426.972.61 5.00 8.18LBS19334665AOC-37AOC-5018.5022.5021.3825.3839.0041.0040.3842.3815.6615.6215.2519.2536.5038.50#201.254.624.685.976.0340.5042.501.061.126.508.318.3795120AOC-54AOC-57AOC-7030.5036.5038.3833.2839.3841.2542.0048.0051.0043.3849.3852.3817.0916.7222.6227.2532.7534.0039.5045.5048.50#24#321.502.004.896.688.446.308.159.9143.7549.7552.751.871.629.0012.3712.12154190322NOTE: All dimensions in inches. We reserve the right to make reasonable design changes without notice.*Inlet and outlet oil ports reversible if relief bypass option is not used.SpecificationsElectric Motor DataNOTE: Amp ratings are per motor.AOCAIRwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 5

AIR COOLED AOCAOC6Selection ProcedurePerformance Curves are based on 50SSU oil leaving the cooler 40°F higherthan the ambient air temperature used for cooling.This is also referred to asa 40°F approach temperature.STEP 1 Determine the Heat Load.This will vary with different systems,but typically coolers are sized to remove 25 to 50% of the inputnameplate horsepower.(Example: 100 HP Power Unit x .33 = 33 HP Heat load.)If BTU/Hr. is known: HP = BTU/Hr2545STEP 2 Determine Approach Temperature. Desired oil leaving cooler°F – Ambient air temp. °F = Actual ApproachSTEP 3 Determine Curve Horsepower Heat Load. Enter theinformation from above:Horsepower heat load x40 x Cv= Curve HorsepowerActual ApproachSTEP 4 Enter curves at oil flow through cooler and curve horsepower.Any curve above the intersecting point will work.STEP 5 Determine Oil Pressure Drop from Curves:l = 5 PSI; n = 10 PSI; s = 20 PSI; ; = 40 PSI. Multiplypressure drop from curve by correction factor found in oilcorrection curve.Performance CurvesHORSEPOWER REMOVED IN COOLER100908070605040302520151098765432.522.5●●●●■● ■ ▲ ✛3 4 5 6 7 8 9 10 15 20 25 30 40 50 60 70 80 90100150 200 250 300OIL FLOW - G.P.M.TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com●●■■■●▲●■■▲▲▲■▲P■▲AOC-22AOC-19✛AOC-24▲✛▲AOC-33Desired Reservoir TemperatureReturn Line Cooling: Desired temperature is the oil temperature leaving thecooler. This will be the same temperature that will be found in the reservoir.Off-Line Recirculation Cooling Loop: Desired temperature is the oil temperatureentering the cooler. In this case, the oil temperature change must bedetermined so that the actual oil leaving temperature can be found.Calculate the oil temperature change (oil T) with this formula:Oil T = (BTU’s/Hr.) / (GPM Oil Flow x 210).To calculate the oil leaving temperature from the cooler, use this formula:Oil Leaving Temp. = Oil Entering Temp – Oil T.This formula may also be used in any application where the only temperatureavailable is the entering oil temperature.Oil Pressure Drop: Most systems can tolerate a pressure drop through theheat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.Care should be taken to limit pressure drop to 5 PSI or less for case drainapplications where high back pressure may damage the pump shaft seals.Oil TemperatureTypical operating temperature ranges are:Hydraulic Motor Oil 110° - 130°FHydrostatic Drive Oil 130° - 180°FBearing Lube Oil 120° - 160°FLube Oil Circuits 110° - 130°F✛AOC-37✛✛AOC-50AOC-54AOC-57Oil ▲P● = 5 PSI■ = 10 PSI▲ = 20 PSI✛ = 40 PSIAOC-70OIL P MULTIPLIER5432150 100 200300400 500OIL VISCOSITY - SSUDe-rate cooler performance by 10%when used in 50Hz service.OIL P MULTIPLIEROIL321.51.8P CORRECTION CURVEOIL P CORRECTION CURVE.650 60 80 100 150 300 400 500OIL VISCOSITY - SSU

C V Viscosity CorrectionOILSAE 5 SAE 10 SAE 20 SAE 30 SAE 40Average 110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°FOil Temp °F 40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F100 1.14 1.22 1.35 1.58 1.77150 1.01 1.05 1.11 1.21 1.31200 .99 1.00 1.01 1.08 1.10250 .95 .98 .99 1.00 1.00AOC-08 Model OnlyOne PassHORSEPOWER REMOVED IN COOLER1.51● ■.9.8.7.61.5 2 2.5 3 4 5 6 7 8 10 15 20OIL FLOW - GPM8.3111.123/4" NPT,#12 SAE,7.50or BSPP (2-PLACES).34 DIA. HOLE (BOTH SIDES)9.4112.259.19AIRFLOW1.502.31AIR COOLED AOCTwo PassHORSEPOWER REMOVED IN COOLER1.51.9●■▲.8.7.6.9 1 1.5 2 2.5 3 4 5 6 7 8 9OIL FLOW - GPM8.3113.12.34 DIA. HOLE (BOTH SIDES)9.414.003.801/2" NPT,#8 SAE,or BSPP(2-PLACES)9.50AIRFLOW7.501.502.31Four PassHORSEPOWER REMOVED IN COOLER1.51.9.8.7● ■ ▲.6.4 .5 .6 .7 .8 .9 1 1.5 2 2.5 3 4 5OIL FLOW - GPMSpecificationsElectric Motor DataMODELAOC-08MOTOR POWER1/30115/230 VOLT115 VOLT230 VOLT50/60 Hz1.1 Amps Full Load.7 Amps Full LoadTYPETEAO8.31RPM300013.501/2" NPT,#8 SAE,or BSPP(2-PLACES)AOC.34 DIA. HOLE (BOTH SIDES)1.509.41 1.502.31BEARINGSB-BALL S-SLEEVESTHERMALOVERLOADYESwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 76.002.839.50AIRFLOWSHIPPINGWEIGHT (lbs.)127.50dB(A) 3 FT.70

FLUID COOLING | <strong>Industrial</strong> AO SeriesFEATURESn Young Interchange – OCHn Adjustable Louversn Medium Flow Ratesn Moderate Heat Removaln One or Two PassnFluid Power SystemsAIR COOLED AO/AORnGear DrivesnInjection Molding MachinesnMachine ToolsnTorque ConvertersnHydraulic PressesOPTIONSSAE & Metric ConnectionsRelief BypassFoot BracketsCorrosive ResistantMarine CoatingRatingsOperating Pressure - 300 psiTest Pressure - 300 psiOperating Temperature - 400° FMaterialsTubes CopperFins AluminumTurbulators SteelFan Blade Aluminum with steel hubFan Guard Zinc plated steelCabinet Steel with baked enamel finishManifolds SteelConnections S t e elWeightsMODELNet Weight (lbs)AO-5 47AO-10 62AO-15 72AO-20 86AO-25 120AO-30 135AO-35 160AO-40 1858One Pass (Medium to High Oil Flows)Model Number Flow Range GPM (USA)AOR - 5-1 2 - 80AOR - 10-1 3 - 80AOR - 15-1 4 - 80AOR - 20-1 5 - 80AOR - 25-1 6 - 100AOR - 30-1 7 - 100AOR - 35-1 8 - 112AOR - 40-1 9 - 118How to OrderAOModelSeriesAOAOR-IncludesBypass–Model SizeSelectedTwo Pass (Low to Medium Oil Flows)Model Number Flow Range GPM (USA)AOR - 5-2 2 - 25AOR - 10-2 2 - 30AOR - 15-2 2 - 30AOR - 20-2 2 - 40AOR - 25-2 2 - 40AOR - 30-2 2 - 40AOR - 35-2 3 - 40AOR - 40-2 4 - 40Number of Passes*Blank - No Bypass1 - One Pass2 - Two Pass*ADD FOR AOR MODELS ONLY: Relief Bypass Setting & Number of Passes–ConnectionTypeBlank - NPTS - SAEM - MetricTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.comRelief BypassSetting*30-30 psi60 - 60 psiOne PassTwo PassFoot MountedBracketsBlank - NoBracketsFB - Foot BracketsOilOil ININ– –– –Specify MotorRequiredSingle PhaseSingle Phase Expl. ProofThree PhaseThree Phase 575 VoltThree Phase Expl. ProofOilOUT OilOUTOilOUT OilOUTOilOil ININ

