Silk Reeling and Re reeling - Seri.ap.gov.in

Silk Reeling and Re reeling - Seri.ap.gov.in

Silk Reeling and Re reeling - Seri.ap.gov.in

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

REELING & RE-REELING TECHNIQUES<strong>Silk</strong> <strong><strong>Re</strong>el<strong>in</strong>g</strong> is simply the unw<strong>in</strong>d<strong>in</strong>g of filaments from a group of cocoons <strong>in</strong>hot water bath on to a reel.There are two methods of <strong>reel<strong>in</strong>g</strong> a) Direct <strong><strong>Re</strong>el<strong>in</strong>g</strong> method onst<strong>and</strong>ard reels <strong>and</strong> b) Indirect method which <strong>in</strong>cludes prelim<strong>in</strong>ary <strong>reel<strong>in</strong>g</strong> onsmall sized reels <strong>and</strong> transferr<strong>in</strong>g the reeled silk directly from the reels tost<strong>and</strong>ard sized reels on re-<strong>reel<strong>in</strong>g</strong> mach<strong>in</strong>es.Before <strong>reel<strong>in</strong>g</strong>, cocoons have to pass various stages <strong>and</strong> production of qualitysilk depends upon various factors:Purchase of Cocoons :Selection of cocoons must be done carefully as any carelessness is thisrespect would spell serious losses to the <strong>reel<strong>in</strong>g</strong> enterprise. Selectivepurchase of cocoons <strong>in</strong> an open market is extremely difficult, <strong>and</strong> becomesimperfect particularly <strong>in</strong> the absence of determ<strong>in</strong>ed st<strong>and</strong>ards of quality forcocoons, <strong>and</strong> st<strong>and</strong>ard methods of test<strong>in</strong>g for classify<strong>in</strong>g cocoons <strong>in</strong>to qualitygrades.Cocoons should not be too flossy. Floss merely adds to the weight of cocoonswhen yield<strong>in</strong>g silk for <strong>reel<strong>in</strong>g</strong>. Cocoons should have well-rounded <strong>and</strong> firmends <strong>and</strong> must not have too pronounced po<strong>in</strong>ts. Well po<strong>in</strong>ted ends are easy todetect because of their sh<strong>ap</strong>e; th<strong>in</strong> ends can be detected by the lighter shadeof colour at the end which when pressed yields readily, when floss is peeledoff the cocoons, the surface must be f<strong>in</strong>e gra<strong>in</strong>ed <strong>and</strong> not deeply wr<strong>in</strong>kled.Transport<strong>in</strong>g Techniques :The selected cocoons must be transported safely <strong>in</strong> perforated bamboobaskets or <strong>in</strong> loosely packed plastic crates, <strong>and</strong> must be transported dur<strong>in</strong>gthe cool hours. Pack<strong>in</strong>g the cocoons tightly <strong>and</strong> transport<strong>in</strong>g them <strong>in</strong> the hotsun must always be avoided.COCOON STIFLING & PRESERVATIONCOCOON STIFLING:Cocoons <strong>in</strong> their fresh condition with the pupae alive <strong>in</strong> them cannot bestored for a long time as the liv<strong>in</strong>g pupae are soon transformed <strong>in</strong>to moths.They are useless for <strong>reel<strong>in</strong>g</strong> raw silk because the cont<strong>in</strong>uity of the bave <strong>in</strong>them is broken. <strong><strong>Re</strong>el<strong>in</strong>g</strong> cocoons, therefore, have to be subjected to a processof stifl<strong>in</strong>g with the object of kill<strong>in</strong>g the pupae <strong>in</strong>side without <strong>in</strong> anyway<strong>in</strong>terfer<strong>in</strong>g with the structure of the silk shell around it. Cocoons can be stifled

