Job Specification of items under Forest Schedule of Rates

Job Specification of items under Forest Schedule of Rates

Job Specification of items under Forest Schedule of Rates

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

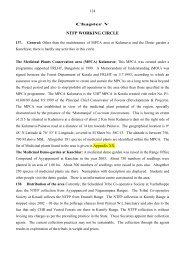

No.Plg2-183/04<strong>Forest</strong> Head Quarters,Thiruvananthapuram.Dated: 20-11-2004.CIRCULARSub: <strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> <strong>Rates</strong> – <strong>Job</strong> <strong>Specification</strong>s <strong>of</strong> various <strong>items</strong> prescribed – Orders issued.Ref:<strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> <strong>Rates</strong> (FSR) was first issued in 1963 vide GO (Rt) No. 1931/63/ Agri dated08-07-1963 prescribing the rates to be followed for various <strong>items</strong> <strong>of</strong> forestry works. This was modifiedseveral times since then. However, there has never been any authoritative instruction specifying the exactjobs expected to be done <strong>under</strong> each item. This lacuna gave rise to varied perceptions <strong>of</strong> different work<strong>items</strong> in the past and on many an occasion served as an escape route for suspected delinquency. Amarginal change occurred with the issue <strong>of</strong> notification No. 7899/E1/LBR dated 01-04-1974 on the basis<strong>of</strong> the recommendations <strong>of</strong> the Minimum Wages Advisory Board, wherein schedule <strong>of</strong> rates for certain<strong>items</strong> were notified together with job specifications <strong>of</strong> various <strong>items</strong> and the details <strong>of</strong> work study. In thecase <strong>of</strong> the other <strong>items</strong> the situation continued as before.It was strongly felt that this undesirable situation had to be discontinued at the earliest, in the bestinterests <strong>of</strong> the department. Accordingly, a committee <strong>of</strong> experienced forest <strong>of</strong>ficers was constituted forprescribing and consolidating the job specifications <strong>of</strong> all the <strong>items</strong> <strong>of</strong> work included in the FSR. Thecommittee submitted their recommendations after due deliberations and consultations <strong>under</strong> thesupervisory directions <strong>of</strong> the Chief Conservator <strong>of</strong> <strong>Forest</strong>s (Planning). The draft report was circulated forcomments in the Senior <strong>Forest</strong> Officers’ meeting attended by Chief Conservators <strong>of</strong> <strong>Forest</strong>s andConservators <strong>of</strong> <strong>Forest</strong>s. Copies <strong>of</strong> the recommendations were also given to service associations <strong>of</strong>Rangers and ACFs. Valuable suggestions emerged from all <strong>of</strong> them have been incorporated and a finalshape has been given to the job specifications, which is enclosed herewith.It is hereby ordered that the specifications issued as above shall be followed forthwith, whileexecuting forestry works in the department. If the rate prescribed for any <strong>of</strong> the <strong>items</strong> is found to beinsufficient, it can be taken up at the appropriate level for a proper work study and consequent revision.Encl: As aboveSd/-Principal Chief Conservator <strong>of</strong> <strong>Forest</strong>sC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc1

IntroductionJOB SPECIFICATION OFITEMS UNDER FOREST SCHEDULE OF RATESThe Chief Conservator <strong>of</strong> <strong>Forest</strong>s (Planning) has directed the Working Plan Officer, Kollam todescribe the job specifications intended <strong>under</strong> each item <strong>of</strong> the <strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> <strong>Rates</strong> to give clarityto the <strong>items</strong>. For this purpose, a Committee was formed with the following members.1. Shri. V. Sasidharan, Working Plan Officer, Kollam2. Shri. S. Karthikeyan, Assistant Conservator <strong>of</strong> <strong>Forest</strong>s3. Shri. T. Pradeep Kumar, Assistant Conservator <strong>of</strong> <strong>Forest</strong>s4. Shri. S. Janardhanan, Assistant Conservator <strong>of</strong> <strong>Forest</strong>sThe members had many discussions and finally a draft statement <strong>of</strong> the job specification <strong>of</strong>various <strong>items</strong> covered in the <strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> <strong>Rates</strong> was prepared and there was preliminarydiscussion with the Conservator <strong>of</strong> <strong>Forest</strong>s (Working Plan and Research Circle) and the Chief Conservator<strong>of</strong> <strong>Forest</strong>s (Planning). Finally, it is decided to call for the remarks <strong>of</strong> the <strong>of</strong>ficers who have greatpractical experience in the field to finalise the draft and hence this draft statement is presented forvaluable remarks.Draft report <strong>of</strong> <strong>Job</strong> <strong>Specification</strong>s <strong>of</strong> various <strong>items</strong> <strong>of</strong> <strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> <strong>Rates</strong>The <strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> <strong>Rates</strong> (FSR) was published in 1963 as per GO (Rt) No. 1931/63/Agri dated08-07-1963. The <strong>items</strong> included in the FSR were not arrived at by actual work-study. From experience,the labour content for various schedule <strong>items</strong> were fixed and rates arrived at. Now also, in almost allcases, the same labour content is followed. Labour rates are being revised from time to time andapplying this to the labour content <strong>of</strong> each item, the rates are arrived at. Later on, in 1974, on thebasis <strong>of</strong> the recommendations <strong>of</strong> the Minimum Wages Advisory Board, Minimum Wage for the following<strong>items</strong> <strong>of</strong> schedule <strong>of</strong> rates was published as per notification No. 7899/E1/LBR dated 01-04-1974. In thiscase, work-study was conducted for the <strong>items</strong> given below:A. i) Felling and collection <strong>of</strong> Hardwood timberBEstablishment <strong>of</strong> Eucalyptus Plantation1. Forming <strong>of</strong> nursery seed bed and sowing seeds2. Watering Eucalyptus nursery3. Collection and sieving <strong>of</strong> forest soil for filling polythene bags4. Filling polythene bags with fine soil (12 x 18 cm)5. Pulling out Eucalyptus seedlings from seedbed nursery and transplanting into polythenebags.6. Digging pits 25 x 25 x 25 cm in ordinary moist forest soil7. Digging pits 25 x 25 x 25 cm in boundary moist forest soil8. Transport <strong>of</strong> Eucalyptus poly-bag seedlings and distribution <strong>of</strong> seedlings9. Covering planting pits 25 x 25 x 25 cm and digging planting hole for planting eucalyptus10. Planting poly-bag eucalyptus seedlingsC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc2

