Smiling customers, every site, every visit, every day

Smiling customers, every site, every visit, every day

Smiling customers, every site, every visit, every day

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

welcomeDear Colleagues,Welcome to the last edition of Shell World UK magazine for 2008. In <strong>every</strong> issue, wefeature a different part of the business in the UK, providing readers an insight into thelives of other Shell people. In this Winter issue, we take a closer look at our retail business.We’ve been operating in very tough market conditions lately – record-high productcosts and pump prices prompting market volume decline as people drive less, greatpressure on margins, followed more recently by dramatic pump price reductions.Despite these challenges, our network is growing for the first time in many years. Wehave been winning new dealer business from the competition, and have added 14 newmotorway locations in the last 12 months. Although we are the fourth largest networkin the UK, we believe we are first in fuel volume market share. We are one of the fewbrands with a genuinely nationwide UK network and our <strong>site</strong>s process between 4.5 and5 million transactions per week.To find out more about the activities of the retail team, we start by talking to twoemployees to find out about their typical <strong>day</strong>s at work. See pages 7–9 to learn more aboutour colleagues John Franke, a territory manager, and training manager Allan England.As well as meeting current Shell employees, we meet two of our pensioner readers andhear a bit more about the paths their careers took them on at Shell, what they think haschanged over the years and what advice they can offer us to<strong>day</strong>. See the article on pages10–12 to read on.Safety remains a top priority for Shell, so I encourage you to read the article on pages13–14 in which you will meet new Group Road Safety Manager, Mike Watson, and findout more about how Shell’s new road safety programme will work – as well as his viewson the challenge of changing the corporate mindset to reach our Goal Zero aspirations.There has been a lot written in the press about Shell in Nigeria recently. If you wouldlike to find out more, please see pages 15–16 for an interview with Shell’s CountryChair in Nigeria, Basil Omiyi. Our own Country Chairman James Smith is alsointerviewed in this issue, in the Energy Challenge feature on pages 19–20, where heshares with us his latest views on this important topic.Finally, remember that the team at Shell World UK magazine are always interested tohear from readers. Please see page 3 for details on how to get in touch with them.I hope you enjoy the magazine.Nick AdamsHead of UK Retail SHELL WORLD UK

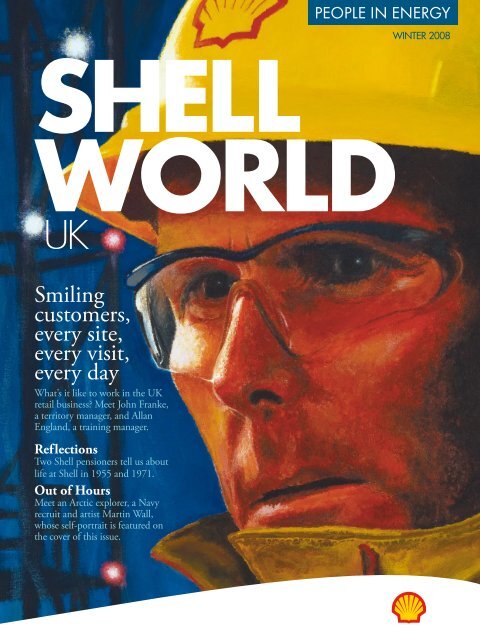

SHELLWORLDUKCONTENTSSMILINGCUSTOMERS,EVERY SITE,EVERY VISIT,EVERY DAYWhat’s it like to work in the UKretail business? Meet John Franke,a territory manager, and AllanEngland, a training manager.072103Editor’s lettersResponses to your feedback and queries aboutthe last issue of Shell World UK magazine.05NEWS in briefFour new fields open up in the North Sea,Shell V-Power celebrates its tenthanniversary, and we find out more aboutShell Livewire and the ‘Learning to LoveScience’ report.10REFLECTIONSTwo Shell pensioners tell us about life atShell in 1955 and 1971.13Driving the road safetystrategyMike Watson tells us about how he hopesto change the way we all think aboutroad safety.17Choosing shellWhat influences public opinion of Shell?We talk to Stewart Lewis, head of thereputation centre at leading researchcompany Ipsos-MORI, to find out moreabout how Shell tracks its reputation.19Energy ChallengeJames Smith, Chairman of Shell UK,gives us his latest views on the changingface of energy.21People andEnvironmentCan more be done to prepare localresidents for future earthquakes in theSichuan region in China? Shell geologistNick Richardson was part of a team ofexperts called in to explore the fault lines.23Technology andInnovationProfessor Geoff Chamberlain, who joinedShell in 1973, retired in November. Beforehe left, he told us about his fascinatingwork, and the advances he has seen, inMajor Hazards management.25SHELL IN THE COMMUNITYI’m a Shell employee, get me out of here!Bianca Ruakere recently returned fromBrazil after three weeks of field work,adventure and travel for Project Betterworld– find out how she got on with all theinsects in the jungle…28Out of HoursMeet an Arctic explorer, a Navy recruit andartist Martin Wall, whose self-portrait isfeatured on the cover of this issue.15Shell in NigeriaFind out more about Shell’s involvement inNigeria and how our relationship with thegovernment there works.19SHELL WORLD UK

EditorShelley HoppeManaging EditorKay BruceTo contact themagazineShell World UK, CA-CX,Shell Centre, London,SE1 7NAE-MailShellworlduk@shell.comWeb<strong>site</strong> addresswww.shell.co.uk/shellworldukShell World UK isedited, designedand produced byThe Fifth Business,4th floor,71 Broadwick Street,London, W1F 9QYPh: +44 0207 534 9099ContributorsNicole ErasmusAnnalisa FiorentinoShelley HoppeNigeria article:Michael Adandeand Norbert BothYOURMAGAZINECompetitionwinnerCongratulations toJennifer Pape from ShellCentre in London onwinning our subscriptioncompetition inSeptember. Yoursubscription to ‘HistoryTo<strong>day</strong>’ has beenpurchased, and the firstcopy should be wingingits way to you as wespeak! Thanks also to<strong>every</strong>one else whoentered the competitionand joined ourdistribution list.EDITOR’S LETTERSMeet the teamIf you have any feedback, or would like to suggestcontent, please contact us.Shellworlduk@shell.comShell World UK, CA-CX, Shell Centre, London,SE1 7NAShelley HoppeEditorE-Mail: Shelley.Hoppe@shell.comPh: +44 207 534 9099Kay BruceManaging EditorShell UK CommunicationsE-Mail: Kay.Bruce@shell.comPh: +44 207 934 7780Unless otherwise specified,copyright in text, images andother information in Shell Worldmagazine belongs to ShellInternational B.V. or othercompanies. Permission is given toreproduce, store or transmit anypart of this publication providedthat the copyright of ShellInternational B.V. or such otherShell company is acknowledged.This does not include the right toamend or modify text, images and/or other information and it does notextend to any material of which thecopyright is identified as belongingto a third party (i.e. other than ShellInternational B.V. or othercompanies). Authorisation toreproduce such third-party materialmust be obtained from the relevantcopyright holders.WE USE RECYCLED PAPERHi,I was wondering if it is possible to sign up ourShell Lubricants distributors to the Shell WorldUK magazine in the UK? I think sharing themagazine will help build their sense of beingpart of the family!Please advise if this is OK – how many extrasubscribers can we have?Thanks in advance,Iain Croft, ManchesterDear Iain,We welcome subscribers to the magazinefrom both inside and outside Shell – so, yes,please do add your Distributors to ourdistribution list by e-mailing us atshellworlduk@shell.com. There is no limit tohow many you can add.Dear Editor,I am a Shell pensioner and currently receiveShell World UK magazine. However, untilabout a year ago, I received a copy of Shell WorldInternational magazine – which suited myinterests better, as my Shell work was mainly inthe international arena.Is Shell World International magazine (or asubstitute) still published? If so, how may Iobtain a copy on a regular basis?Thanks for your help,James McGrory.Dear James,A few people have asked this question – tofind out more about global Shell Worldarticles, some of which are currentlypublished online, please e-mail RishmaBinda on Rishma.Binda@shell.com. SHELL WORLD UK