y several methods but the popular methods <strong>in</strong> <strong>reel<strong>in</strong>g</strong> <strong>in</strong>dustry are sundry<strong>in</strong>g, steam stifl<strong>in</strong>g <strong>and</strong> hot air condition<strong>in</strong>g.PRESERVATION:Storage of cocoons is an important problem especially when the stiledcocoons have to be stored for a very long period. Complete desiccation ofcocoons is a fairly satisfactory solution to the problem but even fullydesiccated cocoons are liable to mould damage if the storage room is keptdry.The other source of damage to cocoons <strong>in</strong> storage comes from the beetlepest, Dermestes lardarius. The follow<strong>in</strong>g measures have to be followed forpreservation of cocoons.• Complete desiccation of cocoons before stor<strong>in</strong>g should be ensured.• All care should be taken to see that the relative humidity <strong>in</strong> the storeroom does not rise above 70%.• The store room must have good ventilation.• Cocoons should be given regular <strong>and</strong> frequent turn<strong>in</strong>gs dur<strong>in</strong>g the periodof storage <strong>and</strong> on no account should they be allowed to become damp.• When fumigants are used care should be taken to keep the doors <strong>and</strong>w<strong>in</strong>dows open until all the traces of fumigants are removedREELING & RE-REELING TECHNIQUES<strong>Silk</strong> <strong><strong>Re</strong>el<strong>in</strong>g</strong> is simply the unw<strong>in</strong>d<strong>in</strong>g of filaments from a group of cocoons <strong>in</strong>hot water bath on to a reel.There are two methods of <strong>reel<strong>in</strong>g</strong> a) Direct <strong><strong>Re</strong>el<strong>in</strong>g</strong> method on st<strong>and</strong>ard reels<strong>and</strong> b) Indirect method which <strong>in</strong>cludes prelim<strong>in</strong>ary <strong>reel<strong>in</strong>g</strong> on small sized reels<strong>and</strong> transferr<strong>in</strong>g the reeled silk directly from the reels to st<strong>and</strong>ard sized reelson re-<strong>reel<strong>in</strong>g</strong> mach<strong>in</strong>es.Systems of <strong><strong>Re</strong>el<strong>in</strong>g</strong>There are two systems of <strong>reel<strong>in</strong>g</strong> cocoons :( i ) Float<strong>in</strong>g System( ii ) Sunken System

Float<strong>in</strong>g System of <strong><strong>Re</strong>el<strong>in</strong>g</strong>In float<strong>in</strong>g system, the cocoons are cooked only to the extent the shellbecomes wet, but is still impervious to water, so that they float <strong>in</strong> water whenthe cooked cocoons are put <strong>in</strong>to the <strong>reel<strong>in</strong>g</strong> bas<strong>in</strong>. Float<strong>in</strong>g system isassociated with1. <strong><strong>Re</strong>el<strong>in</strong>g</strong> of cooked cocoons which float <strong>in</strong> <strong>reel<strong>in</strong>g</strong> bas<strong>in</strong>.2. High speed <strong>reel<strong>in</strong>g</strong>.3. High bas<strong>in</strong> temperature.4. Less number of <strong>reel<strong>in</strong>g</strong> ends.Sunken System of <strong><strong>Re</strong>el<strong>in</strong>g</strong>In this system, the cooked cocoons s<strong>in</strong>k <strong>in</strong> water at the time of <strong>reel<strong>in</strong>g</strong>.In this system, not only the shell is cooked but <strong>in</strong> the process, the cocoon alsogets filled with water <strong>in</strong>side to the extent of 97 to 98%, with the result, thecocoon becomes heavy <strong>and</strong> s<strong>in</strong>ks <strong>in</strong> the <strong>reel<strong>in</strong>g</strong> water. This system of <strong>reel<strong>in</strong>g</strong>is associated with :1. <strong><strong>Re</strong>el<strong>in</strong>g</strong> of cooked cocoons which s<strong>in</strong>k under water <strong>in</strong> <strong>reel<strong>in</strong>g</strong> bas<strong>in</strong>.2. Slow speed <strong>reel<strong>in</strong>g</strong>.3. Low bas<strong>in</strong> temperature <strong>reel<strong>in</strong>g</strong>.4. Large number of <strong>reel<strong>in</strong>g</strong> ends.This system is suitable for superior quality cocoons like bivolt<strong>in</strong>e.RE – REELING<strong>Re</strong> – <strong>reel<strong>in</strong>g</strong> is done to transfer the raw silk <strong>in</strong>to st<strong>and</strong>ard sized hanks. Thegrant <strong>reel<strong>in</strong>g</strong> helps <strong>in</strong> f<strong>in</strong>d<strong>in</strong>g of broken ends of the thread <strong>and</strong> also itsknott<strong>in</strong>g. In grant <strong>reel<strong>in</strong>g</strong> the hank is divided <strong>in</strong>to several parts which can bekept separately by means of lac<strong>in</strong>g. The ratio of the bevels determ<strong>in</strong>e thewidth of the diamond. For f<strong>in</strong>er denier silk, more number of teeth have to beused. <strong>Re</strong> – <strong>reel<strong>in</strong>g</strong> speed is almost double the <strong>reel<strong>in</strong>g</strong> speed. So one end re<strong>reel<strong>in</strong>g</strong>will be enough to take the <strong>in</strong>put of two end <strong>reel<strong>in</strong>g</strong>. 13/24 bevelcomb<strong>in</strong>ation will produce 13 diamonds.SKEININGThe st<strong>and</strong>ard size hanks from the swift are carefully exam<strong>in</strong>ed for defects ifany,it is laced <strong>and</strong> folded upon itself to form a ske<strong>in</strong> with the help of ske<strong>in</strong><strong>in</strong>gmach<strong>in</strong>e. The weight of the ske<strong>in</strong>s varies from 50 g. to more that 100 g.The ske<strong>in</strong>s of raw silk are then made <strong>in</strong>to books <strong>and</strong> bales are marketed later.

