Electronic Stand-Alone Locks Service Manual - Best Access Systems

Electronic Stand-Alone Locks Service Manual - Best Access Systems

Electronic Stand-Alone Locks Service Manual - Best Access Systems

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SERVICE MANUALSERVICE MANUALB.A.S.I.S. LOCKSKEYPAD EZ LOCKS®®

CREDITS/COPYRIGHTCopyright © 2000–2004 Stanley Security Solutions, Inc. and Stanley Logistics, Inc. Allrights reserved. Printed in the United States of America.Information in this document is subject to change without notice and does notrepresent a commitment on the part of Stanley Security Solutions, Inc. The softwaredescribed in this document are furnished under a license agreement or nondisclosureagreement.This publication is intended to be an accurate description and set of instructionspertaining to its subject matter. However, as with any publication of this complexity,errors or omissions are possible. Please call your BEST ® distributor or Stanley SecuritySolutions, Inc., <strong>Best</strong> <strong>Access</strong> <strong>Systems</strong> at (317) 849-2250 if you see any errors or have anyquestions. No part of this manual and/or databases may be reproduced or transmittedin any form or by any means, electronic or mechanical, including photocopying,recording, or information storage and retrieval systems, for any purpose, without theexpress written permission of Stanley Security Solutions, Inc.This document is distributed as is, without warranty of any kind, either express orimplied, respecting the contents of this book, including but not limited to impliedwarranties for the publication’s quality, performance, merchantability, or fitness for anyparticular purpose. Neither Stanley Security Solutions, Inc., nor its dealers ordistributors shall be liable to the user or any other person or entity with respect to anyliability, loss, or damage caused or alleged to be caused directly or indirectly by thispublication.DuoProx and ProxCard are registered trademarks of HID Corporation.The Life Safety Code is a registered trademark of the National Fire ProtectionAssociation.Lubriplate is a registered trademark of Fiske Brothers Refining Company.Sargent is a registered trademark of Sargent Manufacturing Co.Von Duprin is a registered trademark of Von Duprin, Inc.Written and designed by Stanley Security Solutions, Inc. and Avalon Group, Inc.,Indianapolis, Indiana.T80935 Rev – ER-7991-6 May 2004

CONTENTSGETTING STARTED 1–1Introduction 1–1B.A.S.I.S. product overview 1–2System overview 1–2Mortise lock overview 1–4Cylindrical lock overview 1–4Keypad EZ product overview 1–5System overview 1–5Mortise lock overview 1–5Cylindrical lock overview 1–6Certifications and standards 1–6<strong>Stand</strong>ard <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> 1–6Mortise locks 1–6Cylindrical locks 1–6Exit hardware trim 1–7Documentation package 1–7Technical support 1–9Support services 1–9Telephone technical support 1–9<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>iii

ContentsSTANDARD FUNCTIONS AND PARTS 2–1Function descriptions 2–2Mortise functions 2–2Cylindrical function 2–4Trim components 2–5B.A.S.I.S. magnetic stripe reader and trim 2–5B.A.S.I.S. smart card reader and trim 2–8B.A.S.I.S. dual validation reader and trim 2–11B.A.S.I.S. V proximity reader and trim 2–14Keypad EZ reader and trim 2–17Mortise components 2–19Mortise case 2–19Other mortise components 2–22Cylindrical components 2–24Cylindrical chassis diagram 2–24Cylindrical chassis 2–24Other cylindrical lock components 2–25EXIT HARDWARE TRIM FUNCTIONS AND PARTS 3–1Function descriptions 3–2Exit hardware trim compatibility 3–2Trim components 3–3B.A.S.I.S. magnetic stripe reader and trim 3–3B.A.S.I.S. smart card reader and trim 3–6B.A.S.I.S. dual validation reader and trim 3–9B.A.S.I.S. V proximity reader and trim 3–12Keypad EZ reader and trim 3–15Cylinders and related components 3–18Mortise cylinder and related components 3–18Rim cylinder and related components 3–18Levers 3–19Lift fingers 3–20iv<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

ContentsSHARED STANDARD AND EXIT HARDWARE TRIM PARTS 4–1B.A.S.I.S. reader conversion 4–2Converting to a magnetic stripe reader 4–2Converting to a smart card reader 4–2Converting to a dual validation reader 4–2Converting to an HID or a Motorola proximity reader 4–2Tasks to perform for converting 4–3Field replacement kits 4–4B.A.S.I.S. reader kits 4–4B.A.S.I.S. G control electronics kits 4–5B.A.S.I.S. V control electronics kits 4–6Battery kits 4–6Cable and harness kits for standard <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> 4–7Screw kits 4–7Shared internal screw kits 4–7Upper escutcheon screw kits for standard<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> 4–8Lower escutcheon screw kits for standard<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> 4–8Battery door screw kits for standard<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> 4–9Screw and spring kits for <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong>Exit Hardware Trim 4–9Internal part kits for <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> Exit Hardware Trim 4–10Sensor module kits for standard <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> 4–10Other B.A.S.I.S. system components 4–11<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>v

ContentsSERVICING STANDARD MORTISE TRIM PARTS 5–1Servicing the levers 5–2Removing the levers 5–2Reinstalling the levers 5–2Servicing the core 5–3Removing the core 5–3Reinstalling the core 5–3Servicing the mortise case faceplate 5–4Removing the mortise case faceplate 5–4Reinstalling the mortise case faceplate 5–4Servicing the Keypad EZ cylinder 5–5Removing the cylinder 5–5Reinstalling the cylinder 5–5Servicing the inside and outside escutcheons 5–6Removing the inside and outside escutcheons 5–6Reinstalling the inside and outside escutcheons 5–10Servicing the mounting plates 5–17Removing the mounting plates 5–17Reinstalling the mounting plates 5–17Servicing the B.A.S.I.S. cylinder 5–18Removing the cylinder 5–18Reinstalling the cylinder 5–18SERVICING STANDARD MORTISE CASE PARTS 6–1Servicing the mortise case 6–2Removing and opening the mortise case 6–2Closing and reinstalling the mortise case 6–3Changing the hand and bevel 6–4Changing hand and bevel quick reference 6–4Changing the hand only 6–6Changing the bevel only 6–6Changing the hand and bevel 6–6Tasks for changing the hand and bevel 6–7Turning over the hubs 6–7Turning over the cylinder clamp plate 6–8Turning over the auxiliary bolt 6–9Turning over the latchbolt 6–10Function conversion 6–11Removing key override 6–11Adding key override 6–12Adding a deadbolt 6–13Removing a deadbolt 6–14vi<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

ContentsServicing parts in the mortise case 6–15Servicing the motor module 6–15Removing the motor module 6–15Reinstalling the motor module 6–16Servicing the sensor module 6–17Removing the sensor module 6–17Reinstalling the sensor module 6–17Servicing the deadbolt, turn knob hub, and spacer 6–18Removing the deadbolt, turn knob hub, and spacer 6–18Reinstalling the deadbolt, turn knob hub, and spacer 6–19Servicing the cylinder clamp plate 6–20Removing the cylinder clamp plate 6–20Reinstalling the cylinder clamp plate 6–20SERVICING CYLINDRICAL PARTS 7–1Servicing the core and throw member 7–2Removing the core and throw member 7–2Reinstalling the core and throw member 7–2Servicing the levers 7–3Removing the levers 7–3Removing the keyed lever 7–3Removing the plain lever 7–3Reinstalling the levers 7–4Servicing the inside and outside escutcheons 7–5Removing the inside and outside escutcheons 7–5Reinstalling the inside and outside escutcheons 7–9Servicing the rose liners 7–16Removing the rose liners 7–16Reinstalling the rose liners 7–17Servicing the cylindrical chassis 7–19Removing the cylindrical chassis 7–19Reinstalling the cylindrical chassis 7–19SERVICING EXIT HARDWARE TRIM PARTS 8–1Servicing the battery cover 8–2Removing the battery cover 8–2Reinstalling the battery cover 8–3Servicing the battery pack 8–4Removing the battery pack 8–4Reinstalling the battery pack 8–5Servicing the battery bracket 8–6Removing the battery bracket 8–6Reinstalling the battery bracket 8–7<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>vii

ContentsServicing the exit hardware 8–8Removing the exit hardware 8–8Reinstalling the exit hardware 8–8Servicing the core 8–9Removing the core 8–9Reinstalling the core 8–9Servicing the cylinder 8–10Removing the mortise cylinder 8–10Reinstalling the mortise cylinder 8–10Removing the rim cylinder for Precision Hardware installations 8–11Reinstalling the rim cylinder for Precision Hardware installations 8–11Removing the rim cylinder for Von Duprin installations 8–12Reinstalling the rim cylinder for Von Duprin installations 8–12Servicing the <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> escutcheon 8–13Removing the escutcheon 8–13Reinstalling the escutcheon 8–14SERVICING STANDARD OUTSIDE ESCUTCHEON PARTS 9–1Servicing the escutcheon gasket 9–2Removing the escutcheon gasket 9–2Reinstalling the escutcheon gasket 9–2Servicing the harness clamp 9–3Removing the harness clamp 9–3Reinstalling the harness clamp 9–3Servicing the B.A.S.I.S. sensor harness 9–4Removing the sensor harness 9–4Reinstalling the sensor harness 9–4Servicing the primary harness 9–5Removing the primary harness 9–5Reinstalling the primary harness 9–6Servicing the control electronics boards 9–8Removing the B.A.S.I.S. magnetic stripe control electronics board 9–8Reinstalling the B.A.S.I.S. magnetic stripe control electronics board 9–9Removing the B.A.S.I.S. smart card control electronics board 9–10Reinstalling the B.A.S.I.S. smart card control electronics board 9–12Removing the B.A.S.I.S. dual validation control electronics board 9–14Reinstalling the B.A.S.I.S. dual validation control electronics board 9–15Removing the B.A.S.I.S. V proximity control electronics board 9–16Reinstalling the B.A.S.I.S. V proximity control electronics board 9–17Removing the Keypad EZ control electronics board 9–18Reinstalling the Keypad EZ control electronics board 9–20viii<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

