HJ830, HJ930: Operating Guide

HJ830, HJ930: Operating Guide

HJ830, HJ930: Operating Guide

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Products presented in this guide are conform torequirements of directives nbr 73/23/CEE and89/336/CEE.Neopost has implemented a program for therecycling of worn machines and machines at theend of their lifetime. Contribute in a responsibleway to the environmental protection by consultingyour retailer internet site, or by contacting him.He will inform you of the collection and treatmentprocesses of these machines.2

Table of ContentsTable of Contents1 Introduction1.1 Pictograms1.2 Notes for the Use of this Manual1.3 Important Terms and Abbreviations1.4 System Requirements2 Safety Notes2.1 General Safety Notes2.2 Handling Ink Cartridges2.3 Location of the Printer2.4 Disposal3 Transport and Packaging3.1 Shipping3.2 Unpacking the Printing3.3 Assembly4 Printer Description4.1 Machine Overview4.2 Range of Application4.3 Operation4.4 The Control Panel4.4.1 Keyboard Description4.4.2 Key Combinations4.5 The Display4.5.1 Offline Mode4.5.2 Online Mode4.6 Brief Instructions5 Start-Up and Operation5.1 Setting Up and Connecting the Printer5.2 Installing the Driver4

5.3 Inserting the Ink Cartridge5.3.1 Correctly Inserting the Ink Cartridge5.3.2 Resetting the Ink Counter5.3.3 Display for the Change of Ink Cartridge5.3.4 Set the ink Counter5.3.5 Cleaning the Ink Jets5.4 Print job Setup5.4.1 Setting Media Widths for the Machine5.4.2 Setting the Print Format5.4.3 Checking the Paper Transport5.5 Test Print5.6 Machine Counters5.6.1 Day Counter5.6.2 Service Counter5.6.3 Counting of Job Pages6 The Programming Mode6.1 Purpose of the Programming Mode6.2 The Control Panel in the Programming – Offline- Mode6.3 Keyboard Layout in the Programming Mode6.4 Menu Overview6.5 Explanation of the Individual Menus6.6 Job Parameter6.7 Service6.8 Language6.9 Setting6.9.1 Example of an Application in the Programming Mode6.9.2 Initialization of the Machine7 Troubleshooting7.1 The Meaning of Some of the Display Notes7.2 Error Messages7.3 Warning Messages8 Appendix8.1 Maintenance Notes8.1.1 Cleaning the Ink Cartridge8.1.2 Press Roll and Rollers8.2 Interfaces5

8.2.1 Centronics Parallel Interface8.2.2 RS-232-C Serial Interface8.3 Fonts8.3.1 Terminology8.3.2 Character Set8.3.3 Selection of the Fonts for Printing8.4 Character Sets8.4.1 7-Bit Character Sets8.4.2 8-Bit Character8.5 Side <strong>Guide</strong>8.6 Accessories8.7 Technical Data9 Glossary6

1 IntroductionWith the PRINTER 830/930 you have an innovative digital printer with HP ink jettechnology for printing variable data - for printing mass mailings, for example, withaddresses, serial numbers or other variable information and graphic elements. Themachine has been designed for professional use with high performance.In order to ensure both long service life of PRINTER 830/930 and itscomponents, as well as safe conditions of use, we recommend thatyou read carefully and comply with the operating instructions andsafety notes. Always be aware of all warnings and notes that are affixedto or printed on the machine itself.All persons who are to handle this machine must also be familiar with the operatingmanual.Store this manual in a safe place where it is easily accessible for future reference atany time.1.1 PictogramsGeneral WarningsWarning of danger from electricity or electrical shockInformation / Note indicating important information regarding thehandling of the machine.7

1.2 Notes for the Use of this ManualThe following sections provide all the general information and explanations required,in order to be able to carry out the subsequent tasks and procedures..When some action is expected from the assembler or operator, the text is alwayspreceded by a dot, for example:• First step.• Next step.Please, always read through to the action texts, so that you will obtain all of thenecessary information. Do not anticipate what you believe will follow in the manual:It will prevent you from making mistakes!Chronology and ReferenceThis manual is structured chronologically, and therefore ordered sequentially fromthe receipt of the machine packed up to its ready-for-use state. This is followed byinformation for operation, programming, and then finally technical data.When you are unfamiliar with the machine, it is best to read through the manualfrom beginning to end. You will be guided step by step, and in this way, you caneasily and quickly have the machine in operation.If you are already familiar with the PRINTER 830/930, it will make things easy ifyou to use this manual as a reference work.1.3 Important Terms and AbbreviationsThere are a few terms and abbreviations you need to know, in connection with thePRINTER 830/930:• Cartridge = Crt = C, C1, C2, C3.• Printing unit = Unit = U, U1,We refer to one unit here, since three cartridges have been combined.• Paper width = Extension of the medium to be printed in the transport direction.• Paper height = Extension of the medium to be printed crosswise to the transportdirection.• Print object width = Extension of the print object in the transport direction.• Print object height = Extension of the print object crosswise to the transportdirection.• The print object is the medium to be printed.1.4 System RequirementsThe PRINTER 830/930 is designed for use on a PC (at least Pentium 200 MHz) withparallel interface. It can be run with the Windows 2000 or Windows NT4 or WindowsXP operating systems.The interface cable must be a shielded twisted-pair parallel interface cable.As an alternative, the printer can be connected with a USB cable, when using Windows2000 and Windows XP.8

2 Safety NotesFor your own safety and the proper functioning of the machine, please, read carefullythe following instructions, before starting your machine. Always be aware of allwarnings and notes that are affixed to or printed on the machine itself. Store thismanual in a safe place where it is easily accessible for future reference, at anytime.The address PRINTER 830/930 is a state-of-the-art construction and reliable in operation.Nevertheless, the device may present hazards when operated by untrainedpersonnel. The same applies to use that is inappropriate and not in keeping with itsintended purpose.Failure to comply with this manual’s instructions might result in:• an electrical shock,• injuries due to the rotating rollers,• damage to the machine.9

2.1 General Safety NotesCaution!Please, read these notes with care.Save this manual for future reference.All notes and warnings found on the machine are to be followed.Installing theMachineElectricalHazards<strong>Operating</strong>SafetyCleaning theMachineA safe, level position is necessary, when installing the machine.Injuries may be caused by tipping, rolling away or falling.The machine is to be protected from moisture.WARNING!This is a Class A device. This device may cause radio frequencydisturbances in residential areas; in this case, the operator maybe required to implement the necessary corrective measures.Depending upon the country-specific version, the addressPRINTER 830/930 may only be connected to either a voltage of230 V/50 Hz or 115 V/60 Hz.The mains plug may only be connected with a socket having aninstalled protective contact! The protective effect may not becompromised by the use of an extension line without a protectivegrounding conductor. All interruptions of the protective groundingconductor, within or outside of the machine, are prohibited.The device is double pole fused! When fuse failure occurs, electricalmachine parts can still carry voltage.When making the connection to the mains power, be aware ofthe connection values on the rating plate.Inspect the voltage setting on the device’s power unit.Run the power cords in such a way, that no-one may trip overthem. Do not place any objects upon the power cord.When the machine is not in use over a long period of time, itshould be disconnected from the power supply in order to avoidany damage in the event of a voltage surge.Protect the device from moisture. When moisture enters the machine,there is a danger of electrical shock.Never open the machine. For reasons of electrical safety, themachine should only be opened by authorized service personnel.Never put your hands inside the machine when it is running!The danger of injuries exists, through pulling in and crushing onthe rotating rollers. In addition, keep long hair and parts of looseclothing far from the machine in operation.In order to prevent damage to the machine, only factory authorizedaccessory parts should only be used.Prior to cleaning the machine, it should be disconnected from themains outlet.When cleaning the machine, do not use liquid or spray cleaners,but only a cloth dampened with water.10

Allow theMachine tobe Inspectedby the ServicePartner!Spare PartsRepairsIn the following cases, you should unplug the machine from themains and contact an authorized service technician:• When the power cord or its plug is worn or damaged.• When water or other liquid has entered the device.• When the device does not function properly, in spite offollowing the instruction provided.• When the device has fallen down or the housing is damaged.• When there is a significant change in the performance ofthe machine.When repair work is carried out, only original spare parts orspare parts approved by the manufacturer may be used.Do not disassemble the machine any further than is described inthis manual. The opening of the machine by unauthorized personnelis not permitted. Repairs may only be carried out by authorizedservice personnel.Modification is not permitted:For safety reasons, your own reworking and modifications arenot permitted.The PRINTER 830/930 is a Class A device. This device maycause radio frequency disturbances in residential areas; in thiscase, the operator may be required to implement the necessarycorrective measures.11