C. Establishment <strong>of</strong> Teak Plantation1. Formation <strong>of</strong> nursery bed for teak2. Sowing seeds <strong>of</strong> teak in nursery bed3. Aligning and staking 2m x 2m4. Pulling out two year old teak seedlings and preparation <strong>of</strong> stumps5. Pulling out one year old teak seedlings and preparation <strong>of</strong> stumps6. Watering one year old teak nursery during dry weather to facilitate pulling out <strong>of</strong> teakseedlings7. Planting teak in crow bar holesThis minimum wage were revised as per notification GO (Rt) No. 1081/88/LBR dated 18-06-2004in suppression <strong>of</strong> notification No. 7899/E3/73/LBR dated 01-04-1974. As far as labour content isconcerned, one more item, viz, felling and preparation <strong>of</strong> s<strong>of</strong>t wood is seen included in thisnotification. The other <strong>items</strong> in the schedule <strong>of</strong> rates, which are based on certain data or work-study,are given below.1. De-sapping ebony logs – GO (Rt) No. 245/66/Agri dated 25-11-19652. Collection <strong>of</strong> Eucalyptus seeds – GO (Rt) 2965/66/Agri dated 26-12-19663. Reduction <strong>of</strong> coppice shoots – GO(Rt) No. 2744/75 AD dated 15-10-19754. Digging earth around Rosewood trees and removing the sap wood on rose wood logs at midgirth – GO (Rt) 2337/76/AD dated 03-07-19765. Chisel numbering s<strong>of</strong>twood logs – GO (Rt) 193/78/AD dated 25-01-19786. Fire Protection works – GO (Rt) No. 614/79/AD dated 08-03-19797. Transport <strong>of</strong> teak stumps – GO (Rt) No. 2379/80/AD dated 16-08-19808. Cross cutting <strong>of</strong> logs – GO (Rt) no. 2752/80/GAD dated 04-10-19809. Loranthus cutting in Teak plantations – GO (Rt) No. 1479/81/<strong>Forest</strong> dated 04-11-198110. Collection <strong>of</strong> timber and firewood from thinning excluding the charges <strong>of</strong> felling – GO (Rt)1105/82/AD dated 20-04-198211. Uprooting sandalwood tree – GO (MS) 22/88/F&WLD dated 07-05-198812. Digging pits <strong>of</strong> size 30 cm3 – GO (Rt) No. 101/90/F&WLD dated 13-02-199013. Head load transport <strong>of</strong> sandalwood from <strong>Forest</strong> – GO No. 10/93/<strong>Forest</strong>s dated 12-02-1993For the other <strong>items</strong>, the labour content <strong>of</strong> schedules <strong>items</strong> is arrived at from the experience inthe field. Hence most <strong>of</strong> the <strong>items</strong> are arrived at based on certain other similar <strong>items</strong>. As a result,certain <strong>items</strong> included are not practicable in the field. The weeding <strong>items</strong> provided for raising andmaintenance <strong>of</strong> plantations are some <strong>of</strong> the examples. So plantation maintenance has become aproblem and the fate <strong>of</strong> the plantations rose after abolishing taungya cultivation bear a living testimony<strong>of</strong> this. A detailed study <strong>of</strong> the various <strong>items</strong> coming in the <strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> Rate is appended herewith.There are <strong>items</strong> in the FSR for elephant capturing operations, boat work, maintenance <strong>of</strong>coconut tope etc., which has only limited application or no application at all in the present context.Such <strong>items</strong> can be retained as such or some <strong>of</strong> them can be deleted. For the other <strong>items</strong>, labourcontents <strong>of</strong> each schedule item has to be worked out on the basis <strong>of</strong> detailed work study to beconducted in the field. At least the <strong>items</strong> for which the rates are impracticable are to be revised. Forweeding <strong>items</strong>, rates are to be formulated according to the nature <strong>of</strong> the weeds and the intensity <strong>of</strong>C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc3

weeds and Conservators <strong>of</strong> <strong>Forest</strong>s are to be given powers to sanction the rates considering the natureand intensity <strong>of</strong> weeds for the maintenance <strong>of</strong> plantations. There are <strong>items</strong>, which are not covered inthe schedule <strong>of</strong> rates, and which are now being constantly practised in the field. For such <strong>items</strong> also,labour content is to be worked out on the basis <strong>of</strong> work study which has to be <strong>under</strong>taken.There are separate schedule <strong>of</strong> rates for rubber plantation works and c<strong>of</strong>fee plantation works,which have only limited applications. Maintenance <strong>of</strong> coconut plantation can also be included like this.During the discussion, it has also come up that there is anomaly in the categorisation <strong>of</strong> ranges intoordinary, difficult and very difficult areas. For this assessment, many parameters are seen consideredby the Minimum Wage Committee. It is proposed that these parameters may be rechecked andreassessment may be conducted by the committee, which will be constituted for revision <strong>of</strong> schedule <strong>of</strong>rates.A committee may be constituted to revise the labour content <strong>of</strong> the various schedule <strong>items</strong> onthe basis <strong>of</strong> the work-study to be conducted in the field. Detailed reports are to be called for from thefield from Division level stating the difficulties faced in the implementation <strong>of</strong> works as per the existingforest schedule <strong>of</strong> rates. New <strong>items</strong> to be included may also be called for. On the basis <strong>of</strong> these reports,the <strong>Forest</strong> <strong>Schedule</strong> <strong>of</strong> <strong>Rates</strong> may be revised on the basis <strong>of</strong> the work-study to be <strong>under</strong>taken in thefield.Yours faithfullyV. SasidharanWorking Plan Officer, KollamC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc4

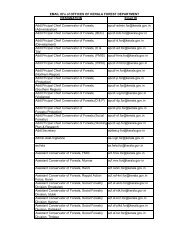

SCHEDULE OF RATES FOR FORESTRY WORKSDRAFT REPORT OF JOB SPECIFICATIONS OF THE VARIOUS ITEMS IN THE FOREST SCHEDULE OF THE RATESSl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description RemarksI. Survey and Demarcation1. Clearing boundary line to a width <strong>of</strong>1.5 m to facilitate survey2. Survey with prismatic compass (outturn / day -1.2 km)2 (a). Survey with prismatic compass (outturn / day 1.2 km) – when lascars areused3. Survey with Theodolite (Out turn / day– 0.8 km)4. Re-fixing and verification work withTheodolite (Out turn / day – 0.8 km)5. Aligning forest road with Ghat tracerfor preliminary alignment5 (a). Aligning forest road with Ghat tracerfor final alignment6. Widening the surveyed boundary to awidth <strong>of</strong> 5.5 m for outer boundary <strong>of</strong>reserves and uprooting <strong>of</strong> all growth3.105 MM Km 1. Clearing jungle growth by cutting with a knife as close tothe ground as possible2. Check the width <strong>of</strong> cleared line with measurement tape.3.105 MM Km 1. Carrying survey instruments to the field2. Collection <strong>of</strong> pegs for fixing at survey stations3. Marking survey stations with pegs and numbering4. Take measurement with prismatic compass & chain andmeasure the distance between stations with chain afterproper alignment.1.863 MM Km 1. Carrying survey instruments to the field2. Collection <strong>of</strong> pegs for fixing at survey stations3. Marking survey stations with pegs and numbering4. Take measurement with prismatic compass & chain andmeasure the distance between stations with chain afterproper alignment.Actual survey is done by thetechnical staffNot in practice7.452 MM Km Survey Department specifications to be followed Survey department work7.452 MM Km Survey Department specifications to be followed Survey department work3.105 MM Km 1. Transport <strong>of</strong> instruments / materials to site2. Collection <strong>of</strong> wooden pegs3. Fixing pegs at the station points and providing all otherlabour assistance for alignment work6.210 MM Km 1. Transport <strong>of</strong> instruments / materials to site2. Collection <strong>of</strong> wooden pegs3. Fixing pegs at the station points and providing all otherlabour assistance for alignment work6.210 to12.420 MMKm 1. Clear jungle growth to a width <strong>of</strong> 2 m on either side <strong>of</strong> thecleared line using knife as close to the ground as possible2. Check the width <strong>of</strong> the widened line to ensure 5.5 m widthThe actual alignment is doneby the technical staffWith the given rate uprooting<strong>of</strong> all growth over a width <strong>of</strong>5.5 m to a distance <strong>of</strong> 1 Km ispractically impossible.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc5