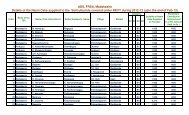

DIFFERENT SILK REELING DEVICES WITH ECONOMICS<strong><strong>Re</strong>el<strong>in</strong>g</strong> Devices:There are three dist<strong>in</strong>ct <strong>reel<strong>in</strong>g</strong> devices <strong>in</strong> mulberry sector namely(a) Charka : It is a crude system of <strong>reel<strong>in</strong>g</strong>. It is a simple h<strong>and</strong> drivendevice consists of a large cook<strong>in</strong>g cum <strong>reel<strong>in</strong>g</strong> pan where boil<strong>in</strong>gwater is kept.(b) Cottage Bas<strong>in</strong> System : It is improved over charka. It consists ofseparate cook<strong>in</strong>g <strong>and</strong> <strong>reel<strong>in</strong>g</strong> bas<strong>in</strong>, where temperature is at boil<strong>in</strong>gpo<strong>in</strong>t only <strong>in</strong> the cook<strong>in</strong>g bas<strong>in</strong>, but <strong>reel<strong>in</strong>g</strong> bas<strong>in</strong> temperature ishardly 40 C.(c) Multiend Bas<strong>in</strong> System : It is a further improved version over theCottage Bas<strong>in</strong> <strong>and</strong> it is power driven. Boilers are <strong>in</strong>stalled <strong>and</strong>steam is used for cook<strong>in</strong>g <strong>and</strong> <strong>reel<strong>in</strong>g</strong> purpose <strong>and</strong> also for cocoonstifl<strong>in</strong>g <strong>in</strong> the special steam chambers.Tw<strong>in</strong> CharkaEconomicsSl.NoIItemCAPITAL INVESTMENTRs. InLakhsIIa) L<strong>and</strong>b) House cum workshedc) Cost of CharkaTotal c<strong>ap</strong>ital costWORKING CAPITALOwn0.300.100.40i. a) Employment : Self employment --b) Workers wages :<strong>Re</strong>elers : 2 (Rs.50/- per day ( 25 days per monthfor one year 300 days)0.30Assistants : (Rs.50/- per day ( 25 days per monthFor one year 300 days)0.15