ContentsServicing the reader assemblies 9–21Removing the B.A.S.I.S. magnetic stripe reader 9–21Reinstalling the B.A.S.I.S. magnetic stripe reader assembly 9–23Removing the B.A.S.I.S. smart card reader assembly 9–24Reinstalling the B.A.S.I.S. smart card reader assembly 9–26Removing the B.A.S.I.S. dual validation reader assembly 9–27Reinstalling the B.A.S.I.S. dual validation reader assembly 9–29Removing the B.A.S.I.S. V proximity reader assembly 9–30Reinstalling the B.A.S.I.S. V proximity reader assembly 9–31Removing the Keypad EZ reader assembly 9–32Reinstalling the Keypad EZ reader assembly 9–34SERVICING EXIT HARDWARE TRIM ESCUTCHEON PARTS 10–1Servicing the mounting standoffs 10–2Removing the mounting standoffs 10–2Reinstalling the mounting standoffs 10–2Servicing the escutcheon gasket 10–3Removing the escutcheon gasket 10–3Reinstalling the escutcheon gasket 10–3Servicing the lift finger 10–4Removing the lift finger 10–4Reinstalling the lift finger 10–5Servicing the mounting plate 10–6Removing the mounting plate 10–6Reinstalling the mounting plate 10–7Servicing the lever return springs 10–8Removing the lever return springs 10–8Reinstalling the lever return springs 10–8Servicing the primary harness 10–9Removing the primary harness 10–9Reinstalling the primary harness 10–9Servicing the control electronics boards 10–10Removing the B.A.S.I.S. magnetic stripe control electronics board 10–10Reinstalling the B.A.S.I.S. magnetic stripe control electronics board 10–10Removing the B.A.S.I.S. smart card control electronics board 10–11Reinstalling the B.A.S.I.S. smart card control electronics board 10–11Removing the B.A.S.I.S. dual validation control electronics board 10–11Reinstalling the B.A.S.I.S. dual validation control electronics board 10–11Removing the B.A.S.I.S. V proximity control electronics board 10–12Reinstalling the B.A.S.I.S. V proximity control electronics board 10–12Removing the Keypad EZ control electronics board 10–12Reinstalling the Keypad EZ control electronics board 10–12<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>ix

ContentsServicing the reader assemblies 10–13Removing the B.A.S.I.S. magnetic stripe reader assembly 10–13Reinstalling the B.A.S.I.S. magnetic stripe reader assembly 10–13Removing the B.A.S.I.S. smart card reader assembly 10–14Reinstalling the B.A.S.I.S. smart card reader assembly 10–14Removing the B.A.S.I.S. dual validation reader assembly 10–14Reinstalling the B.A.S.I.S. dual validation reader assembly 10–14Removing the B.A.S.I.S. V proximity reader assembly 10–15Reinstalling the B.A.S.I.S. V proximity reader assembly 10–15Removing the Keypad EZ reader assembly 10–15Reinstalling the Keypad EZ reader assembly 10–15Servicing the motor assembly 10–16Removing the motor assembly 10–16Reinstalling the motor assembly 10–17Servicing the locking plate 10–20Removing the locking plate 10–20Reinstalling the locking plate 10–21Servicing the yoke 10–22Removing the yoke 10–22Reinstalling the yoke 10–23Servicing the beam and beam roller 10–24Removing the beam and beam roller 10–24Reinstalling the beam and beam roller 10–25Servicing the lever assembly 10–26Removing the lever assembly 10–26Reinstalling the lever assembly 10–27Servicing the shear pin 10–28Removing the shear pin 10–28Reinstalling the shear pin 10–29Changing the handing 10–30MAINTENANCE 11–1Replacing the B.A.S.I.S. backup battery 11–2Removing the backup battery 11–2Reinstalling the backup battery 11–3Replacing or upgrading the battery pack 11–4Average expected battery life 11–4Removing the battery pack for a standard lock 11–4Reinstalling the battery pack for a standard lock 11–6Removing the battery pack for exit hardware trim 11–8Reinstalling the battery pack for exit hardware trim 11–9Adding key override sensing to standard B.A.S.I.S. Mortise <strong>Locks</strong> 11–10x<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

ContentsPerforming diagnostics using a PDA 11–13Diagnostics overview 11–13Viewing diagnostics information 11–14Changing a lock’s online mode 11–18Unlocking a door temporarily 11–19Resetting the use count 11–19Clearing the diagnostics code 11–20TROUBLESHOOTING 12–1Visual and audible response quick reference 12–2Shared responses 12–2Additional B.A.S.I.S. responses 12–2Additional Keypad EZ responses 12–2Enabling communications for B.A.S.I.S. <strong>Locks</strong> without a card or password 12–3Opening a standard B.A.S.I.S. Lock with dead batteries 12–6Responding to problems 12–7B.A.S.I.S. LOCK HISTORY EVENT TYPES A–1INSTALLATION INSTRUCTIONS B–1INDEX C–1<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>xi

Contentsxii<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

FIGURESGETTING STARTEDSystem overview diagram 1–3Mortise lock overview diagram 1–4Cylindrical lock overview diagram 1–4Mortise lock overview diagram 1–5Cylindrical lock overview diagram 1–6STANDARD FUNCTIONS AND PARTSUnderstanding mortise function drawings 2–2Understanding the cylindrical function drawing 2–4Other mortise components 2–22Cylindrical chassis diagram 2–24Other cylindrical lock components 2–25EXIT HARDWARE TRIM FUNCTIONS AND PARTSMortise cylinder and related components diagram 3–18Rim cylinder and related components diagram 3–18Levers diagram 3–19Lift fingers diagram 3–20SHARED STANDARD AND EXIT HARDWARE TRIM PARTSOther system components diagram 4–11<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>xiii

FiguresSERVICING STANDARD MORTISE TRIM PARTSRemoving and reinstalling the levers (B.A.S.I.S. Lock shown) 5–2Removing and reinstalling the core (B.A.S.I.S. Lock shown) 5–3Removing and reinstalling the mortise case faceplate(B.A.S.I.S. Lock shown) 5–4Removing and reinstalling the Keypad EZ cylinder 5–5Removing the battery door (four-cell door shown) 5–6Removing the battery pack (four-cell pack shown) 5–7Removing the inside escutcheon 5–7Disconnecting the motor connector and sensor connector(B.A.S.I.S. Lock shown) 5–8Removing the bushings and trim hole inserts (B.A.S.I.S. Lock shown) 5–9Locating the backup battery tab for B.A.S.I.S. <strong>Locks</strong> 5–10Reinstalling the trim hole inserts and bushings (B.A.S.I.S. Lock shown) 5–11Feeding the wire harness connectors through the harness hole(B.A.S.I.S. Lock shown) 5–12Making the motor connection and sensor connections 5–13Connecting the grounding cable for Keypad EZ <strong>Locks</strong> 5–14Securing the escutcheons 5–14Reinstalling the battery pack (four-cell pack shown) 5–15Reinstalling the battery door (four-cell door shown) 5–16Removing and reinstalling the mounting plates (B.A.S.I.S. Lock shown) 5–17Removing and reinstalling the B.A.S.I.S. cylinder 5–18SERVICING STANDARDMORTISE CASE PARTSRemoving and reinstalling the mortise case (B.A.S.I.S. Lock shown) 6–2Explanation of the hand and bevel of the door 6–4Motor module and locking bar in place 6–8Turning over the auxiliary bolt 6–9Latchbolt with anti-friction latch lever in position 6–10Removing and reinstalling the motor module 6–15Positioning the turn knob hub and deadbolt spring 6–19Removing and reinstalling the cylinder clamp plate 6–20SERVICING CYLINDRICAL PARTSRemoving the core and throw member 7–2Reinstalling the core and throw member 7–2Removing the keyed lever 7–3Removing the plain lever 7–3xiv<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