2.2 Handling Ink CartridgesStore ink cartridges out of the reach of children. Normally, no inkleakage can occur. Immediately wash off sprays of ink from the skinunder running water. Should ink get into the eyes, rinse it out immediatelywith sufficient water.The ink cartridge should not be shaken, allowed to fall, or hit with the hand or ahard surface.Install the ink cartridge immediately after removing the protective strip. The expirationdate may not be exceeded.Do not attempt to open or refill an ink cartridge. This can damage the machine.Clean the ink cartridge as described in chapter 8.1 – “Maintenance Notes”.2.3 Location of the PrinterBe aware when installing the machine that it must stand on a smooth and level surfacethat is larger than the printer.The floor space for the printer must be sufficiently stable. The tipping over or fallingof the machine can lead to injuries, as well as damage to the machine.When selecting the installation or storage location for the printer, keep in mind thatit must be protected from strong temperature and humidity changes, direct sunlightand excessive heat.The printer must not be subject to vibrations or shocks.Install the printer near a mains outlet, so that the power cord can be disconnectedtrouble-free at all times.2.4 DisposalThe printer may not be disposed of in the conventional manner of household waste.Please, dispose of the printer in accordance with the regulations in force.12

3 Transport and Packaging3.1 ShippingThe PRINTER 830/930 is shipped in packaging designed for the purpose of deliveryat its intended destination, via regular transportation, in undamaged condition.The forwarding agent is liable for damages occurring in transit. Transport and storageshould take place under normal conditions, i.e. at temperatures between +5°Cand +70°C, and maximum relative humidity of 80%. During unauthorized conditions,damage may occur that is not outwardly visible.3.2 Unpacking the PrintingRemove all packaging and take out the device with accessories. Check to see, if allparts of the printer according to the following list are present in total and in undamagedcondition:• 1 PRINTER 830/930• 2 Side guides, short• 1 Side guide, middle (Optional for the Printer 830)• 1 Side guide, long (Optional for the Printer 830)• 1 Stack extension• 1 <strong>Guide</strong> bracket• 1 Printer driver & User <strong>Guide</strong> CD• 1 Power cord• 1 USB / Parallel interface cable• 3 ink cartridgesShould you not have any need for the packaging – e.g. sending it back for maintenancepurposes – dispose of it in an environmentally friendly manner.13

3.3 AssemblyAssembly of the Paper Support Plate and Side <strong>Guide</strong>1. Set the side guide in the lower metal opening and lock in place with a quarterturn of the bayonet coupling.2. In the same manner, set the guide bracket in the upper metal opening.Illustration 3-1: PRINTER 830/930 assembly14

4 Printer Description4.1 Machine OverviewIllustration 4-1: PRINTER 830/930 back side1. USB Connection2. Serial Status Connection3. ON/OFF Switch4. Printer Parallel Cable Connection5. Power cord Connection6. Fuse holder15

Illustration 4-2: PRINTER 830/930 front side1. Control panel with display2. Side guide middle3. Side guide shortNo ill.: Side guide long4. <strong>Guide</strong> bracket5. Separator6. Knurled screw separator7. Printing unit8. Knurled screw printing unit carriage9. Printing unit height adjustment10. Knurled screw height adjustmentoutfeed rollers11. Locking lever f. ink cartridge12. Ink cartridge13. Stack extension14. Discharge brush cpl, optional4.2 Range of ApplicationThe PRINTER 830/930 is a high speed & high quality ink jet printer. It prints correctlypositioned addresses on various print objects such as letter envelopes, letterheads,cards, prospectuses and newspapers up to:• Minimum140 mm x 70 mm with a thickness of 0.1 mm• MaximumPrinter 830: 508 mm x 355 mm with a thickness of 2 mmPrinter 930: 508 mm x 355 mm with a thickness of 6.3 mmThe maximum printing surface is 508 mm in width and 38 mm in height (equivalentto 9 lines with a font-size of 12 pt with a line spacing of 12 pt).16

4.3 OperationThe PRINTER 830/930 is designed for operation on an IBM-compatible PC. Printingcan be carried out from most word processing, database and address processingprograms.The printer has a printing unit with three HP ink cartridges. This allows the printingof addresses with no movement of the printing unit itself.The print object is - exactly positioned by the side guide - inserted above the printingunit. Printing is carried out when the print object passes under the printing unit.The direction of the font is always initially in the transport direction; the print canbe readable from the front or rotated by 180°.As a rule, the positioning of the address in height is carried out by moving theprinting unit. The positioning of the address in width may be carried out either viathe software on the PC or settings on the printer.The operation is very simple. For the first start-up, you will require about 30 minutes.4.4 The Control PanelIllustration 4-3: Control panel4.4.1 Keyboard DescriptionOnly in the Offline ModeKeys Key (X) alone Together with “Quick” Key1 Home = Main Menu2 Quick Menu =To find importantfunctions very fast3 Arrow up Start Test Print4 Arrow left Run Paper5 Arrow right Measure Paper Length6 Arrow down Purge Cartridges7 Cancel / Offline Mode8 OK (Confirm) / Online Mode17

LED FunctionsGreen LED = OnlineBlue LED = OfflineOrange LED= WarningRed LED = ErrorIn online mode the printer can only be switched to offline by pressing the “Offline”(7) button.4.4.2 Key CombinationsThe key combinations have, in connection with the switching on of the machine, thefollowing functions:PoweronHome Quick OK Cancel Down Up Left Right DescriptionX X Reset settings exceptingmechanical ResetX X Default ResetX X X X Firmware Download withoutstarting applicationX X X X X Firmware DownloadNote:x means- key is pressed at power-up.18

4.5 The DisplayMeaning of the display information:This is just an example and could looks different, depending on the printer setup.C o u n t. P o w r. O N : 1I n k C o s t s / J o b : 0 . 0 0 0M e t e r / S e c o n d : 0 . 0 0 0X J o b P a g e s / h : 06 X 6 d p iN o ro n l i n e214681357Illustration 4-4: Display indicationsMeaning of the display1 Job Counter, after powering up of o the printer2 Averaged ink costs of job3 Current transport speed4 Throughput per hour5 Print resolution measured in dots per inch6 Rotate print by 180° Nor = Normal, Rev = Reverse7 Indicates printer mode On or Offline8 Ink level of each cartridge. Here from Cartridge 1(left bar) tocartridge 6 (right bar)4.5.1 Offline ModeIn this type of operation, you can configure the machine via the keyboard.By using the "ONLINE" key, you access the online condition.19

4.5.2 Online ModeIn this type of operation, you can start the machine via command sequences fromyour computer. Printing is carried out in this type of operation.4.6 Brief InstructionsIn order to be able to quickly carry out a test print with no previous experience, youshould follow the operational steps listed in the table below, in the correct order. Inthe pages listed in the right hand column, you will find the detailed description ofoperational steps.Operational Step Chapter PageConnect device 5.1 22Switch on device 0 23Operate device via USB 5.2 23Set device for media thickness 5.4.1 36Set the format of the device 5.4.2 39Paper run without printing 5.4.3 42Test print 5.5 4220

5 Start-Up and Operation5.1 Setting Up and Connecting the PrinterInstall the printer as described in chapter 2.3 - “Location of the Printer“.Power CordSee Illustration 4-2: PRINTER 830/930 front side on page 17Caution!The PRINTER 830/930 is a device of class 1!The machine may only be operated on electrical circuits with protectivegrounding conductors (ground)!Connect the power cord to the printer. Insert the mains plug into a socket with protectivecontact.Change the fuses (also necessary when changing the mains voltage)Caution!When changing the fuse, you must always remove the power cordbeforehand!Open the holding compartment with a fingernail or small pen. Change the fuse asshown in the following illustration.See chapter 8.7 - „Technical Data“ – starting on page 89.Illustration 5-1: Changing the fusesInterface CableIf you wish to operate the printer via USB, then read through thechapter 5.2 “Installing the Driver“ starting on page 23 now.See Illustration 4-2: PRINTER 830/930 front side on page 17Insert the interface cable into the connector at the back side of the machine (lockthe parallel connector). Connect the cable with your computer.21

5.2 Installing the Driver for Your PrinterNote:• When several user accounts are used on the system, you must make certain that you haveAdministrator Privileges. According to the Windows security model, only the Administratorcan install the driver.1. Insert the CD labelled Hasler Address Printer Installation. Theinstallation program should start automatically, if it doesn’t,browse the CD and open the file named Install_Menu.2. Hold down the Ctrl key and click >>Driver Installation for yourmodel printer.22

3. You will be brought to the welcome screen of the PrinterInstallation Wizard. The wizard will walk you through the processof installing the driver. Click Next.4. Select Local printer attached to this computer. Click Next.23

5. Select the appropriate printer port. Click Next.6. Choose your printer model from the menu. Click Next.24

7. Select wether or not you wish to set this as your default printer. ClickNext.8. You are now given the choice of sharing this printer on your network.Click Next.25

9. Choose wether or not you’d like to print a test page. Click Next.10. Verify all of your information and click Finish to complete theinstallation.26

11. You may receive the warning seen below. Click Continue Anyway tocomplete the installation.12. Installation is now complete.27