SpecificationsElectric motor & Fan data*ModelSoundFullCFM dB(A)**HorseVolts Phase LoadNemaPowerHz RPM Type Circuitat 7 ft.AmpsFrameThermalOverloadBearingB-BalS-SleeveAO-5401/487 Sound 68 1/12 110/115 1 1.2/1.2 Full 50/601400/1700 TEAO A48No Bearing494 70 1/4 208-230/460 3 1.4-1.3/.65 60 1725 TEFC DBCFM dB(A)**HorseVolts Phase LoadNemaThermalHz RPM Type CircuitB-BalModelat Sound Power7 ft.Amps FullFrameOverload S-Sleeve Bearing576/700 68 1/12 110/115 1 1.2/1.2 50/60AO-1048 1400/1700 TEAO ANoBAO-5401/487 CFM dB(A)**Horse710 68 70 1/12 1/4 208-230/460 110/115 Volts Phase LoadNemaThermal13 1.4-1.3/.65 1.2/1.2 50/60 Hz 1400/1700 RPM1725 TEAO Type CircuitB-BalModelPowerat 7 ft.AmpsFrameTEFC A48D Overload No S-Sleeve494 70 1/4 208-230/460 3 1.4-1.3/.65 60 1725 TEFC DB824/1000 69 AO-15 AO-5401/487 68 1/12 110/115 1 1.2/1.2 50/601400/1700 TEAO A576/700 1015 494 68 71 70 1/12 1/4 208-230/460 110/115 1 3 1.4-1.3/.65 1.2/1.2 50/60 48AO-1048 1400/1700 1725 TEAO TEFC ADNoBNoB710 70 1/4 208-230/460 3 1.4-1.3/.65 60 1725 TEFC D576/700 70 68 1/12 1/6 115/208-230 110/115AO-20 15551 4/2.1-2 1.2/1.2 50/60 TEFC CAO-1048 1400/1700 TEAO A1725NoB824/1000AO-15 710 69 70 72 1/12 1/4 208-230/460 110/115 13 1.4-1.3/.65 1.2/1.2 50/60481400/1700 1725 TEAO TEFC A DNoB1015 71 1/4 208-230/460 3 1.4-1.3/.65 60 1725 TEFC D824/1000 69 72 1/12 115/208-230 110/115 1 1.2/1.2 4.6/2.2 50/60AO-25 22401/660 CAO-15481400/1700 TEAO A70 1140 TEFC73 1/6 115/208-230AO-20 15551 1.3-1.2/.6 4/2.1-2 48 CNoB1015 71 1/4 208-230/460 3 1.4-1.3/.65 60 1725 1725 TEFC DNoB72 1/4 208-230/460 3 1.4-1.3/.65 60 TEFC D70AO-30 3100751/6 115/208-2301/65.2/2.7-2.6AO-20 15551 4/2.1-2 6060 48TEFC C1140 TEFC76 115/208-230 1.3-1.2/.6 4.6/2.21725AO-25 22401/660 48CNoB72 1/4 208-230/460 3 1.4-1.3/.65 601140 TEFC TEFC DNoB73 208-230/460 1.3-1.2/.6 D72 76115/208-230 1 AO-358/4.2-4 4.6/2.2AO-25 2240 43701/65677 AO-30 3100751/6115/208-230 160 48C5.2/2.7-2.61140 TEFC2.5-2.4/1.2CNoB73 208-230/460 3 1.3-1.2/.6 60 48 1140 TEFC DNoB76 208-230/460 3 1.3-1.2/.6 D788/4.2-4AO-30 AO-40 31007554501/6115/208-230 1 5.2/2.7-2.6C607948 115/208-2305611140 TEFCAO-35 2.5-2.4/1.2 8/4.2-4CNoB76 208-230/460 3 1.3-1.2/.6 D437060 5677 208-230/4601140 TEFCNoB3 2.5-2.4/1.2D*Published electrical ratings 76 are approximate, and 115/208-230 may vary because 1AO-35 of motor 8/4.2-4 brand. Actual ratings are on motor nameplate.C4370 78115/208-230 160 56**Catalog dB(A) sound levels are at seven (7) feet. dB(A) sound levels increase 8/4.2-4CAO-40 545077 208-230/4601140 TEFCNoB3 2.5-2.4/1.279by six (6) dB(A) for halving this distance and decrease by six (6) dB(A) for doubling this distance.360 56 D1140 TEFC No B208-230/4602.5-2.4/1.2DSound 78115/208-230 1FullBearingThermalModel CFM dB(A)**Horse8/4.2-4Power Volts Phase LoadNemaCAO-40 545079360 56 1140 TEFC NoHz RPM Type CircuitB-Bal B208-230/4602.5-2.4/1.2at 7 ft.AmpsFrameDExplosion Proof Motors (Class I GP.D & Class II GP.F, G)*Overload S-Sleeve68115/230 1 5.8/2.9CAO-5 494 Sound 701/4208-230/460 3 1.4-1.3/.65 Full 60 48 1725 FCDYes Bearing BModel CFM dB(A)**Horse68115/230 Volts Phase LoadNemaThermal1 5.8/2.9 Hz RPM Type CircuitB-BalAO-10C710 at Sound Power770ft. 1/4Amps FullFrame208-230/460 3 1.4-1.3/.65 60 48 1725 FCOverloadDYes S-Sleeve Bearing BModel CFM dB(A)**Horse68115/230 Volts Phase 1 5.8/2.9 LoadNemaThermalHz RPM Type Circuit CB-BalAO-5 49469 Power 115/230 5.8/2.9AO-15at C1015 70 7 ft. 1/471 1/4 208-230/460 3 1.4-1.3/.65 Amps 60 Frame 48 1725 FC208-230/460 1.4-1.3/.65 60 48 1725 FCD Overload Yes S-Sleeve BDYesB68115/230 1 5.8/2.9AO-10CAO-5 710 494115/230 1 5.8/2.9AO-20C155570 1/4 1/472 1/4208-230/460 3 1.4-1.3/.65 60 60 48 48 1725 1725 FC FCYes208-230/460 3 1.4-1.3/.65 60 48 1725 FCDYesBDYesB69 68115/230 115/230 1 5.8/2.9 5.8/2.9AO-15 AO-10C1015 71072 1/4 115/230 1 6.8/3.4 60 48 1725 FCAO-25C Yes224071 70 1/473 1/3208-230/460 208-230/460 3 1.4-1.3/.65 1.4-1.3/.65 60 48 1725 FC208-230/460 3 1.8-1.6/.8 60 56 1140 FCDYesBDYesB70 69115/230 115/230 1 5.8/2.9 5.8/2.9AO-20 AO-15C1555 101575 1/4 115/230 1 6.8/3.4 60 48 1725 FCAO-30C Yes310072 71 1/476 1/3208-230/460 208-230/460 3 1.4-1.3/.65 1.4-1.3/.65 60 48 1725 FC208-230/460 3 1.8-1.6/.8 60 56 1140 FCDYesBDYesB72 70115/230 115/230 1 6.8/3.4 5.8/2.9AO-25 AO-20C2240 155576 1/3 115/230 1 8/4 60 56 1140 FCAO-35C Yes437073 72 1/477 1/2208-230/460 208-230/460 3 1.4-1.3/.65 60 48 1725 FC1.8-1.6/.8208-230/460 3 2.5-2.4/1.2 60 56 1140 FCDYesBDYesB75 72115/230 115/230 1 6.8/3.4 6.8/3.4AO-30 AO-25C3100 224078 1/3 115/230 1 8/4 60 56 1140 FCC YesAO-40 545076 73 1/379 1/2208-230/460 208-230/460 3 1.8-1.6/.8 1.8-1.6/.8 60 56 1140 FC208-230/460 3 2.5-2.4/1.260 56 1140 FCDYesBDYesB76 75115/230 115/230 1 6.8/3.4 8/4AO-35 AO-30C4370 310077 76 1/2 1/3208-230/460208-230/460 3 2.5-2.4/1.2 1.8-1.6/.8 60 60 56 56 1140 1140 FC FCD Yes YesB78 76115/230 115/230 1 8/4 8/4AO-40 AO-35C5450 437079 77 1/2 1/2208-230/46032.5-2.4/1.22.5-2.4/1.2 60 60 56 56 1140 1140 FC FCD Yes YesBSound 78FullBearingModel CFM dB(A)**Horse115/230 1 8/4Volts Phase LoadNemaC*Published AO-40 electrical 5450 ratings 79 are approximate, 1/2 and 208-230/460 may vary because 3 of motor Hz RPM Type CircuitThermal B-BalPower2.5-2.4/1.2 brand. Actual 60 ratings are 56 on motor nameplate. 1140 FCDYesBat 7 ft.AmpsFrameOverload S-SleeveAO-5 494 70 1/4 575 3 .52 60 48 1725 TEFC D No B575 SoundFullBearingAO-10 Volt 710 70 1/4 575 3 .52 60 48 1725 TEFC D No BModel AO-15CFM dB(A)**Horse1015 71 1/4Volts575Phase LoadNema3 .52Hz60 48RPM1725TypeTEFCCircuitThermal B-BalPowerat Sound 7 ft.Amps FullFrameD Overload No S-Sleeve Bearing BAO-20AO-51555494 70721/41/45755753 .52.526060484817251725TEFCTEFCD NoNoBModel CFM dB(A)**HorseVolts Phase LoadNemaHz RPM Type CircuitThermal B-BalPowerAO-10AO-25 2240710at7073 7 ft.1/41/25755753 AmpsFrame.52.886060485617251140TEFCTEFCD OverloadNoNo S-SleeveBAO-15AO-30 AO-5 10153100 494 7176 70 1/41/2 1/4 575 575 3 .52.88 .52 60 60 4856 48 17251140 1725 TEFC TEFC D No No BAO-20AO-35 AO-10 15554370 710 7277 70 1/41/2 1/4 575 575 3 .52.88 .52 60 60 4856 48 17251140 1725 TEFC TEFC D No No BAO-25 AO-40 AO-15 2240 5450 1015 73 79 71 1/2 1/2 1/4 575 575 3 .88 .88 .52 60 60 56 56 48 1140 1725 TEFC TEFC D No No BAO-30 AO-20 3100 1555 76 72 1/2 1/4 575 575 3 .88 .52 60 60 56 48 1140 1725 TEFC TEFC D No No BAO-35 AO-25 4370 2240 77 73 1/2 1/2 575 575 3 .88 .88 60 60 56 56 1140 1140 TEFC TEFC D No No BAO-40AO-305450310079761/21/2575575 3.88.886060565611401140TEFCTEFC DNoNo BAO-35 4370 77 1/2 575 3 .88 60 56 1140 TEFC D No BAO-40 5450 79 1/2 575 3 .88 60 56 1140 TEFC D No B1/21/21/21/21/21/2*D Squirrel Cage**Catalog dB (A) sound levels at seven (7) feet. dB (A) sound levels increase by six (6) dB (A) for halving this distance, and decrease by six (6) dB (A) for doubling this distance.AIR COOLED AO/AORLubrication NotesCaution: Do not over oil or over grease. Ball bearings – No grease needed at start up. Grease as follows:5,000 Hours/Year 5 Year Grease IntervalContinuousNormal Applications2 YearsSeasonal ServiceMotor is idle for 6 months or more1 YearContinuousHigh ambients, dirty or moist locations, high vibration6 MonthsAOwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 9

FLUID COOLING | <strong>Industrial</strong> AOVH SeriesFEATURESn High Performance AOn High Flow Ratesn Compactn One or Two PassAIR COOLED AOVHnFluid Power SystemsnGear DrivesnInjection Molding MachinesnMachine ToolsnTorque ConvertersnHydraulic PressesOPTIONSInternal SAE Straight ThreadsSAE & Metric ConnectionsRelief BypassCorrosive ResistantMarine Coating12RatingsOperating Pressure - 300 psiOperating Temperature - 400° FTwo Pass Only (Low to Medium Oil Flows)Model NumberAOVHFlow Range GPM (USA)AOVHR - 5-2 4 - 50AOVHR - 10-2 4 - 60AOVHR - 15-2 4 - 60AOVHR - 20-2 4 - 80AOVHR - 25-2 4 - 80AOVHR - 30-2 4 - 80AOVHR - 35-2 6 - 80AOVHR - 40-2 8 - 80How to OrderModelSeriesAOVHAOVHR-IncludesBypass–Model SizeSelectedMaterialsTubes CopperFins AluminumTurbulators SteelFan Blade Aluminum with steel Oil hubFan Guard Zinc plated steel OUTCabinet Steel with baked enamel finishManifolds SteelConnections S t e elAOVHR SeriesNumber of Passes*Blank - No Bypass2 - Two Pass Only*ADD FOR AOVHR MODELS ONLY: Relief Bypass Setting & Number of Passes–TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.comOilINConnectionTypeBlank - NPTS - SAEM - MetricOilOUTOilIN– ––Relief BypassSetting*30-30 psi60 - 60 psiWeightsMODELNet Weight (LBS)AOVHR - 5 67AOVHR - 10 78AOVHR - 15 90AOVHR - 20 110AOVHR - 25 157AOVHR - 30 190AOVHR - 35 315AOVHR - 40 350Specify MotorRequiredSingle PhaseSingle Phase Expl. ProofThree PhaseThree Phase 575 VoltThree Phase Expl. Proof

DimensionsModel A B C D EF G K LM MNet WtN P QNPT SAE(Lbs.)AOVH-5 7.40 14.81 5.90 11.81 19.93 9.19 8.31 3.84 7.69 #24 SAE 5.84 11.69 16.81 67AOVH-10 9.50 19.00 6.56 13.12 19.49 10.50 12.50 4.44 8.88 1-1/2” 1-7/8-12UN 7.94 15.88 21.00 78AOVH-15 10.19 20.38 7.87 15.75 19.49 13.12 13.88 5.75 11.50 Thread 8.62 17.25 22.38 90AOVH-20 11.91 23.81 9.19 18.38 19.49 15.75 17.19 7.00 14.00 10.28 20.56 25.81 110AOVH-25 13.34 26.68 11.81 23.62 23.58 21.00 20.19 9.62 19.25 #32 SAE 11.78 23.56 28.68 157AOVH-30 15.81 31.62 13.78 27.56 23.33 24.94 25.12 11.59 23.19 2” 2-1/2-12UN 14.25 28.50 33.62 190AOVH-35 16.90 33.81 15.09 30.19 23.06 27.56 27.31 12.90 25.81 Thread 15.34 30.69 35.81 315AOVH-40 20.81 41.62 18.37 36.75 23.06 34.12 35.12 16.19 32.38 19.25 38.50 43.62 350NOTE: All dimensions in inches.Fan Rotation Clockwise/Facing Motor ShaftAIR COOLED AOVHAIRFLOWInstallation Piping DiagramOilINOne Oil PassOilOUTTwo Oil Passes*See dimension chart for NPT or optional internal SAE connection size.OilOUTOilINCap<strong>Air</strong>OilOUTOilOUTOilINLubrication NotesCaution: Do not over oil or over grease.Ball bearings – No grease needed at start up. Grease as follows:Continuous <strong>Air</strong>Normal ApplicationsSeasonal ServiceMotor is idle for 6 months or moreContinuousHigh ambients, dirty or moist locations,high vibrationAOVH5,000 Hours/Year 5 Year Grease Interval2 Years1 Year6 Monthswww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 13

