Operating Manual - KLARO GmbH

Operating Manual - KLARO GmbH

Operating Manual - KLARO GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

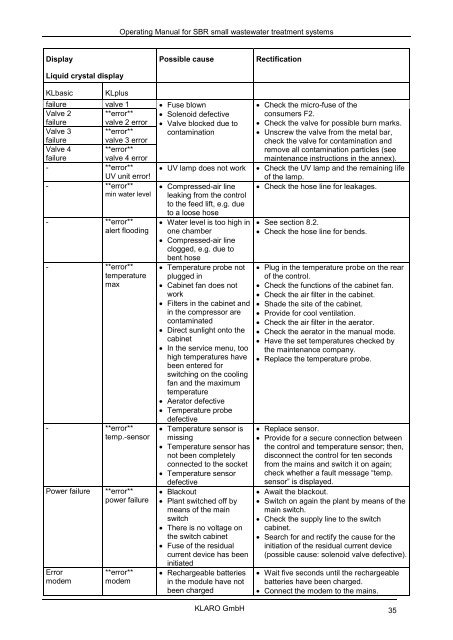

<strong>Operating</strong> <strong>Manual</strong> for SBR small wastewater treatment systemsDisplayLiquid crystal displayPossible causeRectificationKLbasic KLplusfailureValve 2failureValve 3valve 1**error**valve 2 error**error**• Fuse blown• Solenoid defective• Valve blocked due tocontaminationfailurevalve 3 errorValve 4 **error**failurevalve 4 error- **error** • UV lamp does not workUV unit error!- **error** • Compressed-air linemin water level leaking from the controlto the feed lift, e.g. due- **error**alert flooding- **error**temperaturemax- **error**temp.-sensorPower failureErrormodem**error**power failure**error**modemto a loose hose• Water level is too high inone chamber• Compressed-air lineclogged, e.g. due tobent hose• Temperature probe notplugged in• Cabinet fan does notwork• Filters in the cabinet andin the compressor arecontaminated• Direct sunlight onto thecabinet• In the service menu, toohigh temperatures havebeen entered forswitching on the coolingfan and the maximumtemperature• Aerator defective• Temperature probedefective• Temperature sensor ismissing• Temperature sensor hasnot been completelyconnected to the socket• Temperature sensordefective• Blackout• Plant switched off bymeans of the mainswitch• There is no voltage onthe switch cabinet• Fuse of the residualcurrent device has beeninitiated• Rechargeable batteriesin the module have notbeen charged• Check the micro-fuse of theconsumers F2.• Check the valve for possible burn marks.• Unscrew the valve from the metal bar,check the valve for contamination andremove all contamination particles (seemaintenance instructions in the annex).• Check the UV lamp and the remaining lifeof the lamp.• Check the hose line for leakages.• See section 8.2.• Check the hose line for bends.• Plug in the temperature probe on the rearof the control.• Check the functions of the cabinet fan.• Check the air filter in the cabinet.• Shade the site of the cabinet.• Provide for cool ventilation.• Check the air filter in the aerator.• Check the aerator in the manual mode.• Have the set temperatures checked bythe maintenance company.• Replace the temperature probe.• Replace sensor.• Provide for a secure connection betweenthe control and temperature sensor; then,disconnect the control for ten secondsfrom the mains and switch it on again;check whether a fault message “temp.sensor” is displayed.• Await the blackout.• Switch on again the plant by means of themain switch.• Check the supply line to the switchcabinet.• Search for and rectify the cause for theinitiation of the residual current device(possible cause: solenoid valve defective).• Wait five seconds until the rechargeablebatteries have been charged.• Connect the modem to the mains.<strong>KLARO</strong> <strong>GmbH</strong> 35