5.3.1 Correctly Inserting the Ink CartridgeFirst, you must have access to the cartridge holder.In the event that the printing unit is found on the front sidewall, unscrew the thumbscrew on the printing unit and push the printing unit into the middle.1. Lift completely all locking levers (upward).2. Take the ink cartridge out of the packaging and remove the protective strip.Do not touch the contact plate…In order to ensure a secure contact for the ink cartridge to the electronics ofthe printer, the locking lever has two functions:• Tipping the ink cartridge into the end position• Secure locking during operation3. Set the ink cartridge, with the jet surface downward, with a straight motioninto the holder – do not press in the direction of the locking lever – .The ink cartridge stands at a slight slant, prior to the closing of the lockinglever. The locking lever then tips the ink cartridge into the end position.4. Close the locking lever.Do not tip the ink cartridge into the end position by hand! Thisis taken care of by the locking lever. Otherwise, you can damagethe ink cartridge or the contact plate!Illustration 5-21: Open locking lever28

Illustration 5-22: Inserting the ink cartridgeIllustration 5-23: Close locking lever5.3.2 Resetting the Ink CounterIf you are online, change to offline mode with the Offline button.Press the Home button.Change to the Printer Configuration menu and confirm with the Arrow Rightbutton.Change to the Ink menu, confirm with the Arrow Right button and here, selectthe Cartridge Reset menu and confirm again.Now you have the option to either reset all cartridges as a whole or to selectivelyreset only individual cartridges.If you want to reset all cartridges, move to the All Cartridges field with the ArrowUp or Arrow Down button. Confirm with OK.If you want to reset particular cartridges only, move to the corresponding cartridgefield with the Arrow Up or Arrow Down button and confirm. To leave this menu,press the Cancel button; thus you reach the next higher menu.5.3.3 Display for the Change of Ink CartridgeC o u n t . P w r O n : 1I n k C o s t s / J o b : 0 . 0 0 0M e t e r / S e c o n d : 0 . 0 0 0X J o b P a g e s / h : 06 X 6 d p iN o ro f f l i n e29

If less than 5% ink is in the cartridge the ink level bars are not displayed and youget an error message:NO INK !!CHANGE PRINTHEADIn the menu “Error Level” you can select:STOP: Printer should stop if “No Ink” is displayedIGNORE: Printer should print if “No Ink” is displayed5.3.4 Set the ink CounterThe calibration is carried out in offline mode. Press the Arrow Down or Arrow Upbutton and confirm “Offline” with the Arrow Left button.C o u n t . P w r O n : 1I n k C o s t s / J o b : 0 . 0 0 0M e t e r / S e c o n d : 0 . 0 0 0X J o b P a g e s / h : 06 X 6 d p iC 1 : 9 7 %o f f l i n eThe display will show the following:The right ink-level bar gets a frame around that you can check which cartridge youwant to change.Here it is cartridge 1 from unit 2 and the ink level is 97%.To change the level, press the Arrow Down or Arrow Up button.To change to another cartridge, press the Arrow Left button.With this menu you are able to change each level from each cartridge very fast.For comparison, the ink level display of an ink cartridge HP 51645A is on the backside.30

Illustration 5-24: Ink supply displayFor replacing the cartridge, switch the printer offline using the start key (Off mustbe indicated on the display). Carry out a “CARTRIDGE RESET“ in the menu.5.3.5 Cleaning the Ink JetsFor time to time, the ink jets need to be cleaned or unclogged.1. Insert a single sheet of paper into the feeder.2. Switch the PRINTER 830/930 into the Offline mode.3. At the same time, activate the Quick and Arrow down keys.The ink jets are then sprayed onto the fed sheet of paper, in order to unclog themselves.5.4 Print job SetupSo that a correct and sharp print appears on an exact position on the print object,the printer has to be set for each print object. The printer processes various widths(up to 6 mm) and various formats (from postcard size to B4 format, with specialaccessories up to format C3). This is why it is necessary to implement settings forthe widths and format. For this work process, keep ready the next print object thatyou would like to print.5.4.1 Setting Media Widths for the Machine5.4.1.1 Setting the Printing Unit to the Media WidthFor a sharp print, it is important to set the height of the printing unit over the printobject. This is only possible with a loosened printer-unit carriage:31

Illustration 5-25: Set printer1. To do this, loosen the thumb screws (1) of the printing unit.2. Use the scale button (2) to set the width of the print object. The button has amillimetre scale.3. Screw the thumb screw of the printing unit in tightly.5.4.1.2 Setting the Media Width for the Sheet Separating SystemHeight adjustment of the pickup rollersUp to a print object width from 1.5 mm to 2 mm, the rollers can remain in the lowestposition. With a thicker print object, the distance should be set, so that the printobject is subject to the appropriate printing pressure on the rollers. This can beeasily tested with the insertion of the print object. The press rollers lift up on millimetreper revolution.Illustration 5-26: Height adjustment of the pickup rollersSetting the Height of both sheet separatorsIn order that only one print object is fed in, both separators are to be set for theprint object.32

Both sheet separators must always be set, even when – for example –a small format print object only lies on one separator. When this is notdone, the free separator may drag on the transport rollers. This leadsto increased wear on the transport rollers; entry may cause damage.Illustration 5-27: Setting the separating finger1. Loosen the knurled screws (2) of both separators.2. Lift up both separators (1) and lay the print object under the separating finger(3). With narrow print objects, it may be the case that only two innerseparating fingers reach the print object, e.g. postcards, DL envelopes, No.10 envelopes. In this case, lift the outer separator (1) up to the upper stopand clamp it fast.This step is also recommended, when narrow print objects are partiallyreached by a separating finger, e.g. with C6 and DL envelopes.When only three separating fingers reach the print object, then an additionalprint object is to be placed under the fourth separating finger. (It may be possiblehere, that you have to remove the outer side guide)33

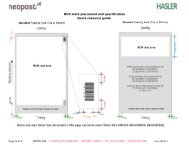

Testprint RENA 613 SLTest Test TestTest Test TestTest Test TestTest Test TestTest Test TestTest Test TestTest Test TestTest Test TestFailure to comply with these steps can lead to premature wear on theseparation rollers.3. Allow both separators (1), without exerting pressure, to fall upon the printobject and again fix the knurled screws (2) in position.5.4.2 Setting the Print Format5.4.2.1 Setting the Print Position of the AddressBefore setting the desired address position, you must know in which area printing ispossible.The positioning of the address height is carried out by moving the printing unit. Theprintable area results from the necessary margins and the traverse path of theprinting unit:X+Y = 2 mm (0,078“)38(1,5) 15(0,6)145(5,7)Not printable Print area Printing unit traverse areaIllustration 5-28: Setting the print position for the addressThe upper margin depicted here of 15 mm can be reduced to 0 mm, when required.To do this, push the rear side guide onto the red marking. Now printing can be carriedout without margins.Illustration 5-29: Setting the print position for the addressThe printing direction depends upon the size of your print object and the uppermargin. When the desired margin space is not reachable for the printing unit, thenthe address block and thereby the print object must be rotated by 180°.34

5.4.2.2 Positioning the Address in HeightThe PRINTER 830/930 is a WYSIWYG printer 1 with limitations. The limitations liein the vertical position of the address. Heeding the following note is important foryour document:1. In your page layout, set your document to the portrait format.2. As a rule, enter the value 0 for the upper margin.3. The last position in the print is set through the mechanical positioning of theprinting unit:4. Lay the print object in the printer.5. Loosen the knurled screw on carriage of the printing unit.6. Move the printing unit, so that the jet surfaces of the ink cartridge lie at thedesired position. If the desired distance from the edge is not reachable for thejet surfaces, then turn the print object around 180°. Now position the jet surfacefor this situation.7. Fix the carriage again in position.8. If you have placed the print object in at 180°, then the print must also be setat 180° (Rev):9. In the event that the printer is in the offline mode, press the Offline key andswitch the printer to OFFLINE.10. Press the Quick key, navigate with the Arrow up key to the “Orientation”Menu and confirm with OK. Now you can change the print direction fromNormal to Reverse (Rev).5.4.2.3 Positioning the Address in WidthThe positioning in width is determined via the software on the PC:• Position the address as desired, for example with the help of the left marginsetting, with the tabulator, or other suitable formatting.So that the positioning, as entered into the program, can be carried out correctlyon the print object, the printer must recognize the exact length of theprint object. This is determined in a length measurement.5.4.2.4 Setting the Directional Control5.4.2.4.1 Setting the Side <strong>Guide</strong>First, you must know whether the print object runs lengthwise or widthwise throughthe printer.The lines are always printed in the direction the print object is run.If the lines run parallel to the longer side, the intake occurs using the narrow side.1 WYSIWYG (What You See Is What You Get)35

Illustration 5-30: Setting the print object formatIf the lines run parallel to the shorter side, the intake occurs using the longer side.Illustration 5-31: Setting the print object format1. Push the rear side guide completely to the side wall of the machine.2. Lay the print object between the side guides. <strong>Guide</strong> it toward the separator.3. Push the frontal side guide up to the print object. The print object must notbe jammed. With very narrow formats, the outer side guide may have to beturned.When the print object is larger than can be reached by both delivered side guides –as an alternative to the frontal side guide – a middle and a longer side guides (seepage 88 – “Accessories“) are available.Which side guide should be used for various formats can be selected from the overviewtable of the parameter PAPER SIZE on page 50 and from chapter 8.5 “Side<strong>Guide</strong>“ in Appendix.5.4.2.5 Setting the paper Support Plate1. Lay a single print object in the feeder.2. Position the bracket in the middle, between both side guides.3. Push the plastic part (tray support) on the guide bracket so far up to the printobject, that it just touches it.4. Fan the print-object stack, so that the lowermost sheet can be fed in first,and place it on the guide bracket.5. Push the plastic horizontal strut of the guide bracket completely to the printobject. The lowermost print object should be just touching the horizontalstrut.36