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks7. Erecting permanent cairns <strong>of</strong> size120 X 120 cm at bottom, 60 X 60 cm attop and 120 cm height with collectedrubble and necessary tarred junglewood posts <strong>of</strong> 15 X 22 cm in diameter inthe centre, chiselling, numbering, etc.,complete8. Providing Theodolite granite stones <strong>of</strong>90 X 22 cm with a plummet hole 2 cmdeep on the top and a shank mark1.24 cm deep on one <strong>of</strong> the sides.8 (a). Providing Theodolite granite stones <strong>of</strong>60 X 15 X 15 cm with a plummet hole2 cm deep on the top and a shank mark1.25 cm deep on the one <strong>of</strong> the sides9. Providing ordinary survey stones <strong>of</strong>90 X 22 X 22 cm with a shank mark1.25 cm deep on one <strong>of</strong> the sides10. Providing Rock marks where rocks areavailable at stations by benching rock15 X 15 cm and cutting plummet hole2 cm deep and shank mark 1.25 cmdeep on one <strong>of</strong> the sides11. Widening surveyed line to 3 m wide andputting station pegs11 (a). Collection <strong>of</strong> jungle wood posts 30 cm,27 cm, 37 cm in girth, 120 cm lengthand transporting to site. Felling andputting them at stump site. Transportto site and putting them at surveyedstations and forming earthen cairns.1 MM + 1 SMM 1. Collection and transport <strong>of</strong> rubble to the already fixedsurvey station2. Collection <strong>of</strong> wooden posts3. Chisel numbering the post4. Tarring wooden posts5. Fixing the posts at the station-point6. Packing the rubble around the post to get the size <strong>of</strong> 120 x120 cm at bottom, 60 x 60 cm at top and 120 cm height.SurveyDepartmentratesapplicable<strong>Specification</strong> as per Survey Department norms3.105 MM Km 1. Clear jungle growth to a further width <strong>of</strong> 75 cm on eitherside <strong>of</strong> the cleared survey line as close to the ground aspossible.2. Check the width <strong>of</strong> widened line and ensure 3 m width8 MM 100 Nos. 1. Felling and collection <strong>of</strong> jungle wood posts <strong>of</strong> the size 30cm, 27 cm, 37 cm in girth and 120 cm length2. Transport <strong>of</strong> posts to the site.3. Forming earthen cairns4. Fixing the posts at the survey station in the centre <strong>of</strong> thecairnNowadays only permanentcairns are being constructedwith cement mortar and hencenot in practiceNot requiredNot requiredNot requiredNot requiredFSR item no.6 is for surveylines running along theperiphery <strong>of</strong> the reserveforests. This item is for othersurvey lines like final fellingcoupe boundary etc.,This item has no practicalapplication at present. Thismay be deleted.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc6

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks12. Constructing cairns 60 X 60 cm atbottom, 30 X 30 cm at top and 60 cmhigh including collection <strong>of</strong> stones1 MM Cairn 1. Collection <strong>of</strong> jungle stones2. Transportation <strong>of</strong> jungle stones3. Packing stones to have a size <strong>of</strong> 60 x 60 cm at bottom, 30 x30 cm at top and 60 x 60 cm height4. Numbering the cairnsII. Timber Working13 (a). Marking at breast height and at baseincluding chisel numbering, tarring,etc., complete in selection fellingcoupes13 (b). Marking at breast height and at baseincluding chisel numbering, tarring,etc., complete in clear felling coupes(in the case <strong>of</strong> conversion coupes wheretrees are marked for depot delivery)C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc6 MM 100 trees 1. Blazing at breast height and at base <strong>of</strong> size 22.5 X 22.5 cm.2. Affixing chisel number at breast height and at base3. Tarring around the marked trees4.5 MM 100 trees 1. Blazing at breast height and at base <strong>of</strong> size 22.5 X 22.5 cm.2. Affixing chisel number at breast height and at base3. Tarring around the marked treesNote: (i) If no tarring is to be done rate <strong>of</strong> ½ man mazdoor must be deducted both for 13(a) and 13(b)13 (c). Marking at breast height and at baseincluding chisel numbering, tarring,etc., in plantations13 (d). Climber cutting in selection fellingcoupes13 (e). Enumeration <strong>of</strong> miscellaneous treesdown to 75 cm at breast height(22.5 x 22.5 cm) and chisel numberingin clear felling coupes14 (a). Felling, conversion, classificationincluding dressing in drag holdingwherever necessary and chiselnumbering for hardwoods for hardwoodlogs (to be debarked)3 MM 100 trees 4. Blazing at breast height and at base <strong>of</strong> size 22.5 X 22.5 cm.5. Affixing chisel number at breast height and at base6. Tarring around the marked trees1.236 MM ha 1. In the case <strong>of</strong> woody climbers, make two cuts on theclimber about 1 m apart and remove the cut portion2. In the case <strong>of</strong> small climbers, cut away the climbers in full3 MM 100 trees 1. Blazing at breast height 22.5 X 22.5 cm2. Affixing chisel number at the blazed portion1. Clear the surroundings <strong>of</strong> the tree to facilitate logingoperations2. Fell all the trees as flesh with the ground as possible3. Trim <strong>of</strong>f the tree stem4. Measure and mark the positions at which the tree has to becross-cut to yield logs <strong>of</strong> suitable quality (not less thanabout 2.50 metres length and 120 cm mid.girth) fit fordepot delivery5. Dress the end portions <strong>of</strong> the logs by properly snountingand dragholing one end <strong>of</strong> the resultant logs and trimming<strong>of</strong> the branches and shaping the knots smoothly6. Debark all species completely except L. lanceolata7. In the case <strong>of</strong> L.lanceolata only the middle portion <strong>of</strong> thelog to a width <strong>of</strong> about 10 cm is to be debarked and crossThis is intended only forselection <strong>of</strong> trees in selectionfelling coupes in naturalforestsThis item is for marking <strong>of</strong>depot delivery species in clearfelling coupes.This is applicable for markingfor thinnings and final fellingin plantations.Rate same as 13 (c). This itempertains to sale coupeenumeration and hence asingle blaze is provided. Ifwork is carried outdepartmentally, doubleblazing is desirable.Work study conducted andminimum wages published asper notification No.7899(E1)73/LBR dated 01-04-1974 and GO(MS) No.393/80/AD dated 17-10-1980.Cross cutting with saw is notintended in this item.7

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks1. 0.5 Cum and below 1 Axe men Cum2. Above 0.5 Cum 0.5 Axe men Cum14 (b) Felling, conversion, classificationincluding dressing in drag holdingwherever necessary and chiselnumbering for s<strong>of</strong>twood logs (not to bedebarked)1. 0.5 Cum and below 0.750Axemen2. Above 0.5 Cum 0.375Axemen14 (c) Felling, conversion, classificationincluding dressing in drag holdingwherever necessary and chiselnumbering for Rosewood, Ayini, Jack,etc. (where removal <strong>of</strong> sapwood is tobe done)CumCum1. 0.5 Cum and below 3.00 Axemen Cum1. Clear the surroundings <strong>of</strong> the tree to facilitate logingoperations2. Fell all the trees as flesh with the ground as possible3. Trim <strong>of</strong>f the tree stem4. Measure and mark the positions at which the tree has to becross-cut to yield logs <strong>of</strong> suitable quality (not less thanabout 2.50 metres length and 120 cm mid.girth) fit fordepot delivery5. Dress the end portions <strong>of</strong> the logs by properly snountingand dragholing one end <strong>of</strong> the resultant logs and trimming<strong>of</strong> the branches and shaping the knots smoothly6. Cross cutting has to be done by sawyers and hence isoutside the purview <strong>of</strong> the job dealt with here.7. In the case <strong>of</strong> logs, which can be turned and debarkedcompletely by the felling crew, it should be done by them.Whereas in the case <strong>of</strong> large logs, elephant power has tobe provided to the felling crew for turning the log.8. Chisel numbering1. Clear the surroundings <strong>of</strong> the tree to facilitate logingoperations2. Fell all the trees as flesh with the ground as possible3. Trim <strong>of</strong>f the tree stem4. Measure and mark the positions at which the tree has to becross-cut to yield logs <strong>of</strong> suitable quality (not less thanabout 2.50 metres length and 120 cm mid.girth) fit for<strong>Rates</strong> as per the abovenotification and GO notedaboveGO(MS) 240/78/AD dated 06-09-1978C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc8