ii. Cost of Raw materialcost of raw material for 300 days ( @ 16 kgs per day@ cost of Rs.90/- per kg for 4800 kgs)4.32iii. Other expenses (Fuel <strong>and</strong> Transport etc) 0.35iv. Total work<strong>in</strong>g c<strong>ap</strong>ital required for one year (i + ii + iii)5.12v. ( Actual work<strong>in</strong>g c<strong>ap</strong>ital required for two (2) months(6 operat<strong>in</strong>g cycles Rs.0.85 lakhs)vi. Interests :a) Interest on C<strong>ap</strong>ital <strong>in</strong>vestment (16%) 0.064b) Interest on work<strong>in</strong>g c<strong>ap</strong>ital (16%)for Rs.0.85 lakhs0.136c) Depreciation on c<strong>ap</strong>ital cost (10%) 0.04IIITotal Production cost ( iv + vi ) 5.36<strong>Re</strong>alisationEstimated production of Raw <strong>Silk</strong> from Tw<strong>in</strong> Charka( 50 kgs per month @ 2 kgs per day for 25 days)Total Raw <strong>Silk</strong> Production : 600 kgs per yeari) Sale value of silk yarn per kg @ Rs.900/-ii)Total value of raw silk producedSale value of <strong>Silk</strong> bye products5.40a) <strong>Silk</strong> waste @ 25% of the yarn@ Rs.150/- per kg for 150 kgs 0.225b) Double Cocoons ( 5% Green cocoons)240 kgs @ Rs.60/- per kg 0.144IV PROFIT :Gross <strong>in</strong>come 5.769Gross <strong>in</strong>come (Annum)Total Expenditure ( Annum)Net <strong>in</strong>come5.7695.3600.409

(6) COTTAGE BASIN SILK REELING UNITS.No. Item Rs. InLakhs1 C<strong>ap</strong>ital Investmenta) L<strong>and</strong> Ownb) Build<strong>in</strong>g Ownc) Cost of <strong>reel<strong>in</strong>g</strong> mach<strong>in</strong>ery 1.002 Operat<strong>in</strong>g cost for production of 1165 kgs of silk yarn/AnnumCost of raw material @ 35 kgs per day for 300 days –10500 10.50kgs @ Rs.100/- per kga) WagesSupervisory Charges (self)1)Total amount towards wages @ Rs.40/- per day 1.44for 12 workers for 300 days2)Other expenses (Fuel, Transport etc) @ Rs.300/- 0.90per dayTotal work<strong>in</strong>g c<strong>ap</strong>ital per annum 12.843 Work<strong>in</strong>g C<strong>ap</strong>ital requirementActual work<strong>in</strong>g c<strong>ap</strong>ital required for two months consider<strong>in</strong>g ( 2.146 ) operat<strong>in</strong>g cycles <strong>in</strong> a year (Rs.12.84/6 )4 InterestDepreciation on c<strong>ap</strong>ital <strong>in</strong>vestment (10%) 0.14Interest on c<strong>ap</strong>ital cost (16%) 0.16Interest on work<strong>in</strong>g c<strong>ap</strong>ital of Rs.2.14 lakhs (16%) 0.342<strong>Re</strong>nt of the build<strong>in</strong>g @ Rs.800/- month for year 0.096Total production cost/Annum (2 + 4) 13.5385 Estimated production of raw silk from 6 bas<strong>in</strong> 6 end 13.048Cottage bas<strong>in</strong>.. 1165 kgs/ per annuma) Total sale value of silk yarn @ Rs 1120/- per kgb) Sale value of silk bye products1) <strong>Silk</strong> waste ( 290 kgs @ Rs. 200/- per kg) 0.582) Double Cocoons (525 kgs @ Rs.65/- per kg) 0.373) Pupae ( 200 kgs @ Rs. 3/- per kg ) 0.06Gross <strong>in</strong>come 14.058ProfitGross <strong>in</strong>come ( per annum ) 14.058Total Expenditure ( per annum ) 13.538Net <strong>in</strong>come 0.5206 BASIN MULTIEND REELING UNITS.No Item Rs. InLakhs1 C<strong>ap</strong>ital <strong>in</strong>vestmenta) L<strong>and</strong> Ownb) Build<strong>in</strong>g Own/rentedc) Cost of <strong>reel<strong>in</strong>g</strong> mach<strong>in</strong>ery 4.702 Operat<strong>in</strong>g cost production of 1260 kgs of silk yarn /Annuma) Cost of Raw material @ 40 kgs per day for 300 13.20Days --- 12000 kgs @ Rs.110/- per kgb) Wages1) Total amount towards wages @ Rs.42/- per day 1.44For 12 workers for 300 days