LEARNING TOLOVE SCIENCEStudying science opens up a world ofpossibilities – and scientists play a vitalrole in UK society, Yet fewer and fewerstudents are opting to study physicaland chemical sciences after the age of 16...Shell wanted to understand why this ishappening, and so commissioned aresearch report to explore schoolstudents’ attitudes to science, establishwhy many disengage with the subjectand discover what can be done toreverse this trend. The recently releasedreport, which is available to downloadfrom www.shell.co.uk/ses, is called‘Learning to Love Science’. It examineswhen and why pupils “switch off” fromscience and the extent to which the UKis missing out on a potential pool ofscientists as a result.Building on the wealth of previousresearch in this area, the reportincludes new, previously unpublished,research commissioned by ShellEducation Service and conducted byspecialist youth research company,Dubit. During the summer term of2008, a poll of 4,000 children aged9–14 was carried out by Dubit; afurther 27 interviews with students,teachers, graduates and employerswere conducted by the ChemicalIndustry Education Centre at theUniversity of York.The end result is a report that bringsfresh perspective on one of thebiggest educational challenges facingthe UK to<strong>day</strong>. To read more,download the full PDF report onwww.shell.co.uk/ses.SUBSCRIBE TO SHELL WORLD UK MAGAZINERemember, you can sign up to receive Shell World UK magazine quarterly, forfree. So please opt in as soon as possible to receive future copies, either byadding your details to our distribution list via our web<strong>site</strong> atwww.shell.co.uk/signup, or by writing to us.If you would like to contribute to the magazine, or give any feedbackon this issue, please contact us.E-mail: Shellworlduk@shell.comPost: Shell World UK, CA-CX, Shell Centre, London SE1 7NASHELLWORLDUKSHELL WORLD UK

NEWSIN BRIEFCelebratingA DECADE ofShellV-PowersuccessFour New North Sea fields in 2008An example of the award-winning Monotour platform designShell has had four new North Sea fieldsstart production this year. They were:• Starling, a sub-sea tie-back toShearwater, in January;• Caravel, a Monotower platform, in April;• Shamrock, another Monotower platform,in May; and• Curlew C, which was brought on streamvia a single new development well, tiedbackto the Maersk Curlew FPSO (afloating, production, storage and offtakevessel), in September.“This provides further demonstration of ourinvestment in North Sea opportunities,which Shell has the technology and theinfrastructure to support, and ourcommitment to energy supply for the UK,”said John Gallagher, Vice PresidentTechnical, Shell Exploration & Productionin Europe.The first two <strong>site</strong>s are operated by ShellU.K. and co-venturer, Esso Exploration andProduction UK Limited (ExxonMobil), butShell operates the Shamrock fieldindependently and holds a 100% interest.The Curlew C field, which lies 6 kms eastof the Maersk Curlew FPSO (floating,production, storage and offtake vessel), isoperated by Maersk on Shell’s behalf.Two of the new platforms, Caravel andShamrock, use the award-winningMonotower platform design speciallydeveloped by Shell engineers. Monotowerplatforms are more environmentally friendly,being powered by wind and solar energy,and cost considerably less to build than atraditional offshore platform.The Curlew C development marks the firsttime that Shell has produced hydrocarbonsfrom a chalk formation in the North Sea.“Curlew C, a challenging chalk reservoir,underlines our determination to developNorth Sea opportunities using Shell’stechnology and expertise,” said John.See the next issue of Shell World UKmagazine for a more in-depth look at Shell’sdevelopment of North Sea opportunities.To celebrate 10 years of Shell V-Power fuels, Shell Retail launchedone of the largest internalinitiatives on October 6, coveringover 55 locations in 35 countries,including the UK, reaching morethan 30,000 staff.Originally launched in HongKong, Shell V-Power wasdeveloped by Shell scientists withthe knowledge and key insightsgained from over 60 years ofshared passion for performancewith Ferrari. It is designed to letmotorists get the most out oftheir vehicles by improvingengine efficiency andresponsiveness. To date, Shell V-Power performance fuels havepowered numerous victories onthe racetrack with Ferrari, Ducatiand Audi Sport and have provenmore and more popular with the<strong>every</strong><strong>day</strong> motorist.Currently available in 60 countriesworldwide – compared to theclosest competitors products,available in 17 countries – Shell V-Power fuels appear poised for more SHELL WORLD UK

The new LiveWIRE web<strong>site</strong> willbe available from mid-Januarysuccess, with new countrieslaunching the product <strong>every</strong> year.In the UK, Shell V-Power fuel wasfirst launched in August 2006,with Shell V-Power Dieselfollowing soon after.“Over the past 10 years,worldwide volume sales of Shell V-Power and Shell V-Power Dieselhave risen by about 6% a year,with a 9% growth recorded lastyear. And although sales have beenhit by this year’s price increases, Ibelieve we are still outperformingthe competition,” said SydneyKimball, Manager, GlobalPremium Gasoline Marketing andbased in Shell Centre.To mark this memorableoccasion a dedicated Shell V-Power 10th anniversaryhomepage has been set up. This<strong>site</strong> also plays host to an onlinegame and competition, offeringstaff an opportunity to winautographed Ferrari merchandise.Staff can view these photos andread more on the Shell V-Power10th Anniversary homepage.Know a buddingyoung entrepreneur?Tell them about ShellLiveWIRE!Many of you know someone whodreams of starting their own business.Did you know that one of Shell’s nationalSocial Investment schemes, ShellLiveWIRE, is here to help them?Shell LiveWIRE is the only scheme of itskind that provides advice, guidance andsupport to young entrepreneurs aged16—30 in a way that works for them.The programme has evolved over 26years, and now helps enterprisingindividuals in over 23 countries to startupand develop their own businesses.Next year will see the much-anticipatedarrival of a refreshed Shell LiveWIREprogramme. This will kick-off with theunveiling of the new Shell LiveWIREweb<strong>site</strong>, which will be brimming withinteractive multimedia content. It willprovide valuable resources such as freeexpert advice, business tools andsocial networking for youngentrepreneurs to share ideas andexperiences. The new web<strong>site</strong> will beavailable from mid-January atwww.shell-livewire.org.The secret to the success of ShellLiveWIRE is the number of high-qualityentrepreneurs who join the network. Themore members, the greater the benefit,as the system is designed to enable usersto support each other. The currentweb<strong>site</strong> boasts 86,000 subscribers todate, so spread the word to continue thesuccess of the scheme.We also need you! If you have a specialistskill or expertise relevant to youngentrepreneurs and are willing to give upsome of your time to help them turn theirdreams into a reality, please let us know.For more information on Shell LiveWIREor to get involved, contact JennyMarsden on 0207 934 8698.Look out for news of progress with theShell LiveWIRE UK programme in a futureedition of Shell World UK magazine.SHELL WORLD UK

John Franke <strong>visit</strong>ing the Liphook North retail <strong>site</strong>SMILINGCUSTOMERS,EVERY SITE,EVERY VISIT,EVERY DAYI enjoy my role – <strong>every</strong> <strong>day</strong> isdifferent, with new challenges,and I enjoy working with thepeople on <strong>site</strong> to always improve.John Franke, Territory Manager SHELL WORLD UK