Illustration 5-32: Setting the guide bracket6. Now test the trouble-free feeding of the print object. To do this, allow a stackof the print object to run through with the help of the paper transport in theOffline mode as follows:Caution! When doing this, do not put your hands inside the machinewhen it is in operation.7. In the event that the printer is not in the offline mode, activate the start keyand switch the printer to Off.8. Press the pap key, and the print object will be transported or ejected. Bypressing the pap key again, the paper transport ends once again.5.4.3 Checking the Paper TransportLength measurementCarry out the length measurement of the medium to be processed by pressing theQUICK + ARROW LEFT keys.Check the displayed value as compared to the actual value. When there is a variancebetween the two values (more than 3 mm), a wrongly set paper feed could bethe cause. When the software transmits the wrong paper length value, the paperlength measurement can be locally locked in the machine. Pressing longer on thekey for paper measurement makes possible the local locking of the paper length(visible on the display with an ”(L)“).Transporting of a single medium• When you press the Quick + Arrow Right keys, the medium found in thefeeder is fed in, transported under the printing unit, and then ejected.When you press the Cancel key again, the paper transport is stopped. It can alsobe halted by pressing the OK key.5.5 Test Print1. Switch on the PRINTER 830/930 using the ON/OFF switch and wait until thestart-up routine has been completed.2. Change from the Online mode to the Offline mode by using the Offlinekey.37

Printing the Test Picture1. Place as many media in the feeder as you would like to use for a test print,e.g. 1 medium.2. Confirm with the Quick +Arrow Up keys. The test print is carried out. Pressthe key again, in order to stop the procedure.3. Using the test print, check the position, the orientation and the quality of theprint on the medium.Possible printout errors:Test picture 1 with errorsTest picture 2 correctIllustration 5-33: Setting the dosing rollThere is too much pressure from the separating finger on the print objectNever put your hands inside the machine when it is in operation!5.6 Machine CountersThree different Counters are installed in this machine:5.6.1 Day CounterEach printout after the paper is ejected is counted and the value is readable in theright upper area.This counter includes the “Job” and the “Service” printouts.After powered off and on the machine, the counter is reset.5.6.2 Service CounterA test page count contains the number of Test prints with the accompanying paperejection.This count is carried out with the activation of the "TEST" key or several “Service”printouts, with the machine in the offline condition.38

5.6.3 Counting of Job PagesA job page count contains the number of data printouts received by the computerwith the accompanying paper ejection.This count is carried out with the machine in the online condition.When you continue data transmission with printouts, counting is resumed.All counters are reset when the machine is switched off!To change the view of the 3 counters you have to be in the Offlinemode. Select and confirm your selection with the arrow up or downbutton and then change it with arrow left or right button.39

6 The Programming Mode6.1 Purpose of the Programming ModeThe programming mode is used for setting manually a number of parameters viathe control panel. Parameters are definitions of set point values for font settings,print quality, papers settings, as well as special and test functions.Since the printer is operated, as a general rule, from a text or address processingprogram, the factory settings have been optimized for this, and normally nochanges are necessary.In individual cases, however, adjusting the parameters may be required. In such acase and should you wish to make full use of your address printer’s capabilities, allof the parameters are discussed in this chapter.This chapter is intended as a reference source for experienced users.6.2 The Control Panel in the Programming – Offline- ModeChange to the programming mode:1. Press the Offline key2. The blue LED has to be on and the display shows OFFLINE.40

6.3 Keyboard Layout in the Programming ModeIllustration 6-1: Keyboard layout for the programming modeIn online mode, the printer can only be switched to offline mode by pressing the „Offline“ button.Quick ButtonThe Quick button can only be used in offline mode.Function when singly applied:By pressing the Quick button, the quick menu can be directly called up at any time;this serves for speedy operation.By pressing the OK button the selected menu function is executed.By using the navigation buttons Arrow Up and Arrow Down, navigationwithin the quick menu is possible.When first pressing the Quick button and then together with another button thesecondary function of that button is called up. (Like the Shift button on the PC).• Quick – Arrow Up = Test printBased on the current settings, a test print is executed. If the combination functionis called up from a menu item, then you return to this item after leaving the testprint. If the button is pressed briefly, a test print is carried out – similar to the papbutton - and afterwards you return to the called-up display again. If you press thebutton for a longer time, a continuous test print is carried out. With Cancel youbreak up the continuous test print and return to the previous display again.• Quick – Arrow Down = Clean HeadsA sheet is supplied and a line pattern is printed onto it, based on the currently adjustedpaper length.41

• Quick – Arrow Left = Run Paper (Supply Paper)If you press the button shortly, only one sheet is transported; afterwards you returnto the previous display. If you press the button for a prolonged time, a continuouspaper run is started. By pressing Cancel you break up the run, and you returnto the previous display.• Quick – Arrow Right = Paper Length (Measure paper length)Using this combination you may measure the paper length. Subsequently, themeasured length is displayed. If you hold this combination pressed for a longertime, the measured length is locked and therefore prevented from being overwrittenby the software.42

6.4 Menu OverviewIf the printer is Offline, press the HOME-k e y and the display will show the mainmenu from the printer. With the Arrow up and Arrow down keys you can navigatethrough this menu. With the OK or Arrow right you are able toconfirm the submenu.HomePrinter ConfigJob ConfigServiceLanguageSettingsMain menu Submenu OptionsPrinter Configuration Maintenance Auto Clean HeadsCapping DelayAdjustment StepsCorrection Patt.Corr. Dist. U1 – U2Corr. Dist. U2 – U3Corr. Dist. U3 – U4Corr. Cart. 1 – 2 UX (X = 1, 2,3, 4)Corr. Cart. 2 – 3 UX (X = 1, 2,3, 4)Boot DefaultsUnit of MeasurementInkCartridge OptimizingWarmingPrewarmingInk Cost. ConfigError HandlingError Level FontEmpty CartridgeBeeper43

Main menu Submenu OptionsJob Parameter Quality 6x6D, 6x3D, 3x6D, 3x3D,2x6D, 2x3D, 1x6D, 1x3DTransport Param.Paper SpeedAuto. Pap. SpeedPaper Time OutLayoutOrientationPaper SizeLeft Margin (mm)Offs. Edge (mm)Font ParameterFontCharacter SpacingCharacter SetTyp of BarcodeZip, bpo4, Kix,2/5i, EAN,Codabar, Code 39,128,Code 93, AUS4state,Canada, OffPaper SensorDos ModeOff, OnLinemodeHEX to ASCIIAuto. LFMain menu Submenu OptionsService Test Pattern Nr1, Nr2Hardware TestDisplayKey TestRam TestRam Test Contin.NV-Ram Test Cont.Speed MeasurementPaper SensorAlignment Horiz.Alignment Vertic.44

Correction PatternCart. Print PatternCheck CartridgesLED/ BeeperConfiguration InfoFirmware: (X.X.XX)SerNr.: (XXXXXXXXXXX)Page Cnt.: (XXXX)RAM: (64 MB)Hardware: (V16-0)DC: (x A)Printing SettingDumpPrinting Input DumpPrint Character SetMain menu Submenu OptionsLanguageEnglisch, DeutschFranz., Ital., EspMain menu Submenu OptionsSettings Nr 0 – Nr 96.5 Explanation of the Individual MenusPrinter ConfigurationSettings affect the printer.Job ConfigurationSettings affect the print job.ServiceTest routine for checking the hardware.45

LanguageDifferent languages can be selected.SettingsSelection of a configuration.Printer ConfigurationMaintenanceAuto Clean HeadsOff is the factory setting. In the setting „1st“, prior to each print job, a page with ablack bar is printed to purge the cartridges.Auto Primeoff = no cleaning of the jets before printing or by means of a test printon = Jets are cleaned before printing, when no paper lies beneath the light barrierAdjustment StepsCorrection Pattern = Test print to detect which value is the correct one for eachcartridge.This kind of calibration may become necessary since a completely tolerance-freeproduction of a print unit is not possible. Slight deviations due to manufacturingtolerances can be balanced via the software of the control device.Calibration can only be carried out at the installed device and can therefore not beperformed by the manufacturer.Press the „Quick“ and „test“ buttons simultaneously and place paper onto the band.The printer will carry out a test print with the cartridges in the particular printheads.Corr. Dist. U1-U2This serves the adjustment of production tolerances between printheads.The resulting misalignment of the ink jet surfaces of two neighbouring cartridgescan be balanced horizontally.Corr. Dist. C1-C2 is for cartridges 1 + 2Corr. Dist. C2-C3 is for cartridges 2 + 3Boot DefaultsUnit of MeasurementMillimeter, Zoll (Feet/Min)Choices of speed and length values for the graphic account on the display.46

