Altor 4560, 5070M, 6070 - Kuhn

Altor 4560, 5070M, 6070 - Kuhn

Altor 4560, 5070M, 6070 - Kuhn

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

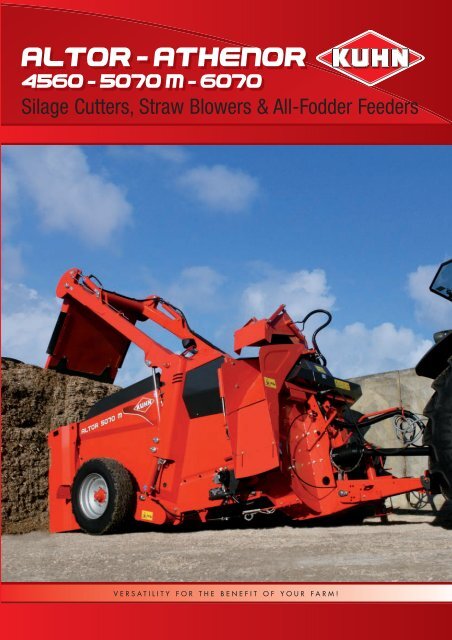

SILAGE CUTTINGIt’s all in the arm movement!The performance of a silage cutter, straw blower & feeder is measured first and foremost by the speedand quality of its loading action. Quality silage cutting is often synonymous with:• A clean, neat clamp face to reduce the air contact area and, therefore, silage oxidation• A straight, vertical clamp face to limit leaching phenomena by rainwater• Easy machine filling for optimum use of the entire body capacity• Clean silage clamp and feeding passageways by reducing fodder losses• Arm movement for easier loading of round and cubic bales with a minimum of manoeuvres.Fast silage cutting and optimum body loadingThe arm pulling strength (up to 2.25 tonnes on <strong>Altor</strong> and Athenor<strong>6070</strong> models) makes for easy loading of all products – even longgrass silage - into the machine.Exceptional arm/grab movement is possible due to the jointbetween the two components being positioned outside the body.All types of bale can be loaded with a minimum of manoeuvres a.3Body dimensions on machines in the <strong>Altor</strong>-Athenor range are designedto enable the grab to penetrate as far as possible inside themachine. On loading silage, fodder is brought as close as possibleto the feed rotor. The entire body can therefore be loaded withoutactivating the conveyor s.The low turbine position improves visibility of the loading operation.Silage cutting can therefore be conducted from the tractor cab.The grab is fitted with a sealing plate mounted on powerful springs.It lifts on loading grass silage to allow the grab teeth to operate.With maize silage and at the end of the loading operation, theplate stays in the down position to leave the clamp floor impeccablyclean and tidy.Two side flaps ensure a perfectly tight machine body: product lossin transit is kept to a minimum.LOADING VOLUMEALTOR <strong>4560</strong> ALTOR 5070 M ALTOR-ATHENOR<strong>6070</strong>4m 35m 36.5m 32.30 m 2.85 m 3.07 m

MIXINGwww.kuhn.comAdd versatility to your machine!Why integrate a “mixing” function into your <strong>Kuhn</strong> silage cutter, straw blower & feeder? <strong>Altor</strong> models canbe fitted with a mixing hopper and the Athenor model with the recycling system. In both cases, mixingvarious ration components offers a number of benefits:• Less appetising products are not left aside at the feeding trough: all animals within the batch consumethe same ration.• Feed efficiency is improved as various products are ingested simultaneously (greater ruminalefficiency).• The addition of concentrates or any other nutritional supplements can be precisely dosed.• The job is less laborious as concentrates and coarse fodder are fed at the same time.KUHN mixing hopper: the Mix Control conceptMixing hoppers are designed to mix coarse fodder (hay, maize, grass silage,etc.) with minerals, cereals and concentrates.ADVANTAGES of the Mix Control concepta High capacity. With a capacity of 575 litres, <strong>Kuhn</strong> mixing hoppers cancope with the various volumes of the <strong>Altor</strong> silage cutter and straw blower range.s Easy to load. With their extra-low profile and two loading doors (right andleft), <strong>Kuhn</strong> mixing hoppers can be filled effortlessly and safely, without having tostraddle the drive shaft.4d Premixing: Minerals and concentrates are mixed in the hopper by meansof an agitator consisting of a double reverse-pitch coil. An even mix is producedthroughout the hopper.f Regular injection. The use of an injection auger prevents blockageproblems. It feeds ingredients continuously into the turbine at a regular rate toguarantee thorough mixing with the coarse fodder.g Precise incorporation. The speed of injection auger rotation determinesthe dosage of concentrates incorporated in the turbine. Simply adjust thepotentiometer knob on the electric control in the cab to modulate the doseincorporated.Athenor version:a mixer at the flick of a switch!You can transform your Athenor <strong>6070</strong>into a true mixer at the flick of a switchwithout leaving your tractor seat. Theturbine flap shuts off the feed chuteand opens the recycling chute, then therecycling cover is unfolded.Made from coated polyester fibre, thecover withstands all types of projections.Its bows are padded to protect the coverwhen folded up.Want to take feedmanagement a step further?Then opt for <strong>Kuhn</strong>electronic weighing!See page 13 for details