FiguresReinstalling the levers (B.A.S.I.S. Lock shown) 7–4Removing the battery door (four-cell door shown) 7–5Removing the battery pack (four-cell pack shown) 7–6Removing the escutcheon 7–6Disconnecting the motor connector (B.A.S.I.S. Lock shown) 7–7Removing the bushings, trim hole inserts, and hub washers(B.A.S.I.S. Lock shown) 7–8Locating the backup battery tab for B.A.S.I.S. <strong>Locks</strong> 7–9Reinstalling the bushings, trim hole inserts, and hub washers(B.A.S.I.S. Lock shown) 7–10Feeding the wire harness connectors through the harness hole(B.A.S.I.S. Lock shown) 7–11Connecting the motor connector 7–12Connecting the grounding cable for Keypad EZ <strong>Locks</strong> 7–13Securing the escutcheons 7–13Reinstalling the battery pack (four-cell pack shown) 7–14Reinstalling the battery door (four-cell door shown) 7–15Removing the inside rose liner (Keypad EZ Lock shown) 7–16Removing the outside rose liner 7–16Reinstalling the outside rose liner 7–17Reinstalling the inside rose liner (Keypad EZ shown) 7–18SERVICING EXIT HARDWARE TRIM PARTSRemoving and reinstalling the battery cover on the battery bracket 8–2Removing and reinstalling the battery pack(B.A.S.I.S.Exit Hardware Trim shown) 8–4Removing and reinstalling the battery bracket on the door(B.A.S.I.S. EX Series Exit Hardware Trim shown) 8–6Removing and reinstalling the com port in the battery bracketfor B.A.S.I.S. EX Series Exit Hardware Trim 8–6Removing and reinstalling the core (B.A.S.I.S. escutcheon shown) 8–9Mortise cylinder components 8–10Rim cylinder components 8–11Removing and reinstalling the rim cylinder forPrecision Hardware installations (B.A.S.I.S. escutcheon shown) 8–11Removing and reinstalling the rim cylinder for Von Duprin installations(B.A.S.I.S. escutcheon shown) 8–12Removing and reinstalling the escutcheon (B.A.S.I.S. escutcheon shown) 8–13<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>xv

FiguresSERVICING STANDARD OUTSIDE ESCUTCHEON PARTSRemoving and reinstalling the escutcheon gasket(B.A.S.I.S. escutcheon shown) 9–2Removing and reinstalling the harness clamp(B.A.S.I.S. smart card reader shown) 9–3Removing and reinstalling the B.A.S.I.S. sensor harness(B.A.S.I.S. smart card reader shown) 9–4Removing and reinstalling the primary harness from theelectronics board (B.A.S.I.S. smart card reader shown) 9–5Disconnecting the sounder and com port from theB.A.S.I.S. outside escutcheon 9–6Connecting the sounder and com port to the B.A.S.I.S.outside escutcheon 9–7Removing and reinstalling the B.A.S.I.S. magnetic stripecontrol electronics board 9–8Removing and reinstalling the B.A.S.I.S. smart cardcontrol electronics board 9–10Disconnecting the flex cable from the B.A.S.I.S. smart cardcontrol electronics board 9–11Connecting the flex cable to the B.A.S.I.S. smart cardcontrol electronics board 9–12Removing and reinstalling the B.A.S.I.S. dual validationcontrol electronics board 9–14Removing and reinstalling the B.A.S.I.S. V proximitycontrol electronics board 9–16Removing and reinstalling the Keypad EZ control electronics board 9–18Disconnecting the flex cable from the Keypad EZcontrol electronics board 9–19Connecting the flex cable to the Keypad EZ control electronics board 9–20Removing and reinstalling the screws for the B.A.S.I.S. magnetic stripereader assembly 9–21Removing the B.A.S.I.S. magnetic stripe reader assembly from theoutside escutcheon 9–22Positioning the B.A.S.I.S. magnetic stripe reader assembly 9–23Removing and reinstalling the screws for the B.A.S.I.S. smart cardreader assembly 9–24Removing the B.A.S.I.S. smart card reader assembly from theoutside escutcheon 9–25Positioning the B.A.S.I.S. smart card reader assembly 9–26Removing and reinstalling the screws for the B.A.S.I.S. dual validationreader assembly 9–27Removing the B.A.S.I.S. dual validation reader assembly from theoutside escutcheon 9–28xvi<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

FiguresPositioning the B.A.S.I.S. dual validation reader assembly 9–29Removing the B.A.S.I.S. V proximity reader assembly from theoutside escutcheon 9–30Positioning the B.A.S.I.S. V proximity reader assembly 9–31Removing and reinstalling the screws for the Keypad EZreader assembly 9–32Removing the Keypad EZ reader assembly from the outside escutcheon 9–33Positioning the Keypad EZ reader assembly 9–34SERVICING EXIT HARDWARE TRIM ESCUTCHEON PARTSRemoving and reinstalling the mounting standoffs 10–2Removing and reinstalling the escutcheon gasket 10–3Removing and reinstalling the lift finger (Precision Hardware rim configurationshown) 10–4Removing and reinstalling the mounting plate 10–6Removing and reinstalling the lever return springs escutcheon(B.A.S.I.S. shown) 10–8Removing the motor assembly (B.A.S.I.S.escutcheon shown) 10–16Rotating the motor assembly gear 10–17Routing the motor harness 10–18Reinstalling the motor assembly (B.A.S.I.S.escutcheon shown) 10–19Removing and reinstalling the locking plate(B.A.S.I.S. escutcheon shown) 10–20Reinstalling the locking plate 10–21Removing and reinstalling the yoke (B.A.S.I.S. escutcheon shown) 10–22Removing and reinstalling the c-clip (B.A.S.I.S.escutcheon shown) 10–24Removing and reinstalling the beam and beam(B.A.S.I.S.escutcheon shown) 10–25Removing and reinstalling the lever assembly (B.A.S.I.S.escutcheon shown) 10–27Removing and reinstalling the shear pin 10–28Changing the handing 10–31MAINTENANCERemoving the B.A.S.I.S. backup battery (escutcheon for standard mortise lockshown) 11–2Reinstalling the B.A.S.I.S. backup battery (escutcheon for standard mortise lockshown) 11–3Removing the battery door (four-cell door shown) 11–5Removing the battery pack (four-cell pack shown) 11–5Reinstalling the battery pack (eight-cell pack shown) 11–6Reinstalling the battery door (eight-cell door shown) 11–7<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>xvii

FiguresRemoving and reinstalling the battery cover on the battery bracket 11–8Removing and reinstalling the battery pack(B.A.S.I.S.Exit Hardware Trim shown) 11–8Connecting the sensor harness to the electronics board 11–10Removing the V Series sensor switch assembly 11–11B.A.S.I.S. Transport Diagnostics window andDiagnostics Codes window 11–13Connecting the PDA to a standard B.A.S.I.S. Lock 11–15Locating the communication port for B.A.S.I.S. EX SeriesExit Hardware Trim 11–15Starting B.A.S.I.S. Transport 11–16Disconnecting the programming cable from a standard B.A.S.I.S. Lock 11–17TROUBLESHOOTINGEnabling communications with the password override button(escutcheon for standard mortise lock shown) 12–4Connecting the programming cable to the lock 12–6xviii<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

1 GETTING STARTEDINTRODUCTIONThe <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>contains essential information to help you maintainyour B.A.S.I.S. <strong>Locks</strong> and B.A.S.I.S. EX Series ExitHardware Trim, as well as your Keypad EZ <strong>Locks</strong> andKeypad EZ Exit Hardware Trim. Throughout thismanual, the term standard B.A.S.I.S. <strong>Locks</strong> is used torefer to 35HG and 35HBV Mortise <strong>Locks</strong> as well as93KG–95KG and 93KBV–95KBV Cylindrical <strong>Locks</strong>.The term standard Keypad EZ <strong>Locks</strong> refers to 35HZMortise <strong>Locks</strong> and 93 KZ–95KZ Cylindrical <strong>Locks</strong>.The term <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> Exit HardwareTrim refers to EXG, EXBV and EXZ Exit HardwareTrim. B.A.S.I.S. EX Series Exit Hardware Trim andKeypad EZ Exit Hardware Trim are available for usewith the following types of exit devicesmanufactured by Precision Hardware (1000 Seriesand 2000 Series) and Von Duprin (98/99 Series):■ rim■ mortise■ surface vertical rod■ concealed vertical rod.B.A.S.I.S. EX Series Exit Hardware Trim andKeypad EZ Exit Hardware Trim also are available foruse with the Sargent (8800 Series) rim exit device.<strong>Stand</strong>ard Keypad EZ <strong>Locks</strong> and Keypad EZ ExitHardware Trim have keypad readers. <strong>Stand</strong>ardB.A.S.I.S. <strong>Locks</strong> and B.A.S.I.S. EX Series ExitHardware Trim are available with the following typesof readers:■ magnetic stripe card readers■ smart card readers■ dual validation (magnetic stripe card/keypad)readers■ Motorola and HID proximity card readers(standard B.A.S.I.S. V <strong>Locks</strong> and B.A.S.I.S. VEX Series Exit Hardware Trim only).<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 1–1