AIR COOLED AOVHPerformance CurvesOne Pass Oil (AOVH)HORSEPOWER TO BE REMOVEDAO V H S E R IE S 1 P AS S100AO V H-4 0 + + AO V H-35 AO V H -30+AO V H -25 +AO V H -20 +AO V H -15 +10AO V H -10 +AO V H -5 +OIL P = 5 PSI = 10 PSI = 15 PSI+ = 20 PSI1110100FLOW (GPM)1000Selection ProcedurePerformance Curves are based on 50SSU oil leaving the cooler 40°F higherthan the ambient air temperature used for cooling.This is also referred to asa 40°F approach temperature.STEP 1 Determine the Heat Load.This will vary with different systems,but typically coolers are sized to remove 25 to 50% of the inputnameplate horsepower.(Example: 100 HP Power Unit x .33 = 33 HP Heat load.)If BTU/Hr. is known: HP = BTU/Hr2545STEP 2 Determine Approach Temperature. Desired oil leaving cooler°F – Ambient air temp. °F = Actual ApproachSTEP 3 Determine Curve Horsepower Heat Load. Enter theinformation from above:Horsepower heat load x40 x Cv= Curve HorsepowerActual ApproachSTEP 4 Enter curves at oil flow through cooler and curve horsepower.Any curve above the intersecting point will work.STEP 5 Determine Oil Pressure Drop from Curves:l = 5 PSI; n = 10 PSI; s = 15 PSI; ; = 20 PSI. Multiplypressure drop from curve by correction factor found in oilcorrection curve.Desired Reservoir TemperaturePTwo Pass Oil (AOVH Vor H S E RAOVHR)IE S 2 P AS SReturn Line Cooling: Desired temperature is the oil temperature leaving thecooler. This will be the same temperature that will be found in the reservoir.14HORSEPOWER TO BE REMOVED10010AOVH1110+++ +FLOW (GPM)AO V H-1 5AO V H-1 0AO V H-5AO V H-4 0AO V H-3 5AO V H-3 0AO V H-2 5AO V H-2 0TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com++++100OIL P = 5 PSI = 10 PSI = 15 PSI= 20 PSI+1000Off-Line Recirculation Cooling Loop: Desired temperature is the oiltemperature entering the cooler. In this case, the oil temperature changemust be determined so that the actual oil leaving temperature can be found.Calculate the oil temperature change (oil T) with this formula:Oil T = (BTU’s/Hr.) / (GPM Oil Flow x 210).To calculate the oil leaving temperature from the cooler, use this formula:Oil Leaving Temp. = Oil Entering Temp – Oil T.This formula may also be used in any application where the only temperatureavailable is the entering oil temperature.Oil Pressure Drop: Most systems can tolerate a pressure drop through theheat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.Care should be taken to limit pressure drop to 5 PSI or less for case drainapplications where high back pressure may damage the pump shaft seals.OIL P MULTIPLIER5432OILP CORRECTION CURVE150 100 200300400 500OIL VISCOSITY - SSUOil TemperatureTypical operating temperatureranges are:Hydraulic Motor Oil 110° - 130°FHydrostatic Drive Oil 130° - 180°FBearing Lube Oil 120° - 160°FLube Oil Circuits 110° - 130°F

C V Viscosity CorrectionOILSAE 5 SAE 10 SAE 20 SAE 30 SAE 40 50-50Average 110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°F Ethylene GlycolOil Temp °F 40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F & Water100 1.14 1.22 1.35 1.58 1.77 1.11150 1.01 1.05 1.11 1.21 1.31 1.02200 .99 1.00 1.01 1.08 1.10 .96250 .95 .98 .99 1.00 1.00 .95SpecificationsElectric motor & Fan data*SoundFullThermalModel CFM dB(A)** HorseNemaBearingLoadVolts Phase HzRPM Type Circuitat 7 ft.PowerAmpsFrameOverloadB-BallS-Sleeve78085 1/2 115/208-230 1 7.4/3.9-3.7 60 48 3450 TEFC C No BAOVH-5SoundFullThermalModel CFM dB(A)** Horse 208-230/460 3 2.1-2./1.Load60 Nema 48 3450 TEFC D No Bearing BVolts Phase HzRPM Type Circuitat 7 ft.PowerAmpsFrameOverloadB-Ball111085 1/2 115/208-230 1 7.4/3.9-3.7 60 48 3450 TEFC A No S-Sleeve BAOVH-10208-230/460 3 2.1-2./1. 60 48 3450 TEFC D78085 1/2 115/208-230 7.4/3.9-3.7 60 48 3450 TEFC C No AOVH-5159091 1/2 115/208-230 208-230/460 1 7.4/3.9-3.7 2.1-2./1. 60 48 3450 TEFC A No BAOVH-15111085 1/2208-230/460 3 2.1-2./1. 60 48 3450 TEFC D115/208-230 7.4/3.9-3.7 60 48 3450 TEFC A No AOVH-10216891 1/2 115/208-230 208-230/460 13 7.4/3.9-3.7 2.1-2./1. 60 48 3450 TEFC D C No BAOVH-20159091 1/2208-230/460115/208-23031 7.4/3.9-3.72.1-2./1. 6060484834503450TEFCTEFCDA No BAOVH-15300081 1 115/208-230 208-230/460 1 12.4/6.5-6.2 2.1-2./1. 60 56 48 1725 3450 TEFC C No BAOVH-25208-230/460 3 3.6-3.4/1.7 60216891 1/2 115/208-230 7.4/3.9-3.7 6056 1725 TEFC D48 3450 TEFC No AOVH-20409584 1 115/208-230208-230/4601 12.4/6.5-6.22.1-2./1. 6060485634501725TEFCTEFC C No BAOVH-30300081 1208-230/460 3 3.6-3.4/1.7 60 56 1725 TEFC D115/208-230 1 12.4/6.5-6.2 60 56 1725 TEFC C No BAOVH-25NOT AVAILABLE 208-230/460 13 3.6-3.4/1.7 60 56 1725 TEFC AOVH-355921 89409584 31 208-230/460 115/208-230 39.-8.6/4.3 60 182T 1725 TEFC D No B1 12.4/6.5-6.2 60 56 1725 TEFC C No AOVH-30NOT AVAILABLE 208-230/460 13 3.6-3.4/1.7 60 56 1725 TEFC AOVH-409609 91NOT AVAILABLE3 208-230/460 3 9.-8.6/4.3 60 182T 1725 TEFC D No B1AOVH-355921 89 3 208-230/460 39.-8.6/4.3 60 182T 1725 TEFC D No B**Published electrical ratings are NOT approximate, AVAILABLE and may vary because of motor 1 brand. Actual ratings are on motor nameplate.AOVH-409609 91 3 208-230/460 3 9.-8.6/4.3 60 182T 1725 TEFC D No B**Catalog dB(A) sound levels are at seven (7) feet. dB(A) sound levels increase by six (6) dB(A) for halving this distance and decrease by six (6) dB(A) for doubling this distance.AIR COOLED AOVHSoundFullThermalModel CFM dB(A)** HorseNemaBearingLoadVolts Phase HzRPM Type Circuitat 7 ft.PowerAmpsFrameOverloadB-BallS-Sleeve115/230 1 7.4/3.7780 Sound 85 1/2Full 60 48 3450 FCCAOVH-5YesThermalModel CFM dB(A)** HorseNemaBearing B208-230/460 3 2.4-2.2/1.1LoadDVolts Phase HzRPM Type Circuitat 7 ft.PowerAmpsFrameOverloadB-Ball115/230 1 7.4/3.7CAOVH-10 1110 85 1/260 48 3450 FCYes S-Sleeve B208-230/460 115/23031 2.4-2.2/1.1 D7.4/3.7780 85 1/260 48 3450 FCCAOVH-5Yes B208-230/460 115/230 31 2.4-2.2/1.1 7.4/3.79D CAOVH-15 1590 91 1/260 48 3450 FCYes B208-230/460115/23031 2.4-2.2/1.1 D7.4/3.7CAOVH-10 1110 85 1/260 48 3450 FCYes B208-230/460 115/230 31 2.4-2.2/1.1 7.4/3.79D CAOVH-20 2168 91 1/260 48 3450 FCYes B208-230/460 115/230 31 2.4-2.2/1.17.4/3.79D CAOVH-15 1590 91 1/260 48 3450 FCYes B208-230/460 115/230 13 2.4-2.2/1.1 12.4/6.2D C YesAOVH-25 3000 81 160 56 1725 FCB230/460 3115/230 13.4/1.7 D7.4/3.79NoAOVH-20 2168 91 1/260 48 3450 FC4095 84 1 208-230/460 115/230 13 2.4-2.2/1.1 12.4/6.2C YesAOVH-3060 56 1725 FCB230/460115/230 13 3.4/1.7 D12.4/6.2CNoYesAOVH-25 3000 81 NOT AVAILABLE 160 56 1725 FCB230/460 1 3.4/1.7 AOVH-355921 89 3 230/4604095 84 1 115/230 138.6/4.3 60 182T 1725 FC D No B12.4/6.2C YesAOVH-30NOT AVAILABLE 60 56 1725 FCB230/460 313.4/1.7 AOVH-408.6/4.3 60 182T 1725 FC D No B9609 91 NOT AVAILABLE 3 230/460 13AOVH-35 5921 89 3 230/460 38.6/4.3 60 182T 1725 FC D No BNOT AVAILABLE 1AOVH-408.6/4.3 60 182T 1725 FC D No B9609 91 3 230/460 3Explosion Proof Motors (Class I GP.D & Class II GP.F, G)**Published Ball bearings: electrical No grease ratings needed are approximate, at start up. Grease and may as follows vary because : of motor brand. Actual ratings are on motor nameplate.Caution: Do not over oil or over grease. = CL. 1,5,000GP. DHrs./Yr.only TEFC = Totally5 Yr.enclosed,Grease Intervafan cooledlFC = Fan cooled C = Capacitor start - Induction run D = Squirrel cageContinuousBall bearings:Normal ApplicationsNo grease needed at2startYr. Greaseup. GreaseIntervaaslfollows : CL. 1, GP. D onlySeasonal 5,000 Hrs./Yr. Service 5 Yr. Grease Interva l Caution: TEFC = Totally Do not enclosed, over oil or fan over cooled grease.Motor Continuous is idle for 1 Yr. Grease Interva l FC = Fan coole dNormal 6 months Applications or more 2 Yr. Grease Interva l C. CL. Capacitor 1, GP. D start—Induction only runSeasonal Continuous ServiceHigh ambients, Motor is idle dirty formoist 6 Month 1 Yr. Grease Interva l lD. TEFC Squirrel = Totally Cage enclosed, fan cooledFC = Fan coole dlocations, 6 months high or vibratio more nContinuousHigh ambients, dirty or moist 6 Month Grease Interva lC. Capacitor start—Induction runD. Squirrel Cagelocations, high vibratio nAOVHwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 15

FLUID COOLING | <strong>Industrial</strong> AOF SeriesFEATURESn AO with Removable Filtern Adjustable Louversn Medium Flow Ratesn Moderate Heat Removaln One or Two Pass OptionAIR COOLED AOFnFluid Power SystemsnGear DrivesnInjection Molding MachinesnMachine ToolsnTorque ConvertersnHydraulic PressesOPTIONSSAE & Metric ConnectionsBuilt-in Bypass ReliefFoot Mounting BracketsCorrosion Resistant/MarineDuty CoatingRatingsOperating Pressure - 300 psiTest Pressure - 300 psiOperating Temperature - 400° FReplacement <strong>Air</strong> FiltersMODELFiberglassDisposable TypePart NumberAluminumWashable TypePart NumberAOF - 5 65528 65559AOF - 10 65530 65560AOF - 15 65507 65561AOF - 20 65532 65562AOF - 25 65519 65563AOF - 30 65535 65564AOF - 35 65537 65565AOF - 40 65543 65566MaterialsTubes CopperFins AluminumTurbulators SteelFan Blade Aluminum with steel hubFan Guard Zinc plated steelCabinet Steel with baked enamel finishManifolds and Connection Pipes S t e elWeightsMODELNet Weight (lbs)AOF-5 60AOF-10 70AOF-15 80AOF-20 95AOF-25 125AOF-30 140AOF-35 165AOF-40 23016How to OrderAOFModelSeriesAOF - No BypassAOFR - IncludesBypass–Model SizeSelectedNumber of Passes*Blank - No Bypass1 - One Pass2 - Two Pass*ADD FOR AOFR MODELS ONLY: Relief Bypass Setting & Number of Passes–ConnectionTypeBlank - NPTS - SAEM - MetricTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com– –– –Relief BypassSetting*30-30 psi60 - 60 psiFoot MountedBracketsBlank - NoBracketsFB - Foot BracketsSpecify MotorRequiredSingle PhaseSingle Phase Expl. ProofThree PhaseThree Phase 575 VoltThree Phase Expl. Proof