STRAW BLOWINGwww.kuhn.comStraw bedding synonymous with animal welfare!Bedding quality is an important link in the health chain established on your farm.That’s why the solutions provided by <strong>Kuhn</strong> silage cutters, straw blowers & feeders guarantee:• An even quantity of straw spread over the entire bedding area to limit the risks of litteroverheating• Preservation of the straw structure to maintain full absorbability and therefore extend litter life• Reduced straw consumption for greater control over the “health and hygiene” budget.a Turbine wheel with removable bladesThe turbine wheel is fitted with eight bolted-on blades. This concept guaranteesgood turbine wheel balance and simplifies replacement operations in the event ofblade damage. Two of these eight blades are longer than the others to generatea speed differential in the turbine. The straw spread over the entire surface ofthe turbine by the feed rotor will therefore be blown in identical quantities overthe entire depth of the bedding area (while keeping animal discomfort to aminimum).Upward movements of the chute cap to ensure a good spread of litter are nolonger necessary.Straw is blown up to a distance of 18 metres.6s Pneumatic separating chamber – exclusive to <strong>Kuhn</strong>!A 150 mm deep space has been designed in the turbine volute between theblades and the turbine inlet: the “pneumatic separating chamber”.The volume of air in motion in this chamber sucks up the product while gentlyseparating it. The straw remains whole. The bedding keeps together better andlasts longer, and your livestock will appreciate the extra comfort!Farmers looking for a machine that does the job cleanly will appreciate thePOLYDRIVE ® disengageable belt drive system. A single switch in the cab stopsboth the feed rotor and the conveyor and prevents debris straw from being lefton the head gates on passing the pillars.

ALTOR <strong>4560</strong>4 cu.m in a compact machine!Why has it becomethe market leader?Work light fitted as standard.Switched on from the machine’selectric controls.Turbine speed (270/540 rpm)switched by a remote control cable.New generation electric controlsfitted as standard.With this compact, intuitive control unit, all driverswill soon have all of the machine’s functions well inhand. A sheltered compartment is provided to storethe control unit when the machine is unhitched.7POLYDRIVE ® patented feed rotordrive system.The flexibility of the hydraulic clutchcombined with the power of the mechanicaldrive.The most compact machine in its category!Overall length of 4.60 m with an effective capacity of 4 cu.m.Supplied with its tow bar, its turning angle is one of the shortest around!Body structure consolidated byreinforcement posts.The extremely rigid rear body sectionwithstands wedging phenomena onsilage loading without any deformation.The axle and arm rams are attachedin the same plane to a 6 mm thickplate post, thereby reducing the risksof body shear.A certified machine complyingwith current standards.Acceptance test performed by DREAL (formerlyDRIRE), hydraulic braking compliant with theMinisterial Order of 12 January 2006.a Suited to low-power tractors.s Silage loading: 4 cu.m effectivecapacity!d Mixing hopper: Mix Control concept.f Feeding: long fibre included!g Loading: all round bale sizes!h Straw “showered” up to 18 metres.

4m 3www.kuhn.comGrab position and conveyor rotationindicators fully visibleProjection guard.This device positioned over the feed rotor controlsfodder projections at the end of the feedingoperation. The front of your machine is kept clean.It can also be used to channel layers of cubic balesinto the body.Rounded arm/grab joints.At the end of the silage cutting operation, there is no longer any risk ofa clamp face collapse when the body is lifted.The arm rams are positioned on the outside of the body.No risk of ram rod oxidation by the silage juices.Grab actuated by two rams.Forces on the grab during silage cutting and loading are split symmetrically.The risks of premature arm deformation are thus reduced.8Turbine shoe and wear blade on the body heel.When positioned at the clamp, the machine is protected against friction.285/70 R19.5 tyres designed for abrasive ground.Bolted oversized conveyor.This integral subassembly comprises a frame, marine-gradechain and tubular slats and is guided by four ductile cast ironsprockets for failsafe durability.As it is bolted onto the machine body, it can be dismantledvery quickly.Conveyor cleaning door with doublegalvanised steel bottom.The conveyor bottom has been madeeasier to clean. At the end of the strawblowing operation, the lower compartmentis completely emptied simply by reversingthe conveyor.