TALKING TO JOHN FRANKE,TERRITORY MANAGERJohn Franke is one of 25 Territory Managers in the UK. TerritoryManagers are the key interface with the retailers who operateretail <strong>site</strong>s – their role is to offer support and be an advisor, coachand mentor.John started in the petrol industry in 1986 as a forecourt cleaner.He went on to become a cashier, was promoted to manager andthen to auditor, managing stock and reviewing the <strong>site</strong>. From there,when he was just 23, John became self-employed and operatedfour <strong>site</strong>s.He joined Shell in 1999 as a Territory Manager and is nowresponsible for 27 retail <strong>site</strong>s in a territory that stretches fromSouthampton to Portsmouth, to the south of Guildford and toStaines. These 27 <strong>site</strong>s are operated by four different retailers andJohn aims to <strong>visit</strong> each <strong>site</strong> at least once a month and meet up witheach retailer two or three times a month.So, what is it like working as a Territory Manager? We spoke toJohn to find out more.“The community of Territory Managers is important. Our DistrictManager, Andrew Braxton, organises a meeting for us <strong>every</strong> othermonth and we have telephone conferences to talk about newinitiatives and the best way forward. Andrew keeps us all focusedand there’s a real sense of team.There are over 900 servicestations in the Shell UK networkto<strong>day</strong> – and the network isgrowing for the first time in manyyears: 14 new motorway andover 60 dealer locations wereadded in the last year, with moreplanned for 2009 and 2010.Shell is one of the few brands with agenuinely nationwide UK network; our <strong>site</strong>sprocess between 4.5 and 5 milliontransactions per week. What’s more, the ShellRetail Team has no intention of stopping there.The customer-focused team is dedicated togrowing fuel volume, improving profitabilityand raising the standards our <strong>customers</strong>experience on <strong>site</strong>. They have setthemselves the ultimate customer objectiveof “smiling <strong>customers</strong>, <strong>every</strong> <strong>site</strong>, <strong>every</strong> <strong>visit</strong>,<strong>every</strong> <strong>day</strong>”, because “smiling <strong>customers</strong>come back.” This attitude was clearlyevidenced by John Franke, TerritoryManager, and Allan England, RetailTraining Manager, when Shell World UKcaught up with them.“We work to a quarterly call planning cycle, which helps ensurethat our workload is staggered so that we can manage it well. It’salso a way of creating a work-life balance – but it doesn’t alwayswork for me. I find managing my work-life balance harder than myactual job!“I’ve been on many courses relating to my role over the years. The‘Trusted Advisor’ course, for example, gave me more insight intothe retailer and how to build that trust and belief that they need tohave in me. Retailers are self-employed, so Territory Managersneed to get them to buy into initiatives and deliver good <strong>customers</strong>ervice at all their <strong>site</strong>s at all times. I recently went on a fantasticpresentation and facilitation course as well. People attended fromacross the business – it was so interesting and valuable to learnabout their frustrations and highs and lows. It really opened myeyes – and you can go back and use the skills right away.“Health & Safety is always at the front of my mind. TerritoryManagers do quite a lot of driving from <strong>site</strong> to <strong>site</strong>, so wecomplete a ‘Drive and Survive’ course <strong>every</strong> two years to ensurethat we are competent and haven’t picked up bad habits overtime. From a customer perspective, we carry out safety walks withretailers and ensure that daily health and safety checks take place.“My greatest challenge is delivering global and operating unitperformance standards on a consistent basis across all <strong>site</strong>s. Someof my territories have finished as high as number 3 in the UKrankings, but the key is to keep it consistent.“I enjoy my role – <strong>every</strong> <strong>day</strong> is different, with new challenges, andI enjoy working with the people on <strong>site</strong> to always improve. In 10years’ time, if I’m still doing this role, I’ll be happy.”SHELL WORLD UK

My teaching approach is to createa safe environment that’s fun,stress-free and relaxed so thatpeople can have a chance and theconfidence to try new things.Allan England, Retail Training ManagerTALKING TO ALLANENGLAND, RETAILTRAINING MANAGERAllan England joined Shell 11 years agoand first worked as a Territory Manager forfour years. As he was always interested inpeople and development, he applied for arecruitment and training role as soon as oneopened up.One of Allan’s tasks was to support theGlobal Operator Platform Change (OPC)programme by developing territorymanager training. “OPC is aboutsimplifying and standardising Retail <strong>site</strong>sand processes. It is about changing theway we interact with our retail outlets –both company-owned and dealer-owned –and it is about improving the delivery ofour Customer Value Proposition. It bringswith it a complete shift in attitude, andallows Shell to become morestandardised,” says Allan.The objective of the programme is toprovide Territory Managers with the toolsfor the management, operation andexecution of the Retail Customer ValueProposition and to help successfully executethe transition to their Business Unit’s chosenoperating platform – Retailer BusinessAgreement and Dealer Owned in the UK.“Developing training modules and workingon a programme with a global reach wasone of my proudest moments,” says Allan.Next, Allan supported the launch of aprogramme called People Make theDifference Real (PMTDR), which looked athow to improve the customer experienceeven further. “PMTDR has introducedreward and recognition initiatives andaims to train and develop people todeliver a consistently high level of service,”says Allan.Despite enjoying the global aspect of theseprogrammes, Allan found that he missedbeing really hands-on – so, he took up hiscurrent role of Retail Training Manager forthe UK 16 months ago. He adds: “I waslargely home-based in my European rolesand worked with a virtual team. Now Ihave a lot of people contact – although Ido travel away from home a lot of the time,which can be hard.”As Retail Training Manager, Allan dealswith three main <strong>customers</strong> under the retailumbrella – namely, Shell retail employees,the retailers, and their <strong>site</strong> staff. The UKtraining team is made up of: Allan; MartinWatkins, a Trainer; and Kerry Piper, theTraining Co-ordinator, based in the Stainesoffice. Allan told us more:“Working as a team is important to me.Together, we develop a training calendarfor the year and come up with the requiredlearning interventions to meet the businessneeds and increase the competency ofattendees. There is a very flat managementstructure and we all have input into thedirection we take.“There is also a sense of communityamong the trainers. We actively sharenew inspiration and have monthlytelecons. The 14 European TrainingManagers meet face-to-face once a yearand this breaks the language barrier andmakes for better interaction.“My teaching approach is to create a safeenvironment that’s fun, stress-free andrelaxed so that people can have a chanceand the confidence to try new things.“My greatest challenge is coming up withnew and creative ways to encourageimprovement at <strong>site</strong>s. We need to ensurethat our <strong>customers</strong> receive the highest levelof service. We even have mystery motoristswho go around and rate <strong>site</strong>s!“I most enjoy the people aspect of my role.The people I work with come from all overthe world as well as the UK, and differentcultures, backgrounds and markets bring somuch more to the learning. After theexperience of a global role, I’m reallyaware of the learning that comes fromsharing different experiences, and if there isavailability on a course, I’ll always offer thespace to colleagues from abroad. I like tosee people develop and gain knowledgeand confidence.” SHELL WORLD UK

REFLECTIONSBrent platformsShell World UK caught up with twoShell pensioners to find out about theirexperiences at Shell and how thingshave changed over the years.TALKING TO COLIN VINGOE (64)Colin Vingoe started out in the partsdepartment of a garage, but extensiveknowledge of technical equipment landedhim his first job in Shell UK Exploration &Production in 1971. “As a local lad fromLowestoft in Suffolk, it was a uniqueopportunity – I was very lucky to find myselfinvolved in a number of Shell Brent projects.”At the time, there was not much localequipment, so most had to be importedfrom Japan and America. Colin wasresponsible for handling customs andensuring that Shell did not pay duty on theequipment – a vital cost saving.BRENT PLATFORMSWith buying and customs experience underhis belt, Colin was asked to go to Norwayto help with the building of the Brent Bravoand Brent Delta platforms.These large structures, built in Stavangerand shipped offshore during the crucialweather window (between May andAugust), were a great success and led toColin’s appointment as Senior MaterialsSupervisor for the Brent Charlie Project.(Regular readers may recall that thisplatform was recently featured in a previousissue of Shell World UK magazine – seepage 7–10 in the summer issue.)The Brent Charlie construction, begun onthe West Coast of Scotland and completedin Stavanger in Norway, needed to betowed to the North Sea in time for theweather window of June 1978.Not far into the project, the team realisedthat the wrong specification of pipe hadbeen installed on the platform; it was up toColin as Materials Supervisor to source thecorrect pipe in time. Missing the weatherwindow would mean a year-long wait – adisaster for Shell!There was a greatculture in that itwas informal andthere was a realphilosophy ofequals.Colin Vingoe to<strong>day</strong>Colin Vingoe at Shell1971 – 1972 Project AssistantAssisted the Project Manager responsible for building gas platforms in the North Sea1972 – 1974 BuyerResponsible for buying oil field materials1974 – 1978 Senior Materials SupervisorProjects included the Brent Bravo, Brent Delta, Brent Charlie and Brent Spar projects1979 – 1980 Project Supervisor at LowestoftLogistics, co-ordination and despatch of materials1980 – 1981 Operations SupervisorResponsible for air transport, supply, all vessels and relevant activities1981 – 1982 Head of Purchasing Services in NorwayA cross-posting with a colleague in Norway1982 – 1993 Head of Supply OperationsResponsible for all the transport – marine, land and air services (air services separated in 1986)1994 – 1999 Head of Marine ServicesSHELL WORLD UK 10