DimensionsModel A B C D E F G H J K LMNPTMSAEN P Q R S TAOF-5 7.40 14.81 5.90 11.81 17.50 9.19 8.31 6.47 12.94 3.78 7.69 1”#16 SAE5.84 11.69 10.06 1.09 3.92 —AOF-10 9.50 19.00 6.56 13.12 17.00 10.50 12.50 8.56 17.12 4.44 8.88 1” 1-5/16-12UN-2B 7.94 15.88 14.38 1.09 3.92 —AOF-15 10.19 20.38 7.87 15.75 17.62 13.12 13.88 9.25 18.50 5.75 11.50 1”Thread8.62 17.25 15.62 1.09 3.92 —AOF-20 11.91 23.81 9.19 18.38 19.62 15.75 17.91 10.90 21.81 7.00 14.00 1-1/4” 10.28 20.56 18.62 1.09 3.92 —AOF-25 13.34 26.68 11.81 23.62 20.68 21.00 20.19 12.40 24.81 9.62 19.25 1-1/4”#20 SAE11.78 23.56 21.62 1.09 3.92 —AOF-30 15.81 31.62 13.78 27.56 20.12 24.94 25.12 14.87 29.75 11.59 23.19 1-1/4” 1-5/8-12UN-2B 14.25 28.50 26.62 1.09 3.92 11.00AOF-35 16.90 33.81 15.09 30.19 21.25 27.56 27.31 15.97 31.94 12.90 25.81 1-1/4” Thread 15.34 30.69 28.88 1.09 3.94 11.00AOF-40 20.81 41.62 18.37 36.75 20.31 34.12 35.12 19.87 Oil 39.75 16.19 32.38 1-1/4” 19.25 38.50 37.00 1.18 3.87 13.25OUTInstallation Piping DiagramOne Oil PassOilOUTOilINTwo Oil PassesOilOUTFan Rotation Clockwise/Facing Motor Shaft<strong>Air</strong>1/2-13 UNC-284 Places8 Places onAO-30, 35 & 40(Top & Bottom)AIR COOLED AOFOilINCapOilIN*See dimension chart for NPT or optional internal SAE connection size.NOTE: All dimensions in inches.AIRFLOWOilOUT<strong>Air</strong>NOTE: MOTOR MOUNTING BRACKET ONAO-5 & AO-10 IS ROTATED 90°CapOilINLubrication NotesCaution: Do not over oil or over grease. Ball bearings – No grease needed at start up. Grease as follows:5,000 Hours/Year 5 Year Grease IntervalContinuousNormal Applications2 YearsSeasonal ServiceMotor is idle for 6 months or more1 YearContinuousHigh ambients, dirty or moist locations, high vibration6 MonthsAOFwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 17

Performance CurvesOne Pass Oil100AOF SERIES 1 PASSSelection ProcedurePerformance Curves are based on 50SSU oil leaving the cooler 40°F higherthan the ambient air temperature used for cooling.This is also referred to asa 40°F approach temperature.AIR COOLED AOFHORSEPOWER TO BE REMOVED101110 FLOW (GPM) ++++++++AOF-30AO-25AOF-20AOF-15AOF-10AOF-5100AOF-40AO-35OIL P = 5 PSI = 10 PSI = 15 PSI= 20 PSI+1000STEP 1 Determine the Heat Load.This will vary with different systems,but typically coolers are sized to remove 25 to 50% of the inputnameplate horsepower.(Example: 100 HP Power Unit x .33 = 33 HP Heat load.)If BTU/Hr. is known: HP = BTU/Hr2545STEP 2 Determine Approach Temperature. Desired oil leaving cooler°F – Ambient air temp. °F = Actual ApproachSTEP 3 Determine Curve Horsepower Heat Load. Enter theinformation from above:Horsepower heat load x40 x Cv= Curve HorsepowerActual ApproachSTEP 4 Enter curves at oil flow through cooler and curve horsepower.Any curve above the intersecting point will work.STEP 5 Determine Oil Pressure Drop from Curves:l = 5 PSI; n = 10 PSI; s = 15 PSI; ; = 20 PSI. Multiplypressure drop from curve by correction factor found in oilcorrection curve.Desired Reservoir TemperaturePTwo Pass OilAO F S E R IE S 2 P AS SReturn Line Cooling: Desired temperature is the oil temperature leaving thecooler. This will be the same temperature that will be found in the reservoir.HORSEPOWER TO BE REMOVED10010 +++++AO F - 40AO F -35AO F -30AO F -25AO F -20Off-Line Recirculation Cooling Loop: Desired temperature is the oiltemperature entering the cooler. In this case, the oil temperature changemust be determined so that the actual oil leaving temperature can be found.Calculate the oil temperature change (oil T) with this formula:Oil T = (BTU’s/Hr.) / (GPM Oil Flow x 210).To calculate the oil leaving temperature from the cooler, use this formula:Oil Leaving Temp. = Oil Entering Temp – Oil T.This formula may also be used in any application where the only temperatureavailable is the entering oil temperature.Oil Pressure Drop: Most systems can tolerate a pressure drop through theheat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.Care should be taken to limit pressure drop to 5 PSI or less for case drainapplications where high back pressure may damage the pump shaft seals.18AOF11 AO F -15AO F -10AO F -5OIL P = 5 PSI = 10 PSI = 15 PSI= 20 PSI10100FLOW (GPM)TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com++++OIL P MULTIPLIEROIL P CORRECTION CURVE5432150 100 200300400 500OIL VISCOSITY - SSUOil TemperatureTypical operating temperatureranges are:Hydraulic Motor Oil 110° - 130°FHydrostatic Drive Oil 130° - 180°FBearing Lube Oil 120° - 160°FLube Oil Circuits 110° - 130°F

C V Viscosity CorrectionOILSAE 5 SAE 10 SAE 20 SAE 30 SAE 40 50-50Average 110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°F Ethylene GlycolOil Temp °F 40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F & Water100 1.14 1.22 1.35 1.58 1.77 1.11150 1.01 1.05 1.11 1.21 1.31 1.02200 .99 1.00 1.01 1.08 1.10 .96250 .95 .98 .99 1.00 1.00 .95SpecificationsElectric motor & Fan data*SoundFullThermalModel CFM Sound dB(A)** HorseNemaBearingLoadThermalModel CFM dB(A)** HorseVolts PhaseFull HzLoadNema RPM Type Circuit Bearingat 7 ft.PowerAmpsFrameOverloadB-BallVolts Phase HzS-SleeveRPM Type Circuitat 7 ft.PowerAmpsFrameOverloadB-Ball465 115/208-230 1S-SleeveAOF-5Sound 68 1/6 4./2.1-2 FullC465 68 1/6 115/208-230 1 4./2.1-2 60 48 1725494 70 1/4 TEFCCNo B208-230/460 3 1.4-1.3/.65 D ThermalAOF-5 Model CFM dB(A)** HorseNemaBearingLoadVolts 60 48 1725494 70 1/4Phase HzTEFC No B208-230/460 3 1.4-1.3/.65RPM Type Circuit669 at 68 7 ft.Power1/6 115/208-230 1 4./2.1-2 AmpsFrameD OverloadB-BallCS-SleeveAOF-10669 60 48 1725 TEFC No B465 710 68 70 1/6 1/4 115/208-230 208-230/460 131.4-1.3/.65 4./2.1-2C DAOF-5 AOF-10710 956 69115/208-230 15.8/3-2.9 60 48 1725494 70 1/4 TEFC No B208-230/460 3 1.4-1.3/.65 D CAOF-15956 691/45.8/3-2.9 60 48 17251015TEFC No B669 68 71 1/6 115/208-230 208-230/460 131.4-1.3/.65 4./2.1-2C DAOF-10 AOF-151015 71 115/208-230 160 48 17251460 710 70 70 1/4 TEFC No B208-230/460 3 1.4-1.3/.65 7.8/4.1-3.9DCAOF-201/21460 707.8/4.1-3.960 48 1725 TEFC No B1555 956 69 72 115/208-230 208-230/460 135.8/3-2.9 2.1-2./1. C DAOF-15 AOF-201/21555 72 1/4115/208-230 1 2.1-2./1. 60 48 17251015 2160 71TEFC No B72208-230/460 3 1.4-1.3/.65 8/4.2-4DCAOF-251/22160 72208-230/460 3 8/4.2-460 56 1140 TEFC No B1460 2240 70 73 115/208-230 1 7.8/4.1-3.9 2.5-2.4/1.2 C DAOF-20 AOF-2556 11402240 2990 73 1/275115/208-230 1 2.5-2.4/1.2 60 48 1725 TEFC8/4.2-4No B1555 72 208-230/460 3 2.1-2./1. DAOF-301/22990 7560 56 TEFCCNo B208-230/460 311403100 76 2.5-2.4/1.2 AOF-302160 72115/208-230 1 8/4.2-4DCAOF-25 3100 76 1/2NOT AVAILABLE 208-230/460 3160 56 1140 TEFC No B2240 73 2.5-2.4/1.2 DAOF-354-3.8/1.9NOT AVAILABLE 208-230/460 56360 TEFC No B4370 771.0 115/208-230 11140DAOF-352990 754-3.8/1.9 8/4.2-4AOF-304370 771.0NOT AVAILABLE 160 56 TEFCC1/2No B208-230/460 311403100 76 2.5-2.4/1.2 DAOF-40565450 791.0 208-230/460 3 4-3.8/1.9 60 1140 TEFC No BAOF-40NOT AVAILABLE 1AOF-35565450 794-3.8/1.956208-230/460 360 TEFC No B4370 771.01140D**Published electrical ratings are approximate, NOT AVAILABLE and may vary because of motor 1 brand. Actual ratings are on motor nameplate.AOF-40565450 791.0 208-230/460 3 4-3.8/1.9 60 1140 TEFC D No B**Catalog dB(A) sound levels are at seven (7) feet. dB(A) sound levels increase by six (6) dB(A) for halving this distance and decrease by six (6) dB(A) for doubling this distance.AIR COOLED AOFExplosion Proof Motors (Class I GP.D & Class II GP.F, G)*SoundFullThermalModel CFM Sound dB(A)** HorseNemaBearingLoadThermalModel CFM dB(A)** HorseVolts PhaseFull HzLoadNema RPM Type Circuit Bearingat 7 ft.PowerAmpsFrameOverloadB-BallVolts Phase HzS-SleeveRPM Type Circuitat 7 ft.PowerAmpsFrameOverloadB-Ball68115/230 1 5.8/2.9S-Sleeve4941/468115/230 160 485.8/2.91725 FCCAOF-5SoundYes B70 208-230/460 3 1.4-1.3/.65 Full494701/460 481.4-1.3/.651725 FCC DAOF-5Thermal Yes BModel CFM dB(A)** HorseNemaBearing208-230/460 3Load68115/230 Volts Phase 1D7101/45.8/2.9 HzRPM Type Circuit CAOF-10at 7 ft.PowerAmpsFrameOverloadB-Ball68 70 115/230 60 48 1725 FCYes S-Sleeve B208-230/460 3 1.4-1.3/.767101/45.8/2.9DAOF-1070 68115/230 160 481.4-1.3/.761725 FCYes208-230/460 5.8/2.9494101569 1/4115/230 1 5.8/2.9 60 48 1725 FCCAOF-5Yes BAOF-1570 1/4 208-230/460 3 1.4-1.3/.65101569115/230 60 48 1725 FC D Yes B71 208-230/460 3 1.4-1.3/.65 5.8/2.9AOF-1571681/460 481.4-1.3/.651725 FCYes208-230/460115/230 17101555 1/45.8/2.9CAOF-10115/230 1 7.8/3.9CAOF-207060 48 1725 FCYes B1/2 208-230/460 3 1.4-1.3/.761555 70115/230 60 48 1725 FC D Yes B72 7.8/3.9AOF-20208-230/460 3 2.1-2./1.D1/260 48 1725 FCYes101569115/230 1208-230/460 2.1-2./1.5.8/2.9CAOF-1572 1/422401/2115/230 18./4. 60 48 1725 FC C Yes BAOF-2571 208-230/460 3 1.4-1.3/.6572 73 8./4.2240731/2115/230 2.5-2.4/1.2 60 56 1140 FC DCYes B230/460 3 AOF-252.5-2.4/1.2 60 56 1140 FCYes1555 7075230/460 115/230 1D31001/2115/230 7.8/3.9CAOF-208./4.AOF-301/2606048 1725 FC114075 7631001/2115/230 156 FCYesYesB72 208-230/460 3 230/460 2.1-2./1.2.5-2.4/1.2 8./4.CDAOF-306076 7256 1140 FCYes B2240NOT AVAILABLE 1/2230/460 115/230 312.5-2.4/1.2 8./4.D CAOF-25AOF-35734370 NOT 77 AVAILABLE 1.01 3.8/1.91140230/460 2.5-2.4/1.2 60 60 56 561140 FCYes B230/460 3 FC DNo AOF-354370 77 751.03.8/1.956 1140230/460 360 FC D No 3100NOT AVAILABLE 1/2115/230 18./4.CAOF-3060AOF-40765450 NOT AVAILABLE 1.01 3.8/1.9 60 56 561140 FCYes B230/460230/46031140 FC No 792.5-2.4/1.2DAOF-403.8/1.9 60 5654501.0230/4601140 FC D No B79 NOT AVAILABLE 1 AOF-35 = AOF 35 & 40, 4370 CL. 1, GP. D only 77 TEFC = 1.0 Totally enclosed, 3.8/1.91140230/460 fan cooled FC 3 = Fan cooled C = Capacitor 60 start 56 - Induction run D = Squirrel FC cageD No B*Published electrical ratings are NOT approximate, AVAILABLE and may vary because of motor 1 brand. Actual ratings are on motor nameplate.AOF-403.8/1.9 60 565450 Sound1.01140 FC D No B79230/460 3FullSoundFullThermalModel CFM dB(A)** HorseNemaBearingLoadThermalModel CFM dB(A)** HorseVolts Phase HzLoadNema RPM Type Circuit* OverloadBearing7 ft.PowerAmpsFrameB-Ball575 Volt SpecificationsVolts Phase HzS-SleeveRPM Typeat 7 ft.PowerAmpsFrameCircuit* OverloadB-BallAOF-5 494 70 1/4 575 3 .52 60 48 1725 TEFC D No S-Sleeve BAOF-5 AOF-10 494 710 Sound 70 70 1/4 1/4 575 575 3 Full .52 .52 60 60 48 48 1725 1725 TEFC TEFC D No No Thermal BModel AOF-10 AOF-15 CFM 1015 710 dB(A)** HorseNemaBearing70 71 1/4 1/4 575 575 LoadVolts Phase 3 .52 .52 Hz 60 60 48 48 RPM 1725 1725 TEFC Type TEFC Circuit*D No No at 7 ft.PowerAmpsFrameOverloadB-BallS-SleeveBAOF-15 AOF-20 1015 1555 71 72 1/4 1/2 575 .52 .80 60 48 1725 TEFC No AOF-5 494 70 1/4 575 3 .52 60 48 1725 TEFC D No BAOF-20 AOF-25 1555 2240 72 73 1/2 1/2 575 .80 .88 60 60 48 56 1725 1140 TEFC No AOF-10 710 70 1/4 575 3 .52 60 48 1725 TEFC D No BAOF-25 AOF-30 2240 3100 73 76 1/2 1/2 575 .88 .88 60 60 56 56 1140 1140 TEFC No No AOF-15 1015 71 1/4 575 3 .52 60 48 1725 TEFC D No BAOF-30 AOF-35 3100 4370 76 77 1/2 1.0 575 575 .88 1.6 60 60 56 56 1140 1140 TEFC No No AOF-20 1555 72 1/2 575 3 .80 60 48 1725 TEFC D No BAOF-35 4370 77 1.0 575 1.6 60 56 1140 TEFC No AOF-25 2240 73 1/2 575 3 .88 60 56 1140 TEFC D No BAOF-30 3100 76 1/2 575 3 .88 60 56 1140 TEFC D No BAOF-35 4370 77 1.0 575 3 1.6 60 56 1140 TEFC D No BCatalog dB (A) sound levels at seven (7) feet. dB (A) sound levels increase by six (6) dB (A) for halving this distance, and decrease by six (6) dB (A) for doubling this distance.AOFwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 19