Getting StartedB.A.S.I.S. PRODUCT OVERVIEWSystemoverviewFigure 1.1 shows the components of the B.A.S.I.S. system. The tablebelow defines each of the components in the system.ComponentsMagnetic stripeelectronic lockSmart cardelectronic lock(not shown)Dual validationelectronic lock(not shown)Proximity cardelectronic lock(not shown)Exit hardware trim(not shown)Programming cableSerial cablePDA runningB.A.S.I.S. TransportsoftwareB.A.S.I.S. softwareMagnetic stripe cardencoderSmart card encoder(not shown)<strong>Access</strong> cardDefinitionA battery-powered, self-contained, programmable lock thatuses standard magnetic stripe cards and controls access to adoor.A battery-powered, self-contained, programmable lock thatuses smart cards and controls access to a door.A battery-powered, self-contained, programmable lock thatuses standard magnetic stripe cards and PINs, and controlsaccess to a door.A battery-powered, self-contained, programmable lock thatuses proximity cards and controls access to a door. Availableonly for standard B.A.S.I.S. V <strong>Locks</strong> and B.A.S.I.S. V EX SeriesExit Hardware Trim.B.A.S.I.S. escutcheon assembly (including B.A.S.I.S. reader andcontrol electronics) and external battery compartment usedwith mortise, rim, concealed vertical rod, and surface verticalrod exit hardware (panic) devices.A cable for connecting B.A.S.I.S. <strong>Locks</strong> and B.A.S.I.S. EX SeriesExit Hardware Trim to the serial cable.A cable for connecting the programming cable to the PDA.Device that lets you transfer reader configurations fromB.A.S.I.S. System Administration to the locks, transfer historyrecords from B.A.S.I.S. <strong>Locks</strong> and B.A.S.I.S. EX Series ExitHardware Trim to System Administration, and viewdiagnostics information for B.A.S.I.S. <strong>Locks</strong> and B.A.S.I.S.EX Series Exit Hardware Trim.Software that lets you define programming settings and theuser database for groups of locks, as well as individual locks.The software lets you view and print information about locksat any time.Device that reads, encodes, and erases information on amagnetic stripe card.Device that reads, encodes, and erases information on a smartcard.A card containing identification information. A card is given toa user and is similar to a key, letting the user gain access to acontrolled area.1–2 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

Getting StartedPersonal computer runningB.A.S.I.S. softwareMagnetic stripecard encoderPersonal digital assistant(PDA) running B.A.S.I.S.Transport software<strong>Access</strong> cardSerial cableProgramming cableMortisemagnetic stripeelectronic lockNot shown:– Cylindrical magnetic stripeelectronic lock– Mortise and cylindrical smartcard electronic locks– Mortise and cylindricalproximity electronic locks– Mortise and cylindrical dualvalidation electronic locks– Exit hardware trim– Smart card encoderFigure 1.1System overview diagram<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 1–3

Getting StartedMortise lockoverviewThe diagram below shows an exploded view of the components of theB.A.S.I.S. Mortise Lock, indicating their orientation to the door.Inside trimOutside trimFigure 1.2Mortise lock overview diagramCylindrical lockoverviewThe diagram below shows an exploded view of the components of theB.A.S.I.S. Cylindrical Lock, indicating their orientation to the door.Inside trimOutside trimFigure 1.3Cylindrical lock overview diagram1–4 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

1 2 34 5 67 8 9*0 #Getting StartedKEYPAD EZ PRODUCT OVERVIEWSystemoverviewMortise lockoverview<strong>Stand</strong>ard Keypad EZ <strong>Locks</strong> and Keypad EZ Exit Hardware Trim areprogrammed and accessed directly from the keypad. No additionalcomponents are necessary.The diagram below shows an exploded view of the components of theKeypad EZ Mortise Lock, indicating their orientation to the door.Inside trimOutside trimFigure 1.4Mortise lock overview diagram<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 1–5

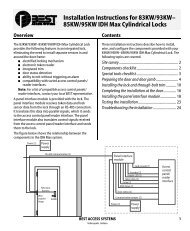

1 2 34 5 67 8 9*0 #Getting StartedCylindrical lockoverviewThe diagram below shows an exploded view of the components of theKeypad EZ Cylindrical Lock, indicating their orientation to the door.Inside trimFigure 1.5Outside trimCylindrical lock overview diagramCERTIFICATIONS AND STANDARDS<strong>Stand</strong>ard <strong>Electronic</strong><strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong>9KG, 9KBV and 9KZ <strong>Locks</strong>, as well as 35HG, 35HBV and 35 HZ <strong>Locks</strong>,comply with the following standards:■ FCC and Canadian EMC requirements■ UL10C Positive Pressure Fire Test of Door Assemblies■ ANSI 156.25 Electrified Locking Devices.Mortise locks ■ The strike, lock case, and faceplate dimensions fit the standard doorframe cutout as specified in ANSI A115.1.■ The 35H <strong>Locks</strong> meet or exceed ANSI A156.13, Series 1000,Grade 1 Operational, and Grade 2 Security standards.■ The 35H <strong>Locks</strong> are certified in the Builders Hardware ManufacturersAssociation Directory.■ The #3, #14 and #15 lever handles conform to CaliforniaAdministrative Code Title 19 and Title 24.Cylindrical locks ■ The 9K <strong>Locks</strong> comply with ANSI A156.2, Series 4000 Grade 1standards.■ The chassis conforms to ANSI A115.2.■ The #14 and #15 lever handles conform to California AdministrativeCode Title 19 and Title 24.■ The #14, #15 and #16 lever handles conform to the Illinois<strong>Access</strong>ibility <strong>Stand</strong>ard.1–6 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

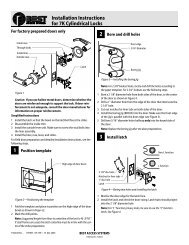

Getting StartedExit hardware trim ■ The <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> Exit Hardware Trim complies with FCCand Canadian EMC requirements.■The <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> Exit Hardware Trim meetsANSI/BHMA A156.3 for panic devices.DOCUMENTATION PACKAGEThe following documentation is available to help you with theinstallation, start-up, and maintenance of your <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong><strong>Locks</strong>.The installation and upgrade instructions also can be orderedseparately:Document TitleInstallation Instructions for <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong>Cylindrical <strong>Locks</strong> †Installation Instructions for <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong>Mortise <strong>Locks</strong> †Installation Instructions for <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong>EX Series Exit Hardware Trim †Installation Instructions for Keypad EZ Remote UnlockInstructions for Upgrading V Series <strong>Locks</strong> toB.A.S.I.S. <strong>Locks</strong>†. These installation instructions are included in this manual.See Installation Instructions (page B–1).Doc. No.T61835T61836T61828T80922T61837The templates and specifications required for lock and exit hardwaretrim installations also can be ordered separately:Document TitleG01 Template; Installation Specifications for 93KG,93KBV, and 93KZ Cylindrical <strong>Locks</strong> with Small StrikeG02 Template; Installation Specifications for 93KG,93KBV, and 93IZ Cylindrical <strong>Locks</strong> with Large StrikeG03 Template; Installation Specifications for 35HG,35HBV, and 93KZ Mortise <strong>Locks</strong>G04 Template; Hole Pattern Chart for 35HG, 35HBV,and 35 HZ Mortise <strong>Locks</strong>G05 Template; Installation Template for 93KG, 93KBV,and 93 KZ Cylindrical <strong>Locks</strong>G06 Template; Installation Template for 35HG, 35HBV,and 35 HZ Mortise <strong>Locks</strong>G07 Template; Installation Template for EXG, EXBV,and EXZ Exit Hardware Trim for Use with Von Duprin98/99 Series <strong>Locks</strong>Doc. No.T63305T63310T63306T63311T63303T63304T61824<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 1–7

Getting StartedDocument TitleG08 Template; Installation Template for EXG, EXBV,and EXZ Exit Hardware Trim for Use with PrecisionHardware 1000/2000 Series and Sargent 8800 Series<strong>Locks</strong>G09 Installation Specification for EXG, EXBV, and EXZExit Hardware Trim for Use with Von Duprin 98/99Series <strong>Locks</strong>G10 Installation Specification for EXG, EXBV, and EXZExit Hardware Trim for Use with Precision Hardware1000/2000 Series and Sargent 8800 Series <strong>Locks</strong>Doc. No.T61825T61826T61827The service manuals referred to in this manual also can be orderedseparately:Document TitleH Series <strong>Service</strong> <strong>Manual</strong>9K Series <strong>Service</strong> <strong>Manual</strong>8K Series <strong>Service</strong> <strong>Manual</strong>Doc. No.T61964T56082T56081The BEST documents for the B.A.S.I.S. software also can be orderedseparately:Document TitleB.A.S.I.S. G Getting Started GuideB.A.S.I.S. Transport User’s GuideB.A.S.I.S. Offline Setup GuideDoc. No.T63308T63307T80946The Keypad EZ programming documents also can be orderedseparately:Document TitleEZ Series Keypad EZ Lock Programming GuideKeypad EZ Quick ReferenceManaging Keypad EZ User PINsDoc. No.T80911T80912T809411–8 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

Getting StartedTECHNICAL SUPPORTSupportservicesTelephonetechnicalsupportWhen you have a problem with an <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> Lock or ExitHardware Trim, your first resource for help is the <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>. If you cannot find a satisfactory answer,contact your local BEST Representative.A factory-trained Certified Product Specialist (CPS) is available in yourarea whenever you need help. Before you call, however, please makesure that the product is in your immediate vicinity, and that you areprepared to give the following information:■■what happened and what you were doing when the problem arosewhat you have done so far to correct the problem.<strong>Best</strong> <strong>Access</strong> <strong>Systems</strong> Representatives provide telephone technicalsupport for all <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> products. You may locate theRepresentative nearest you by calling (317) 849-2250 Monday throughFriday, between 7:00 a.m. and 4:00 p.m. eastern standard time; or visitthe web page www.<strong>Best</strong><strong>Access</strong>.com.<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 1–9