2) Other expenses (Fuel, Transport etc) @ Rs.350/- 1.05Per dayTotal work<strong>in</strong>g c<strong>ap</strong>ital per annum 15.693 Work<strong>in</strong>g C<strong>ap</strong>ital requirementActual work<strong>in</strong>g c<strong>ap</strong>ital required for two monthsConsider<strong>in</strong>g 6 operat<strong>in</strong>g cycles <strong>in</strong> a year ( Rs.15.69 /6 )Rs.2.614 InterestDepreciation on c<strong>ap</strong>ital cost ( 10% ) 0.320Interest on work<strong>in</strong>g c<strong>ap</strong>ital of Rs. 2.61 ( 16% ) 0.417Total production cost per annum ( 2 + 4 ) 16.4075 <strong>Re</strong>alisationEstimated production of raw silk from 6 bas<strong>in</strong>Multiend <strong><strong>Re</strong>el<strong>in</strong>g</strong> unit…..1260/- kgs / annuma) Total sale value of silk yarn @ Rs.1250/- per kg 15.75b) Sale value of <strong>Silk</strong> bye products1) <strong>Silk</strong> waste ( 315 kgs @ Rs.275/- per kg ) 0.8662) Double Cocoons (600 kgs @ Rs.70/- kg ) 0.4203) Pupae ( 200 kgs @ Rs.3/- per kg ) 0.060Gross <strong>in</strong>come 17.096ProfitGross <strong>in</strong>come ( per annum ) 17.096Total expenditure ( per annum ) 16.487Net <strong>in</strong>come 0.609BYE – PRODUCTS USESDur<strong>in</strong>g the process of mulberry silk <strong>reel<strong>in</strong>g</strong>, the different qualities of mulberrysilk waste obta<strong>in</strong>ed as bye-products:a) Waste from cocoons:Floss or Blaze, Spelaia (Italian) or Keba (J<strong>ap</strong>an)Discarded cocoons, pierced, double, sta<strong>in</strong>ed etc.,Floss or Blaze: Floss silk or blaze also known as borra is the first part ofthe bave extruded by the worm for the frame work of the cocoon. Most ofit is removed from the cocoons dur<strong>in</strong>g their collection <strong>and</strong> rest whilesort<strong>in</strong>g. This can be used for noil sp<strong>in</strong>n<strong>in</strong>g.Discarded cocoons : This <strong>in</strong>cludes all cocoons found to be unreelabledur<strong>in</strong>g sort<strong>in</strong>g like :Double Cocoons: which are jo<strong>in</strong>tly formed by the comb<strong>in</strong>ation of twoworms <strong>in</strong> the same shell <strong>and</strong> which due to the the <strong>in</strong>terlock<strong>in</strong>g of thecont<strong>in</strong>uous filaments cannot be reeled alongwith good cocoons. Thesecocoons are also employed for <strong>reel<strong>in</strong>g</strong> ‘dupion silk’Inferior Cocoons:The improperly built cocoons <strong>and</strong> those deformed <strong>in</strong> sh<strong>ap</strong>e<strong>and</strong> also melted cocoons <strong>and</strong> other cocoons which become unfit for <strong>reel<strong>in</strong>g</strong>due to some reason or the other.b) <strong><strong>Re</strong>el<strong>in</strong>g</strong> waste :It may be filature, Cottage bas<strong>in</strong> or charka silk wastec) W<strong>in</strong>d<strong>in</strong>g waste: <strong>Re</strong>-<strong>reel<strong>in</strong>g</strong>, w<strong>in</strong>d<strong>in</strong>g or throwster’s waste,Weav<strong>in</strong>g waste (Hard waste)***