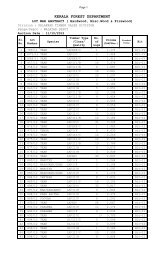

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks1. In selection felling coupes 2.00 MM 100 trees 1. Blazing at breast height to a size <strong>of</strong> 22.5X 22.5 cm2. Writing number at the blazed portion using pencil2. In clear felling coupes and strips<strong>of</strong> sample plots1.50 MM 100 trees 1. Blazing at breast height to a size <strong>of</strong> 22.5 X 22.5 cm2. Writing number at the blazed portion using pencilThis is intended for marking <strong>of</strong>sale coupes for valuation.-do-III. Collection <strong>of</strong> Fuel, Bamboo, Reeds, etc.16 (a) Felling, billeting and stocking at sitefuel in selection felling area16 (b) Felling, billeting and stocking at sitefuel in clear felling areasBilleting and stacking at site <strong>of</strong> fuelexcluding felling0.872Axemen0.872AxemenTonne 1. Felling fuel wood2. Billeting fuel wood at 1 m length3. Stacking fuel wood at site, at 1 m heightTonne 1. Felling fuel wood2. Billeting fuel wood at 1 m length3. Stacking fuel wood at site, at 1 m height0.7083 SMM Tonne 1. Billeting fuel wood at 1 m length2. Stacking fuel wood at site, at 1m height16 (c) Transport by head load 20-200 m 0.872 MM Tonne 1. Transport by head load including lifting and conveying2. Stack the wood at the new siteTransport by head load for every0.581 MM Tonne 1. Transport by head load including lifting and conveying2additional 200 m ( <strong>of</strong> the above rate) 2. Stack the wood at the new site316 (d) Cross cutting with saw 1. Marking the points on the logs for cross cutting2. Cross cutting with saw1. Below 125 cm girth 0.111 Sawyer Per cut 1. Marking the points on the logs for cross cutting2. Cross cutting with saw2. 125 to 150 cm girth 0.166 Sawyer Per cut 1. Marking the points on the logs for cross cutting2. Cross cutting with saw3. Above 150 cm girth 0.333 Sawyer Per cut 1. Marking the points on the logs for cross cutting2. Cross cutting with saw16 (e) Loading firewood in lorries 1.500 SSMM Tonne 1. Lifting, conveying to a lead <strong>of</strong> 20 m and placing thefirewood on the platform <strong>of</strong> the lorry in a compact manner2. Tying the load firmly using ropes ensuring stability f theloadGO (Rt.) No. 1105/82/ADdated 20-04-1982Same rate. One item can bedeleted.GO (Rt.) No. 1105/82/ADdated 20-04-1982GO (Rt.) No. 2572/80/ADdated 04-10-1980GO (MS) No. 184/79/AD dated28-04-1979C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc10

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks16 (f) Unloading firewood and stacking 0.872 SSMM Tonne 1. Untying the load2. Dismantling load and pushing down the firewood from theplatform to the ground3. Stacking firewood following standard measurementsTransport in lorries to be included17 Felling and collection <strong>of</strong> reeds 10.00 SSMM 1000Nos.18 (a) Felling and collection <strong>of</strong> bamboosincluding bottom1. Selection <strong>of</strong> suitable culms for felling and felling <strong>of</strong> reeds2. Collection <strong>of</strong> reeds by lopping branches / leaves, etc.3. Tying reeds in bundles <strong>of</strong> suitable number4. Bringing the bundles to the transportation point near theroadside.25.00 SSMM 100 Nos. 1. Selection <strong>of</strong> suitable culms2. Felling bamboos at ground level3. Collection <strong>of</strong> bamboos by pruning the branches etc4. Converting the bamboos into pieces18 (b) Felling and collection <strong>of</strong> top bamboos 12.00 SSMM 100 Nos. 1. Felling bamboos by cutting at the desired height fromground level2. Collection <strong>of</strong> cut bamboos by pruning <strong>of</strong>f the branchesetc.,GO (MS) No. 184/79/AD dated28-04-1979Distance is not mentioned.Hence collection from interiorarea will be a problem.The rate is for 100 nos. <strong>of</strong> fullbamboos which can beconverted into more than onepieceWhere felling at bottom is notpossible due to the position <strong>of</strong>the bamboos at the centre <strong>of</strong>the Clump18 (c) Felling and collection <strong>of</strong> bottombamboos19 Collection <strong>of</strong> thatching grass 3.00 MM cart load/ 20headload15.00 SSMM 100 Nos. 1. Selection and felling <strong>of</strong> suitable culms2. Collection <strong>of</strong> bottom portion by pruning <strong>of</strong>f the branches1. Cutting thatching grass as close to the ground as possible2. Trying the cut grass in bundles and bundles to head load3. Transporting grass bundles to the cart by head load20 Collection <strong>of</strong> big bees honey 0.548 MM Litre 1. Climbing the trees and collection <strong>of</strong> honey2. Heating in the sunshine3. Sieving / cleaning the collected honey4. Bottling the cleaned honey5. Transport to collecting centres21 Collection <strong>of</strong> small bees honey 1.099 MM Litre 1. Climbing the trees and collection <strong>of</strong> honey2. Sieving / cleaning the collected honey3. Bottling the cleaned honey4. Transport to collecting centresWhere bottom portion only isavailableNow there is no departmentalcollectionNow there is no departmentalcollectionC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc11

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks29 Collection <strong>of</strong> seeds in normal seed year– Thembavu30 Collection <strong>of</strong> seeds in normal seed year– Hopea31 Collection <strong>of</strong> seeds in normal seed year– Maruthy32 Collection <strong>of</strong> seeds in normal seed year– Venteak33 Collection <strong>of</strong> seeds in normal seed year– Mahagony34 Collection <strong>of</strong> seeds in normal seed year– Irul5.511 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the trees3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point16.534 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the trees3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point5.511 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the trees3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point16.534 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweep the floor around the trees3. Gather the ripened capsules from the tree by shaking orlopping the terminal branches4. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point27.557 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Clearing the ground around the trees3. Gather the ripened fruits from the tree4. Open the fruit and collect the seeds5. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point110.231 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Clearing the ground around the trees3. Gather the ripened pods from the tree4. Open the pods and collect the seeds5. Clean the seeds, dry and fill in cloth bags and transport totemporary storage pointC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc13