FLUID COOLING | <strong>Industrial</strong> RM SeriesFEATURESn Mounts to Rear ofElectric Motor – TEFCn Utilizes Electric Motor Fan <strong>Air</strong> Flown Ideal for Case Drain Applicationsn Compact, Efficient Designn Low Flow & Heat RemovalAIR COOLED RMnMounts Behind Existing TEFC Motorfor Compact, Low Cost ApplicationnSAE, NPT or Metric ConversionnMounting Brackets IncludedMotor not included.RatingsOperating Pressure - 300 psiTest Pressure - 300 psiOperating Temperature - 350° FMaterialsTubes CopperFins AluminumTurbulators AluminumCabinet Steel with baked enamel finishFilter Stainless frame with washable mediaManifolds Copper; RM-08Steel; RM-19 & RM-24Connections Brass; RM-08Steel; RM-19 & RM-24Nameplate AluminumHow to Order - RM-08 Models OnlyRM – 0 8 –ModelSeriesModel SizeSelectedNumber ofPasses1 - 1 Pass2 - 2 Pass4 - 4 PassConnectionType1 - NPT2 - SAE3 - BSPPHow to Order - all models except RM-08 Size20RMRMModelSeries– –Model SizeSelectedNumber ofPasses1 - 1 Pass2 - 2 PassConnectionType1 - NPT2 - SAE3 - BSPPTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

DimensionsRM-08-1One Pass"IN"12.2511.127.38DIA9.193/4 NPT#12 SAE3/4 BSPP2 PLACES.25GASKET3.22AIR FLOWRM-08-2Two Pass13.127.38DIA4.009.411/2 NPT#8 SAE1/2 BSPP2 PLACES.25GASKET3.22AIR FLOW4.58.34 DIA HOLE1 EACH BRKTRM-08-4Four Pass9.4113.504.71BRACKETS ADJUST.75 & 1.75 DOWN& 1.OO UP FROMPOSITION SHOWN1/2 NPT#8 SAE1/2 BSPP2 PLACES.251.502.313.22COREGUARD5.33.34 DIA HOLE1 EACH BRKT9.414.71"IN"3.83BRACKETS ADJUST.75 & 1.75 UP OR 1.00 DOWNFROM POSITION SHOWN1.502.31COREGUARDAIR COOLED RM7.38DIA6.009.41GASKETAIR FLOW5.33.34 DIA HOLE1 EACH BRKT9.414.71"IN"2.83BRACKETS ADJUST.75 & 1.75 UP& 1.00 DOWN FROMPOSITION SHOWN1.502.31COREGUARDRM-19-1, RM-24-1One Pass1/2 NPTFOR OPTIONALTEMP. SENSORAKMBELDIANDIAF (2 PLACES)IN / OUTGASKET &MTG PLATED.25AIRFLOWCGAIR FILTERRM-19-2, RM-24-2Two PassKMBLDIANDIA1/2 NPTFOR OPTIONALTEMP. SENSOROUTINEDF (2 PLACES)A.25GASKET &MTG PLATEAIRFLOWCGAIR FILTERJH.41 X 1.19 SLOT2.622 EACH BRKT 5.008.18J.41 X 1.19 SLOT2.622 EACH BRKT 5.00H 8.18ModelRM-19-1*RM-19-2*RM-24-1*RM-24-2*A B C D EFSAE NPT/BSPP SAE NPT/BSPP10.31 15.0013.62 16.50 5.1114.75 7.38 6.81 10.38 5.81 7.504.31 6.00#12 .75 3.05 4.1216.31 23.2519.62 24.75 5.8521.44 10.72 9.81 14.62 8.56 12.004.31 12.00Note: We reserve the right to make reasonable design changes without notice. All dimensions are in inches.GHJ K L MRMwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 21NNET WTS.16163131

Performance CurvesAIR COOLED RMHORSEPOWER REMOVED BY COOLER54321.51.8.6.5.4.33975 42186OIL P MULTIPLIEROIL P CORRECTION CURVE5432150 100 200300400 500OIL VISCOSITY - SSU.3 .4 .5 .6 .8 1 1.5 2 3 4 5 6 8 10 15 20 30 40OIL FLOW - GPM22Selection ProcedurePerformance Curves are based on 50SSU oil leaving the cooler 40°F higherthan the ambient air temperature used for cooling and 1800 RPM motorspeed. This is also referred to as a 40° approach temperature.STEP 1 Determine the Heat Load.This will vary with different systems,but typically coolers are sized to remove 25 to 50% of the inputnameplate horsepower.(Example: 100 HP Power Unit x .33 = 33 HP Heat load. For 1200RPM motors, multiply Heat Load by 1.5.)If BTU/Hr. is known: HP = BTU/Hr2545STEP 2 Determine Approach Temperature.Desired oil leaving cooler °F – Ambient air temp.°F = Actual ApproachSTEP 3 Determine Curve Horsepower Heat Load. Enter theinformation from above:Horsepower heat load x40 x Cv= Curve HorsepowerActual ApproachSTEP 4 Enter curves at oil flow through cooler and curve horsepower.Any curve above the intersecting point will work.STEP 5 Determine Oil Pressure Drop from Curves:l = 5 PSI; n = 10 PSI; s = 20 PSI. Multiply pressure drop fromcurve by correction factor found in oil P correction curve.RMTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.comDesired Reservoir TemperatureReturn Line Cooling: Desired temperature is the oil temperature leaving thecooler. This will be the same temperature that will be found in the reservoir.Off-Line Recirculation Cooling Loop: Desired temperature is the oiltemperature entering the cooler. In this case, the oil temperature changemust be determined so that the actual oil leaving temperature can be found.Calculate the oil temperature change (oil T) with this formula:Oil T = (BTU’s/Hr.) / (GPM Oil Flow x 210).To calculate the oil leaving temperature from the cooler, use this formula:Oil Leaving Temp. = Oil Entering Temp – Oil T.This formula may also be used in any application where the only temperatureavailable is the entering oil temperature.Oil Pressure Drop: Most systems can tolerate a pressure drop through theheat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.Care should be taken to limit pressure drop to 5 PSI or less for case drainapplications where high back pressure may damage the pump shaft seals.Oil TemperatureTypical operating temperature ranges are:Hydraulic Motor Oil 110° - 130°FHydrostatic Drive Oil 130° - 180°FBearing Lube Oil 120° - 160°FLube Oil Circuits 110° - 130°F

C V Viscosity CorrectionOILSAE 5 SAE 10 SAE 20 SAE 30 SAE 40Average 110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°FOil Temp °F 40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F100 1.14 1.22 1.35 1.58 1.77150 1.01 1.05 1.11 1.21 1.31200 .99 1.00 1.01 1.08 1.10250 .95 .98 .99 1.00 1.00Curve Model TEFC Motor Frame Sizes1 RM-08-1*2 RM-08-2*48-1843 RM-08-4*4 RM-19-1*213-2565 RM-19-2*6 RM-24-1*254-2867 RM-24-2*8 RM-24-1*324-3659 RM-24-2*AIR COOLED RMRMwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 23

