Shrinking Dimensions Typify Today's Multilayer Ceramic ... - Murata

Shrinking Dimensions Typify Today's Multilayer Ceramic ... - Murata

Shrinking Dimensions Typify Today's Multilayer Ceramic ... - Murata

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

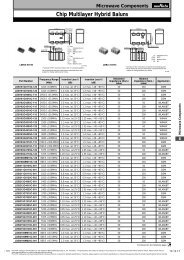

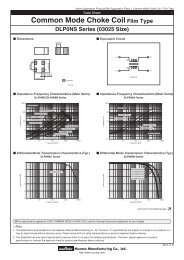

<strong>Shrinking</strong> <strong>Dimensions</strong> <strong>Typify</strong> Today’s<strong>Multilayer</strong> <strong>Ceramic</strong> CapacitorsAdvances in high-density mountingtechnology and furtherminiaturization of electronicparts are being required as electronicequipment becomes increasinglycompact and thin, integrates more functions,and delivers higher performance.Parts manufacturers have developed ahighly integrated and high-performancesemiconductor integrated circuit. On theother hand, even in many electronic partssuch as a multilayer ceramic capacitorused in electronic equipment, miniaturizationand high capacity are being promotedand compact-size products are increasinglybeing used. In chip multilayerceramic capacitors, the latest trend is subminiatureproducts of less than 1005 size(1.0 × 0.5 mm).Trends in Chip SizesSubminiature products are increasinglybeing used not only in electronic equipmentthat requires compact and high-densitymounting but even in products thatoffer sufficient mounting space. This isdriven by the expanding demand for compactchips brought about by the growingmarket for mobile products like mobilephones, digital cameras, and digital audioequipment, and by the established mountingtechnology of compact chips in assemblymanufacturing.As a result, the use of 1005 (1.0 × 0.5mm) and 0603-size (0.6 × 0.3 mm) multilayerceramic capacitors has expanded,with size shifting from 1608 (1.6 × 0.8mm) to 1005 (1.0 × 0.5 mm) (Fig.1). Inaddition, 0402 size (0.4 × 02 mm), whichis the smallest in multilayer ceramic capacitor,has started to be employed.Subminiature <strong>Multilayer</strong> <strong>Ceramic</strong>CapacitorsFor the development of subminiaturemultilayer ceramic capacitor, size is notonly miniaturized by the introduction ofhigh-precision processing technology, butalso the approach for realizing compactnessand higher capacity is promoted bythe introduction of high-electrostatic capacitytechnology. A high capacity ofmore than 1µF was previously realized inthe size exceeding 1608 (1.6 × 0.8mm). However, with the progressof the thin-/multilayer technologyand high-precision processingtechnology of a dielectric element,the capacity acquired has been expandedeven in subminiature size.For a 1005-size capacitor, a capacityof up to 1µF canbe currently acquired intemperature characteristics:B. Furthermore, theapproach for developmentof a 2.2µF capacity has been made.Therefore, a 1005-size capacitor can alsobe used for the decoupling of a power linefor which higher capacity is required, andhas been increasingly employed in mobilephones, personal computers, and digitalA/V equipment.Meanwhile, a capacity of up to 0.1uFcan be acquired in temperature characteristics:B can be acquired for 0603-sizecapacitor. Moreover, the approach for developmentof a 0.22uF capacity has beenmade.A 0603-size capacitor used in compactmobile equipment like mobile phones cancover almost the capacity requirementsby realizing a 0.1µF capacity. This meansthat the use of a 0603-size capacitor canbe expanded from the high-frequencymodule parts, which use a capacitor withFig. 2: 1005- and 0603-size multilayer ceramiccapacitorsTable 1: Electrostatic capacity range of subminiatureproductsFig. 1: Trends in sizes of multilayer ceramic capacitorsAEI November 2005Copyright © 2005 Dempa Publications, Inc.51