Getting Started1–10 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

2 STANDARD FUNCTIONS ANDPARTSThe following pages contain function descriptionsfor all standard <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong>. Thischapter also includes exploded diagrams that showall field-serviceable mechanical parts, diagrams oftrim and other miscellaneous parts, as well as trimand reader conversion information.<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–1

<strong>Stand</strong>ard Functions and PartsFUNCTION DESCRIPTIONSThis section includes function descriptions grouped by the followingfunction types:■ mortise■ cylindrical.Mortise functionsThe following lists describe how the latchbolt, deadbolt, outside lever,and inside lever operate for each standard <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong>mortise function.Outside keyLatchboltOutsideDeadboltTurn knobAuxiliary dead latchInsideFigure 2.1Understanding mortise function drawingsEV–Latchbolt with key overrideLatchbolt operated by:■ outside key■ outside lever—unless lockedby internal motor drivemechanism■ inside leverOutside lever locked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINOutside lever unlocked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINInside lever is alwaysunlockedFV–Deadbolt with key overrideLatchbolt operated by:■ outside key■ outside lever—unless lockedby internal motor drivemechanism■ inside leverLatchbolt deadlocked byauxiliary latchDeadbolt operated by:■ outside key■ inside turn–knob■ outside lever when lever isunlocked by internal motordrive mechanism (retractsonly)■ inside lever (retracts only)Outside lever locked andunlocked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PIN (if deadboltis thrown, deadbolt overrideprivilege is required)Inside lever is alwaysunlocked2–2 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsLV–Deadbolt without key overrideLatchbolt operated by:■ outside lever—unless lockedby internal motor drivemechanism■ inside lever (deadlocked byauxiliary latch)Latchbolt deadlocked byauxiliary latchDeadbolt operated by:■ inside turn–knob■ outside lever when lever isunlocked by internal motordrive mechanism (retractsonly)■ inside lever (retracts only)Outside lever locked andunlocked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PIN (if deadboltis thrown, deadbolt overrideprivilege is required)Inside lever is alwaysunlockedNV–Latchbolt without key overrideLatchbolt operated by:■ outside lever—unless lockedby internal motor drivemechanism■ inside leverOutside lever locked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINOutside lever unlocked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINInside lever is alwaysunlocked<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–3

<strong>Stand</strong>ard Functions and PartsCylindrical functionThe following list describes how the latchbolt, outside lever, and insidelever operate for the standard <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> cylindricalfunction.LatchboltOutside keyOutsideInsideFigure 2.2Understanding the cylindrical function drawingDV–Latchbolt with key overrideLatchbolt operated by:■ outside key■ outside lever—unless lockedby internal motor drivemechanism■ inside leverOutside lever locked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINOutside lever unlocked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINInside lever is alwaysunlocked2–4 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–5TRIM COMPONENTSB.A.S.I.S. MAGNETIC STRIPE READER AND TRIM EXPLODED DIAGRAMFigure 2.3231456B.A.S.I.S. magnetic stripe reader and trim exploded diagram (mortise shown)89101112 13 147161718152022231921<strong>Stand</strong>ard Functions and Parts

<strong>Stand</strong>ard Functions and PartsB.A.S.I.S. magneticstripe reader andtrim parts listRefer to Figure 2.3 and the table below to find the part that you need.Item Part No. Qty. Part1 A35455 1 #15 outside lever assembly a (mortise locks) ornot shown B55168 1 #15 keyed lever handle b (cylindrical locks)2 See magnetic stripereader kits(page 4–4)1 Magnetic stripe reader3 B60321 1 Reader gasket4 D62506 1 35HG/35HBV outside escutcheon with key(EV and FV functions) ornot shown D62508 1 35HG/35HBV outside escutcheon for use withnon-BEST cores (EV and FV functions) ornot shown D62505 1 35HG/35HBV outside escutcheon without key(LV and NV functions) ornot shown D62507 1 9KG/9KBV outside escutcheon assembly(DV function)5 A60317 2 Lens covernot shown A60318 2 Lens retaining ring6 See screw kits 4 Reader assembly mounting screw(page 4–7)7 See primary harnesskit (page 4–7)1 Tape for mounting the sounder8 See magnetic stripecontrol electronicskit (page 4–5)9 See backup batterykit (page 4–6)10 See sensor harnesskit (page 4–7)11 See primary harnesskit (page 4–7)12 See screw kits(page 4–7)1 Magnetic stripe control electronics boardassembly (with backup battery)1 Backup battery1 Sensor harness1 Primary harness2 <strong>Electronic</strong>s board mounting screw13 B63294 1 Harness clamp14 A60800 1 Outside escutcheon gasket15 1818846 2 Bushing16 B61439 2 Trim hole insert17 B60726 1 Battery pack ornot shown B62101 1 Eight-cell battery pack c18 C80894 1 35HG/35HBV inside escutcheon with turnknob d (FV and LV functions) ornot shown D62104 1 35HG/35HBV inside escutcheon without turnknob for (EV and NV functions) ornot shown D62102 1 9KG/9KBV inside escutcheon(DV function)2–6 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsItem Part No. Qty. Part19 See screw kits 1 Lower escutcheon screw(page 4–7)20 See screw kits 1 Upper escutcheon screw(page 4–7)21 A35454 1 #15 inside lever assembly a (mortise locks) ornot shown D55169 1 #15 plain lever handle b (cylindrical locks)22 B62128 1 Battery doornot shown B62101 1 Eight-cell battery door c23 See screw kits 1 Battery door screw (TORX with post head) or(page 4–7)not shown See screw kits 1 Battery door screw (McGard head) or(page 4–7)not shown A34087 1 Battery door screw (Phillips head)a. See the H Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.b. See the 9K Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.c. If you need to upgrade to the eight-cell battery pack and door, see the Eight-Cell BatteryUpgrade kit on page 4–6.d. This item includes the battery door.<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–7

<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–8B.A.S.I.S. SMART CARD READER AND TRIM EXPLODED DIAGRAM129101186453213 1471Figure 2.4 B.A.S.I.S. smart card reader and trim exploded diagram (mortise shown)161718152022231921<strong>Stand</strong>ard Functions and Parts

<strong>Stand</strong>ard Functions and PartsB.A.S.I.S. smart cardreader and trimparts listRefer to Figure 2.4 and the table below to find the part that you need.Item Part No. Qty. Part1 A35455 1 #15 outside lever assembly a (mortise locks) ornot shown B55168 1 #15 keyed lever handle b (cylindrical locks)2 See smart card 1 Smart card readerreader kit (page 4–4)3 B60321 1 Reader gasket4 D62506 1 35HG/35HBV outside escutcheon with key(EV and FV functions) ornot shown D62508 1 35HG/35HBV outside escutcheon for use withnon-BEST cores (EV and FV functions) ornot shown D62505 1 35HG/35HBV outside escutcheon without key(LV and NV functions) ornot shown D62507 1 9KG/9KBV outside escutcheon assembly(DV function)5 A60317 2 Lens covernot shown A60318 2 Lens retaining ring6 See screw kits 4 Reader assembly mounting screw(page 4–7)7 See primary harnesskit (page 4–7)1 Tape for mounting the sounder8 See smart cardcontrol electronicskit (page 4–5)9 See backup batterykit (page 4–6)10 See sensor harnesskit (page 4–7)11 See primary harnesskit (page 4–7)12 See screw kits(page 4–7)1 Smart card control electronics board assembly(with backup battery)1 Backup battery1 Sensor harness1 Primary harness2 <strong>Electronic</strong>s board mounting screw13 B63294 1 Harness clamp14 A60800 1 Outside escutcheon gasket15 1818846 2 Bushing16 B61439 2 Trim hole insert17 B60726 1 Battery pack ornot shown B62101 1 Eight-cell battery pack c18 C80894 1 35HG/35HBV inside escutcheon with turnknob d (FV and LV functions) ornot shown D62104 1 35HG/35HBV inside escutcheon without turnknob for (EV and NV functions) ornot shown D62102 1 9KG/9KBV inside escutcheon(DV function)<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–9

<strong>Stand</strong>ard Functions and PartsItem Part No. Qty. Part19 See screw kits 1 Lower escutcheon screw(page 4–7)20 See screw kits 1 Upper escutcheon screw(page 4–7)21 A35454 1 #15 inside lever assembly a (mortise locks) ornot shown D55169 1 #15 plain lever handle b (cylindrical locks)22 B62128 1 Battery doornot shown B62101 1 Eight-cell battery door c23 See screw kits 1 Battery door screw (TORX with post head) or(page 4–7)not shown See screw kits 1 Battery door screw (McGard head) or(page 4–7)not shown A34087 1 Battery door screw (Phillips head)a. See the H Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.b. See the 9K Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.c. If you need to upgrade to the eight-cell battery pack and door, see the Eight-Cell BatteryUpgrade kit on page 4–6.d. This item includes the battery door.2–10 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–11B.A.S.I.S. DUAL VALIDATION READER AND TRIM EXPLODED DIAGRAM161411 12 1391086453271Figure 2.5 B.A.S.I.S. dual validation reader and trim exploded diagram (mortise shown)1718152022231921<strong>Stand</strong>ard Functions and Parts