FLUID COOLING | <strong>Mobile</strong> AOC SeriesAIR COOLED AOCFeaturesnnnnnnnnnnnLow AMP Draw MotorsRemote MountDoes Not Block MainEngine RadiatorLong Life Hydraulic MotorHeavy Duty Construction3/4” Tube SizeHeat Removal up to 160 HPOil Flows to 150 GPMDC or Hydraulic MotorsSAE Connections StandardHigh Performance <strong>Air</strong> Side Fin Design12 or 24 Volt MotorsOPTIONSBuilt-in Serviceable Bypass ValveNPT or BSPP or SAE ConnectionsHydraulic Motor DriveRatingsOperating Pressure 300 psiTest Pressure 300 psiOperating Temperature 350° FMaterialsTubes CopperFins AluminumTurbulators AluminumFan Blade (DC Motor) High Impact PlasticFan Blade (Hydraulic motor) Aluminum withsteel hubFan Guard (Hydraulic Motor) Steel with blackbaked enamel finishManifolds SteelConnections S t e elCabinet Steel with baked enamel finishFilter Stainless frame with washable mediaNameplate AluminumRelief Bypass Valve OptionMODEL DescriptionAOC-19 Available in either 30 psi or 60 psithru settings. 3/4”, external, all steelAOC-33 valve. May be removed for servicing.AOC-37 Available in either 30 psi or 60 psithru settings. 1-1/2”, external, all steelAOC-70 valve. May be removed for servicing.24How to OrderAOCAOCModelSeriesAOC - Standard– – – –Model SizeSelectedConnectionType*1 - NPT2 - SAE3 - BSPP*Other connection types available. Please consult factory for assistance.Relief BypassBlank - NoBypass30 - 30 psi60 - 60 psiSpecify MotorRequiredNM - No Motor4A - 12 Volt4B - 24 Volt9 - Hydraulic MotorTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

DimensionsAOC-19 thruAOC-33TEMP. SENSORAD1/2 NPTFOR OPTIONALTEMP. SENSORAD2.06* IN or OUT(OPTIONAL)AOC - 19 THROUGH AOC - 33AIR FLOW#8B C C#8 SAE"IN"SAEF ( 2 PLACES)JJE "OUT".41 X 1.19 SLOTG.41 X 1.19 SLOTGMMH 2.06* IN or OUT(OPTIONAL)PPAIRFILTERAIR FLOWAIRFILTERAIR FLOWHYDRAULIC MOTOR 12 or 24 VOLT DC MOTORAIR FLOWAIRFILTERAIRFILTERAOC-37 thruAOC-701/2 NPTFOR OPTIONALTEMP. SENSORAD"IN"2.06#8 SAE #8 SAE"IN" "OUT"HBE.41 X 1.19 SLOTAOC - 37 THROUGH AOC - 70SERVICEABLEBYPASS VALVE30 OR 60 PSIF (2 PLACES)AOC - 37 THROUGH AOC - 70JJ.41 X 1.19 SLOTMMPPHydraulic Motor12 or 24 Volt DC MotorHYDRAULIC MOTOR 12 or 24 VOLT DC MOTOR1/2 NPTBFOR OPTIONALSERVICEABLEECCTEMP. SENSOR#8 SAE #8 SAEBYPASS VALVEGG"IN" "OUT" 2.063/8 NPT30 OR 60 PSI .53 DIA HOLEJ .53 DIA HOLEDRAINJF (2 PLACES) 2 EACH BRKTM2 EACH BRKTM"IN"HPAIRPAIRUnit shown"OUT"FILTERFILTERUnit with shown optional with Bypass optional Valve Bypass ValveHydraulic Motor 12 or 24 Volt DC MotorHYDRAULIC MOTOR 12 or 24 VOLT DC MOTORAAIR FLOWAIR FLOWA D B CFGNO WITH NO WITH HYD DCSAE NPT & SAE NPT &WeightMODEL BYPASS BYPASS BYPASS BYPASS MOTOR MOTORDEH J M PBSPPBSPPLBS.AOC-19 13.62 16.00 16.50 18.16 #8 SAE #8 SAE10.31 15.00 14.75 30"IN" "OUT"3/8 NPT10.40 7.92.53 DIA HOLEDRAINJ .53 DIA HOLEJAOC-22 15.62 18.00 22.00 23.6612.31 20.502 EACH BRKT #12 .75 M24.12EACH BRKT 18.69 M33H3.05 2.61 5.00 8.18AOC-24 19.62 22.00 24.75 26.419.69 16.31 23.25 P21.44 P46Unit shown with optional Bypass 11.58 ValveAOC-33 25.62 28.00 30.25 31.919.31 22.31 28.75 #16 HYDRAULIC 1.00 MOTOR 4.34 12 or 26.97 24 VOLT DC MOTOR65AOC-37 18.50 21.38 39.00 40.3815.25 36.504.62 5.97 40.50 1.068.319514.06 10.84#20 1.256.50AOC-50 22.50 25.38 41.00 42.3819.25 38.504.68 6.03 42.50 1.128.37120AOC-54 30.50 33.28 42.00 43.3827.25 39.50 #24 1.50 4.89 6.30 43.75 15414.93 15.081.87 12.37AOC-57 36.50 39.38 48.00 49.3832.75 45.506.68 8.15 49.75 9.00190#32 2.00AOC-70 38.38 41.25 51.00 52.38 17.79 24.62 34.00 48.508.44 9.91 52.75 1.62 12.12 304Notes: Maximum pressure is 2000 PSI. Stated Minimum Operating Pressure is at Inlet Port of Motor. 1000 PSI Allowable Back Pressure.SpecificationsHydraulic motor dataNUMBER MAXIMUM OIL FLOW MINIMUM OPERATING MOTOR (IN3/REV)MODEL OF FANS FAN SPEED REQUIRED PER FAN (GPM) PRESSURE (PSI) DISPLACEMENTAOC - 19 thru AOC - 33 11.6 300 .22AOC - 37 thru AOC - 571725 RPM2AOC - 70 3.4 500 .45"OUT"All dimensions in inches. We reserve the right to make reasonable design changes without notice. *Inlet and outlet oil ports reversible if relief bypass option is not used.12 and 24 volt DC motor dataAIR FLOWCGAIRFILTERAIR FLOWCOOLED AOCAOCAIRNUMBER FULL LOAD AMPS PER MOTOR HORSEPOWER FAN FANMODEL OF FANS 12 VOLT 24 VOLT PER MOTOR SPEED DIAMETER (INCHES)AOC - 19 10AOC - 22 1AOC - 24, 3312.5 6.3 1/5141800 RPMAOC - 37 12AOC - 50, 54, 57 2 14AOC - 70 80 39 1 20www.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 25CGAIRFILTER12

Performance Curves250,000AOC - with DC Motor200,000■150,000AIR COOLED AOCHEAT DISSIPATION BTU/HR AT 50F E.T.D.100,00090,00080,00070,00060,00050,00040,00030,00025,00020,00015,00010,0009,0008,000■■■■■■■Oil ▲P● = 5 PSI■ = 10 PSI▲ = 20 PSI7,0006,0005,0002.5 3 4 5 6 7 8 9 10 15 20 25 30 40 50 60 70 80 90 100 150 200 250 300OIL FLOW - G.P.M.AOC - with Hydraulic Motor250,000200,000■▲AOC-70150,000●26HEAT DISSIPATION BTU/HR AT 50F E.T.D.100,00090,00080,00070,00060,00050,00040,00030,00025,00020,00015,000AOC10,0009,0008,0007,0006,000●TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com●●●●■■■●5,0002.5 3 4 5 6 7 8 9 10 15 20 25 30 40 50 60 70 80 90 100 150 200 250 300■▲●■▲●AOC-19OIL FLOW - G.P.M.■AOC-22▲■▲AOC-24■▲AOC-33▲AOC-37▲AOC-50AOC-54AOC-57Oil ▲P● = 5 PSI■ = 10 PSI▲ = 20 PSI

Selection ProcedurePerformance Curves are based on 50SSU oil entering the cooler 50°F higherthan the ambient air temperature used for cooling. This is also referred to asa 50°F Entering Temperature Difference (ETD).STEP 1 Determine the Heat Load.This will vary with different systems,but typically coolers are sized to remove 25 to 50% of the inputnameplate horsepower.(Example: 100 HP Power Unit x .33 = 33 HP Heat load.)To convert HP to BTU/Hr: HP x 2545 = BTU/HrSTEP 2 Entering Temperature Difference. Desired oil entering cooler°F – Ambient air temp. °F = Actual ETDSTEP 3 Determine Curve BTU/Hr Heat Load. Enter the informationfrom above:BTU/Hr heat load x50 x Cv= Curve BTU/HrETDSTEP 4 Enter curves at oil flow through cooler and curve horsepower.Any curve above the intersecting point will work.STEP 5 Determine Oil Pressure Drop from Curves:l = 5 PSI; n = 10 PSI; s = 20 PSI. Multiply pressure drop fromcurve by correction factor found in oil P correction curve.54OILP CORRECTION CURVEDesired Reservoir TemperatureReturn Line Cooling: Desired temperature is the oil temperature leaving thecooler. This will be the same temperature that will be found in the reservoir.Off-Line Recirculation Cooling Loop: Desired temperature is the oiltemperature entering the cooler. In this case, the oil temperature changemust be determined so that the actual oil leaving temperature can be found.Calculate the oil temperature change (oil T) with this formula:Oil T = (BTU’s/Hr.) / (GPM Oil Flow x 210).To calculate the oil leaving temperature from the cooler, use this formula:Oil Leaving Temp. = Oil Entering Temp – Oil T.This formula may also be used in any application where the only temperatureavailable is the entering oil temperature.Oil Pressure Drop: Most systems can tolerate a pressure drop through theheat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.Care should be taken to limit pressure drop to 5 PSI or less for case drainapplications where high back pressure may damage the pump shaft seals.Oil TemperatureTypical operating temperature ranges are:Hydraulic Motor Oil 110° - 130°FHydrostatic Drive Oil 130° - 180°FBearing Lube Oil 120° - 160°FLube Oil Circuits 110° - 130°FCOOLED AOCOIL P MULTIPLIER32150 100 200300400 500OIL VISCOSITY - SSUC V Viscosity CorrectionOILSAE 5 SAE 10 SAE 20 SAE 30 SAE 40Average 110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°FOil Temp °F 40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F100 1.14 1.22 1.35 1.58 1.77150 1.01 1.05 1.11 1.21 1.31200 .99 1.00 1.01 1.08 1.10250 .95 .98 .99 1.00 1.00AOCAIRwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 27

FLUID COOLING | <strong>Mobile</strong> DH SeriesAIR COOLED DHFeaturesnnnnnnnnnnnnHayden InterchangeExcellent for RadiatorFace Mount Cooling3/4” Tube SizeSteel or Aluminum FinCopper Manifolds – One RowSteel Manifolds – Two RowHigh Performance Oil TurbulatorsRugged Off-Highway Steel DesignsAvailableOil Flows to 150 GPM, Heat Removalto 175,000 BTU/HROil CoolerTransmission CoolerFuel CoolerMaterialsOPTIONSBuilt-in Relief BypassSteel ComponentsCustom Sizes/Mounting BracketsConnection Sizes/LocationsCorrosion ResistantMarine CoatingRatingsOperating Pressure 300 psiTest Pressure 300 psiOperating Temperature 350° FTubes CopperFins Aluminum or SteelTurbulators AluminumManifolds Copper: Models DH-051 – DH-447Steel: Models DH-513 – DH-670Connections Brass: Models DH-051 – DH-447Steel: Models DH-513 – DH-670Relief Bypass Valve OptionMODELDH-051thruDH-447DH-513DH-524thruDH-670DescriptionAvailable in either 30 psi or 60 psisettings. Bypass valve is built intotubes and does not effect externaldimensions. All steel valves. Notserviceable.Available in either 30 psi or 60 psisettings. 3/4”, external all steel valve.May be removed for servicing.Available in either 30 psi or 60 psisettings. 1-1/2”, external, all steelvalve. May be removed for servicing.How to Order– – ––28ModelSeriesDHDHR - ReliefBypass IncludedDHModel Size SelectedConnectionType*1 - NPT2 - SAEFin Material1 - Aluminum2 - SteelExamples: DH-051-1-1 or DHR-062-2-2-30Note: All positions must be filled. Mounting Kits (where needed) must be ordered separately, by part number.*Other connection types available. Please consult factory for assistance.TTPSales@thermasys.com 262.554.8330 www.thermaltransfer.comRelief BypassBlank - No Bypass30 - 30 psi60 - 60 psiADD FOR DHR MODELS ONLY