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks35 Collection <strong>of</strong> seeds in normal seed year– Rosewood36 Collection <strong>of</strong> seeds in normal seed year– Vateria indica37 Collection <strong>of</strong> seeds in normal seed year– Mango38 Collection <strong>of</strong> seeds in normal seed year– Bombax malabaricum39 Collection <strong>of</strong> seeds in normal seed year– Evodia roxburghiana110.231 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the trees3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point5.511 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the tree3. Collect the ripened fruits (pale brown in colour)immediately on ripening from the tree by shaking orlopping the terminal branches4. Open the fruits and collect the seeds5. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point6. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point5.511 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the tree3. Collection <strong>of</strong> fallen fruits4. De-pulping the fruits to get the seeds5. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point137.78 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Clearing the ground around the trees3. Collection <strong>of</strong> fruits from the tree4. Open the fruits and collect the seeds from the flaws5. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point137.78 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the trees3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage pointC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc14

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks40 Collection <strong>of</strong> seeds in normal seed year– Ailanthus malabaricum / excelsa40 (a) Collection <strong>of</strong> seeds in normal seed year– Bamboo41 Collection <strong>of</strong> Evodia, Mahagony,Bamboos and other natural seedlings41 (a) Collection <strong>of</strong> Rauwolfia serpentianaseedlings330.69 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Clearing the ground around the trees3. Gather the ripened seeds from the tree4. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point33.069 MM 100 Kg 1. Locate the flowered bamboo area2. Clean the surroundings <strong>of</strong> the clump3. Collect the seeds from the clump by shaking4. Clean the seeds, dry and fill in cloth bags and transport totemporary storage point3 MM 100 Kg 1. Collection <strong>of</strong> seedlings <strong>of</strong> suitable size2. Tying into bundles5 MM 100 Nos. 1. Collection <strong>of</strong> seedlings <strong>of</strong> suitable size2. Tying into bundles41 (b) Collection <strong>of</strong> Bamboo rhizomes 3 Mm 100 Nos. 1. Collection <strong>of</strong> bamboo rhizomes41 (c) Collection <strong>of</strong> Bamboo seedlings 2 to 3years old with ¾" to 1" stock with bowl<strong>of</strong> earth4 MM 100 Nos. 1. Collection <strong>of</strong> 2 to 3 years old bamboo seedlings42 Collection <strong>of</strong> Kulamavu seeds 55.115 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Sweeping the ground around the trees3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point43 (a) Collection <strong>of</strong> Pala (Alstomia) seeds 110.231 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Clearing the ground around the trees3. Collection <strong>of</strong> fruits from the tree4. Open the fruit and collect the seed5. Cleaning, drying the seeds in sun shine and transport totemporary storage point43 (b) Collection <strong>of</strong> Rauwolfia seeds 38.580 MM 100 Kg 1. Select mature plants2. Collect the ripened fruits3. De-pulp the fruit to get seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage pointC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc15

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks43 (c) Collection <strong>of</strong> Paper mulberry seeds 11.023 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable plants2. Clearing the ground around the plants3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point43 (d) Collection <strong>of</strong> Balsa seeds 17.636 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable plants2. Clearing the ground around the trees3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point43 (e) Collection <strong>of</strong> Papitta seeds 33.009 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Clearing the ground around the plants3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point43 (f) Collection <strong>of</strong> Sterculia campanulataseeds55.115 MM 100 Kg 1. Selection <strong>of</strong> matured and desirable plants2. Clearing the ground around the plants3. Collection <strong>of</strong> seeds4. Cleaning, drying the seeds in sun shine and transport totemporary storage point43 (g) Collection <strong>of</strong> Eucalyptus seeds 10.000 MM 1 Kg 1. Selection <strong>of</strong> matured and desirable trees2. Clean the ground around the tree3. Collect the ripened fruits from the tree by shaking orlopping the terminal branches4. Collect the seeds from the fruit5. Cleaning, drying the seeds in sun shine and transport totemporary storage pointFor considerably large supplies or in poor years, rates may beincreased up to 50% for all seeds, as per GO(Rt.) No.1590/81/<strong>Forest</strong> dated 24-12-1981.GO(Rt.) No. 2965/Agri dated26-12-1966In either condition, 50%enhancement is allowed.V. Fire Protection44 Re-clearing outer boundaries <strong>of</strong>reserves to a width <strong>of</strong> 6 m to 7 m6.210 to7.452 MMKm 1. Re-clear the boundary using knife to a width <strong>of</strong> 6 m to 7 m2. Ensure that the width <strong>of</strong> cleared boundary is 6 m to 7 mC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc16

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks45 Re-clearing the enclosure boundaries <strong>of</strong>Reserves, preliminary demarcatedboundaries <strong>of</strong> proposed reserves,plantation boundaries, etc., to a width<strong>of</strong> 3 m46 (a) Re-erecting boundary cairns (full size)completely damaged46 (b) Re-erecting boundary cairns (full size)partly damaged3.726 MM Km 1. Re-clearing the boundary using knife to a width <strong>of</strong> 3 m andmeasure the length2. Ensure that the width <strong>of</strong> cleared boundary is 3 m1.000 MM Each 1. Locate the completely damaged boundary cairn2. Re-erect the boundary cairn (full size) in accordance withthe approved specifications i.e., 120 x 120 cm at top, 60cm x 60 cm at bottom and 120 cm height0.500 MM Each 1. Locate the completely damaged boundary cairn2. Re-erect the boundary cairn (full size) in accordance withthe approved specifications i.e., 120 x 120 cm at top, 60cm x 60 cm at bottom and 120 cm height47 Re-clearing <strong>of</strong> coupe lines 2.484 MM Km 1. Identify exact boundary <strong>of</strong> the coupe2. Re-clear the coupe line with knife up to ground level48 Clearing boundary line to a width <strong>of</strong>5.2 m20 MM Km 1. Clearing boundary line using knife2. Heaping the cleared materials to the middle portion3. Ensure that the width <strong>of</strong> the cleared portion is 5.2 m48 (a) Fire Tracing 20 MM Km 1. Scrape 1.8 m on either side <strong>of</strong> cleared line2. Heap the scraped material to the middle portion <strong>of</strong> 1.6 m3. Burn the heaped material in the middle49 Frontier lines cutting and scraping 3 mwide guide line and burning50 Clearing growth on district boundary4.5 m wide51 Clearing boundary between Thekkadyand Kollengode private forest (3.6 m)9.935 MM Km 1. Cut the materials along the frontier line using knife2. Scrape 3 m wide guideline using mammatty3. Burning the debris without damaging the forest6.831 MM Km 1. Identify the district boundary2. Clearing the growth along the boundary to a width <strong>of</strong> 4.5 m3. Ensure the width <strong>of</strong> cleared line to be 4.5 mFor Reserve BoundaryFor interior coupe lineclearanceGO (Rt.) No. 614/75/AD dated05-03-1979GO (Rt.) No. 614/75/AD dated05-03-1979Fire tracing includes 17 ft(5.2 m) scraping 6 ft (180 cms)on either side and fire tracinga centre belt <strong>of</strong> 5 ft (150 cms48 (a) follows 48 as part <strong>of</strong> fireprotection worksNot in usual practiceNot in usual practice4.968 MM Km Not Required/ not in practicenowC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc17