Women working atShell in the 1950sAt about 10 o’clock the tealadies brought coffee toyour desk and in theafternoon they broughttea. On Wednes<strong>day</strong> theybrought fruit cake too.Jo O’DonnellColin sourced the straight pipe needed fromGermany, but the 30-inch tee pieces andelbows, all with differing angles, were moredifficult to come by. Fortunately, Colin had acontact in Italy and, together, they came upwith a schedule to meet Shell’s target. “Wegot on very well because he was an ACMilan supporter and I used to play football,so we had something in common to discussoutside of the immediate problem.”The team in Stavanger completed the buildand the platform was on time for the towoutto the North Sea.Colin was also involved in the Brent Spar,north of Norway, built to store the oil fromsurrounding platforms as there wasn’t apipeline. Tankers would approach the BrentSpar and transport the stored oil from thearea. The Brent Spar was so remote that itwas difficult to get food and supplies tothose working on the build. “I organised fora Stavanger fisherman to take supplies tothe team in his fishing boat and I flew in byseaplane twice a month.”MOVING UPIn 1982, Colin took on the role of Head ofSupply Operations, and was responsiblefor all the transport – marine, land and airservices. This role quickly grew big enoughfor other people to take on the land and airsections, leaving Colin to focus on marineservices until 1999 when he retired. “Iloved my career,” says Colin. “I met themost interesting people and had the mostinspiring bosses.”We had a few more questions for Colin...Has health and safety always beenimportant to Shell? “Health and safety hasalways been a priority for Shell, although ithas become more formalised. One safetyoperation I was involved in was re-createdand filmed for the Rescue 999 TVprogramme. The situation included an oiltanker on fire and dangerously close to theSean Papa Platform as well as sailors in theicy sea, but disaster was avoided!”What was the culture like – do you thinkthings have changed? “There was a greatculture in that it was informal and there wasa real philosophy of equals. Over time, Ithink things have become more business-like.”How do you spend your time now thatyou’ve retired? “After retiring, I consultedfor different companies on projects as farafield as America and Libya.“Now, I spend time as a magistrate inLowestoft, which is very rewarding. Lastyear the Lord Chief Justice acknowledgedme for completing 20 years of service.“I’m also a watch keeper at a lighthousethat was built in 1834, and a member ofthe Shell Pensioners Association.”After retiring,I consulted fordifferentcompanies onprojects as farafield as Americaand Libya.Colin VingoeJo O’Donnell to<strong>day</strong>TALKING TO JO O’DONNELL (74)Jo was first interviewed in 1955 – and itseems Shell have made great strides in theirinterviewing standards since then, as shewas told that one of the key criteria forgetting the job was “being good looking”!She started in the Trademarks Division inAugust that year.“Coming to Shell from a working classbackground where women didn’t have muchambition was like going to university,” saysJo. Once at Shell, she was encouraged toattend evening classes.She transferred to the Shell Education Service10 years later and soon after landed a jobthat she came to love, in Editorial Services.11 SHELL WORLD UK

DRIVING THE ROADSAFETY STRATEGYAn interview withGroup RoadSafety Manager,Mike WatsonGroup Road Safety Manager, Mike Watson, isfaced with the challenge of changing thecorporate mindset to reach our Goal Zeroaspirations. Here, he talks about his new role,how he plans to bring Shell’s road safetyprogramme to life, and how he hopes tochange the way we think about road safety.“Driving-related accidents are the singlelargest cause of fatalities in Shell companies.This is why we are making considerableefforts to meet the challenge of this globalconcern,” says Mike.It’s all aboutsaving lives andeliminatingincidents.Introducing Mike…Mike is no stranger to the road safetyenvironment and is well-equipped to handlethis demanding role. He has experience ofLogistics Management in EP, has previouslyworked as Downstream Transport andTerminals Manager and has worked on astring of Regional and Global assignments inSupply and Distribution.As the new Road Safety Manager, Mike will befocused on four key activities:1. Ensuring the implementation of the GroupRoad Safety standards across Shell, andembedding the new HSSE controlframework for driver safety.2. A group-wide road safety improvementstrategy across all businesses, with anemphasis on high-risk countries.3. Enhanced road safety capability, focusingon the important role of proactiveleadership in making this happen.4. Raising the level of safety performance;sharing knowledge, experience and bestpractice; and ensuring that there isalignment across the businesses.13 SHELL WORLD UK

Did you know?As road safety is such a majorarea of concern for the energyindustry, several joint projectshave been set up to address theissue. In 2007, Shell and otherinternational majors, Exxon, BP,Chevron, Conoco-Phillips andTotal, joined forces to form aglobal benchmarking group toshare and develop best practicesin HSSE. A separate road safetysubgroup was created because itwas felt that road safety is not justabout measuring where we are; itis also about pushing throughindustry-wide improvements andstandards, and this is particularlyimportant in high-risk countries.Making it happen…“Functional leadership will play a veryimportant role in making this happen,” Mikecontinued, “but we also intend to use a varietyof channels and tools to get our messagesacross and to embed the programme.”A starting point is the development of a RoadSafety Expertise Centre. “This is about gettingan aligned message into the heart of theorganisation. Development of the Centre isalready underway and key people within HSSEand the businesses are involved. Part of theirrole is to leverage existing best practices and, ifsomething works well, use it across the wholeorganisation. The idea is not to reinvent thewheel, but to approach the implementation ina standardised and unified way,” says Mike.We want all our employeesand contractors to returnhome as healthy as they werewhen they arrived for work.The centre will also have an online presenceoffering a wide range of tools and information;it will provide access to cross-businessprogrammes that look at a range of topicsincluding driver behaviours, supervision skillsand managing compliance.Changing ways of thinking…Simplifying requirements and developing newways of working is all very well, but how do wego about changing the corporate mindset?According to Mike, it will be a case ofembedding the Golden Rules and looking atconsequence management. “Whilst not allcountries have the same infrastructure orstandards of vehicle maintenance, they do allhave seatbelts and rules about speeding. TheGolden Rules also address areas such as notusing your mobile phone while driving andintervening when you see other peoplecommitting unsafe acts.” Consequencemanagement is about leaders enforcing therules locally and managing issues that arise.Another way to help change mindset is tobuild safe driving practices into the logisticsfor new projects and, as such, design out risk.The Pearl project in Qatar is a good example ofhow efforts to limit exposure in all areas ofsafety, including the implementation of roadsafety measures, were built into the projectduring the design phase. To find out moreabout Pearl and Shell’s other Major Projects,go to www.shell.co.uk/strategy.And what about individuals? Can we play arole in changing the corporate mindset?“Absolutely,” says Mike, “we need to focus onwhat we know, feel and do: know that there isa standard in place and that it must beimplemented; feel a personal responsibility toensure that we meet these standards, i.e. wear asafety belt, keep to the speed limit, avoid usinga mobile phone while driving; embed this inour businesses and in our home lives – beprepared to intervene when we see the rulesbeing broken, which includes challengingwork colleagues, employees, contractors ordrivers who are committing unsafe acts.”Driving the message home…“At the end of the <strong>day</strong>, the overarchingmessage is that we want all our employees andcontractors to return home as healthy as theywere when they arrived for work,” Mike says.“Breaking the rules leads to accidents, whichcan result in injury or fatalities. Even if you’renot the one who gets hurt, do you wantsomeone else’s injury on your conscience? Bysetting a good example, and intervening whennecessary, you may even prevent someone elsefrom causing the accident that injures or killsyou. We all have to take ownership; it’s timeto do our part, and together we can make areal difference.”A first-handexperienceElena Vorontsova-Kasumyan, anenvironmental advisor for SakhalinEnergy, knows first-hand that whenindividuals take responsibility forsafety, lives can be saved.Travelling to the north of SakhalinIsland in 2005, Elena’s car crashedinto a deep hole where the road hadbeen washed away during a storm.The vehicle was badly damaged; thewindscreen smashed and the frontend was crushed like a concertina.Thanks to the driver’s firm but politeinstruction to use the seat belts, Elenaand two passengers survived theaccident. A fourth passenger, whochose to ignore the driver’s instruction,suffered multiple injuries and laterdied. “If I hadn’t been wearing myseat belt I would not have survived,”said Elena. “Why be in a hurry toyour own death?”If you have anything you wantto share on this subject, Mikecan be contacted via a newGroup Road Safety mailbox:Road.safety@shell.comSHELL WORLD UK 14