.53 DIA4 PLACESDimensions & WeightsDH-051 thru DH-447BG.53 DIA4 PLACES2.50BG3.00F2 PLACESCADE.34 DIA6 HOLESEACH STRAPMOUNTINGSTRAPMounting KitsOptional Mounting Kits are available with orwithout straps.Part NumberWith strap L-84741Without strap L-84740.12B"G" DIA1.50CORESHOCKMOUNTINGKITF G QTY MTG FACE AREA WEIGHTMODEL A B C D E NPT SAE DIA KITS SQ FT LBS.DH-051 4.004.50 15.00 14.12 2 0.31 211.25DH-062 15.00 14.12 0.47 3DH-073 6.00 14.25 6.50 18.00 17.12 0.60 3DH-084 20.25 24.00 23.12 0.50 #10 0.88 0.84 4DH-095 14.25 18.00 17.12 0.79 4DH-106 8.00 17.25 8.50 21.00 20.12 4 0.96 5DH-117 20.25 24.00 23.12 1.12 5DH-194 13.75 18.00 16.88 1.15 6DH-205 12.00 16.75 12.73 21.00 19.88 1.40 7DH-216 24.00 22.88 0.75 #12 1.12 1.64 8DH-227 14.00 19.75 14.73 24.00 22.88 1.92 9DH-249 18.00 18.73 24.00 22.88 6 2.47 12DH-32619.2524.00 22.62 3.21 1624.0025.00DH-337 25.25 30.00 28.62 4.21 20DH-348 19.25 24.00 22.62 1.00 #16 1.38 4.00 19DH-359 30.00 25.25 31.00 30.00 28.62 8 5.26 24DH-370 31.25 36.00 34.62 6.51 28DH-425 36.00 24.75 37.41 30.00 28.386.19 321.25 #20 1.62DH-447 40.00 36.75 41.41 42.00 40.38 10.21 43AIR COOLED DHAll dimensions in inches. Weights are for aluminum fins.After making your base model selection with the connection of your choice, please refer to the How to Order section.Note: We reserve the right to make reasonable design changes without notice.DHwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 29

Dimensions & WeightsDH-513 thru DH-670DH SeriesDHR SeriesDEDEHHDEDEHRELIEF H RELIEFBYPASS BYPASSVALVE VALVECCAAFFCCAAFFAIR COOLED DH.53 DIA .53 DIA4 PLACES 4 PLACESBGBG2.56 2.56.53 DIA .53 DIA4 PLACES 4 PLACESB2.50 2.50GBG2.56 2.563.00 3.00C D H FACE AREA WEIGHTMODEL A B DH DHR DH DHR E F G NPT SAE SQ FT LBSDH-513 12.00 13.75 15.00 16.25 20.75 22.41 18.25 8.00 22.250.75 #121.15 16DH-524 18.00 19.75 21.00 23.25 26.75 28.13 24.25 14.00 28.25 2.47 27DH-535 F F 24.00 19.25 27.00D D29.25 26.75 27.63 23.75 20.00 27.75 1.00 #16 3.21 53MOUNTING MOUNTINGDH-626 2 PLACES 2 PLACES36.00 22.75 39.03 E E 41.20 29.75 31.13 STRAP STRAP 27.25 32.00 31.255.69 602.00 #32DH-670 40.00 34.75 43.03 45.28 41.75 43.13 39.25 36.00 43.25 9.65 115All dimensions in inches. Weights are for aluminum fins.After making your base model selection with the connection of your choice, .34 DIA .34 please DIA refer to the How to Order section.C C6 HOLES 6 HOLESA AEACH EACH STRAP STRAPDesired Reservoir TemperatureOff-Line Recirculation Cooling Loop: Desired temperature is the oiltemperature entering the cooler. In this case, the oil temperature changemust be determined so that the actual oil leaving temperature can be found.Calculate the oil temperature change (oil T) with this formula:Oil T = (BTU’s/Hr.) / (GPM Oil Flow x 210).To calculate the oil leaving temperature from the cooler, use this formula:Oil Leaving Temp. = Oil Entering Temp – Oil T.This formula may also be used in any application where the only temperatureavailable is the entering oil temperature.Oil Pressure Drop: Most systems can tolerate a pressure drop through theheat exchanger of 20 to 30 PSI. Excessive pressure drop should be avoided.Care should be taken to limit pressure drop to 5 PSI or less for case drainapplications where high back pressure may damage the pump shaft seals.Oil TemperatureSHOCK SHOCKMOUNTINGReturn Line Cooling: Desired temperature is the oil temperature leaving the Typical operating temperature KIT ranges KIT are:.12 .12cooler. This will be the same temperature B B that will be found in the reservoir. 1.50 1.50Hydraulic Motor Oil 110° - 130°F"G" DIA "G" DIACORE COREHydrostatic Drive Oil 130° - 180°FBearing Lube Oil 120° - 160°FLube Oil Circuits 110° - 130°FTYPICAL OIL VISCOSITY, SSUOil Temp °FSAE5SAE10SAE20SAE30SAE40100 110 150 275 500 750150 60 70 100 135 190210 40 43 50 65 7530DHTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

Performance Curves54Oil P Correction CurveHEAT DISSIPATION BTU/HR @ 50˚F E.T.D.200,000150,000100,00090,00080,00070,00060,00050,000DH-447DH-370 DH-425DH-535DH-359DH-524DH-348 DH-33740,000DH-32630,000DH-24925,000DH-51320,000DH-227DH-21615,000DH-205DH-194 DH-117DH-10610,0009,000DH-084DH-0958,0007,0006,000DH-073<strong>Air</strong> Velocity Correction Curve Oil P Correction Curve2.055,000DH-062OIL PRESSURE41.5DROP4,000DH-051= 53PSI3,000= 10 PSI2,500= 20 PSI21.0.92,000.81 1.5 2 2.5 3 4 5 6 7 8 9 10 15 20.725 30 40 50 60 70 80 90 100 150 200.6OIL FLOW - GPMSelection Procedure.5400 500 600 700Performance Curves are based on 50 SSU oil, 1000 Standard Feet per Minute(SFPM) <strong>Air</strong> Velocity, and a 50°F Entering Temperature Difference (E.T.D.)E.T.D. = Entering oil temperature - Ambient air temperatureStep 1Step 2Step 3Determine Heat Load: Heat load may be expressed as eitherHorsepower or BTU/Hr. BTU/Hr. = Horsepower x 2545Determine entering temperature difference: The enteringoil temperature is generally the maximum desired systemtemperature. E.T.D. = Entering oil temperature - Ambient airtemperature.Determine the corrected heat dissipation to use the curves:Corrected BTU/Hr. 50°F x CvHeat Dissipation = x(Heat Load) Desired <strong>Air</strong> VelocityxE.T.D. CorrectionFactorCorrection Factor800 1000 1500 2000 2500Oil P MultiplierDH-670DH-626115050 60 70 80 90 100 200 400 300 500Correction FactorAmbient <strong>Air</strong> P - Inches of Water2.01.51.0.9.8.7.6<strong>Air</strong> Velocity Correction Curve.5400 500 600 7004.03.02.52.01.51.0.9.8.7.6.5.4.3.25.2.15.1400800 1000 1500 2000 2500Face Velocity SFPM<strong>Air</strong> Static Pressure Drop3 ROW2 ROW1 ROW500 600 700 800 1000 1500 2000 2500Face Velocity SFPM Oil Viscosity SSU Face Velocity SFPMStep 4Step 5Step 6Enter the Performance Curves at the bottom with the GPM oilflow and proceed upward to the adjusted heat load from Step 3.Any curve on or above this point will meet these conditions.Calculate actual SFPM <strong>Air</strong> Velocity or SCFM (Standard CubicFeet Per Minute) using the Face Area from the table.A. SFPM <strong>Air</strong> Velocity* =SCFM <strong>Air</strong> FlowSquare Feet Face AreaB. SCFM <strong>Air</strong> Flow = SFPM <strong>Air</strong> Velocity x Square Feet Face Area*If the <strong>Air</strong> Velocity calculated is different than the value in Step 3,recheck Corrected oil Pressure Drop.Multiply Oil Pressure Drop from curve by correction factorfound in Oil s P Correction Curve.*Note: If air velocity is unknown assume 750 SFPM.Oil P Multiplier32150 100200 300 400 500Oil Viscosity SSUOil P Multiplier5432Oil P Correction CAIR COOLED DH150 60 70 80 90 100 150 200Oil Viscosity SSUC V Viscosity CorrectionOILSAE 5 SAE 10 SAE 20 SAE 30 SAE 40Average 110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°FOil Temp °F 40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F100 1.14 1.22 1.35 1.58 1.77150 1.01 1.05 1.11 1.21 1.31200 .99 1.00 1.01 1.08 1.10250 .95 .98 .99 1.00 1.00DHwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 31

FLUID COOLING | <strong>Mobile</strong> DF SeriesAIR COOLED DFFeaturesnnnnnnnnnnnnnnSame as DH with DC Fan3/4” Tube SizeLow AMP Draw 12 or 24 VoltDC MotorsHeavy Duty ConstructionOptional Serviceable ReliefBypass ValveOptional Fan Control SwitchLong Life Hydraulic MotorsRugged ApplicationsSteel ManifoldsHeat Removal TO 35,000 BTU/Hr.Oil Flows to 110 GPMMounting Brackets IncludedSAE, NPT or 37° Flare Oil ConnectionsDamage Resistant Steel FinsMaterialsRatingsOperating Pressure 300 psiTest Pressure 300 psiOperating Temperature 350° FTubes CopperFins SteelTurbulators AluminumManifolds S t e elFan Assembly High Impact PlasticMotor Displacement . 2 2in 3 /Rev. (Hydraulic)Maximum Pressure 2000 PSI (Hydraulic)Allowable Backpressure 1000 PSI (Hydraulic)Relief Bypass Valve OptionMODELDFR-11Description3/4”, external, all steel valve.Available in either 30 PSI or 60PSI settings. May be removed forservicing.DFR-12 1-1/2”, external, all steel valve.DFR-22 Available in either 30 PSI or 60PSI settings. May be removed forservicing.DC current requiredHydraulic Motor DataNumber Oil Flow Required Minimum Operating Maximum Fan Speedof Fans 12 Volt 24 Volt (GPM) Pressure (PSI) (RPM)1 12.5 amps 6.3 amps 2.1 300 22002 25 amps 12.6 amps 4.2 300 2200How to Order– – ––32ModelSeriesDFDFR - ReliefBypass IncludedDFModel Size SelectedConnectionType*1 - NPT2 - SAE3 - BSPP7 - 37° Male Flare*Other connection types available. Please consult factory for assistance.MotorSpecificationNM - No Motor4A - 12 Volt DC4B - 24 Volt DC9 - HydraulicMotorTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.comRelief BypassBlank - No Bypass30 - 30 psi60 - 60 psiADD FOR DFR MODELS ONLY