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks52 Clearing guidance lines 2.5 m wide 3.415 MM Km 1. Lay out the guidance line2. Cut the weeds using knife to a width <strong>of</strong> 2.5 m3. Ensure the width to be 2.5 m53 Clearing guidance lines 3.6 m wide 4.657 MM Km 1. Lay out the guidance line2. Cut the weeds using knife to a width <strong>of</strong> 3.6 m3. Ensure the width to be 3.6 m53 (a) Burning cleared lines 2.4 m to 3.6 mwide0.310 MM Km 1. Burning cleared line 2.4 m to 3.6 m wide without spread <strong>of</strong>fire to the adjoining areas53 (b) Clearing guidelines 0.90 m to 1.5 wide 2.484 MM Km 1. Identify guide-line2. Clearing guideline 0.90 m to 1.5 m wide54 First burning lines between twoguidance lines1.863 MM Km 1. Make sure that the burning line between two guide line isready for burning2. Burn the fire without spread <strong>of</strong> fire to the adjoining area55 Second burning 1.242 MM Km 1. Heap the debris2. Second burning without spread <strong>of</strong> fire55 (a) Early burning grass area 2.471 MM 100 ha 1. Identify the area to burn by demarcating boundary2. After clearing guidelines around the boundary, carry outthe burning without spread <strong>of</strong> fire to the adjoining areas55 (b) Fire tracing wooden culverts andbridges56 Cutting internal boundaries <strong>of</strong>plantations 3.6 m wide1.000 MM 5 Nos. 1. Locate the wooden culverts and bridges which are to befire traced2. Clear the weeds and other vegetative matter around thewooden culvert / bridges by scraping with a mammatty toa width <strong>of</strong> 5.5 m4.657 MM Km 1. Clear a line at a width <strong>of</strong> 3.6 m using knife, along theprescribed direction and to the desired length.57 Clearing around buildings and colonies 9.884 MM Ha 1. Identify the portion to be cleared around buildings andcolonies2. Clear the surrounding by knife weeding as close to theground as possible58 Clearing footpath and bridge path 3.726 MM Km 1. Identify the footpath and bridle path2. Clear knife weeding along the footpath and bridle pathusing knifeThis item is intended forcontrol burning-do-Guidelines are to be takenwith the appropriate FSR itemThe width <strong>of</strong> clearance is notprovided in the item. Sincetrek path is taken with 1.5 mwidth, this width should be atleast 1.5 mC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc18

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description RemarksVI. Boat Work59 Scooping out logs in the shape <strong>of</strong> a boatby Axemen in Anjily or Jack60 Carpentry work such as neatlyfashioning into a boat and providingpaddles61 Extra to <strong>items</strong> 59 and 50 for boats inKambagom (25% extra)1500 Axemen Vannam Not in use1500carpenterVannamNot in use0.375 SMM Vannam Not in use62 Fish oiling the boat 1.5 MM Vannam Not in useVII. Other works63 Erecting temporary shed with junglewood posts, bamboos, reeds, etc.,clearing and levelling site, scraping andthatching with grass, etc.64 Clearing jungle growth on either side <strong>of</strong>the road (1.8 m on the upper and 0.9 mon the lower sides) once in a year65 Clearing jungle growth on either side <strong>of</strong>the road (1.8 m on the upper and 0.9 mon the lower sides) twice in a year66 Repairing the road surface by clearing,filling up ruts sectioning and forming,repairing side drains, etc., completedurign the year (once)66 (a) Cutting and removing wind fallen treesfrom Road – 76 cm to 120 cm girth10.763 MM 10 sq.m 1. Identify site for erecting the temporary shed2. Clearing the site using knife3. Scraping and levelling the site with mammatty4. Collect and transport to site the required jungle woodposts, bamboos, reeds etc.,5. Erect the temporary shed6. Thatching the shed with grass4.968 MM Km 1. Clearing jungle growth 1.8m wide on the upper side and0.9m wide on the lower side <strong>of</strong> the roads using knife.7.452 MM Km 1. Clearing jungle growth 1.8m wide on the upper side and0.9m wide on the lower side <strong>of</strong> the roads using knife twotimes a year.15.525 MM Km 1. Identify the portion <strong>of</strong> the road required repairs2. Clear the weeds on the road surface using knife3. Fill up the ruts using earth excavator from the adjoiningarea followed by sectioning, forming, repairing side drainsetc.,0.500AxemanPer tree 1. Mark the wind fallen trees2. Cut and remove the trees <strong>of</strong> size 76 cm to 120 cm from theroad surfaceC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc19

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description RemarksCutting and removing wind fallen treesfrom Road – 121 cm to 180 cm girthCutting and removing wind fallen treesfrom Road – over 180 cm girth66 (b) Cutting and removing bamboo clumpsup to 180 cm circumferenceCutting and removing bamboo clumps181 cm to 360 cm circumferenceCutting and removing bamboo clumpsabove 360 cm circumference1.000Axeman1.500AxemanPer tree 1. Mark the wind fallen trees2. Cut and remove the trees <strong>of</strong> size 121 cm to 180 cm fromthe road surfacePer tree 1. Mark the wind fallen trees2. Cut and remove the trees size over 180 cm from the roadsurfaceIf the wind fallen are useful and are to be converted as timberlogs and above expenditure should not be incurred, but theexpenditure should be incurred as per conversion rate1 MM Each 1. Identify the bamboo clumps to be removed2. Measure the circumference <strong>of</strong> the clumps3. Remove the clumps upto 180 cm circumference by diggingaround and uprooting the rhizomes2 MM Each 1. Identify the bamboo clumps to be removed2. Measure the circumference <strong>of</strong> the clumps3. Remove the clumps upto 181 cm to 360 cm circumferenceby digging around and uprooting the rhizomes3 MM Each 1. Identify the bamboo clumps to be removed2. Measure the circumference <strong>of</strong> the clumps3. Remove the clumps above 360 cm circumference by diggingaround and uprooting the rhizomes67 Special clearing <strong>of</strong> side drains 2.484 MM Km 1. Identify the side drain2. Clear the drain <strong>of</strong> all materials obstructing water flowduring rains3. Measure the cleared length67 (a) Clearing vents <strong>of</strong> culverts, bridges andIrish drains68 Providing sign boards in plantation(60 cm X 30 cm X 30 cm size) excludingcost <strong>of</strong> timber0.375 MM Each 1. Clearing obstructions in vents <strong>of</strong> culverts, bridges and Irishdrains2. Removing the cleared materials1.000 SMM Board 1. Making sign boards <strong>of</strong> size (60 cm X 30 cm X 2.5 cm size)made <strong>of</strong> timber2. Painting the sign boards3. Writing the board4. Erecting the board in the required locationC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc20