ALTOR 5070 MAll types of bale with a single feed rotor!In what ways will it becomethe new benchmark?Rounded arm/grab joints.At the end of the silage cutting operation, there is nolonger any risk of a clamp face collapse when the body is lifted.Grab actuated by two rams.Forces on the grab during silage cutting and loading are split symmetrically.The risks of premature arm deformation are thus reduced.Grab position and conveyor rotation indicators fully visible9The arm rams are positioned on the outside of the body.No risk of ram rod oxidation by the silage juices.Indestructible rear LED lights forsilage cutting and machine loadingmanoeuvres.Turbine shoe and wear blade on the body heel.When positioned at the clamp, the machine is protected against friction.285/70 R19.5 tyres designed for abrasive ground.Body structure consolidated by reinforcement posts.The extremely rigid rear body section withstands wedgingphenomena on silage loading without any deformation.The axle and arm rams are attached in the same plane toa 6 mm thick plate post, thereby reducing the risks of body shear.A certified machine complyingwith current standards.Acceptance test performed by DREAL(formerly DRIRE), hydraulic brakingcompliant with the Ministerial Order of12 January 2006.a Optimum height-to-length ratio for goodvisibility.s Silage loading: 5 cu.m effective capacity!d Mixing hopper: Mix Control concept.f Feeding: all fodder(including long fibre).g Loading: all types of round andcubic bale.h Straw “showered” up to 18 metres.

5m 3www.kuhn.comBolted oversized conveyor.This integral subassembly comprises a frame, 12 mm marinegradechain and tubular slats and is guided by four ductile castiron sprockets for failsafe durability.As it is bolted onto the machine body, it can be dismantledvery quickly.Conveyor cleaning door with doublegalvanised steel bottom.The conveyor bottom has been made easier toclean. At the end of the straw blowing operation,the lower compartment is completely emptiedsimply by reversing the conveyor.Projection guard.This device positioned over the feed rotor controls fodder projectionsat the end of the feeding operation. The front of your machine iskept clean. It can also be used to channel stacks of cubic bales intothe body.Work light fitted as standard.Switched on from the machine’s electric controls.Universal straw blowing and feeding chute.Pre-equipped to take the 300° kit to blow straw on both sidesof the machine.Turbine speed (270/540 rpm) switched by a remote control cable.10New generation electric controlsfitted as standard.With this compact, intuitive controlunit, all drivers will soon have all of themachine’s functions well in hand.A sheltered compartment is provided tostore the control unit when the machineis unhitched.Hydraulically adjustable toboggan.The string of silage is deposited by gravityinto the trough. Independent of the machine’sfan, the flow of product is fully channelledinto the trough.Stainless steel turbinebottom for longer life.POLYDRIVE ® patented feedrotor drive system.The flexibility of the hydraulicclutch combined with the powerof the mechanical drive.

ALTOR - ATHENOR <strong>6070</strong> MEssential dual feed rotor machines!In what ways is it considered to offerthe best performance in its category?Grab position and conveyor rotation indicators fully visiblePOLYDRIVE ® patented feed rotordrive systemThe flexibility of the hydraulic clutchcombined with the power of the mechanicaldrive.11Body structure consolidated by reinforcement posts.The extremely rigid rear body section withstands wedgingphenomena on silage loading without any deformation.The axle and arm rams are attached in the same plane toa 6 mm thick plate post, thereby reducing the risks of body shear.285/70 R19.5 tyres designed for abrasive ground.Turbine shoe and wear blade on the body heel.When positioned at the clamp, the machine is protectedagainst friction.Impact plate at the baseof the ecycling cover.Improved ageing when recyclingpotatoes, beet, etc.A certified machine complying with current standards.Acceptance test performed by DREAL (formerly DRIRE), hydraulicbraking compliant with the Ministerial Order of 12 January 2006.a Silage loading: 6.5 cu.m effectivecapacity!s Mixing hopper: Mix Control concept.d Recycling: a mixed ration for over fiftydairy cows.f Feeding: long fibre included!g Loading: all types of bale.h Straw blowing: up to 18 m.

www.kuhn.com6.5mm 3Bank of hydraulically adjustable regulating tines.The angle of feed rotor attack is controlled from the tractor cab.Work light fitted as standard.Switched on from the machine’selectric controls.Two concentric-coil feed rotors.Positioned on different vertical planesfor optimum straw blowing andfeeding rates.The upper feed rotor is driven by afour-strand PowerBand belt via thelower feed rotor.Loading platform with dualcontrol as standard.Positioned on the machine centreline for perfect visibility without acricked neck!New generation electric controlsfitted as standardWith this compact, intuitive controlunit, all drivers will soon have all ofthe machine’s functions well in hand.A sheltered compartment is providedto store the control unit when themachine is unhitched.12Turbine speed (270/540 rpm) switchedby a remote control cable.Stainless steel turbine bottom for longer life.Athenor model put into “recycling” modeby a single switch from the electric controls.