.53 DIAGAIR FLOWMODELDF-11DF-12DF-224 HOLES3/8 NPT PORTDimensions TEMP SENSOR - 12 & 24 Volt DC MotorsFOR TEMP OPTIONALSENSORModels DF-11 and DF-12POWER LEAD12" LONG.53 DIA4 HOLES3/8 NPT PORTFOR OPTIONALTEMP SENSORGHIN*FLOW FDBEFLOWFUnits shown with optional G bypass valveJ (2 PLACES)ABERELIEF BYPASSVALVE (OPTIONAL)RELIEF BYPASS VALVE (OPTIONAL)A AIR FLOWJ (2 PLACES)RELIEF BYPASSVALVE K(OPTIONAL)F3/8 NPT PORTHGFOR OPTIONALRELIEF BYPASS VALVE (OPTIONAL)K(2 PLACES)AJ4 .53 HOLESDIATEMP. SENSORCDimensions - Hydraulic MotorsBAB EDF DFR DF DFRIN*16.12 18.00 19.25 20.91.53 DIAFLOW17.004 HOLES 18.25 F 22.9121.2531.47 33.7322.62LGC5.517.01J (2 PLACES)D E F G20.75 RELIEF 17.75 BYPASS 1.507.50VALVE (OPTIONAL)22.75 18.75 2.5014.2514.25ARELIEF BYPASS AIR VALVE FLOW (OPTIONAL)LAC.53 DIALABJMODELHC D E F G HK LBSH DF DFRGDF DFR2.06NPT SAE3/8 NPT PORT DF-11 16.12 POWER 18.00LEADS4 HOLESFOR OPTIONAL12" LONG #8 19.25 SAE TYP IN20.915.51 20.75 17.75 1.501.50 38FK7.50 3.69 1.00 #16TEMP SENSOR DF-12 17.00 3/8 NPT PORT18.2522.91B5721.257.01 22.75 18.75 2.50 AB E 3.00 J (2 PLACES)DF-22 31.47 FOR OPTIONALDC33.7322.62C D E F GIN*MODELAIR FLOWDF14.25DFR7.69DF1.50DFR#24110TEMP. SENSORIN*DF-11 16.12 .53 DIA18.00 19.25 20.91FLOW5.51 20.75 RELIEF 17.75BYPASS1.50Note: All dimensions are in inches. We reserve the right to make reasonable design changes 7.50DF-12 without 17.00 4 HOLES notice. 18.25 *Inlet and 22.91 outlet oil connections VALVE (OPTIONAL)can be Dreversed when the bypass valve is not used. E21.257.01 22.75 18.75 2.50BDF-22 31.47 33.7322.6214.25AGAIR FLOWModels DF-11 and DF-12H3/8 NPT PORTFOR OPTIONALTEMP. SENSOR3/8 NPT PORTFOR OPTIONAL.53 DIA4 HOLESD2.06#8 SAE TYP INDD2.06Units shown with optional bypass valveHIN*FGPOWER LEADS12" LONGFLOWCAKFLOWH3.697.69IN*FLOWJNPT1.001.50IN*AIR FLOWEBESAE#16#24BJ(2 PLACES)J (2 PLACES)AIR FLOWModel DF-223/8 NPT PORTFOR OPTIONALTEMP SENSORAIR FLOWModel DF-22DFHCH3/8 NPT PORTFOR OPTIONALTEMP. SENSOR3/8 NPT PORTFOR OPTIONALKTEMP. SENSOR LBS1.50 38573.00110KD 2.06CFHKHLDGPOWER LEADS12" LONG#8 SAE TYP INDGRELIEF BYPASS VALVE (OPTIONAL)A2.0614.25RELIEF BYPASS VALVE (OPTIONAL)AFFLFLOW.53 DIA4 HOLES.53 DIA4 HOLESFLOWIN*IN*EBJ (2 PLACES)EBJ(2 PLACES)AIR FLOWCKAIR FLOWCKKCH3.697.69CKJNPT1.001.50AIR COOLED DFSAEK#161.50#243.003/8 NPT PORT MODEL HFOR OPTIONALTEMP. SENSORDF-11DF-12DF-22ABDFGDFR DF .53 DIADFR4 HOLES16.1217.0031.4718.0018.2533.7319.2521.2520.9122.91ABIN*MODELC D E F G22.62AIR FLOW14.25DF 7.69DFR 1.50 DF #24DFR7.60 110DF-11 16.12 18.00 19.25 20.91 7.47 20.75 17.75 1.507.50Note: DF-12 17.00 18.2522.91D All dimensions are in inches. We reserve the right to make reasonable design changes without notice. *Inlet and2.06E21.25outlet oil connections 9.46 22.75 can be 18.75 2.50reversed when the bypass valve is not used.BDF-22 31.47 33.7322.6214.25FLOWC7.479.46D20.7522.75E F G17.75 1.507.5018.75 2.50H3.69JNPT1.00SAE#16K L LBS1.50 387.56573.00H3.697.69JNPT1.001.50SAE#16#2413MODELFL14.25KRELIEF BYPASS VALVE (OPTIONAL)JCA(2 PLACES)ABJC D E F G HK L LBSDF DFR DF DFR NPT SAEDFwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 33

AIR COOLED DFPerformance CurvesHEAT DISSIPATION BTU/HR. AT 50˚F E.T.D.50,00040,00030,00025,00020,00015,00010,0009,0008,0007,0006,000OIL FLOW - GPMOIL PRESSUREDROP= 5 PSI= 10 PSI5,0003 4 5 6 7 8 9 10 15 20 25 30 40 50 60 70 80 90 100 150DF - 11DF - 12DF - 22Oil P Multiplier5432Oil P Correction Curve150 100200 300 400 500Oil Viscosity SSUSelection ProcedurePerformance Curves are based on 50 SSU oil entering the cooler 50°F higherthan the ambient air temperature used for cooling. This is referred to as a50°F E.T.D.Step 1Step 2Step 3Determine the Heat Load. Heat load may be expressed as eitherhorsepower or BTU/Hr. To convert horsepower to BTU/Hr.:BTU/HR = Horsepower x 2545Determine Entering Temperature Difference. The entering oiltemperature is generally the maximum desired oil temperature.Entering oil temperature – Ambient air temperature = E.T.D.Determine the Corrected Heat Dissipation to use the curves.50°F x CvCorrected Heat Dissipation = BTU/HR heat load xE.T.D.Step 4OIL P MULTIPLIERStep 5Any OIL curve P CORRECTION above the CURVE intersecting point will work.5432Enter curves at oil flow through cooler and curve heat dissipation.Determine Oil Pressure Drop from Curves:l = 5 PSI; n = 10 PSI; Multiply pressure drop from curve bycorrection factor found in oil s P correction curve.Oil Temperature150 60 70 80 90 100 150 200 300 400 500Typical operating OIL VISCOSITY temperature - SSU ranges are:Hydraulic Motor Oil 120°F - 180°FHydrostatic Drive Oil 160°F - 180°FEngine Lube Oil 180°F - 200°FAutomatic Transmission Fluid 200°F - 300°FC V Viscosity CorrectionOILSAE 5 SAE 10 SAE 20 SAE 30 SAE 40Average 110 SSU at 100°F 150 SSU at 100°F 275 SSU at 100°F 500 SSU at 100°F 750 SSU at 100°FOil Temp °F 40 SSU at 210°F 43 SSU at 210°F 50 SSU at 210°F 65 SSU at 210°F 75 SSU at 210°F100 1.14 1.22 1.35 1.58 1.77150 1.01 1.05 1.11 1.21 1.31200 .99 1.00 1.01 1.08 1.10250 .95 .98 .99 1.00 1.0034DFTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

Thermostatic Temperature Control Option (DC)This controller was designed to mount on the cooler without requiringextensive wiring or plumbing. It provides accurate temperature controlby cycling the cooling fan(s) to maintain desired oil temperature.n 12 or 24 volt operationn Adjustable temperature settings range from 100°F thru 210°F in20°F incrementsn For use with one or two fan modelsn Temperature sensor providedn Wiring provided for remote manual overriden Mounting hardware includedPart NumberDescription96171 Electronic Fan Control Kit68790 Replacement Control Only67699 Replacement Sensor OnlySide View.90 ±.2TEMPERATURESELECT SWITCHConnection AssemblyAIR COOLED DF.121.12Top ViewElectrical SchematicNOTE: This switch should be fused to prevent damage if ground is lost. A 30 amp fuse is required in the power supply.DFwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 35

FLUID COOLING | <strong>Mobile</strong> M SeriesAIR COOLED MFeaturesnnnnnnnnnHigh Strength Construction3/8” Tube SizeEliminate Piping, Reduce Cost withOptional Built-in Relief BypassAluminum FinsRugged Steel ManifoldsHeat Removal up to 90,000 BTU/Hr.Oil Flows to 100 GPMMounting Brackets IncludedSAE, NPT or 37° Flair Oil ConnectionsMaterialsRatingsOperating Pressure 300 psiTest Pressure 300 psiOperating Temperature 400° FTubes CopperFins AluminumTurbulators SteelManifolds S t e elRelief Valve S t e elConnections S t e elHow to Order– ––ModelSeriesMMR - ReliefBypassIncludedModel Size SelectedConnectionType*Blank - NPTS - SAERelief BypassBlank - No Bypass30 - 30 psi60 - 60 psiADD FOR MR MODELS ONLY*Other connection types available. Please consult factory for assistance.36MTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com

Dimensions & WeightsGEGEH H2 PLACES2 PLACESGEGEH H2 PLACES2 PLACESFLOWFLOWFFACACFFACAC1.881.881.881.881.861.86DBDB.62 1.50 .62 SQ 1.50 SQ.53 DIA .53 DIA4 MOUNTING 4 MOUNTING HOLES HOLES1.861.86B B.62 1.50 .62SQ1.50 SQD D.53 DIA .53 DIA4 MOUNTING 4 MOUNTING HOLES HOLESUnit shown with optional Bypass ValveAIR COOLED MModelM-10CA BM Series MR SeriesD E F G6.008.88 10.563.50NPTHSAEFace Area(Sq. Ft.).60ShippingWeight Lbs.11M-15M-208.0012.0014.5010.8814.8812.5616.5618.2216.725.509.5019.721.00#16.811.211216M-2518.0020.5020.8822.5624.2222.7215.5025.722.5628M-30M-35M-40M-4524.0030.0036.0019.5025.0035.5026.8832.8838.6228.6234.6240.6923.2228.7239.2221.7227.2237.7221.5027.5033.5024.7230.2240.721.25#203.254.066.258.8834405673Mwww.thermaltransfer.com TTPSales@thermasys.com 262.554.8330 37

Performance Curves150,0002.01.5<strong>Air</strong> Static Pressure Drop-45-40AIR COOLED M150M38Correction Factor Oil P Multiplier Ambient HEAT <strong>Air</strong> DISSIPATION P - Inches of BTU/HR. Water AT 50F E.T.D.100,00090,00080,00070,00060,000<strong>Air</strong> Static Pressure Drop2.050,0001.540,0001.0.830,000.625,000.5.420,000.3.25.215,000.15.110,000.08 9,000400 8,000 500 600 800 1000 1500 2000 25007,0006,0005Face Velocity SFPMOil P Correction Curve4 5,000OIL PRESSUREDROP= 5 PSI34,000= 10 PSI2.5= 20 PSI21.53,0001.5 2 2.5 3 4 5 6 7 8 9 10 15 20 25 30 40 50 60 708090100 150150 60 80 100 150 200 300 400500Oil Viscosity SSU21.51.9.8.7.6<strong>Air</strong> Velocity Correction Curve.5400 500 600 800 1000 1500 2000 2500Face Velocity SFPMM-25OIL FLOW - GPMM-35M-30M-45M-40M-10M-15M-20M-25Oil5P Correction CurveTTPSales@thermasys.com 262.554.8330 www.thermaltransfer.com4iplier Ambient <strong>Air</strong> P - Inches of Water2.01.51.0.8.6.5.4.3.25.2.15.1.083M-35M-30<strong>Air</strong> Static Pressure DropM-45M-40400 500 600 800 1000 1500 2000 2500Face Velocity SFPMCorrection Factor Oil P Multiplier Ambient <strong>Air</strong> P - Inches of Water1.0.8.6.5.4.3.25.2.15.1.085432.521.5400 500 600 800 1000 1500 2000 2500Face Velocity SFPM150 60 80 100 150 200 300 400500Oil Viscosity SSU21.51.9.8.7.6Oil P Correction Curve<strong>Air</strong> Velocity Correction Curve.5400 500 600 800 1000 1500 2000 2500Face Velocity SFPM