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks68 (a) Providing Plantation Boards(22 cm X 10 cm X 2.5 cm size)excluding cost <strong>of</strong> timber0.167 SMM Board 1. Making sign boards <strong>of</strong> size (22 cm X 10 cm X 2.5 cm size)made <strong>of</strong> timber2. Painting the sign boards3. Writing the year, species, direction etc.,4. Erecting the board in the required location69 (a) Girdling trees below 150 cm girth 15 MM 100 trees 1. Identify and mark the trees below 150 cm girth2. Removing bark and sapwood to a width <strong>of</strong> 30 cm aroundthe tree at the base <strong>of</strong> the tree69 (b) Girdling trees 150 cm and above 25 MM 100 trees 1. Identify and mark the trees 150 cm and above2. Removing bark and sapwood to a width <strong>of</strong> 30 cm aroundthe tree at the base <strong>of</strong> the tree69 (c) Poisoning trees after girdling (labouronly)70 (a) Conversion and classification <strong>of</strong> teakpoles I Class2 MM 100 trees Not in practice0.083AxemanPole 1. Identify the poles2. Dress the pole by lopping <strong>of</strong>f the branches and the topportion3. Take measurements for the purpose <strong>of</strong> classification andclassify70 (b) Haulage up to 400 m 0.875 MM Pole 1. Manual dragging <strong>of</strong> poles to the dumping site upto 400 M71 (a) Conversion and classification <strong>of</strong> II ClassPoles0.063 MM Pole 1. Identify the poles2. Dress the pole by lopping <strong>of</strong>f the branches and the topportion3. Take measurements for the purpose <strong>of</strong> classification andclassify71 (b) Haulage up to 400 m 0.656 MM Pole 1. Manual dragging <strong>of</strong> poles to the dumping site upto 400 M72 (a) Conversion and classification <strong>of</strong> III ClassPoles0.042AxemanPole 1. Identify the poles2. Dress the pole by lopping <strong>of</strong>f the branches and the topportion3. Take measurements for the purpose <strong>of</strong> classification andclassify72 (b) Haulage up to 400 m 0.438 MM Pole 1. Manual dragging <strong>of</strong> poles to the dumping site upto 400 MC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc21

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks73 (a) Conversion and classification <strong>of</strong> IV ClassPoles0.033AxemanPole 1. Identify the poles2. Dress the pole by lopping <strong>of</strong>f the branches and the topportion3. Take measurements for the purpose <strong>of</strong> classification andclassify73 (b) Haulage up to 400 m 0.15 MM Pole 1. Manual dragging <strong>of</strong> poles to the dumping site upto 400 M74 (a) Conversion and classification <strong>of</strong> V ClassPoles (No chiselling either number orclass)0.017AxemanPole 1. Identify the poles2. Dress the pole by lopping <strong>of</strong>f the branches and the topportion3. Take measurements for the purpose <strong>of</strong> classification andclassify74 (b) Haulage up to 400 m 0.075 MM Pole 1. Manual dragging <strong>of</strong> poles to the dumping site upto 400 M74 (c) Collection <strong>of</strong> Kappukals 0.025 MM Pole 1. Collection <strong>of</strong> small sized poles below 5 th class by trimming<strong>of</strong>f side branches74 (d) Haulage <strong>of</strong> Kappukals 0.025 MM Pole 1. Tie few Kappukals together for dragging2. Manual dragging <strong>of</strong> the Kappukals from the site up to 400mItems 70 to 74 (for haulage over 400 m25% <strong>of</strong> the rate may be added everyadditional 200 m)75 Dibbling seeds <strong>of</strong> any species at 1.8 mapart in crow-bar holes76 (a) Pit planting seedlings <strong>of</strong> any species 0.5 MM1.0 WMItems 70 to 74 (for haulage over 400 m 25% <strong>of</strong> the rate may beadded every additional 200 m)6.177 MM Ha 1. Identify the location for dibbling2. Make crow bar holes at 1.8 M interval to a depth <strong>of</strong> thesize <strong>of</strong> the seed3. Dibble the seed in crow bar holes and cover100 plant 1. Carry the seedling to the taken pits2. Cover the pit and dig a planting hole3. Plant the seedlings in the planting hole and compact thesoil around the seedling76 (b) 1. Pitting in ordinary soil 0.706 MM Cum 1. Locating the pit points2. Pitting to the required size3. Measure and check the size <strong>of</strong> the pitsThis item is not in practiceNot in practice. For roottrainerseedlings, only gentlepressing is sufficient.A general provision for pitting.The rate is per M 3 . This isintended for planting whichare not specifically covered byother schedule <strong>items</strong>.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc22

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks2. Pitting in hard soil 1.059 MM Cum 1. Locating the pit points2. Pitting to the required size in the hard soil3. Measure and check the size <strong>of</strong> the pits76 (c) Pit planting coconut seedlings 3.500 MM 100plants76 (d) Opening the base <strong>of</strong> the coconut palmto a radius <strong>of</strong> 1.2 m and heaping thesoil along the periphery76 (e) Opening the base <strong>of</strong> young coconutplant and covering with earth aftermanuring76 (f) Ploughing the ground one round incoconut tope77 Basketing, dibbling seeds or plantingseedlings after filling the baskets withthe required soil, sand, manure, etc.77 (a) Cost <strong>of</strong> bamboo and basket10 cm X 23 cm supply at nursery site77 (b) Cost <strong>of</strong> bamboo and basket10 cm X 15 cm supply at nursery site78 Clearing climber cutting, stubbing outunwanted species from coppice coupe79 Clearing strip lines (3 m wide & 20 m)apart in strip generation coupe1. Covering pits to the requires depth2. Planting coconut seedlings in the pit0.066 MM Each 1. Open the base <strong>of</strong> coconut palm to a radius <strong>of</strong> 1.2 m2. Heap the soil along the periphery to form a bund0.050 MM Each 1. Open the base <strong>of</strong> young coconut plant2. Soil working and manuring3. Covering with earth after manuring6.177 MM +hire <strong>of</strong> bull2 MM 100plantsHa 1. Plough the ground one round using hired bulls in coconuttope2. Assess the extent ploughed1. Mix the soil and manure in the required proportion2. Fill the baskets with the mixture3. Water the filled baskets sufficiently4. Dibble the seeds or plants the seedlings in the wateredbaskets1.75 MM 100 Nos. 1. Supply <strong>of</strong> bamboo baskets <strong>of</strong> size 10 cm X 23 cm at nurserysite2. Assess the size and number <strong>of</strong> bamboo baskets supplied atnursery site1.75 MM 100 Nos. 1. Supply <strong>of</strong> bamboo baskets <strong>of</strong> size 10 cm X 15 cm at nurserysite2. Assess the size and number <strong>of</strong> bamboo baskets supplied atnursery site12.355 MM Ha 1. Clearing the area by knife weeding as close to the ground2. Cut the climbers that grew onto the coppice shoots3. Remove unwanted species4.942 MM Ha 1. Mark points for making strip lines at 20 m apart forclearing strip lines2. From the marked point clear 1.5 m on either side to getthe strip line <strong>of</strong> width 3 m.A general provision for pitting.The rate is per M 3 . This isintended for planting whichare not specifically covered byother schedule <strong>items</strong>.Not in practice for coconutplanting.Not in practice for coconutplanting.Not in practice for coconutplanting.Not in practice for coconutplanting.Not in practice.Not in practiceNot in practiceNot generally in practice.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc23