OPTIONAL EQUIPMENTAdapt the machine to your needs…13Auxiliary hydraulic power unitA 45 l/min hydraulic pump will render the machineindependent of tractors with a low oil flow ratewhile minimising loading timeThe compact, well protected hydraulic unit isfully integrated into the front left-hand side of themachine and mounted directly on the gearbox.Platform with dual control*For small-sized tractors, the platform can be used to load the machinesafely and efficiently.Positioned to the front of the turbine, you will be working on the centreline of the machine. Arm/grab movements are all the more intuitive! aAs arm and axle functions are transferred to the dual electric control unit,you will be able to control the machine without toing-and-froing betweenthe platform and cab.A full tilting hood protects this dual control from the elements s.* Fitted as standard on <strong>Altor</strong>-Athenor <strong>6070</strong>.300°Weighing for perfect feed managementFor quality feeding and better management of fodderstocks, a precision electronic weighing systemon the silage cutter, straw blower & feeder is anessential tool.On the “simple” version, the weight indicationincreases on loading and decreases on discharging.The “programmable” version allows you to integratethe ration(s) per animal into the weighingfunction. Only the number of head needs to beentered on each change to the herd.Swivel chute for 300° straw blowing<strong>Altor</strong> and Athenor models can be equipped with a swivel chute to blowstraw to the left and right of the turbine. This chute is the solution to strawblowing in buildings with no separate exit or with difficult access.The swivel chute is mounted on a turntable for 300° rotation. Straw canbe blown up to a distance of 13 m on the left-hand side simply by meansof the fingertip controls in the cab.On models <strong>4560</strong> and <strong>6070</strong>, the swivel chute is mounted on top of theturbine a.Meanwhile on the ALTOR 5070 M, the turbine design enables a 300° kitto be fitted to turn the standard chute into a swivel chute s.

SERVICESNo less than you’d expect for a machine in everyday use!14Aftersales supportYou might never see them, but dozens of people work everyday to satisfy <strong>Kuhn</strong> customers’ needs (producing technicaldocumentation, training our network of partners, developingdiagnostic aids, and so on).The technical departments of partners trained in <strong>Kuhn</strong>technologies through attendance at special training courses,commission the machines and are ready to step in when youneed them most.Spare parts serviceOur various worldwide production units combined with theEuropean spare part distribution platform – KUHN PARTS –guarantee all users a high rate of component availability.Distributed by our network of approved partners, the availabilityof replacement parts is boosted by being on the user’sdoorstep: you are assured of being quickly up and running.