SHELL INNIGERIAFind out more about Shell’s involvement inNigeria and how our relationship with theGovernment THERE works.Basil OmiyiThis year’s Reputation Trackerreveals that public opinion ofShell’s involvement in Nigeriais largely unfavourable.Presenting to the UK in October, Shell’sCountry Chair in Nigeria, Basil Omiyi,said he knew that each Shell person is anadvocate for the company and maytherefore be faced with questions regardingits global activities - including its activityin Nigeria. His aim was to provide adifferent perspective from inside Shell inNigeria on a variety of key topics: thecompany’s relationship with the federalstate, Shell’s social investment in the localcommunity and environmental issues,amongst others.SHELL’S RELATIONSHIP WITHTHE GOVERNMENTSo, what is Shell’s involvement in Nigeriaand how does Shell’s relationship with thegovernment work? Shell companies inNigeria are producing oil from land andswamps in the Niger Delta and from deepwater reserves some 120 kilometres off thecoast, as well as participating in Nigeria’slargest liquefied natural gas (LNG) plant,which exports all over the world.Shell’s primary interest in Nigeria is throughThe Shell Petroleum DevelopmentCompany of Nigeria (SPDC), a joint venturein which the government, through theNigerian National Petroleum Corporation(NNPC), holds 55%, Shell 30%, ElfPetroleum Limited 10% and Agip 5%.Approximately 95% of the revenue aftercosts is paid to the government in tax androyalties; and, the company has more than4,000 staff, 95% of whom are Nigerian.From this example alone, we can see thatShell makes a substantial economiccontribution to the country – Nigeriadepends on the oil industry for 95% of exportearnings and 80% of government revenue.So, why do the local people still feel like theirresources are being stolen from them?Unfortunately, corruption has been one ofthe barriers to turning oil revenues intobenefits for the people of Nigeria. Thenagain, even if well spent, Nigeria’s oilreserves do not go far when dividedamongst its 140 million people – itamounts to less than $1 per person per <strong>day</strong>.And it’s poverty that is the real problem –particularly in the Delta, where theswampy landscape has made infrastructureand development difficult and causedpolitical and social tensions to increase.SOCIAL INVESTMENTShell’s investment in Nigeria goes a lotfurther than pure economics – Shell activelyinvests in projects to help buildinfrastructure, provide health care, improve15 SHELL WORLD UK

I do understand where thefrustration comes from. Theneed on the ground is so greatand people feel more should bedone. Many people wish the oilcompanies could fill this gap.Basil OmiyiChairman of Shell Nigeriaeducation and promote small business.Much of this is done in partnership withthe government, other companies, local andinternational non-governmentorganisations (NGOs) and the UnitedNations Development Programme.Shell has realised that projects can havemixed success rates if they are notsustainable and the local communities areunable to maintain them. This is why anew approach to community developmenthas recently been launched.“After a number of experiments, we choseto engage local communities and, sincethere are so many, we work together withNGOs to group them into clusters,” Basilexplains. “This provides critical mass and,hopefully, alignment across broadersegments of society.“In this new form of cooperation, thecommunities themselves are in charge ofidentifying and implementing projects,with the help of NGOs. We hope thisform of cooperation will contribute tobuilding self-help capacity, increasingsocial cohesion, and reducing crime.”Despite this, many people still believe thatoil companies are at least partly to blamefor Nigeria’s problems. So, just howresponsible are oil companies for gettingthe Delta region into a mess and,hopefully, out of it again some <strong>day</strong>?“It’s convenient to scapegoat oil companiesfor what is truly a very complex situation.Some of our critics seem to believe thatbecause the oil companies are the avenuesthrough which the central governmentgets its oil revenue, we are therefore partyto the dispute – which we’re not,” saysBasil. “What they forget is that companieslike Shell have to abide by the laws of thecountry. A company can only createemployment through its activities,produce oil, create wealth for the nation,pay its taxes and levies as due. It’s not theirrole to replace government.”He goes on to say: “I do understand wherethe frustration comes from. The need onthe ground is so great and people feel moreshould be done. Many people, includingjournalists, wish the oil companies couldfill this gap.”ENVIRONMENTAL ISSUESShell also faces criticism when it comes toenvironmental issues such as oil spills. So,just who or what is responsible and whatcan be done to limit the damage they cause?“Around 70% of the oil spills aredeliberately caused. I’m talking about actsof sabotage for political reasons oreconomic benefit,” says Basil. “Our criticsmay not want to hear it, but this is thereality. Compared with local income, suchfinancial compensation is significant and itis a sad human story of poverty that leadsindividuals to seek profit in this way.“The remaining 30% of the spills resultfrom operational failures. We try tominimise these by improving the integrityof our assets. Once a spill occurs, whateverthe cause, we try to go in to stop the spill,contain it and clean it up.”Flaring is another key environmentalconcern. When Nigeria first found oil, thepriority was generating income from oil,regardless of the associated gas emittedduring oil production. Shell recognisedthat this approach was unsustainable andthat an outlet for the flared gas wasneeded, and began to promote gasutilisation to industries and power plants.To<strong>day</strong>, some 60% of power generation inNigeria is fuelled by natural gas fromShell-run operations. In addition, for over20 years Shell promoted a project toexport liquefied natural gas (LNG). Thecampaign ultimately led to the creation ofNigeria LNG, a successful joint venturebetween Shell and the Nigeriangovernment that supplies LNG to theworld’s markets.Progress is being made so, what remainsthe issue?“The federal government mandated all gasflares to be put out by the end of 2008,and we as a company supported that,”explains Basil. “We drew up all the plans,but our government-owned partner raninto a funding crunch. At the same time,the security situation deteriorated,blocking access to many locations andmaking it impossible to complete theprogramme this year. Hopefully, we willsoon be able to continue.“Shell Nigeria has the same core values ofhonesty, integrity, and respect for people asother Shell companies worldwide andapplies principles consistent with Shell’sGeneral Business Principles,” says AliceAjeh, International Relations Manager forNigeria. “Our environmental standardsare also consistent with those of Shell.”Basil qualifies this: “All in all, I’m veryproud of what we at Shell have done andachieved over the years. People who want tobe fair recognise us for this and, fortunately,there are many people who do.”Find out more about Nigeriain Shell’s global onlinemagazine, Shell WorldOnline, which can be foundon www.shell.com in theMedia section.SHELL WORLD UK 16

Did you know?• 67% of academics think highly of Shell, rating it morefavourable than its competitors.• Academics particularly commend Shell’s developmentin technology and performance management.• 54% of Special Publics rated Shell’s media relationsteam ‘better than average’ or ‘the best’.Academics also think highly of Shell, with67% rating it more favourable than itscompetitors. They particularly commend itsdevelopment in technology and performancemanagement, according to Stewart’s report.But one group remains sceptical - NGOs.Many of these non-governmentorganisations are pressure groups andaccording to the Reputation Tracker, 40% ofNGOs would be critical of Shell.“With the pressure groups, you wouldexpect them to be more challenging to oilcompanies. This is where Shell is seen as anotch behind BP, who have a long history ofengagement and pioneering work withNGOs,” Stewart explains. “However, Shellis gaining more respect – for being serious,consistent and not over-promising.”While Shell is regarded very highly bymost Special Publics, there are twoconcerns that all groups shared: Shell’sperceived behaviour in Nigeria and itsperceived lack of environmentalconcern. According to the ShellReputation Tracker report, there is asense, mostly from pressure groups, thatIt reflects one of the things thatpeople seem to admire most aboutShell - its consistency and reliabilityand that’s very important.Stewart LewisHead of the Reputation Center at Ipsos-MORIShell could improve the standards towhich it works in these areas. And whiletwo-thirds of Special Publics see Shellmoving in the right direction, theywould like to see a greater focus ondeveloping alternative energy sources – apriority which is key to sustainingpositive opinion within this group:“If Shell is to be even better regarded than itis, it needs to show Special Publics that ithas a committed, clear and responsible viewon these issues. There’s a need for greaterclarity and better promotion of the policiesand schemes that Shell have in place.”Stewart believes.The general public’s results were verydifferent from the other audiences. Thesurvey was conducted in June and July thisyear – the absolute height of rising oil andfuel prices and when company profits wereannounced. These factors caused the publicto become disenchanted with the industry asa whole.However, the public remain open-minded.According to the report, they would still beinterested to hear about Shell’s vision forthe long-term future and about its responseto energy challenges. “It may be that a moreeffective explanation of profits, inparticular on how they are reinvested intofinding different forms of energy, wouldhelp here. As would continued positivemessages from Shell regardingenvironmental issues,” says Stewart.Each year, the Shell Reputation Tracker ispresented to Shell’s head office in TheHague, and then to Country Chairs,Corporate Affairs teams, Business Leadersand communicators. Representatives fromIPSOS <strong>visit</strong> many of the national offices tohelp shape strategic plans for theforthcoming year.Stewart believes that a lot of value comesfrom working with teams at individualcountry level to discuss how results shouldcolour their reputation and communicationsplan going forward. This is a formula that isclearly working: “This year, there’s been a lotof recognition for Shell’s media relationsteam in the UK - the British pressacknowledge an improved relationship withthem, which is nice to see in findings. 54% ofSpecial Publics rated Shell’s media relationsteam ‘better than average’ or ‘the best’, whichis a 15% improvement from last year.”“The Shell Reputation Tracker is a great toolfor us to assess where we’re at with differentaudiences on different topics. It is also agood feedback mechanism on how ourstakeholders want to receive informationfrom us versus how they are actuallyreceiving information from us,” says AndrewEddy, Head of UK Communications.“Every year, face-to-face engagements comestop of the list of how our stakeholders wantto be communicated with. That’s why ahealthy reputation requires Shell people tobe out there talking about what we’re doingand the realities of the energy environment.”Following the findings of this year’s ShellReputation Tracker, the UKcommunications team has already identifiedsome topics where more communication isneeded. One example is Shell in Nigeria.Basil Omiyi, Country Chairman in Nigeria,spoke to staff in London in October aboutthe realities of running a company in acountry as complex as Nigeria. For moreinformation on this, see pages 15-16.How has Shell’s reputation changed over theyears? Has there been a marked jump inopinion at any point? “There hasn’t reallybeen a jump in opinion but it has shown asteady progress and, in many ways, that’sideal,” says Stewart. “It reflects one of thethings that people seem to admire mostabout Shell - its consistency and reliabilityand that’s very important - a company likeShell needs to be seen as serious andresponsible. If you could add someexcitement to it as well then even better!”SHELL WORLD UK 18

