64 410/112 ED FLOW RESTRICTOR VALVE - Duplomatic

64 410/112 ED FLOW RESTRICTOR VALVE - Duplomatic

64 410/112 ED FLOW RESTRICTOR VALVE - Duplomatic

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

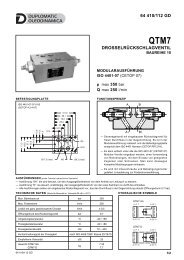

<strong>64</strong> <strong>410</strong>/<strong>112</strong> <strong>ED</strong>QTM7<strong>FLOW</strong> <strong>RESTRICTOR</strong> <strong>VALVE</strong>SERIES 10MODULAR VERSIONISO 4401-07 (CETOP 07)p max 350 barQ max 250 l/minMOUNTING INTERFACEOPERATING PRINCIPLEISO 4401-07-07-0-05(CETOP 4.2-4-07)71.569.857.255.634.915.914.31.618.3Ø17.5 (max)101.688.176.665.95034.1LGTAM6PGBXYØ4M10Ø6.3 (max)— This is a flow restrictor valve with built in check valve forreverse free flow, made as a modular version withmounting surface according to the ISO 4401 (CETOP RP12H) standards.— It can be assembled quickly under all ISO 4401-07(CETOP 07) modular valves without use of pipes, usingsuitable tie-rods or bolts, thus forming compact modulargroups.— It is supplied with countersunk hex adjustment screw andlocking nut. Rotate anticlockwise to increase the flow rate.CONFIGURATIONS (see hydraulic symbols table)— Configuration “SA”: Allows the flow control exiting from the actuator on line A.— Configuration “D”: Allows independent control of the flow exiting from the chambers A and B of the actuator.— All the configurations have a built-in check valve that allows free reverse flow (cracking pressure of 0,7 bar).PERFORMANCES (measured with mineral oil of viscosity 36cSt at 50°C)HYDRAULIC SYMBOLSMaximum operating pressure bar 350Maximum flow rate l/min 250Leakage flow with restrictor closed l/min ≤ 0,5Check valve opening pressure bar 0,7Ambient temperature range °C -20 / +50Fluid temperature range °C -20 / +80Fluid viscosity range cSt 10 ÷ 400Fluid contamination degreeAccording to ISO 4406:1999class 20/18/15Recommended viscosity cSt 25Mass:QTM7-SAQTM7-Dkg7,357,7<strong>64</strong> <strong>410</strong>/<strong>112</strong> <strong>ED</strong> 1/2

QTM7SERIES 101 - IDENTIFICATION CODEQ T M 7 - / 10 /Flow restrictor valveModular versionISO 4401-07 (CETOP 07) sizeSA = meter out control on line AD = meter out control on lines A and BS = adjustment screw (standard)K = adjustment knobSeals:N= Seals in NBR for mineral oils (standard)V = Seals in FPM for special fluidsSeries No. (the overall and mountingdimensions remain unchanged from 10 to 19)2 - CHARACTERISTIC CURVES (values obtained with viscosity of 36 cSt at 50°C)CONTROLL<strong>ED</strong> <strong>FLOW</strong>ADJUSTMENT SCREW TURNSPRESSURE DROPS ∆p - Q1) pressure drops through thecheck valve with closedrestrictorcontrolled flowversus ∆pwith differentrestrictoropening values2) pressure dropsA 1 - A (B 1 - B) through thecheck valve with openrestrictor3) pressure drops through thefree ports3 - HYDRAULIC FLUIDSUse mineral oil-based hydraulic fluids HL or HM type, according to ISO 6743-4. For these fluids, use NBR seals. For fluids HFDR type(phosphate esters) use FPM seals (code V). For the use of other kinds of fluid such as HFA, HFB, HFC, please consult our technicaldepartment. Using fluids at temperatures higher than 80 °C causes a faster degradation of the fluid and of the seals characteristics.The fluid must be preserved in its physical and chemical characteristics.4 - OVERALL AND MOUNTING DIMENSIONSdimensions in mm1 Mounting surface with sealing rings:4 OR type 3087 (21.89x2.62)2 ORM-0100-20 (10x2)2 Countersunk hex adjustment screw: spanner 8(standard)Rotate anticlockwise to increase the flow3 Locking nut: spanner 244 Adjustment knob (option): KRotate clockwise to increase the flowDUPLOMATIC OLEODINAMICA S.p.A.20015 PARABIAGO (MI) • Via M. Re Depaolini 24Tel. +39 0331.895.111Fax +39 0331.895.339www.duplomatic.com • e-mail: sales.exp@duplomatic.com<strong>64</strong> <strong>410</strong>/<strong>112</strong> <strong>ED</strong> REPRODUCTION IS FORBIDDEN. THE COMPANY RESERVES THE RIGHT TO APPLY ANY MODIFICATIONS.2/2