Small-Scale Industry Coal Gasifier Stove - BioEnergy Discussion Lists

Small-Scale Industry Coal Gasifier Stove - BioEnergy Discussion Lists

Small-Scale Industry Coal Gasifier Stove - BioEnergy Discussion Lists

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

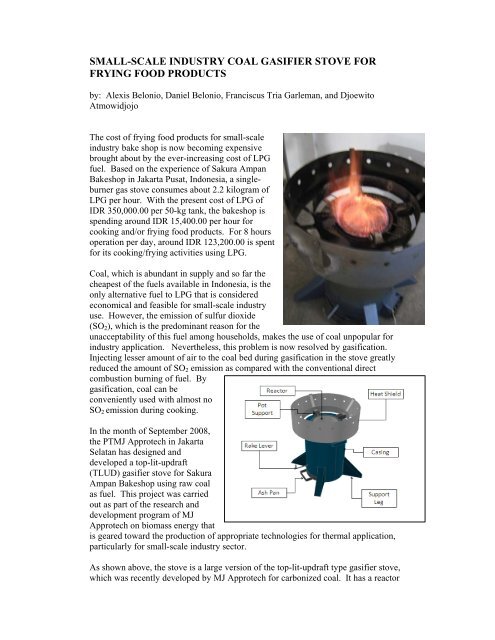

SMALL-SCALE INDUSTRY COAL GASIFIER STOVE FORFRYING FOOD PRODUCTSby: Alexis Belonio, Daniel Belonio, Franciscus Tria Garleman, and DjoewitoAtmowidjojoThe cost of frying food products for small-scaleindustry bake shop is now becoming expensivebrought about by the ever-increasing cost of LPGfuel. Based on the experience of Sakura AmpanBakeshop in Jakarta Pusat, Indonesia, a singleburnergas stove consumes about 2.2 kilogram ofLPG per hour. With the present cost of LPG ofIDR 350,000.00 per 50-kg tank, the bakeshop isspending around IDR 15,400.00 per hour forcooking and/or frying food products. For 8 hoursoperation per day, around IDR 123,200.00 is spentfor its cooking/frying activities using LPG.<strong>Coal</strong>, which is abundant in supply and so far thecheapest of the fuels available in Indonesia, is theonly alternative fuel to LPG that is consideredeconomical and feasible for small-scale industryuse. However, the emission of sulfur dioxide(SO 2 ), which is the predominant reason for theunacceptability of this fuel among households, makes the use of coal unpopular forindustry application. Nevertheless, this problem is now resolved by gasification.Injecting lesser amount of air to the coal bed during gasification in the stove greatlyreduced the amount of SO 2 emission as compared with the conventional directcombustion burning of fuel. Bygasification, coal can beconveniently used with almost noSO 2 emission during cooking.In the month of September 2008,the PTMJ Approtech in JakartaSelatan has designed anddeveloped a top-lit-updraft(TLUD) gasifier stove for SakuraAmpan Bakeshop using raw coalas fuel. This project was carriedout as part of the research anddevelopment program of MJApprotech on biomass energy thatis geared toward the production of appropriate technologies for thermal application,particularly for small-scale industry sector.As shown above, the stove is a large version of the top-lit-updraft type gasifier stove,which was recently developed by MJ Approtech for carbonized coal. It has a reactor

having a diameter of 20 cm and a height of 50 cm. It is made of 3/16-in. thickstainless steel plate to minimize oxidation of heat on the metal. The reactor issurrounded by two concentric cylinders (inner and outer) of the same height having adiameter of 28 cm and 30 cm, respectively. The reactor and the heat shield areencased by a 1.2-mm thick metal with a diameter of 50 cm ad a height of 60 cm. A12cm, 16-watt computer fan is used to supply the air required to gasify the fuel. It isprovided with a switch to control the speed of the fan thereby providing a controlmechanism to increase or decrease the intensity of the flame. The temperature of thestove is cooled down by allowing ambient air to pass through the inner wall of thestove casing. The heat producedinside the gasifier is releasedthrough the 16 holes on top of thestove casing having a diameter of 20mm. The fuel is held in place by agrate made of 10-mm diameterstainless steel rod with 10-mmspacing. Ashes are discharged fromthe grate using a sliding rake.Combustible gases are burned in theplate burner consisting of 40 and 45holes at the inner and the outercircles, respectively, with 10-mmdiameterThe stove was tested in terms ofwater boiling and kitchenperformance tests. The waterboiling test was done at the PTMJApprotech R&D Unit at TamanTekno, BSD City, Serpong,Tangerang, Banten, Indonesia. Theperformance of the stove wasevaluated by measuring thefollowing parameters: fuelconsumption rate, thermal efficiency, power output, and others. Kitchen performancetests were carried out at the Sakura Ampan Bakeshop in their actual frying of foodproducts. The food products, specifically egg rolls, were fried in the stove in batches.Comparison of the quality of foodproducts fried in the coal gas stoveand those fried in their existingindustrial LPG stoves was done bythe Chef of Sakura AmpanBakeshop.Results showed that the coal gasstove operates at an average of 2.97kg of raw coal per hour. One fullloadof fuel in the stove requires 8 to9 kg of coal fuel. It was observedfurther that the fuel is ignited using