THE ENERGYCHALLENGEIn this issue, Shell World UK magazine talks toShell UK Chairman, James Smith about his viewson the energy challenge.Kids should be inspired to getinvolved, but we need toencourage more children tostudy the science andtechnology that the energyindustry will need.What is the energy challenge and what canwe do about it? “The world needs moreenergy and it needs to emit less CO2. In fact,it needs quite a lot more energy and it needsto emit quite a lot less CO2. More energy isneeded, especially in the developing world,where increased energy goes hand in handwith people lifting themselves out of poverty.“Stepping up to the energy challenge meansusing energy much more efficiently,mitigating the CO2 associated with fossilfuels and effecting very substantial growth inalternative energy sources. We need energyefficiency in <strong>every</strong> nook, corner and crannyof the economy.“People say to me, ‘We need an energysource that is clean and cheap and alwayson.’ People also say, ‘We need to find aninnovative company like Google, but inthe energy sector.’ They sometimes wantto strike energy sources off the list ofpossible solutions.“But no single source of energy meets thecriteria of ‘clean and cheap and always on’.And we shouldn’t think that such a source isgoing to be invented soon. So I believe weneed all the energy sources we can think of.And we need to make each one fit forpurpose. Where the energy is cheap butproduces too much CO2, such as coal, thenwe need to capture the CO2 and make itsafe. Where there is less CO2 but the energyis a lot more expensive and also morevariable, such as with wind, then we needbetter technology to bring the costs downand energy storage so we can even out thepeaks and troughs.“Individual companies need to choose theset of energies they will work on to makethem fit for purpose for the energy challenge.At Shell, we work on cleaner fossil fuels andwe work on alternatives such as sustainablebiofuels, wind, hydrogen and solar.”19 SHELL WORLD UK

There is no doubt that theworld’s energy system in2100 will be verydifferent from to<strong>day</strong>’s...Do you think people have a bigger roleto play than they currently do in savingenergy? “Yes, absolutely, we need tochange our attitudes and habits. There areso many examples of this – VW Golfs havebecome bigger over the years, so are stillusing the same amount of energy, evenwith more efficient engines. Things likefridges and houses are more energyefficientnow, but we seem to respond bygetting more fridges and using moreenergy in our homes.“If we are going to save energy then ourdriving habits and the way we use energyin our homes will need to change.”How can we get people to change – doesit come down to governmentintervention? “Regulation must come intoit, yes. But this is a tricky quandary formodern politicians. Some of theregulations that we would ideally needmay be unpopular with people at first.“And I think it’s not just down to thepoliticians. We have to see the benefit forourselves. Maybe companies have a role toplay in helping consumers use energy moreefficiently. Supermarkets are making theirstores more energy-efficient, and in Shell wegive tips to drivers on getting more miles pergallon. Our Liquid Petroleum Gas businessgives advice to householders on how theycan cut their energy needs at home.“Also we need to get more peopleinterested and involved in the problem,especially young people.”Why young people in particular?“Because they are going to need to takeover solving the problem from us in thefuture. The energy industry is fascinating,because energy is universally so needed.Kids should be inspired to get involved,but we need to encourage more children tostudy the science and technology that theenergy industry will need. We’ve beenlooking into this in the ‘Learning to LoveScience’ report we recently commissioned(see page 4 for more information).“So we need to find ways to get childreninterested, show them what good careersthere are in energy and get more and moreof them to consider a career in science. Wedo a lot of work through Shell EducationServices trying to achieve this.”How do the Shell energy scenarios fitinto this? “There is no doubt that theworld’s energy system in 2100 will be verydifferent from to<strong>day</strong>’s – so the scenarios areabout exploring how the transition in theenergy system will play out.“Will national governments scramble tosecure energy resources for themselves,devoting limited attention to moreefficient energy use until supplies are tight,and not seriously addressing greenhousegas emissions until there is major climatevolatility? Or will the spread of increasinglocal actions create blueprints thataccelerate the large-scale globalapplication of key technologies to meetthe energy challenge?“We presented two views of the future –‘Scramble’ and ‘Blueprints’ – in the ShellEnergy Scenarios, and, for the first time ,we have publicly said that we prefer one ofthe scenario outcomes to the other, namelythe ‘Blueprints’ scenario.“The bottom line in the Blueprintsscenario is that it is an interdependentenergy world and successfully meting theenergy challenge needs collaborative effort.“Shell has the vision, the technology and,most of all, the people to do well inresponding to the energy challenge.”James Smithin profileJames Smith was appointedChairman of Shell UK in 2004.He has been with Shell since1983 and has worked in all theGroup’s major businesses.He was previously on the boardof Shell Chemicals and chairedShell’s CRI catalyst businessduring a period of restructuringfor profitability. He has beenhead of resourcing, whichinvolved ensuring there is atalented and diverse group ofleaders for the top 200 jobs inShell. Much of his early careerwas in upstream oil and gasproduction. He lived for four anda half years in Malaysia andBrunei and has been involved inShell businesses in a number ofMiddle Eastern countries and inthe US.James has a degree in physics and is achartered accountant. Before joiningShell he worked with Accenture.He is married with one son. Hishobbies include tennis, golf,skiing, hill walking and gardening.For more information aboutthe Shell scenarios, go towww.shell.com to the‘About us/Strategy’ section.SHELL WORLD UK 20

PEOPLE &ENVIRONMENTCan more be done to prepare local residents for future earthquakesin the Sichuan region in China? Shell geologist Nick Richardson waspart of a team of experts called in to explore the fault lines.academics at Chengdu University and theSichuan Earthquake Administration –how did they use your expertise? “I hadworked with them before and we share adeep understanding of the local geology soit made sense for me to return in August thisyear. Put simply, mapping out where theactive faults lie, how much they havemoved, and in what way they have moved isessential to understanding what kind ofseismic, landslide and flood activity mightoccur in future events within the region.Nick Richardson, an explorationgeologist based in Aberdeen, waspart of a small international teamof experts called to explore thefault lines that caused thedevastating earthquake in Sichuanon 12 May this year, killing69,000 people.Nick’s research will increase the scientificunderstanding of the fault network withinwestern Sichuan so that the impact of futuredisasters may be mitigated and the regionbetter prepared.His extensive knowledge of the area has beenbuilt up over several years of internationalcollaborative study – since 2003 he hasregularly vi<strong>site</strong>d the Sichuan region, where hestudied tectonics and sedimentation as part ofhis doctorate. His academic group was theThe earthquake caused extensive damageonly one to warn of the possibility of a massiveearthquake in a report published by theacademic journal, Tectonics only last summer.Describe the moment you heard about theearthquake earlier this year. “I was amazedthat it had happened during my lifetime –based on our knowledge of previousearthquakes, I had expected it to happen afew hundred years from now. There weremany little clues in the landscape thatsuggested large earthquakes had occurred inthe past and we knew that it was likely tohappen in the future and close to one ofChina’s most densely populated areas. We justdidn’t know when or to what extent. The lastsentence of our published research paper wasalmost prophetic: ‘The faults are sufficientlylong to sustain a strong ground-shakingearthquake, making them potentially serioussources of regional seismic hazard’.”Shortly after the earthquake, you wereasked back to the region by leading“I helped to identify exactly where futuresurface breaks may occur so that people canavoid building over them – a structure thatspans a fault rupture will split in half in theevent of an earthquake and so building acouple of metres away from the fault canmake all the difference. Geology can helpreduce the likelihood of future casualties byinfluencing town planning and structuralbuilding regulations.”Were Shell supportive of your decisionto return to Sichuan? “Yes, very. I think alarge multi-national corporation such asShell see it as their corporate socialresponsibility to provide scientific expertiseif it helps prevent loss of life. As well asdonating my expertise, Shell China haveprovided substantial financialcontributions to aid the local community,and other Shell employees have given uptheir personal time to work as volunteerssupporting the relief effort.”How had the area changed on your latest<strong>visit</strong>? “I was struck by how quickly theChinese government had responded to thedisaster – they had moved survivors out ofdevastated areas and into temporaryvillages, providing them with sanitation andclean water to prevent the spread ofinfection. The people were not visiblyshocked, but were stoical and resourceful,continuing with their lives despite terrible21 SHELL WORLD UK