InkCartridge OptimizingOptimizing the cartridge temperature (TTOE)• Selection possibilities:all: all three cartridges are optimizedCrt1: only cartridge 1 is optimizedCrt2: only cartridge 2 is optimizedCrt3: only cartridge 3 is optimizedno: no action is carried outCheck: Testing and display of the condition for each cartridgeFor the optimization, no paper may lie underneath the cartridges. The printing unitsmust be positioned in a set area.For this reason, the query is displayed:Paper RemovedOK=YES Cancel=NoAfter pressing the Enter key, the second query is displayed:Print units Centered?OK=YES Cancel=NoAfter pressing the Enter key, the following is displayed:Optimizing C#.....Please WaitOptimizing C#......OK#=1,2,3,4,5,6,allCartridge ResetResetting the display for ink used, following the insertion of the new cartridge(s)Selection possibilities:all: all six cartridges are resetCrt n:no:only cartridge n is resetno cartridge is resetWarmingWarming function for the ink jets.off = no warmingon = warming during the printing processPrewarming = warming and pre-warming prior to the printing processInk Cost. ConfigConfiguration of the ink consumption – costs.47

Volume Cart. (ml): Capacity of the cartridgeVolume Drop (pl): Capacity of the dropCosts/ Cartridge: Costs for one cartridgeCurrency: Euro, Dollar, Pound, Yuan, otherError HandlingError Level FontLow = Printer doesn’t stop if it gets an undefined character during transfer from thePC.High = Printer stops printing if it gets an undefined character during transfer.Empty CartridgeStop = Printer stops if warning “No Ink” is comingIgnore = Printer doesn’t stop if warning “No Ink” is comingBeeperChoices of configuration for the Beeper: short, long or intermittent6.6 Job ParameterPrint QualitySelection of print quality with the maximum permissible printing speed for theprinting quality (compare “Erreur ! Source du renvoi introuvable.” on pageErreur ! Signet non défini.).The higher the number, the better the print quality.1x3 = 150x300dpi, 1x6 = 150x600dpi, 2x3 = 200x600dpi, 2x6 = 200x300dpi,3x3 = 300x300dpi, 3x6 = 300x600dpi, 6x3 = 600x300dpi, 6x6 = 600x600dpiTransport Param.Paper SpeedThe PRINTER 830/930 has 10 speed settings. The easiest way to set the speed is touse the PRINT QUALITY menu (see page 48). As soon as you select a certain qualitythere, PRINTER 830/930 automatically sets the maximum speed possible for thisquality.Example: When the quality 3x3 is selected, the speed is automatically set to level 7[1080mm/s].Should the automatically set speed be too fast, for some reason, then you can reducethe maximum speed that corresponds to the print quality via the PAPERSPEED menu.PRINT QUALITY Speed Level Max. Speedin mm/s / inch/s1x3, 1x6 MAX 1820 / 71.6548

PRINT QUALITY Speed Level Max. Speedin mm/s / inch/s2x3, 2x6 9 1520 / 59.848 1320 / 51.973x3, 3x6 7 1080 / 42.56 920 / 36.25 720 / 28.36x6, 6x3 4 540 / 21.263 420 / 16.52 270 / 10.61 120 / 4.72Auto. Pap. SpeedChoose if Auto. Pap. speed should be “On” or “Of”, or reduce to 80 or 60%On = The speed is automatically selectedOff = You are able to reduce the speedPaper Time OutWhen this function is active, paper transport is immediately stopped after the printrequest has ended.LayoutOrientationAddress rotation of 180°.Nor – the printout is readable from the operator’side.Rev – the printout is rotated by 180°.Paper SizeOn the following page, you can see the overview of format sizes, which you canset in the programming mode under the PAPER SIZE menu.The two right columns in the table indicate which side guides must be used.The following side guides can be used:Side guide short (2x) (standard)Side guidemiddle (standard)Side guide long (accessory)Format Designation Type Size in inches in mmSide guideoff No format size -- -- --EXEC Executive Paper 7 1/4 x 10 1/2 184 x 267LETT Letter Paper 8 1/2 x 11 216 x 279LEGA Legal Paper 8 1/2 x 14 216 x 35649

A4 DIN A4 Paper 8 1/4 x 11 11/16 210 x 297A5 DIN A5 Paper 5 13/16 x 8 1/4 148 x 210MONA Monarch Envelope 3 7/8 x 7 1/2 98 x 190,5C10 Com-10 (Business) Envelope 4 1/8 x 9 1/2 105 x 241INTD International DL Envelope 3 7/8 x 7 1/2 98 x 190,5C5 International C5 Envelope 6 3/8 x 9 1/64 110 x 220INSD Inserter DL Envelope 4 1/2 x 9 1/64 114 x 229C6 International C6 Envelope 4 1/2 x 6 3/8 114 x 162A6 DIN A6 Paper 4 1/8 x 5 13/16 105 x 148CRD1File card 1File card4 x 6102 x 152CRD2File card 2File card5 x 8127 x 203HAGAHagakiEnvelope3 15/16 x 5 13/16100 x 1486 15/16 x 9 27/32B5Envelopemax. 30176 x 250USEREnter format width inmmPapermax. 762Overview of the format sizes that the USERS can enter.These format sizes are not supported in the printer menu.B4 9 27/32 x 139/10 250 x 353B6 4 9/10 x 6 15/16 125 x 176C4 9 1/64 x 12 3/4 229 x 324E4 11 x 15 3/4 280 x 400Left Margin (mm)• Setting the left margin in a range of 0 – 304 mm.• The change in the value is carried out in mm increments; when the next or prevkeys are held down, the change in value is carried out in cm increments.Offs. Edge (mm)The shifting of the measured paper from 0 through 304 mm. For the user, it wouldappear as if the left margin would become enlarged. This is necessary with:• Window programs in which the left margin cannot be changed.• Printing of large envelopes with Windows Mail Merge, when the desired printingposition cannot be set on the PC.50

Font ParameterFont13 fonts or font sized have been built into the machine. A font selection can be madehere.Character SpacingIncrease the character spacing in dots of 0 to 90.Character SetNational character sets with some special symbols for the applicable foreign language.Type of BarcodeThe following barcodes may be selected:Option Barcode Option BarcodeZip Barcode USA co39 co39-Barcodebpo4 Barcode Great Britain co93 co93-Barcodekix Barcode Netherlands c128 c128-Barcode2/5 i 2/5 interleaved-Barcode ean EAN-BarcodeCoda coda-Barcode off No BarcodeZip ---- AUTO CHECK DIG. ------------------ ON/OFFC1282/5icodaCo39Co93--------- Small Width ------------ 1…..99 Dots--------- Large Width ------------ 1…..99 Dots--------- Barc. Height ------------ 1…..999 Dotsean--------- Barc. Height ------------ 1…..999 DotsPaper SensorIn order to process print objects with black areas, you can switch off the paper light barrierduring printing. For this purpose, you must definitely set the format size under PAPER SIZE(an incorrect format size can lead to printing outside the paper area).With a switched off paper sensor and a preset format size, the light barrier only queries atpaper infeed.51

Dos ModeLinemodeThis makes possible address separation, through a certain number of line breaks.HEX to ASCIIConversion from HEX to ASCII.When the conversion is switched on, then the printer interpretsthe percent sign “%“ as an unprintable control character. Bothcharacters following the % character will be interpreted as HEXvalues, e.g. %0C = Form Feed.Auto. LFThis menu is used to determine how the printer should interpret control characters:CR = Carriage ReturnLF = Line FeedFF = Form FeedThe settings mean:off: CR = CR LF = LF FF = FFon_1: CR = CR + LF LF = LF FF = FFon_2: CR = CR LF = CR + LF FF = CR + FFon_3: CR = CR + LF LF = CR + LF FF = CR + FF6.7 ServiceTest Pattern = Selection of test address 1 or 2.Hardware testDisplay:= Testing the graphic display. Many different characters are shown in orderto test the function of the display.Key test:= All buttons which are pressed are confirmed by being shown in the display.Ram Test:= All RAMs on the CPU are tested. If an error occurs, this is shown on thedisplay.Ram Test Cont.: = Continuous testing of the RAMs until the test is exited manually.NV Ram Test Cont.: = Continuous testing of the transient RAMs.Speed Measurement: = Shows the actual speed.Paper Sensor = To check if the paper sensor is working- Free or not freeAlignment Horiz. = Printing a special test page to test the horizontal alignment.52

Alignment Vertic. = Printing a special test page to test the vertical alignment.Correction Pattern = Printout to determine the correction value in order to calibrate the cartridges.Cart. Print PatternIn several test prints for the cartridges.The contacts to the jets are shown in a grid. (See following page)Illustration 6-2: Test Print of all cartridgesThe contacts for all jets are controlled sequentially and made visible in a continuous slantingline.Illustration 6-3: Test Print of all jetsExamples of defective printheads:53