SPECIFICATIONS“In European Union countries, our machines comply with the “Machinery” directive; in other countries, they comply with local safety legislation. In our brochures, protective devices may have been removed for thepurposes of illustrating certain details. In all cases, these devices must remain in place in accordance with the instruction manual. We reserve the right to make alternations to our models or their equipment and accessorieswithout notice. Machines and equipment in this leafl et can be covered by at least one patent and/or registered design. Registered trademark(s).“DEALERALTOR <strong>4560</strong> ALTOR 5070 M ALTOR <strong>6070</strong> ATHENOR <strong>6070</strong>Standard Mixing hopper Standard Mixing hopper Standard Mixing hopper Recycling machineBody capacity (cu.m) 4 4 5 5 6.5 6.5 6.5Unladen weight (kg) 3 180 3 440 3 450 3 710 3920 4180 4120Width (m) 1.40 1.40 1.40 1.40 1.50 1.50 1.50Inside bodyLength (1) (m) 2.30 2.30 2.85 2.85 3.07 3.07 3.07dimensionsHeight (m) 1.16 1.16 1.26 1.26 1.32 1.32 1.32Width with chute retracted (m) 2.26 2.26 2.30 2.30 2.42 2.42 2.42Width with chute3.03 3.03 2.30 2.30 3.18 3.18 3.18OveralldimensionsFeedingheight (2)Strawblowingheight (2)extended (m)Outside width at wheels (m) 2.25 2.25 2.25 2.25 2.36 2.36 2.36Length (m) 4.60 5.19 5.12 5.71 6.25 6.25 6.25Height with chute retracted(2) (m)Feeding height at the end ofthe chute bottom plate (m)Height under the feedingtoboggan at an angleof 45° (m)Height under chute (chutein horizontal position) (m)1.97 1.97 2.32 2.32 2.59 2.59 2.810.61 0.61 1.73 1.73 0.73 0.73 0.73- - 0.77 0.77 - - -1.46 1.46 2.25 2.25 1.69 1.69 1.69Straw blowing distance with chute tothe right (m)18 18 18 18 18 18 18Silage cutting height with grab at 30°(2) (m)3.25 3.25 3.25 3.25 3.45 3.45 3.45Maximum diameter/width of round bales (m) 2.00 / 1.35 2.00 / 1.35 2.00 / 1.35 2.00 / 1.35 2.00 / 1.45 2.00 / 1.45 2.00 / 1.45Maximum size of cubic bales (m)1.20 x 1.20 x 1.20 x 1.20 x 1.20 x 1.20 x 1.20 x 1.20 x 1.20 x 1.20 x 1.20 x 1.20 x2.502.502.702.702.702.701.20 x 1.20 x 2.70Number of feed rotors 1 1 1 1 2 2 2Number of regulating tines / Adjustment 5 / fixed 5 / fixed 5 / fixed 5 / fixed 4 / hydraulic 4 / hydraulic 4 / hydraulicType of stand (3)Mechanical, Mechanical,Mechanical, Mechanical, Mechanical,Pin-type Pin-typescrew-type screw-typescrew-type screw-type screw-typeTyres 285/70 R19.5 285/70 R19.5 285/70 R19.5 285/70 R19.5 285/70 R19.5 285/70 R19.5 285/70 R19.5Turbine speed (rpm) 270 / 540 270 / 540 270 / 540 270 / 540 270 / 540 270 / 540 270 / 540Type of control Electric Electric Electric Electric Electric Electric ElectricRecommended tractor power in kW (DIN-hp) 37 (50) 37 (50) 37 (50) 37 (50) 48 (65) 48 (65) 55 (75)Recommended tractor power for long fibrein kW (DIN-hp)51 (70) 51 (70) 51 (70) 51 (70) 59 (80) 59 (80) 66 (90)Tractor output and pressure requirement(l/min at 180 bar)45 60 45 60 45 60 45Hydraulic equipment requirement (3)1 SA valve 1 SA valve 1 SA valve 1 SA valve 1 SA valve 1 SA valve1 SA valve withwith free with free with free with free with free with freefree returnreturn return return return return return(1) Distance separating feed rotor from rear of body (2) Machine on ground (3) Equipment varies from country to countryOTHER EQUIPMENTS*Adaptation to shed layoutFree-wheel PTO shaft + slip friction clutch ■ ■ ■ ■ ■ ■ ■Constant velocity free-wheel PTO shaft + slipfriction clutchOptional Optional Optional Optional Optional Optional Optional300° swivel chute Optional Optional Optional Optional Optional Optional OptionalStraw blowing distance to right 13 m 13 m 18 m 18 m 13 13 13Straw blowing distance to left 13 m 13 m 13 m 13 m 13 13 13Feed managementMixing hopper (capacity: 575 litres) - ■ - ■ - ■ -Loading height (machine on ground) - 1.43 - 1.43 - 1.43 -Simple weighing system Optional Optional Optional Optional Optional Optional OptionalProgrammable weighing system Optional Optional Optional Optional Optional Optional OptionalAdaptation to tractorLoading platform with dual control Optional Optional Optional Optional ■ ■ ■Telescopic stand (crank + pin adjustment) - - Optional Optional - - -Auxiliary hydraulic power unit Optional Optional Optional Optional Optional Optional OptionalPump output at PTO speed of 540 rpm 45 45 45 45 45 45 45Reservoir capacity 45 45 45 45 60 60 60* Optional equipment varies from country to country ■ Standard equipment - UnavailableUSA – KUHN FARM MACHINERY, INC.5390 East Seneca Street – P.O. Box 840VERNON, NY 13476 – 0840Phone: (315) 829 2620 - Fax: (315) 829 2270www.kuhn-usa.comGB – KUHN FARM MACHINERY (U.K.) LTDStafford Park 7,TELFORD, Shropshire TF3 3BQPhone: (01952) 239300/1/2 - Fax: (01952) 290091www.kuhn.co.ukAUS – KUHN FARM MACHINERY PTY. LTD.313-325 Foleys RoadDeer ParkVICTORIA 3023www.kuhn.comTo protect the environment, this leafl et is printed on chlorine-free paper / Printed in France - A72713GB - Copyright KUHN 2011 - Imp LNG.