Many local people told us incredible stories,for example one farmer explained how hewas thrown down to the ground when thefault ripped through his field a few yardsfrom where he stood.Nick RichardsonExploration Geologistloss and with great dignity. Remarkably,they were just as welcoming and friendly asthey had been before the disaster. Theirsmiles must have masked a lot of the horrorthey had been through.‘The devastation was a lot more apparent aswe vi<strong>site</strong>d a number of towns and villagesclosest to the 250 km long fault rupture zone.We saw the landslides, flooding, collapsedbuildings and roads that caused suchextensive loss of life. Places we had vi<strong>site</strong>d inthe past were often reduced to ghost townsand some had been completely buriedbeneath vast landslides. It was a surreal andunsettling experience. But I only witnessedthe physical change. My Chinese colleagueshad immediate experience of the emotional –the bodies, distressed and injured people,stray dogs and livestock running around thestreets. Many local people told us incrediblestories, for example one farmer explainedhow he was thrown down to the groundwhen the fault ripped through his field a fewyards from where he stood. Other peopledescribed entire mountains collapsing.”Nick Richardson back in AberdeenDid you feel endangered at any point? “No– I was provided with some excellent safetyadvice by Shell HSE specialists before I left.There were a number of special hazards to beaware of – many buildings and roads hadbeen compromised structurally, overheadpower cables had fallen to the ground,mountain slopes were unstable, especiallyafter heavy rainfall. We did have special safetyequipment in our 4x4, and I was wearing ahelmet, but if a mountainside crashes downon top of you, a helmet is not going to be ofmuch help!“Although we vi<strong>site</strong>d the region three monthsafter the earthquake had occurred to reducethe probability of experiencing aftershocksand to allow roads to be re-built, we still hadto travel out of the disaster zone each eveningto find safe accommodation.”Had the devastation occurred where youhad predicted in your doctorate research?“In some places it had and worryingly, inothers, it hadn’t – there were somestructures involved that nobody knewexisted before. We also discovered somesimilar, previously unidentified tectonicstructures closer to Chengdu (a city with 10million inhabitants), which is troubling. Allthis will need a lot of further research andfunding – there are currently a lot ofacademic groups working in the area, butbetter collaboration is needed to gain amore complete understanding of the faultsand seismic activity.”Could drilling for oil interfere withseismic activity? “There is no scientificevidence that drilling for and extracting oiland gas can cause large earthquakes.“Sichuan’s petroleum industry may beuniquely placed to assist future damagemitigation. By making their extensiveseismic data available to the academiccommunity, they could help assessments ofthe detailed geometry and location of theregion’s fault network.”Can Shell colleagues do anything to help?“As mentioned, the response to theimmediate disaster has been impressive, butnow the long-term task of permanentlyresettling people and industry in saferlocations presents itself. Structuralengineering skills will be especially valuableduring this effort, and Shell staff can make acontribution through continued financialdonations – please <strong>visit</strong> the EP news intranet<strong>site</strong> for more information.“I would like to express my thanks to<strong>every</strong>one who has helped so far – mymanagers and colleagues at Shell in the UK,the Netherlands and Australia who haveencouraged and facilitated my involvement;the Executive Chairman of Shell China, LimHaw Kuang and his staff; and the manywelcoming people in Sichuan who I havemet over the years, both before and after theearthquake, and who I am glad to be helpingin return.”SHELL WORLD UK 22

TECHNOLOGY& INNOVATIONProfessor Geoff Chamberlain tells us about his fascinating work,and the advances he has seen, in Major Hazards management.Meet Professor GeoffChamberlain. He initiallyjoined Shell Research toresearch solar energy after theoil crisis of 1973. Since then,he has worked for Shell Expro,Shell Global Solutions and asGlobal Discipline Leader ofthe Major HazardsManagement team.He has been instrumental in developingShell’s expertise in hazard analysis and inmanaging the risks associated withhydrocarbon fires, releases and explosionsand has been awarded three medals overthe years for his work by the Institute ofChemical Engineers. His work, and that ofhis Global Solutions HSE Consultancyteam, has been pivotal to the safety ofthose working in the oil and gas industry.Geoff also lectures on fire dynamics, is a<strong>visit</strong>ing professor at LoughboroughUniversity, is editor of the Process Safetyand Environmental Protection journal andis on the investigation team of theBuncefield oil explosion.He retired on the 28th of November this yearafter more than 33 years of service and willconcentrate on his own family-run fireworkdisplay business.That’s an impressive CV, Geoff! Whatsparked your interest in fire andexplosions? “After accidentally setting fireto my family home when I was just twoyears old, I have been fascinated by fireever since! I experimented with chemistrysets as a child and was captivated byfireworks – I led a risky existence as a teen,but learnt an enormous amount! I’m just23 SHELL WORLD UK

The Major Hazard Management TeamGeoff has been central in establishing Shell’sreputation in fire and explosion research and weare now at the forefront of this important field. As aresult of his work, Shell’s Global installations aresafer. Geoff has enhanced the safety of tens ofthousands of people - what greater tribute can therebe? I would like to thank him on behalf of Shell EP.Malcolm Brinded, Executive Director, EPinterested in the way the world works andhow elements react with each other,which is why I studied chemistry atuniversity. Fire is something to berespected though. It’s a ‘good slave and abad master’.”Why is the understanding of MajorHazards such an important topic forShell? “Imagine being told to design yourblast walls based on analysis for domestic gasovens. Or, that if a spill of LNG occurs in theEnglish Channel then Paris would be at risk.Surprised? Well, these were some of theperceptions and statements made in the early<strong>day</strong>s of fire and explosion hazard analysis.“It was clear that we had to understand thereal risks associated with the hazards of ourindustry at a deeper level. This wouldenable us to design against catastrophicevents and convince staff and the publicthat we could operate our facilities safely.Shell and British Gas invested a significantamount of money into detailed researchand I was lucky enough to be involved withteams carrying out large-scale experimentsto validate the scientific theory surroundingspills, jet fires, pool fires, releases andexplosions. This work, presented in over100 papers in the open scientific literature,has not only helped build Shell’s reputationas a Global Leader in Major Hazard safety,but also ensured our plant layouts anddesigns are cutting edge via the applicationof Shell’s detailed computer models basedon these huge experiments.”Has the occurrence of major incidentsbeen reduced since your research waspublished? “The understanding andawareness of major incidents has certainlyimproved, but unfortunately theoccurrence of major incidents in the oiland petrochemical industry has not! Majorincidents causing fatalities can no longer betolerated as the normal fallout of industrialactivity, plus the industry has realized thata major accident could bankrupt them orat least damage their reputation. Anotherfactor is that technological advances incomputing have brought difficult analyseswithin reach of a wider audience. Also,regulatory pressure to control majorincidents has been stepped up in responseto major incidents such as Piper Alpha,Texas City and Buncefield.“The teams I have worked with have helpedmake the industry’s operations safer.However, despite this improvement, majorincidents do still occur at an unacceptablefrequency. Good understanding of fires andexplosions is not enough to guarantee safety– the industry needs effective safetymanagement and a shift of culture. OurGoal Zero philosophy and Group-widedrive on process safety will help, but it willneed continued effort on <strong>every</strong>one’s part. Iam confident that this is the correct wayforward for Shell.”Do you think that your research hasprevented loss of life? “It’s impossible to say!Hopefully, disasters were prevented andhopefully that meant fatalities wereprevented through fewer explosions. I haveinterviewed people with major burn injuriesand seen the fear in the men’s faces afterPiper Alpha. I have seen awful things afterfire and explosions. In Shell, we have themotivation, talent and techniques to stopthese terrible events and must continuallystrive to do so.”You took part in the Piper Alphainvestigation, amongst others, and arecurrently investigating the Buncefieldexplosion. What does this involve? “I hadto explain to the Piper Alpha PublicInquiry what explosions actually were andhow to prevent them. For Buncefield, I alsohave to evaluate the evidence of theexplosion and try to calculate exactly whathad happened on the basis of it, makingrecommendations accordingly.“We’re halfway through the analysis now,but I am not at liberty to reveal thefindings yet.”Teaching, consultancy, further researchand writing for scientific journals takesup a lot of your time. What are thedevelopments in the area of fire dynamics,explosions and hazard management? “Inlight of the three hard truths of increasingenergy demand, no easy oil and climatechange, my team has developed a focusedR&D programme to cope with thechallenges of the future. As the Groupdevelops novel extraction and processingtechnologies and as we begin to explore innew areas with extreme weather conditions,we will need a better understanding ofcomplex dispersion and explosionmechanisms. The development of biofuelswill also bring new challenges.“Finally, I’m sure there will be a drivetowards standardization of major hazard andrisk tools and techniques, which shouldsimplify and promote the use of thisconsiderable body of knowledge across theGroup. It’s a great field to work in and coversall of Shell’s operations.”What will retirement bring for you? “Ihope to carry on with my lecturing and Iwant to develop my firework company –Chester Pyrotechnics Ltd. I love setting offfireworks to music and entertaining crowdson a colossal scale.“My wife and I are also <strong>visit</strong>ing a child inVietnam that we sponsor through thecharity Action Aid, and then moving on tosee the orangutans in Borneo. Plus I haveresurrected my interest in astronomy andhave bought an enormous telescope …I won’t be bored!”SHELL WORLD UK 24