Illustration 6-4: Test print with defective jets• a.1 = no connection at contact “K“ (with printhead H1)a.2 = no connection at contact “B“ (with printhead H3)• b.1 = no connection at contact “10“ (with printhead H1)b.2 = no connection at contact “16“ (with printhead H3)• c = these jets are not cleanWhen a grid or slanting line shows gaps (see illustration above), the contact surfacesand cable contacts of the corresponding printhead are to be cleaned, or theprinthead in question is to be replaced.Check Cartridge = Display of Pen ID, missing jets, as well as optimization of all cartridges.LED / BeeperUpon activation of this function1: All LED’s are going out2: The green LED is flashing for ca. 2 seconds and the display shows the function ofthis LED.3: The LEDs are flashing each in turn for ca. 2 seconds and are described on thedisplay.4: At last, the beeper makes the beep even for 2 seconds.Configuration InfoAll device-specific data is displayed.FirmwareSerNr:Page CntRAMHardwareDC: (5V)Printing Setting DumpPrintout of the 10 setting configurations; 9 sheets are required.Printing Input DumpWith this function, the entire reception buffer is printed with PC8 symbols.The entire printout requires approximately 180 sheets. Prior to the dump print,switch the machine off and on again. Send the print job, and then start the dump54

print. The required data is now at the front of the buffer. Stop the procedure usingthe end key.Print Character SetPrintout of the character set.6.8 LanguageThe displayed text can be shown in different languages: English, German, French,Italian and Spanish.6.9 SettingAn individual configuration can be created for each of the different applications.Configuration No. “0“ is for the factory setting; no changes can be made here.The configurations “No 1 through No 9 “can be individually set.When exiting the programming mode, the changes carried out in the selected settingnumber are saved.Individual parameters can be Locked. Locked parameters are indicated by an “L“ underthe menu field.(When parameters are Local Locked, incompatibility with softwareapplications can occur. Example: When the left margin isLocked, but the software application carries out absolute horizontalpositioning. Other conflicts are alsopossible).• After switching off the machine, the set configurations are maintained.• With a factory initialization (Quick key is held down when switching on themachine), all configuration settings are set to factory settings.6.9.1 Example of an Application in the Programming ModeSuppose you would like to set a configuration, changing the vertical line spacingfrom 6 lines / inch to 8 lines / inch.Switch the machine on.Programming ModePress the "Offline" button.Activate desired menu fieldChange with the "Home" key in the main menu. Press the "Arrow Down" key, selectthe menu "Job Parameter" and confirm with "Arrow Right" In this submenu, you willfind the menu "Font". Confirm it with "OK" and you get other submenus. With "ArrowDown" or "Arrow Up" move to the desired menu field i.e. "Line spacing" andconfirm it with "OK".With the "Arrow down" or "Arrow Up" key, you are able to set the parameter to "8".55

Press the "OK" key. The changed value is saved in the configuration under the selected"Setting No", and the machine is again in offline modeorpress the "Online" key. The machine is again in online mode, so that the print jobcan be resumed immediately.6.9.2 Initialization of the MachineWithout loss of configurationIn order to access the factory configuration, select in programming mode and inmenu field "Setting" the option "No 0". When the "ENTER" key is pressed, the programmingmode is ended. "Set 0U" may appear on the display. The set configurationis maintained under your corresponding setting number (compare with menuitem "Setting").With loss of configurationIn order to restore all changed values and configurations, switch off the machine.When restarting the machine, press and hold down the "Quick" key.The following appears on the display:PRINTER 830/930 PPCDefault ResetThe machine now has the factory settings, and all configurations are those of thefactory. "Set 1U" may be displayed.56

7 Troubleshooting7.1 The Meaning of Some of the Display Notes• ??? blinksData/Addresses were transmitted, but there is no print object.• NoD blinks.The last data/addresses are incomplete (FormFeed is missing)• Wait blinks.Printing has halted, because the control character EOT was sent.Printing can be resumed with the start key.• Off blinks.The printing is stopped for a few seconds, because a pause is being set viasequences. Printing starts when the set time has elapsed.57

7.2 Error MessagesError Messages Cause RemedyNO PAPER !! No paper Insert paperPAPER JAM ORWRONG PAPER LENGTH!NO INK !!CHANGE CARTRIDGECHECKSUM ERROR!MAKE DEFAULT RESETCHECKSUM ERROR!MAKE COUNTER RESETCHECKSUM ERROR!TESTMACRO RESETCHECKSUM ERROR!SETTING RESETCHECKSUM ERROR!RESET PENVALUESTEST MACRO TOO LONGBUFFER OVERFLOW !!RAM ERROR !!VERIFY RAMUNPRINTED ADDESSES!FINISH THE JOBPROGRAM ERRORMAKE DEFAULT RESETUART TIMEOUTRESET THE PRINTER!DISPLAY TIMEOUTRESET THE PRINTER!ERROR FPGA ReadyCALL SERVICECHECK CARTR.START TO CONTINUEPRINTING ERRORREPEAT LAST ADDRESSESReduce Pap. Speed! U#START to continue!Feed Motor Jammed!START to ContinueFeed Motor ControllerFault! Call ServicePaper jamThe cartridge is empty.Error in the buffered RAMError in the buffered RAMError in the buffered RAMError in the buffered RAMError in the buffered RAMThe user-defined test addressis too longOverflow of receptionmemory.RAM error on the CPUboardAddress is not completelyprinted.Error in the program flow.Error in the UART chip orFET transistorError with display controls.Error FPGA-ICCartridge is not insertedSevere errorTransport speed too highfor the printing unit #Error with motor controlFault initializing motor-ICCheck paper widthInsert a new cartridge andreset the counter.Factory setting(PROG key)Default factory setting(ONLY for technicians)Factory setting(PROG key)Factory setting(PROG key)Factory setting(PROG key)Be aware of the maximumlength.Check connection to thePC.Replace the CPU board.Make no changes in theprogramming mode whilea print job is in progress!Factory initialization - reloadfirmwareReplace the CPU boardSwitch off printerCheck cable connectionReplace display unitReplace the boardInsert missing cartridge(s)Reduce speed or data vol.Update Flexmail or mailingsoftwareRemove paper jamReplace board58

Error Messages Cause RemedyERROR PEN BOARD# U#CALL SERVICERAM ERRORCALL SERVICEPRINTER ERRORWRONG BOARD/FIRMWARECPU-HW-ERROR #RESET THE PRINTER!ERROR CARTRIDGECHECK CONNECTIONFONT ERRORLOAD FLASH FONTS!PAP. LEN TOO SMALLMIN. VALUE:ERROR PAPER SENSORCHECK THE SENSORFont LoadingERROR: TIMEOUTFont LoadingERROR:HEADER (SB)Font LoadingERROR:HEADER (F)Font LoadingERROR:FONT ORIENTFont LoadingERROR:CHAR. HEADERFont LoadingERROR:MEMORY (RAM)Font LoadingERROR: CHAR. No.Font LoadingERROR:SUPPL. CHAR.Font LoadingERROR: CHAR: LasFtFont LoadingERROR: DATA LasFtFont LoadingERROR:CHAR. HEIGHTFont LoadingERROR:DL DISABLEDMACRO LOADING ERRORRAM MEMORY IS FULL!Macro Too HighReduce To 5 InchesError of the HP PENboard# #=1,2,3CPU board with small RAMmemorySevere CPU errorCartridge error or TSR iswrongError in flash PROM.Paper too shortPaper light barrierError in download fontError in download fontError in download fontError in download fontError in download fontError in loading the fontinsufficient memoryError in download fontError in download fontError in download fontError in download fontError in download fontError in download fontError in loading macro:memory is insufficientMacro is too highCheck plug connectionReplace PEN boardReplace CPU board.Install correct board andfirmwareReload firmware; checkthe checksums!Check plug connectionReplace cartridgeReload fontsObserve minimum lengthCheck download fontCheck download fontCheck download fontCheck download fontCheck download fontNo more space for thefont in the memoryCheck download fontCheck download fontCheck download fontCheck download fontCheck download fontCheck download fontMacro no longer fits in thememoryReduce graphic height to38.1mm59

7.3 Warning MessagesWarning Message Cause RemedyWarning:Non-ExistentFont Selected!Warning:Non-ExistentMacro Selected!Error Macro IDContact FlexSystems!Error Macro IDReport Err. 2 VendorPosition Warning!Reduce Left Margin!Warning:Wrong Data/Barcode Selected!Error Barcode DataContact FlexSystems!Error Barcode DataReport Err. 2 VendorMacro Too Large OrWrong Hor.Position!Macro Height DoesNot Match!Macro ID# In UseMacro Load Ignored!Image Height ExceedsThe Maximum ValueSelected font does notexist in the printerSelected macro does notexist in the printerError in FlexMail programor in the MailingSoftwareError in the MailingSoftwarePaper length or addressposition are wrongError in PC programError in FlexMail programor in the MailingSoftwareError in the MailingSoftwareMacro too wideError in macroMacro (same number)already exists, overwritingnot possiblePrint data outside of theprinting areaPrinter is switched off andthe PC sends remainingdataAfter the job has ended,the addresses cannot berepeated.Faulty PC program.Contact your dealerContact your dealerCheck paper length,Reduce left margin in thePC programError in PC programContact your dealerContact your dealerComply with maximumwidth for macros you create:Graphic always upper left,then convert to macroDelete macro, define itagain60