<strong>Stand</strong>ard Functions and PartsB.A.S.I.S. dualvalidation readerand trim parts listRefer to Figure 2.5 and the table below to find the part that you need.Item Part No. Qty. Part1 A35455 1 #15 outside lever assembly a (mortise locks) ornot shown B55168 1 #15 keyed lever handle b (cylindrical locks)2 See dual validationreader kits(page 4–4)1 Dual validation reader3 B60321 1 Reader gasket4 D62506 1 35HG/35HBV outside escutcheon with key(EV and FV functions) ornot shown D62508 1 35HG/35HBV outside escutcheon for use withnon-BEST cores (EV and FV functions) ornot shown D62505 1 35HG/35HBV outside escutcheon without key(LV and NV functions) ornot shown D62507 1 9KG/9KBV outside escutcheon assembly(DV function)5 A60317 2 Lens covernot shown A60318 2 Lens retaining ring6 See screw kits 4 Reader assembly mounting screw(page 4–7)7 See primaryharness kit(page 4–7)1 Tape for mounting the sounder8 See dual validationcontrol electronicskit (page 4–5)9 See backup batterykit (page 4–6)10 See sensor harnesskit (page 4–7)11 See primaryharness kit(page 4–7)1 Dual validation control electronics boardassembly (with backup battery)1 Backup battery1 Sensor harness1 Primary harness12 See screw kits 2 <strong>Electronic</strong>s board mounting screw(page 4–7)13 B63294 1 Harness clamp14 A60800 1 Outside escutcheon gasket15 1818846 2 Bushing16 B61439 2 Trim hole insert17 B60726 1 Battery pack ornot shown B62101 1 Eight-cell battery pack c18 C80894 1 35HG/35HBV inside escutcheon with turnknob d (FV and LV functions) or2–12 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsItem Part No. Qty. Partnot shown D62104 1 35HG/35HBV inside escutcheon without turnknob for (EV and NV functions) ornot shown D62102 1 9KG/9KBV inside escutcheon(DV function) or19 See screw kits 1 Lower escutcheon screw(page 4–7)20 See screw kits 1 Upper escutcheon screw(page 4–7)21 A35454 1 #15 inside lever assembly a (mortise locks) ornot shown D55169 1 #15 plain lever handle b (cylindrical locks)22 B62128 1 Battery doornot shown B62101 1 Eight-cell battery door c23 See screw kits 1 Battery door screw (TORX with post head) or(page 4–7)not shown See screw kits 1 Battery door screw (McGard head) or(page 4–7)not shown A34087 1 Battery door screw (Phillips head)a. See the H Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.b. See the 9K Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.c. If you need to upgrade to the eight-cell battery pack and door, see the Eight-Cell BatteryUpgrade kit on page 4–6.d. This item includes the battery door.<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–13

<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–14B.A.S.I.S. V PROXIMITY READER AND TRIM EXPLODED DIAGRAM129101185643213 1471Figure 2.6 B.A.S.I.S. V proximity reader and trim exploded diagram161718152022231921<strong>Stand</strong>ard Functions and Parts

<strong>Stand</strong>ard Functions and PartsB.A.S.I.S. Vproximity readerand trim parts listRefer to Figure 2.5 and the table below to find the part that you need.Item Part No. Qty. Part1 A35455 1 #15 outside lever assembly a (mortise locks) ornot shown B55168 1 #15 keyed lever handle b (cylindrical locks)2 See HID proximity 1 HID proximity reader orreader kit (page 4–4)not shown See Motorolaproximity reader kit(page 4–4)1 Motorola proximity reader3 B60321 1 Reader gasket4 D62506 1 35HBV outside escutcheon with key(EV and FV functions) ornot shown D62508 1 35HBV outside escutcheon for use withnon-BEST cores (EV and FV functions) ornot shown D62505 1 35HBV outside escutcheon without key(LV and NV functions) ornot shown D62507 1 9KBV outside escutcheon assembly(DV function)5 A60317 2 Lens covernot shown A60318 2 Lens retaining ring6 See screw kits 4 Reader assembly mounting screw(page 4–7)7 See primary harnesskit (page 4–7)1 Tape for mounting the sounder8 See HID proximitycontrol electronicskit (page 4–5)not shown See Motorolaproximity controlelectronics kit(page 4–5)1 HID proximity control electronics boardassembly (with backup battery) or1 Motorola proximity control electronics boardassembly (with backup battery)not shown 1837827 1 Jumper (ABA card format only)9 See backup battery 1 Backup batterykit (page 4–6)10 See sensor harness 1 Sensor harnesskit (page 4–7)11 See primary harness 1 Primary harnesskit (page 4–7)12 See screw kits 2 <strong>Electronic</strong>s board mounting screw(page 4–7)13 B63294 1 Harness clamp14 A60800 1 Outside escutcheon gasket15 1818846 2 Bushing16 B61439 2 Trim hole insert17 B60726 1 Battery pack or<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–15

<strong>Stand</strong>ard Functions and PartsItem Part No. Qty. Partnot shown B62101 1 Eight-cell battery pack c18 C80894 1 35HBV inside escutcheon with turn knob d(FV and LV functions) ornot shown D62104 1 35HBV inside escutcheon without turn knob for(EV and NV functions) ornot shown D62102 1 9KBV inside escutcheon(DV function)19 See screw kits 1 Lower escutcheon screw(page 4–7)20 See screw kits 1 Upper escutcheon screw(page 4–7)21 A35454 1 #15 inside lever assembly a (mortise locks) ornot shown D55169 1 #15 plain lever handle b (cylindrical locks)22 B62128 1 Battery doornot shown B62101 1 Eight-cell battery door c23 See screw kits 1 Battery door screw (TORX with post head) or(page 4–7)not shown See screw kits 1 Battery door screw (McGard head) or(page 4–7)not shown A34087 1 Battery door screw (Phillips head)a. See the H Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.b. See the 9K Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.c. If you need to upgrade to the eight-cell battery pack and door, see the Eight-Cell BatteryUpgrade kit on page 4–6.d. This item includes the battery door.2–16 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsKEYPAD EZ READER AND TRIM EXPLODED DIAGRAM22118 9 10745 632211 2 34 5 67 8 9*0 #1Figure 2.7 Keypad EZ reader and trim exploded diagram (mortise shown)1417191220131815 16<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–17

<strong>Stand</strong>ard Functions and PartsKeypad EZ readerand trim parts listRefer to Figure 2.3 and the table below to find the part that you need.Item Part No. Qty. Part1 A35455 1 #15 outside lever assembly a (mortise locks) ornot shown B55168 1 #15 keyed lever handle b (cylindrical locks)2 B60325 1 Keypad reader3 B60321 1 Reader gasket4 D62571 1 35HZ outside escutcheon with key(EV and FV functions) ornot shown D62565 1 35HZ outside escutcheon without key(LV and NV functions) ornot shown D62567 1 9KZ outside escutcheon assembly(DV function)5 A60317 2 Lens covernot shown A60318 2 Lens retaining ring6 See screw kits 4 Reader assembly mounting screw(page 4–7)not shown A60324 1 Foam pad7 B80963 1 Keypad control electronics board assembly8 C61443 1 Primary harness9 A61429 2 <strong>Electronic</strong>s board mounting screw10 B63294 1 Harness clamp11 A60800 1 Outside escutcheon gasket12 1818888 2 Bushing13 B61439 2 Trim hole insert14 B60726 1 Battery pack ornot shown B62101 1 Eight-cell battery pack c15 A61501 1 Grounding cable screw16 1886209 1 Grounding cable17 C80894 1 35HZ inside escutcheon with turn knob d(FV and LV functions) ornot shown D62104 1 35HZ inside escutcheon without turn knob for(EV and NV functions) ornot shown D62102 1 9KZ inside escutcheon (DV function)18 See screw kits 1 Lower escutcheon screw(page 4–7)19 See screw kits 1 Upper escutcheon screw(page 4–7)20 A35454 1 #15 inside lever assembly a (mortise locks) ornot shown D55169 1 #15 plain lever handle b (cylindrical locks)21 B62128 1 Battery doornot shown B62101 1 Eight-cell battery door c2–18 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsItem Part No. Qty. Part22 See screw kits(page 4–7)1 Battery door screw (TORX with post head) ornot shownSee screw kits(page 4–7)1 Battery door screw (McGard head) ornot shown A34087 1 Battery door screw (Phillips head)a. See the H Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.b. See the 9K Series <strong>Service</strong> <strong>Manual</strong> for other lever styles.c. If you need to upgrade to the eight-cell battery pack and door, see the Eight-Cell BatteryUpgrade kit on page 4–6.d. This item includes the battery door.MORTISE COMPONENTSMortise caseassembliesType of lockLock function B.A.S.I.S. G B.A.S.I.S. V Keypad EZNV C60798 C60798 C64502LV (with deadbolt) C60796 C60796 C64501EV (with key override)C64502 aC60797 b C60797 C64502FV (with deadbolt & key override)C64501 aC60795 b C60795 C64501a. Without key override sensing. Key override sensing is optional forB.A.S.I.S. G <strong>Locks</strong> and standard for B.A.S.I.S. V <strong>Locks</strong>. Keypad EZ <strong>Locks</strong>do not have key override sensing.b. With key override sensing.<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–19