SHELL IN THECOMMUNITYMEET BIANCA RUAKERE, WHO TRAVELLED TO BRAZIL TO WORKON PROJECT BETTERWORLD.Bianca back in the London officePROJECT BETTERWORLDBianca Ruakere recently returned from Brazil after three weeksof field work, adventure and travel. The adventure startedwhen Bianca made her way to the Pantanal, a vast wetlandwilderness in the heart of Brazil, for Project Betterworld. “Ihave always been interested in travel,” says Bianca, “and I waskeen to go to a country I’d not vi<strong>site</strong>d before and to a part ofthe world I wouldn’t normally have the opportunity to go to.”Brazil’s Pantanal fits the bill perfectly, being particularlyremote and very difficult to get to.Bianca spent two weeks doing field work on two differentprojects for researchers and scientists. There were 11 people onthe project – five from different Shell locations around theworld and six individuals. The first project involved findingout more about bats in the South Pantanal. These tinymammals are guardians of ecosystem’s health and don’t deservetheir fearsome reputation.BATS OF BRAZIL’S PANTANALSo, how does one go about researching bats? Bianca explains,“We’d head out each afternoon at 4pm and set up mist nets inthe open and in the undergrowth to capture the bats. At dusk,when the insects came out, the bats would start feeding andbecome entangled in the nets. Wearing thick gardening gloves,we untangled the bats from the nets, took their measurements,and collected para<strong>site</strong> samples from their bodies and faecessamples to determine their diet. At first, bats were tagged inmuch the same way as birds, but this did not work well so weplaced what I’d call ‘bling bat medallions’ on them instead.25 SHELL WORLD UK

Wildlife from Brazil’s Pantanal regionAMPHIBIANS AND REPTILES OF BRAZIL’S PANTANALThe second field work project was just as hands-on. This time,the team evaluated the impact of cattle farming on thebiodiversity of the area – cattle farming and eco-tourism beingthe two main income generators for the area.Brazil’s Pantanal regionBianca tells us, “We caught frogs and lizards and snakes in trapsabout 1 metre deep in various areas from high to low impactfarming areas. In the traps you’d find scorpions, giantcockroaches and tarantulas the size of your hand! You’d be downon your hands and knees, getting filthy and you’d have to becareful. We had 20 centimetre long ‘tweezers’ to extract theanimals, but when there’s a tarantula on the end, they’re not longenough! It was interesting as some people were OK with insects,but couldn’t stand the texture of frogs for example and otherpeople were not bothered by frogs, but found insects skincrawling,so it was best to team up with your oppo<strong>site</strong>. No onereally wants a tarantula climbing up their sleeve!”The team would take the animals back to the lab to define thespecies, sex and measurements and mark and release the animalsthe following <strong>day</strong>.Shell World UK wanted to know the truth – was it fun? Frogs andlizards and snakes and ‘creepy crawlies’ just don’t sound attractive.Bianca says philosophically: “It’s not something that <strong>every</strong>onecould do. I have friends who get upset by a wasp flying around!On the project you recognise the importance of the research andrealise you’ve just got to get on with it. No one said, ‘I’m notgoing to do this.’ We were out of our comfort zone, but the goodattitude of team members and the teamwork made it a whole lotmore comfortable. You’ve just got to embrace it wholeheartedly!”Bianca researching bats“We’d catch about 34 bats on a good night and 10 on a quieternight, all of which were released unless they were an unknownspecies and needed further assessment in the lab. We’d headback to the ranch at about 1am.”It doesn’t sound like something for the faint-hearted, butBianca reckons that bats are “quite cute” and that the greatestchallenge was all the insects and especially the mosquitoes.“I returned with 52 mosquito bites and there are ticks thatburrow into your skin.”To be fair, there were a number of perks. On a <strong>day</strong>-to-<strong>day</strong> basis,the team saw magnificent wildlife – giant anteaters, crab-eatingfoxes, armadillos, monkeys, otters, parrots and giant birdsamongst others. “One evening, the rumour of two jaguars nearthe river caused great excitement and anxiety at the ranch. Ratheramusingly, they turned out to be capivara, large guinea pig-likeanimals the size of a small dog – cute and harmless!” says Bianca.A POUSADA/RANCH IN BRAZILThe team stayed at a guest house called a ‘Pousada’ that was run bylocal people – a ranch manager, his family and 20 staff. “Thelanguage was interesting,” says Bianca. “Fortunately we hadDomingo from Shell Spain with us, and he was able to decipher it toa degree! The principal scientific investigators spoke English well.”SHELL WORLD UK 26

ABOUT BIANCA RUAKEREBianca has worked for Shell for about eight years and startedoff as an assistant in the Group Press Office in 1999. She thenjoined a consultancy that deals with crisis management and theagency experience led to her taking up the role of LeadDownstream Press Officer. Bianca is now the External AffairsMedia Relations Manager for Shell’s Chemical Business.PROJECTBETTERWORLDSo, how did Bianca hear about ProjectBetterworld and become involved? “Anote about Project Betterworld wascirculated and at about the same time Ichatted to colleagues who hadparticipated – one had been whalewatching in Canada, another workedon the Belarus wetland and a thirdvi<strong>site</strong>d Kenya. They all had such goodfeedback and found the project sorewarding that I decided to apply forsponsorship.” Shell sponsors employeesand the project itself is run by theEarthwatch Institute.GET INVOLVEDIf you are a Shell employee andwould like to be involved in theproject, you can find moreinformation and the application formon www.shell.com/pbwAccommodation was basic, with three people sharing a room. However, therooms had fans and air conditioning, which was appreciated in the 35-degree heat, as were the swimming pool and hammock area.Bianca also told us about the local food. “It was excellent, with lots of beansand rice and fish. One evening we even had piranha soup! We also had a lot ofsweet, gooey deserts, probably due to the cane sugar that is grown in Brazil.”INDEPENDENT TRAVELS AND HEADING BACK TO THE UK“Two friends flew out to meet me for a week in Brazil after the project. We vi<strong>site</strong>dSalvador, the old capital, Rio and a sleepy beach village. A lot of people took theopportunity to do some independent travel after the project,” says Bianca.Shell World UK wanted to know how such a wild experience relates back toShell and working in an office. “It was an amazing trip, and I was veryappreciative and delighted to be afforded the opportunity,” explains Bianca.“I think it’s particularly important when you work in an office environmentand are responsible for relating company views on many things you’ve not hadpersonal experience of. It’s valuable to understand the impact of man’s activityon the environment and get hands-on experience of making a difference.”EARTHWATCHEarthwatch is an internationalenvironmental charity that engagespeople worldwide in scientific fieldresearch and education to promote theunderstanding and action necessary for asustainable environment. Take a look atwww.earthwatch.org to find out more.27 SHELL WORLD UK