8 Appendix8.1 Maintenance Notes8.1.1 Cleaning the Ink CartridgeClean the jets of the ink cartridge with a cleaning wipe like the TexWipe ® brand.The following materials are NOT suitable for the cleaning of the printheadand the ink cartridge!• Paper towels• Toilet paper• Sponges• Cloths with abrasives or small fibers that can collect on the jet plate of thecartridge• Dry clothsTo achieve an optimum print quality, move the wipe in the direction of the jet rows(see the following Illustration):Illustration 8-1: Cleaning the cartridge8.1.2 Press Roll and RollersMake certain that the press rolls and rollers are always kept clean.After printing, store the cartridges in an upright position in a sealed plastic container,in order to prevent the ink from drying.8.2 InterfacesThe PRINTER 830/930 is equipped with two standard print-data interfaces. Theyboth offer the possibility of connecting the printer to a computer.• USB 1.1• IEEE1284 (Centronics, parallel)In addition, the PRINTER 830/930 has a control/status interface:• RS-232-C serialThe interface connector sockets are located on the rear side of the machine.61

8.2.1 Centronics Parallel InterfaceThe PRINTER 830/930 is equipped with a standard Centronics parallel interface.This interface is most frequently used as a connection to a personal computer.Unlike the RS-232-C serial connection, there are usually no special commands orconfigurations for the printer or computer necessary here. In addition, data istransferred quickly with the Centronics parallel interface cable.The parallel interface connector is a standard 36-pin Amphenol type with two metalretaining clips.8.2.1.1 Connector SocketPlug type: Amphenol female connector stripProduction series: 57 - 40360Max. cable length 2 m withAmphenol multipoint connector 57 – 30360Illustration 8-2: Parallel interface connector socketThe signal description is found on the following page.62

8.2.1.2 Signal DescriptionPINCorrespondingGNDSignalSignal-I/OMeaning1 19 STROBE I This pulse 0.5µs) reports thatdata bits are valid2-9 20-27 DATA 1-8 I Data bits D0-D710 28 ACKNOWLEDGE O Printer reports: Data has beenprocessed (is ready to receive)11 29 BUSY O Printer reports: Data received,data being processed12 30 PE (Paperempty)13 -- SELECT(Online)OOPrinter reports to the computer:No paper availableSignal is high, when the printeris online14 -- Autofeed I No function, only for bidirectionalinterface15 -- Free Free16 -- GND GND17 -- Chassis-GND Chassis GND18,3519-30-- + 5V + 5V above 0.2A Si-- GND GND31 -- INIT I Resets printer32 -- ERROR O Signal is low, when there is anerror in the printer33 -- GND GND34 -- Free Free36 -- SELECT IN I No function, only for bidirectionalinterface63

8.2.1.3 Pulse DiagramIllustration 8-3: Parallel interface pulse diagram8.2.2 RS-232-C Serial InterfaceThis segment describes the RS-232-C serial plug connection and the concept of aserial interface connection. The PRINTER 830/930 has a standard RS-232-C serialinterface, which is compatible with most computers and terminals.8.2.2.1 Connector SocketThe PRINTER 830/930 has a standard DB-9 serial connector socket64

8.2.2.2 Plug AssignmentPIN Signal SignalInput/OutputMeaning1 --- - free2 R x d I Received data3 T x d O Transmitted data4 DTR O Data Terminal Ready5 GND - Signal Ground6 --- - free7 RTS O +12V8 CTS I Clear to Send9 --- - freePin 2Received Data (RxD):Serial transfer of data from the computer to the printer.Pin 3Transmitted Data (TxD):Serial transfer of data from the printer to the computer system or the terminal (e.g.X ON /X OFF symbol ).Pin 4Data Terminal Ready (DTR):Printer output, which allows the transfer of data to the printer or which interrupts it(handshaking). Data transfer is possible, when DTR is high. It is not possible, whenDTR is low.Pin 5Signal Ground (GND):The reference potential for the entire data exchange.Pin 7Request to Send (RTS):This signal is always high with a switched on printer.Pin 8Clear to Send (CTS):Input of the printer, which allows the transfer of data to the computer or which interruptsit. When the input is high, then the printer may transmit the data. For thesoftware handshaking with Xon/Xoff, this input must always be high.65

8.3 Fonts8.3.1 TerminologyA font is a collection of characters and symbols having the same typeface, spacingsize (height), line width and font slant.8.3.1.1 TypefaceTypeface is a set of characters and symbols with a certain design.8.3.1.2 Serif or Sans Serif TypefacesSerifs are small lines on the top or bottom of a character (so-called “feet” onBodoni book type). Cour is a serif typeface Typefaces without serifs are referred toas sans serif. Helv is a sans serif typeface. The following illustration shows the differencebetween a serif typeface and a sans serif typeface.Illustration 8-4: Serif and sans serif8.3.1.3 Font SlantThe characters can either be printed standing straight (normal) or - at a constantangle - standing slanted (italic).This example shows straight standing characters.This example shows characters standing at a slant.8.3.1.4 SpacingSpacing refers to the relative print density between the letters of a font. The characterspacing is either fixed or proportional.66

Fixed SpacingWith fixed character spacing, every letter of a font takes up the same width spaceand has the same spacing as neighbouring letters. Cour and LetGot are fonts withfixed character spacing.Illustration 8-5: Fixed character spacingProportional SpacingWith proportional character spacing, the spacing depends upon the width of the letter.Helv and TmsRm are fonts with proportional character spacing.Illustration 8-6: Proportional character spacing8.3.1.5 Character DensityCharacter density (pitch) refers to the number of printed characters within a linearinch. A font with a character density of 10 cpi prints 10 characters per horizontalinch (cpi = characters per inch). The character density can only be provided forfonts with fixed character spacing.12 characters per inch (12 cpi)10 characters per inch (10 cpi)0” 1”67

8.3.1.6 Character SizeCharacter size (character height) refers to the height of a printed capital letter. Itis measured in pica points. A point is 1/72 of an inch.The height for both fonts, with fixed and proportional character spacing, is measuredin pica points.172 Punkte = 1 ZollPica-Punkt48 Punkte(Zoll)24 Punkte12 Punkte8Punkte0Illustration 8-7: Character size8.3.1.7 UnderlineIn order to especially emphasize a point of text, you can underline it. Your uniformfont face is thereby maintained.You can underline a single word.8.3.1.8 Wide FontThe address image can be printed (e.g. for a large parcel) twice as wide, whilemaintaining the proportional character width / spacing.This is normal width.This is wide font.8.3.1.9 Character SpacingIn order to especially emphasize individual words, you can increase the space betweenletters and words without changing the character size itself.This E x a m p l e is printed voluminously.8.3.1.10 QualityQuality refers to the print quality.You can make a selection among the following print qualities [dpi x dpi]:68

1x3 corresponds to1x6 corresponds to2x3 corresponds to2x6 corresponds to3x3 corresponds to3x6 corresponds to6x3 corresponds to6x6 corresponds to150x300150x600200x300200x600300x300300x600600x300600x6008.3.1.11 Print DirectionThe print direction refers to the (readable) address position on the print object. Itcan be turned around 180°. The arrow in the illustration marks the direction of theprint run.NorRevIllustration 8-8: Print directionNote the information for the image storage capacity in the menu item „HErreur !Source du renvoi introuvable.“ on page Erreur ! Signet non défini..69

8.3.2 Character SetA character set consists of characters and symbols, which contain all elements of alanguage or discipline (country-specific characters), including punctuation marksand numbers.8.3.2.1 7-Bit Character SetA 7-Bit character set corresponds to definitions of the ”International Standards Organisation“(ISO) and the ”American Standard Code for Information Interchange”(ASCII).In a 7-Bit character set there are 128 characters.The following is a depiction of a 7-Bit character set .Illustration 8-9: 7-Bit character set Ger770

8.3.2.2 8-Bit Character setIn the 8-Bit character set there are 256 characters.Many national characters are available with this. The following is a depiction of themost frequently used 8-Bit character set.Illustration 8-10: 8-Bit character set PC88.3.3 Selection of the Fonts for PrintingThe fonts are selected via the software or printer commands.Fonts can be used with great precision, in order to lend a print object a specific appearance.Select the fonts that suit best the content of your text.8.3.3.1 Serif TypefacesThe following example shows an address with the Cour12 typeface:Test printADDRESSPRINTER 830/930PRINTER LAND71

8.3.3.2 Sans Serif TypefacesThe following example shows an address with the Helv12 typeface:Test printADDRESSPRINTER 830/930PRINTER LAND8.4 Character SetsNote for the depiction of character sets:• Character set name: The information in parentheses (e.g. USA7) correspondsto the options field in PRINTER 830/930.• With the ASCII printer command (e.g. E c ( 0 U) you can call up the characterset in your software.8.4.1 7-Bit Character SetsASCII (= USA7)ASCII:E c ( 0 UDecimal: 27 40 48 85Hexadecimal: 1B 28 30 5572

England (= UK7)ASCII:E c ( 1 EDecimal: 27 40 49 69Hexadecimal: 1B 28 31 45France (= Fra7)ASCII:E c ( 1 FDecimal: 27 40 49 70Hexadecimal: 1B 28 31 4673

Germany (= Ger7)ASCII:E c ( 1 GDecimal: 27 40 49 71Hexadecimal: 1B 28 31 47Italy (= Ita7)ASCII:E c ( 0 IDecimal: 27 40 48 73Hexadecimal: 1B 28 30 4974