Fig. 3: 0402-size multilayer ceramic capacitorFig. 4: Area and volume ratios of subminiatureproductslower capacity, to the main body’s circuitof compact mobile equipment. Thus, thedemand for the 0603-size capacitors hasbeen expanding rapidly.<strong>Murata</strong> Manufacturing Co., Ltd. offers1005 (GRM15) and 0603 (GRM03) -sizedcapacitors (Fig.2). Table 1 shows the capacityrange for both kinds.In the future, the lineup of subminiatureproducts will be expanded by realizationof a higher electrostatic capacity,and with chip sizes becoming more andmore miniaturized.The 0402 SizePartly used in high-frequency moduleparts, 0402-size capacitors have been producedon a commercial scale as miniaturizedproducts next to 0603-size products.A 0402-size capacitor is miniaturizedin area ratio by about 45 percent andin volume ratio by about 30 percent ascompared with a 0603-size product(Fig.4).A 0402-size capacitor features reducedinductance because it is smaller in lengthby about 30 percent than a 0603. Thus,Fig. 5: Impedance and frequency characteristicsaside from being smaller insize, the 0402 capacitor can alsobe used in higher frequency. Itis expected that 0402-size capacitorswill contribute to theminiaturization of a high-frequencycircuit or high-frequencymodule parts. Fig.5shows the frequency characteristiccomparison data between0402 and 0603-size capacitors.Processing technology that ishigher in precision than that ofa 0603 must be introduced to realize a0402-size chip multilayer ceramic capacitor.Precision was improved by steppingup the printing, lamination, and cuttingprocesses of high-precision processingtechnology that was cultivated in thequantity production of 0603-size capacitors.To satisfy the needs to the packagingform early used in a 0402-size capacitor,the packaging form began to be suppliedbased on the paper taping (W8P2) specificationsof tape width: 8 mm and part insertionpitch: 2 mm that resultedin 1005 and 0603-sizecapacitors. However, the tapingspecifications of the current0402 are large in theamount of packaging materialsused as compared witha chip size. Therefore, tapingspecifications must beimproved for the taping specificationscorresponding tothe chip size.At present, the approachfor putting the plastic taping(W4P1) of tape width: 4 mm and part insertionpitch: 1 mm to practical use hasbeen made in cooperation with a carriertape manufacturer and chip mounter manufacturer.By satisfying the specificationsof tape width: 4 mm and part insertionpitch: 1 mm, the amount of packaging materialsused per chip is remarkably reducedas compared with the current taping specifications.This also leads to the reductionin the amount of packaging materialsdiscarded. Moreover, by using a plastictape, the amount of fine particles generatedcan be reduced as compared witha paper tape. This contributes to the improvementin a clean level in a mountingprocess. Fig.6 shows the outline of papertaping (W8P2) of tape width: 8 mmand part insertion pitch: 2 mm and plastictaping of tape width: 4 mm and partinsertion pitch: 1 mm.To employ a 0402 size, mounting technologythat is higher in precision than thatof a 0603 is required. In a chip mountermanufacturer, the approach for establish-(Continued on page 55)Fig. 6: Taping specifications of 0402-size multilayerceramic capacitors52 AEI November 2005Copyright © 2005 Dempa Publications, Inc.

<strong>Shrinking</strong> <strong>Dimensions</strong> <strong>Typify</strong> Today’s <strong>Multilayer</strong>...(Continued from page 52)Table 2: Electrostatic capacity range of 0402-size productsment of 0402-size compatible technologyhas been made to improve the chip extractionprecision of a chip mounter andthe precision of the mounting position ona circuit board. A chip mounter that canbe used for 0402 has been developed bytop chip mounter manufacturers. The solderedjoint technology of a chip and circuitboard must also be improved. Thecream solder was improved as well as thesolder printing precision.What the Future HoldsAs compact and high-function electronicequipment continues to advance,the requirement for miniaturized capacitorsis expected to growfurther. In a multilayer ceramiccapacitor, the capacityof 1005 or 0603-size units has been extendedby the expansionof high-capacity technologyto compact products as well as by thedevelopment of new compact productslike 0402-size units. Manufacturers arenot only shifting from conventional-sizeproducts but they are also looking intothe areas of tantalum capacitors or aluminumelectrolytic capacitors.About This Article:The author,Toshikuni Hisaki, worksat the Technical Administration Sectionof the Technical Administration Departmentat the Components BusinessUnit of Fukui <strong>Murata</strong> ManufacturingCo., Ltd.AEI November 2005Copyright © 2005 Dempa Publications, Inc.55