<strong>Stand</strong>ard Functions and PartsMortise caseexploded diagram122532423282922212627204517161967161815891014131112Figure 2.8FV function mortise case exploded diagram (LH case shown)2–20 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsMortise case partslistRefer to Figure 2.8 and the table below to find the part you need.Item Part No. Qty. Description1 A34087 5 Case cover mounting screws2 B60481 1 Case cover3 1833885 1 Sensor module with deadbolt and key override kit(B.A.S.I.S. V FV function, B.A.S.I.S. G FV function withoptional key override sensing)not shown 1838747 1 Sensor module with deadbolt kit (LV function, B.A.S.I.S. GFV function without optional key override sensing,Keypad EZ FV function)not shown 1833927 1 Sensor module with key override kit (B.A.S.I.S. V EVfunction, B.A.S.I.S. G EV function with optional key overridesensing)not shown D63295 1 Key sensor switch housing (NV function, B.A.S.I.S. G EVfunction without optional key override sensing, Keypad EZEV function)4 B35035 1 Deadbolt (FV and LV functions)5 C34011 1 Turn knob hub (FV and LV functions)6 B34032 1 Turn knob hub spacer (FV and LV functions)7 A35257 1 Cylinder clamp plate (EV and FV functions)8 B61500 1 Case assembly (all functions except B.A.S.I.S. V NV function)not shown B61302 1 Case assembly (B.A.S.I.S. V NV function)9 C34053 1 Armored front10 A34045 1 Case mounting screw11 B34092 1 Auxiliary bolt12 A62041 1 Mortise case spacer13 B60493 1 Motor module14 A34236 1 Wire strain relief15 A34065 1 Lower auxiliary spring16 B34020 2 Auxiliary return levers17 A34066 1 Upper auxiliary spring18 A34048 1 Stop pin19 A35004 1 Latch lever20 B35019 1 Latchbolt21 B60467 1 Locking bar22 B34043 1 Inside hub23 B34003 1 Outside hub24 B35490 1 Long hub lever25 A34081 1 Hub lever spring26 A35002 1 Deadlocking lever27 A34315 1 Retaining ring28 A61210 1 Auxiliary bolt spring29 A34018 1 Deadlocking spring<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–21

<strong>Stand</strong>ard Functions and PartsOther mortisecomponentsdiagram124531011612127 899Figure 2.9Other mortise components2–22 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsOther mortisecomponentsparts listRefer to Figure 2.9 and the table below to find the part you need.Item Part no. Qty. Description1not shownnot shownA18991A18992A28993222Mounting plate screw for 1 3/4″ – 2″ thick doorsMounting plate screw for 2 1/4″ – 2 1/2″ thick doorsMounting plate screw for 2 3/4″ – 3″ thick doors2 B35030 1 Inside mounting plate3 B35247 1 Outside mounting plate4not shownnot shownB61231B61232B61233111Concealed cylinder for 1 3/4″ – 2″ thick doors(B.A.S.I.S. EV or FV function)Concealed cylinder for 2 1/4″ – 2 1/2″ thick doors(B.A.S.I.S. EV or FV function)Concealed cylinder for 2 3/4″ – 3″ thick doors(B.A.S.I.S. EV or FV functions)5 B35173 1 Mortise cylinder assembly (Keypad EZ EV or FV function)6 B34380 1 Strike box7 C29517 1 Strike plate for LH/RHRB8 C29516 1 Strike plate for RH/LHRB9not shownA18724A3445022<strong>Stand</strong>ard strike screwSecurity strike screw10 B34515 1 Faceplate for EV and NV functions11 D34095 1 Faceplate for FV and LV functions (deadbolt)12not shownA18722A3445422<strong>Stand</strong>ard faceplate screwSecurity faceplate screw<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–23

<strong>Stand</strong>ard Functions and PartsCYLINDRICAL COMPONENTSCYLINDRICAL CHASSIS DIAGRAMInsideOutsideFigure 2.10Cylindrical chassis diagramCylindrical chassisparts listRefer to Figure 2.10 and the table below to find the part you need.Chassis typePart no.<strong>Stand</strong>ard chassisD60464Chassis for non-BEST cores D60332Free motion chassis D560252–24 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Stand</strong>ard Functions and PartsOther cylindricallock componentsdiagram345129678Figure 2.11Other cylindrical lock componentsOther cylindricallock componentsparts listRefer to Figure 2.11 and the table below to find the part you need.Item Part no. Qty. Description1 B25640 1 <strong>Stand</strong>ard strike box2 B25639 1 <strong>Stand</strong>ard strike plate3 A25359 2 Screw for standard strikenot shown B34380 1 ANSI strike boxnot shown B25641 1 ANSI strike platenot shown A18724 2 Screw for ANSI strike4not shownnot shownC54680C51682C54684111Latch for 2 3/4″ backsetLatch for 3 3/4″ backsetLatch for 5″ backset5 A25359 2 Latch screw6 B55603 1 Small outside rose liner7 C55556 1 Small inside rose liner8 B55557 2 Through-bolt screw9 A80775 2 Hub washer<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 2–25

<strong>Stand</strong>ard Functions and Parts2–26 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

3 EXIT HARDWARE TRIMFUNCTIONS AND PARTSThe following pages contain function descriptionsfor <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> EX Series Exit HardwareTrim. This chapter also includes exploded diagramsshowing all field-serviceable exit hardware trimparts.<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–1

Exit Hardware Trim Functions and PartsFUNCTION DESCRIPTIONSThe following lists describe how the latchbolt, outside lever, and insidetrim operate for each EX Series Exit Hardware Trim function.EV–With key overrideLatchbolt operated by:■ outside key■ outside lever—unless lockedby internal motor drivemechanism■ inside leverOutside lever locked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINOutside lever unlocked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINInside trim is alwaysunlockedNV–Without key overrideLatchbolt operated by:■ outside lever—unless lockedby internal motor drivemechanism■ inside leverOutside lever locked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINOutside lever unlocked by:■ internal motor drivemechanism operated by time–activated electronic signal orby valid card/PINInside trim is alwaysunlockedEXIT HARDWARE TRIM COMPATIBILITYThe following table indicates the compatibility of <strong>Electronic</strong><strong>Stand</strong>-<strong>Alone</strong> Lock Exit Hardware Trim with Precision Hardware,Sargent, and Von Duprin exit hardware devices.Exit hardware manufacturer and product seriesExit hardware typePrecisionHardware1000 SeriesPrecisionHardware2000 SeriesSargent8800 SeriesVon Duprin98/99 SeriesRim ■ †■ ■ † ■Mortise ■ ■ ■ †Surface vertical rod ■ † ■ ■Concealed vertical rod ■ † ■ ■†. Not available with key override.3–2 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–3TRIM COMPONENTSB.A.S.I.S. MAGNETIC STRIPE READER AND TRIM EXPLODED DIAGRAM1Figure 3.135627 11414168 91018171223B.A.S.I.S. magnetic stripe reader and trim exploded diagram (Precision Hardware–rim type shown)132115222419202627252829313230Exit Hardware Trim Functions and Parts

Exit Hardware Trim Functions and PartsB.A.S.I.S. magneticstripe reader andtrim parts listRefer to Figure 3.1 and the table below to find the part that you need.Item Part No. Qty. Part1 See magnetic stripe 1 Magnetic stripe readerreader kits (page 4–4)2 See levers (page 3–19) 1 Lever assembly (#15 lever shown)3 B60321 1 Reader gasket4 See shear pin kit 1 Shear pin(page 4–10)5 C64565 1 Escutcheon with key (EV function) ornot shown C64550 1 Escutcheon without key (NV function)6 A60317 2 Lens covernot shown A60318 2 Lens retaining ring7 See screw kits 4 Reader assembly mounting screw(page 4–7)8 B64557 1 Beam9 A64571 1 Beam roller10 A64609 1 C-clip11 A64610 2 Lever return spring12 C64552 1 Yoke13 See screw kits 4 Shoulder screw(page 4–7)14 See magnetic stripecontrol electronics kit(page 4–5)1 Magnetic stripe control electronics boardassembly (with backup battery)15 B64562 1 Locking plate16 See backup battery kit 1 Backup battery(page 4–6)17 See primary harness 1 Tape for mounting the sounder(page 4–10)18 See screw kits(page 4–7)2 <strong>Electronic</strong>s board mounting screw19 See motor assemblykit (page 4–10)20 See lift fingers(page 3–21)21 A64607 1 Washer22 See screw kits 1 Lift finger screw(page 4–7)23 See primary harness 1 Primary harnesskit (page 4–10)not shown 1879118 1 Cable tie1 Motor assembly (with socket head screw andspacer)1 Lift finger (Precision Hardware rim and rodshown)3–4 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