Spain (= Spa7)ASCII:E c ( 2 SDecimal: 27 40 50 83Hexadecimal: 1B 28 32 53Denmark (= Den7)ASCII:E c ( 1 DDecimal: 27 40 49 68Hexadecimal: 1B 28 31 4475

Norway (= Nor7)ASCII:E c ( 0 DDecimal: 27 40 48 68Hexadecimal: 1B 28 30 44Sweden (= Swe7)ASCII:E c ( 3 SDecimal: 27 40 51 83Hexadecimal: 1B 28 33 5376

Sweden/Names (= SwN7)ASCII:E c ( 0 SDecimal: 27 40 48 83Hexadecimal: 1B 28 30 53Portugal (= Por7)ASCII:E c ( 4 SDecimal: 27 40 52 83Hexadecimal: 1B 28 34 5377

8.4.2 8-Bit CharacterPC-8 (= PC8)ASCII:E c ( 10 UDecimal: 27 40 49 48 85Hexadecimal: 1B 28 31 30 55Roman8 (= Rom8)ASCII:E c ( 8 UDecimal: 27 40 56 85Hexadecimal: 1B 28 38 5578

PC-850 (= P850)ASCII:E c ( 12 UDecimal: 27 40 49 50 85Hexadecimal: 1B 28 31 32 55ECMA-94 Latin 18 (= ECMA)ASCII:E c ( 0 NDecimal: 27 40 48 78Hexadecimal:1B 28 30 4E79

PC-8 Denmark/Norway (= P8DN)ASCII:E c ( 11 UDecimal: 27 40 49 49 85Hexadecimal: 1B 28 31 31 55ICEL (= ICEL)ASCII:E c ( 33 ODecimal: 27 40 51 51 79Hexadecimal:1B 28 33 33 4F80

PC-852 (= P852)ASCII:E c ( 17 UDecimal: 27 40 49 55 85Hexadecimal: 1B 28 31 37 55PC-860 (= P860)ASCII:E c ( 20 UDecimal: 27 40 50 48 85Hexadecimal: 1B 28 32 30 5581

8.5 Side <strong>Guide</strong>• Side guide short (2x) (standard)• Side guide middle (standard)• Side guide long (accessory)Adjustable width of the Side guideThe data (in mm/inches) refers to the print object width crosswise to the transportdirection.• Rear + frontal side guides, short x 2853.351425.612552258.86• Rear side guide, short+Frontal side guide, middle1987.828511.2• Rear side guide, short+Frontal side guide, long27710.936514.37When using the corresponding maximum possible width of the adjustableside guide, there remains an unprintable margin of 15 mm(0.6 inch) from the rear side guide.82

8.6 AccessoriesThe following accessories are available (must be purchased separately):Illustration 8-11: Divert mechanismPos. Description Pieces1 Divert mechanism 1The divert mechanism changes the transport direction of the ejected print object90° on the conveyor belt.83

8.7 Technical DataThroughputFor Printer 830: max. 11,000 postcards /hour at 1x3, 1x6For Printer 930: max. 39,000 post cards /hour at 1x3, 1x6Printheads 3Printing speedFor the Printer 830: 0.54 m/sFor the Printer 930: Minimum 0.15 m/sMaximum 1.84 m/sThroughput For the Printer 830:Postcards (A6) 11,000 pcs./hrC5/C69,000 pcs./hrFor the Printer 930: at 6x6at 1x3Postcards (A6) 14,000 pcs./hr 39.000 pcs./hrC5/C6 9,000 pcs./hr 26.000 pcs./hrPrinting processFixed-Head (fixed printhead) manual positioningGraphics capabilities YESColorsup to 3, Spot ColorPrint object formats Minimum (L x W): 135 x 70 mmMaximum (L x W): 500 x 352 mmL = in transport directionPrint height max. 38 mm per unit / 9 lines Courier 12Print width max.500 mmMaterial thicknessFor the Printer 830: Minimum 0.10 mmMaximum 2 mmFor the Printer 930: Minimum 0.10 mmMaximum 6.35 mm / ¼“Thickness difference Maximum 1 mm – depending on the materialPaper capacityMaximum 350 pcs. / 170 mm / 1 kgTypes of paperSingle sheets, documents, envelopes, booklets etc.Paper quality Inkjet compatible, no foils or high-gloss paper 2Print qualities1x3, 1x6, 2x3, 2x6, 3x3, 3x6, 6x3, 6x6Ink CartridgeHP45A or HP1918 cartridgeCharacter sets13 resident and downloadable fonts<strong>Operating</strong> noiseThe emission value for the place of operation is < 70 db (A) in1 m distance, measured in accordance with ISO 9296.Main memory64 MBAddress storageThe last 20 pagesMains voltage100 - 240VAC at 50 ~ 60Hz<strong>Operating</strong> range10-31°C / 20-80% rel. humidity (no condensation)Status interfacesUSB (1.1) / Parallel Centronics Std. (IEEE1284)Status interfacesSerial (RS-232)DriverWindows 3.1 / NT / 2000 / XPSpecial functionsBarcodes (10 resident barcodes)Configuration memory for 9 user settingsLoadable test addressInk consumption displayDimensions (L x W x H) 425 x 380 x 280 mmWeight22 kg2Possible with suitable inks and drying systems84

9 GlossaryASCll:Barcode:Baud rate:Bit:Bitmap:Buffer:Byte:Carriage:Characterheight:Character sets:Characterdensity:CharacterspacingCharacter:Configuration:Control code:Control panel:CPl:ASCll is the abbreviation for "American Standard Code for InformationInterchange". The printer commands used in this manual havebeen entered with ASCII characters. Decimal and hexadecimal characterscan also be used.Data for a print object is converted to a one-line, language- andsymbol-neutral barcode. A barcode is easy to create, and it is readablewith simple opto-electronic devices. It is also additionallyprinted for the plain text information.The baud rate is the speed at which the data between the computerand printer is transferred on the serial interface. The computer andprinter must have the same baud rate. This can lie between 1200and 9600 baud, depending on the computer that is used. The baudrate is only set, when using a serial interface.Binary digit. As the smallest unit of digital information, a bit is representedby only two positions: "1" or "0".A bitmap represents a collection of dots as a graphic or text graphicin output devices (printer, monitor).The buffer is a storage area of the printer. Certain input and outputdata is stored here until further processing.A storage unit, consisting of 8 bits.The printhead is fixed to a movable carriage.Character height refers to the height of a printed capital letter. It ismeasured in pica points. A point is 1/72 of an inch.A character set is application-specific defined and is usually a collectionof letters, numbers, lines and symbols within a font. Charactersets can also be made up purely of symbols.Character density (pitch) refers to the number of printed characterswithin an inch.All fonts have either constant or variable character spacing In a fontwith constant character spacing, all characters have the same widthspace, regardless of their size. In the case of proportional fonts, thewidth space is determined by the width of the character in question.A character is understood to mean letters, numbers and symbolsthat can be printed.In a configuration, certain printer settings can be stored. You canset up several configurations, and store each of them under an individualconfiguration number.For control code, see printer commands.The control panel comprises the keyboard and display. Settings forthis are carried out internally on the printer.CPI (= Characters Per Inch) is the measuring unit for characters per85

inch for the in character density.Data transfer:Character size:DPl:Driver:Escapecharacter:Escapesequences:Factoryconfiguration:Font cassettes:Data transfer is the transfer of information between the computerand the printer.The character size is measured in pica points. A point is 1/72 of aninch.DPI (= Dots Per Inch) is the measuring unit of dots per inch for theimage definition. The more dots there are, the higher the definition.For driver, see printer driver.The escape character E c is a beginning of a command in ASCII code.This character is not printed; the printer recognizes the followingcharacter as a command code.For escape sequences, see printer commands.The printer is programmed - prior to shipping - with standard settings.These settings are stored in configuration "0", and they remainactive until another configuration number is selected and thesetting changes are carried out.They contain fonts that can be loaded in the printer.Font slant: The characters can either be printed standing straight (normal) or -at a constant angle - standing slanted (italic).Font:Handshake:Hardware:Ink Cartridge:Interface cable:Interfaceconnectorsocket:Line width:Loadable fonts:A font is a collection of characters and symbols with the same typeface,spacing, size (height), line width and font slant. Fonts can beinstalled as resident fonts in the printer, or they can be loaded externallyfrom font cassettes.Handshake is the control of the data transfer between the computerand the printer, in order to prevent overflow or loss of data in theprinter buffer.Hardware describes the components of your computer system, suchas computer, keyboard and printer.The ink cartridge contains the ink for printing. After it has been usedup, the empty cartridge is replaced by a new, commercially availableone.This is the data transmission cable that connects your computer withthe printer or other peripherals.The PRINTER 700/710 is shipped with three interface connectorsockets (USB, parallel and serial). These are located at the rear sideof the machine over the power supply plug. The connector cable foryour computer and printer are connected here.The line width refers to the width of the character line. There arenormal and bold line widthsLoadable fonts (soft or download fonts) are saved on disks. Theycan be transferred to the printer memory.86