Exit Hardware Trim Functions and PartsItem Part No. Qty. Part24 D64551 1 Mounting plate for Precision Hardware andSargent installations ornot shown D64634 1 Mounting plate for Von Duprin installations25 See screw kits 5 Mounting plate screw(page 4–7)26 See screw kits 6 Mounting standoff(page 4–7)27 C64564 1 Escutcheon gasket28 C64560 1 Battery bracket29 B60726 1 Battery pack30 See screw kits 2 Battery bracket screw(page 4–7)31 C64559 1 Battery cover32 See screw kits(page 4–7)1 Battery cover screw (TORX with post head)<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–5

3–6 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>B.A.S.I.S. SMART CARD READER AND TRIM EXPLODED DIAGRAM272624231618147 115 6311721 222520151913128 9 1042Figure 3.2 B.A.S.I.S. smart card reader and trim exploded diagram (Precision Hardware–rim type shown)2829313230Exit Hardware Trim Functions and Parts

Exit Hardware Trim Functions and PartsB.A.S.I.S. smart cardreader and trimparts listRefer to Figure 3.2 and the table below to find the part that you need.Item Part No. Qty. Part1 See smart card reader 1 Smart card readerkit (page 4–4)2 See levers (page 3–19) 1 Lever assembly (#15 lever shown)3 B60321 1 Reader gasket4 See shear pin kit 1 Shear pin(page 4–10)5 C64565 1 Escutcheon with key (EV function) ornot shown C64550 1 Escutcheon without key (NV function)6 A60317 2 Lens covernot shown A60318 2 Lens retaining ring7 See screw kits 4 Reader assembly mounting screw(page 4–7)8 B64557 1 Beam9 A64571 1 Beam roller10 A64609 1 C-clip11 A64610 2 Lever return spring12 C64552 1 Yoke13 See screw kits(page 4–7)4 Shoulder screw14 See smart card controlelectronics kit(page 4–5)1 Smart card control electronics board assembly(with backup battery)15 B64562 1 Locking plate16 See backup battery kit 1 Backup battery(page 4–6)17 See primary harness 1 Tape for mounting the sounderkit (page 4–10)18 See screw kits(page 4–7)2 <strong>Electronic</strong>s board mounting screw19 See motor assemblykit (page 4–10)20 See lift fingers(page 3–21)21 A64607 1 Washer22 See screw kits 1 Lift finger screw(page 4–7)23 See primary harness 1 Primary harnesskit (page 4–10)not shown 1879118 1 Cable tie1 Motor assembly (with socket head screw andspacer)1 Lift finger (Precision Hardware rim and rodshown)<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–7

Exit Hardware Trim Functions and PartsItem Part No. Qty. Part24 D64551 1 Mounting plate for Precision Hardware andSargent installations ornot shown D64634 1 Mounting plate for Von Duprin installations25 See screw kits 5 Mounting plate screw(page 4–7)26 See screw kits 6 Mounting standoff(page 4–7)27 C64564 1 Escutcheon gasket28 C64560 1 Battery bracket29 B60726 1 Battery pack30 See screw kits 2 Battery bracket screw(page 4–7)31 C64559 1 Battery cover32 See screw kits(page 4–7)1 Battery cover screw (TORX with post head)3–8 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–9B.A.S.I.S. DUAL VALIDATION READER AND TRIM EXPLODED DIAGRAM28272624231816147 115 6311721 222520151913128 9 1024Figure 3.3 B.A.S.I.S. dual validation reader and trim exploded diagram (Precision Hardware–rim type shown)29313230Exit Hardware Trim Functions and Parts

Exit Hardware Trim Functions and PartsB.A.S.I.S. dualvalidation readerand trim parts listRefer to Figure 3.3 and the table below to find the part that you need.Item Part No. Qty. Part1 See dual validationreader kits(page 4–4)1 Dual validation reader2 See levers (page 3–19) 1 Lever assembly (#15 lever shown)3 B60321 1 Reader gasket4 See shear pin kit 1 Shear pin(page 4–10)5 C64565 1 Escutcheon with key (EV function) ornot shown C64550 1 Escutcheon without key (NV function)6 A60317 2 Lens covernot shown A60318 2 Lens retaining ring7 See screw kits 4 Reader assembly mounting screw(page 4–7)8 B64557 1 Beam9 A64571 1 Beam roller10 A64609 1 C-clip11 A64610 2 Lever return spring12 C64552 1 Yoke13 See screw kits(page 4–7)4 Shoulder screw14 See dual validationcontrol electronics kit(page 4–5)1 Dual validation control electronics boardassembly (with backup battery)15 B64562 1 Locking plate16 See backup battery kit 1 Backup battery(page 4–6)17 See primary harness 1 Tape for mounting the sounderkit (page 4–10)18 See screw kits(page 4–7)2 <strong>Electronic</strong>s board mounting screw19 See motor assemblykit (page 4–10)20 See lift fingers(page 3–21)21 A64607 1 Washer22 See screw kits 1 Lift finger screw(page 4–7)23 See primary harness 1 Primary harnesskit (page 4–10)not shown 1879118 1 Cable tie1 Motor assembly (with socket head screw andspacer)1 Lift finger (Precision Hardware rim and rodshown)3–10 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

Exit Hardware Trim Functions and PartsItem Part No. Qty. Part24 D64551 1 Mounting plate for Precision Hardware andSargent installations ornot shown D64634 1 Mounting plate for Von Duprin installations25 See screw kits 5 Mounting plate screw(page 4–7)26 See screw kits 6 Mounting standoff(page 4–7)27 C64564 1 Escutcheon gasket28 C64560 1 Battery bracket29 B60726 1 Battery pack30 See screw kits 2 Battery bracket screw(page 4–7)31 C64559 1 Battery cover32 See screw kits(page 4–7)1 Battery cover screw (TORX with post head)<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–11

3–12 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>B.A.S.I.S. V PROXIMITY READER AND TRIM EXPLODED DIAGRAM28272624231816145 6311721 227 11 13252015 19128 9 1042Figure 3.4 B.A.S.I.S. V proximity reader and trim exploded diagram (Precision Hardware–rim type shown)29313230Exit Hardware Trim Functions and Parts

Exit Hardware Trim Functions and PartsB.A.S.I.S. Vproximity readerand trim parts listRefer to Figure 3.4 and the table below to find the part that you need.Item Part No. Qty. Part1 See HID proximityreader kit (page 4–4)not shown See Motorolaproximity reader kit(page 4–4)1 HID proximity reader or1 Motorola proximity reader2 See levers (page 3–19) 1 Lever assembly (#15 lever shown)3 B60321 1 Reader gasket4 See shear pin kit 1 Shear pin(page 4–10)5 C64565 1 Escutcheon with key (EV function) ornot shown C64550 1 Escutcheon without key (NV function)6 A60317 2 Lens covernot shown A60318 2 Lens retaining ring7 See screw kits 4 Reader assembly mounting screw(page 4–7)8 B64557 1 Beam9 A64571 1 Beam roller10 A64609 1 C-clip11 A64610 2 Lever return spring12 C64552 1 Yoke13 See screw kits(page 4–7)4 Shoulder screw14 See HID proximitycontrol electronics kit(page 4–5)not shown See Motorolaproximity controlelectronics kit(page 4–5)1 HID proximity control electronics boardassembly (with backup battery) or1 Motorola proximity control electronics boardassembly (with backup battery)not shown 1837827 1 Jumper (ABA card format only)15 B64562 1 Locking plate16 See backup battery kit 1 Backup battery(page 4–6)17 See primary harness 1 Tape for mounting the sounderkit (page 4–10)18 See screw kits(page 4–7)2 <strong>Electronic</strong>s board mounting screw19 See motor assemblykit (page 4–10)20 See lift fingers(page 3–21)1 Motor assembly (with socket head screw andspacer)1 Lift finger (Precision Hardware rim and rodshown)<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–13

Exit Hardware Trim Functions and PartsItem Part No. Qty. Part21 A64607 1 Washer22 See screw kits 1 Lift finger screw(page 4–7)23 See primary harness 1 Primary harnesskit (page 4–10)not shown 1879118 1 Cable tie24 D64551 1 Mounting plate for Precision Hardware andSargent installations ornot shown D64634 1 Mounting plate for Von Duprin installations25 See screw kits 5 Mounting plate screw(page 4–7)26 See screw kits 6 Mounting standoff(page 4–7)27 C64564 1 Escutcheon gasket28 C64560 1 Battery bracket29 B61917 1 Battery pack30 See screw kits 2 Battery bracket screw(page 4–7)31 C64559 1 Battery cover32 See screw kits(page 4–7)1 Battery cover screw (TORX with post head)3–14 <strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong>

Exit Hardware Trim Functions and PartsKEYPAD EZ READER AND TRIM EXPLODED DIAGRAM293024222116147 115 6311 2 34 5 67 8 9*0 #192018151713128 9 1042Figure 3.5 Keypad EZ reader and trim exploded diagram (Precision Hardware–rim type shown)2523262728<strong>Electronic</strong> <strong>Stand</strong>-<strong>Alone</strong> <strong>Locks</strong> <strong>Service</strong> <strong>Manual</strong> 3–15