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks82 Sowing seeds covering straw orPhyllanthus emplica and removing thecover after germination83 Fencing including collection <strong>of</strong>materials, planting posts 1.5 m apartwith 4 rows <strong>of</strong> bamboo reepers83 (a) - do - - do - and covering with reedor brushwood or thorns0.5 MM Bed 1. Loosen the top soil with mammatty2. Remove roots, muck, pebbles etc by hand3. Level top soil with wooden Levelling plank or othersuitable instrument4. Measure and fetch the required seeds5. Spread the seeds on the bed uniformly6. On top <strong>of</strong> the seeds, spread a thin layer <strong>of</strong> fine soilcollected from the side trenches.7. Gently compact the top layer <strong>of</strong> the soil and seeds below,with hands or wooden plank.8. Cut and fetch twigs <strong>of</strong> locally available weeds and spreadon top <strong>of</strong> the bed13.123 MM 100 RM 1. Cut and fetch junglewood poles and bamboos2. Cross-cut the poles to get 1.5 m long posts3. Split the bamboos to get 5 cm thick reepers4. Set out the line <strong>of</strong> fence and mark the post points at 1.5 minterval5. Dig pits <strong>of</strong> 30 cm depth at each post point, plant the postsin each pit and fill the pits.6. Fasten four rows <strong>of</strong> the reepers, each 30 cm apart from theother, to each <strong>of</strong> the posts, using coir rope or jungle fiber.13.123 MM 100 RM 1. Cut and fetch junglewood poles and reeds, brushwood orthorns2. Cross-cut the poles to get 1.5 m long posts3. Set out the line <strong>of</strong> fence and mark the post points at 1.5 minterval4. Dig pits <strong>of</strong> 30 cm depth at each post point, plant the postsin each pit and fill the pits.5. Fasten reeds, brushwood or thorns to the posts to a height<strong>of</strong> 1.2 m, using coir rope or jungle fiber.As per work study the rate forsowing is 0.479 mazdoors perstandard bed. Removal is notprovided. For sowing alonepart III notification item isapplicable. Including theremoval <strong>of</strong> cover, this rate canbe allowedC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc25

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks84 Providing shade pandal for nursery bedexcluding seigniorage <strong>of</strong> materials85 Providing platforms for keeping pot andbasket plantsTransport <strong>of</strong> bamboos upto a lead <strong>of</strong>3 kmCollection <strong>of</strong> 100 Nos. <strong>of</strong> pegs andpreparing thatties for nursery beds1 MM Bed 1. Cut and fetch junglewood poles and junglewood sticks orbamboos and thatching material2. Cross-cut the poles to get 1.5 m long posts3. If instead <strong>of</strong> sticks, bamboos are collected, split thebamboos to get 5cm thick reepers4. Plant the posts 30 cm deep, around the bed at 1.5 minterval5. Tie the sticks/reepers to the tops <strong>of</strong> the poles all aroundthe bed6. Tie the sticks/reepers to opposite pairs <strong>of</strong> poles across thebed and then, over this, tie four rows <strong>of</strong> sticks/reeperslengthwise in order to form a criss-cross frame to hold thethatching material7. Spread the thatching material over the structure and tie upsecurely.2 MM Bed 1. Clearing the site2. Laying out beds <strong>of</strong> size 12 m X 1.2 m with a gap <strong>of</strong> 40 cm inbetween3. Raising the bed surface 10 cm by scooping the earth fromthe gap and levelling the bed surface4. Collection <strong>of</strong> 30 cm long (minimum) pegs and reeds5. Fixing pegs along the sides <strong>of</strong> beds at 60 cm apart andtying two rows <strong>of</strong> reeds6. Check the measurement <strong>of</strong> beds1 MM 5 Nos. Manually bringing <strong>of</strong> bamboos to the site up to a lead <strong>of</strong> 3 km. GO(Rt.) No. 2509/80/AD dated09-09-19801 MM 100 pegs 1. Collection <strong>of</strong> pegs <strong>of</strong> suitable size (minimum 30 cm)2. Preparation <strong>of</strong> Thatties using the collected bamboosGO (Rt.) No. 2509/80/AD dated09-09-1980. These <strong>items</strong> arealready included in FSR itemNo. 81.IX. Regeneration86 Survey and layout <strong>of</strong> 2 ha plots afterburning0.247 MM Ha 1. Dividing the surveyed area into 2 ha plots using compass2. Collection <strong>of</strong> pegs and fixing stations with the pegsNot in practice. Used intaungya cultivation system todivide the area into plots.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc26

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks88 (e) Aligning and staking 5.5 m X 5.5 m or5.3 m X 5.2 m88 (f) Transport in head loads <strong>of</strong> tube orbasket plants from nursery site toplanting site up to 400 m88 (g) Transport in head loads <strong>of</strong> tube orbasket plants from nursery site toplanting site 400 m to 800 m88 (h) Transport in head loads <strong>of</strong> tube orbasket plants from nursery site toplanting site for every additional 400 m89 (a) Uprooting teak seedlings from nurseryand preparing stumps4.324 MM Ha 1. Lay out a base line8. Align with the help <strong>of</strong> alignment wire <strong>of</strong> sufficient length,graduated at intervals equal to espacement, i.e.,5.5 m X 5.5 m and 5.2 m X 5.2 m, basing on the baseline2. Fix stakes all along on the ground against the graduatedpoints.3. In slopes hold the alignment wire as horizontal as possible0.5 MM 100 1. Load sufficient number <strong>of</strong> plants in the head load baskets2. Taking the seedlings in baskets by head load upto adistance <strong>of</strong> 400 m3. Unload the plants intact without damaging the road systemand distribute to the planting pit.1 MM 100 4. Load sufficient number <strong>of</strong> plants in the head load baskets5. Taking the seedlings in baskets by head load upto adistance <strong>of</strong> 400 to 800 m1. Unload the plants intact without damaging the root systemand distribute to the planting pit.As per Minimum WagesNotification <strong>Schedule</strong> III, item(t) rate for 400 m transport is0.2789 Mazdoors, which is notsufficient. Since this is onlythe minimum rate to be giventhe rate provided here can beapplied since the other rate isnot practicableAs per Minimum WagesNotification <strong>Schedule</strong> III, item(t) rate for 400 m transport is0.2789 mazdoors which is notsufficient. Since this is onlythe minimum rate to be giventhe rate provided here can beapplied since the other rate isnot practicable0.25 100 Taking the seedlings by head load beyond a distance <strong>of</strong> 800 m. Increase <strong>of</strong> rate for everyadditional 400 m <strong>of</strong> distance,exceeding 800 m2 MM 1000 1. Pulling out seedlings one-by-one. If necessary, soil may beworked up by pick-axe before pulling.2. Count the seedlings, bundle them and transport to theplace where stumps have to be prepared3. Select good quality seedlings and prepare stumps with20 cm root portion and 2.54 cm shoot4. Trim-<strong>of</strong>f the side roots <strong>of</strong> the stump and stackWork study conducted. Therate as per minimum wages ishigher than the rate providedhere. Minimum wages <strong>items</strong>(d) and (e) to be followed.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc28

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks1. Uprooting bombax seedlings 1year old2. Uprooting bombax seedlings 2years old2 MM 1000 1. Pulling out seedlings one-by-one. If necessary, soil may beworked up by pick-axe before pulling.2. Count the seedlings, bundle them and transport to theplace where stumps have to be prepared3. Select good quality seedlings and prepare stumps with20 cm root portion and 2.54 cm shoot4. Trim-<strong>of</strong>f the side roots <strong>of</strong> the stump and stack3 MM 1000 1. Pulling out seedlings one-by-one. If necessary, soil may beworked up by pick-axe before pulling.2. Count the seedlings, bundle them and transport to theplace where stumps have to be prepared3. Select good quality seedlings and prepare stumps with20 cm root portion and 2.54 cm shoot4. Trim-<strong>of</strong>f the side roots <strong>of</strong> the stump and stack3. Uprooting other seedlings 1.5 MM 1000 1. Pulling out seedlings one-by-one. If necessary, soil may beworked up by pick-axe before pulling.2. Count the seedlings, bundle them and transport to theplace where stumps have to be prepared3. Select good quality seedlings and prepare stumps with20 cm root portion and 2.54 cm shoot4. Trim-<strong>of</strong>f the side roots <strong>of</strong> the stump and stack89 (b) Transport <strong>of</strong> stumps from nursery toplanting area up to 800 m lead89 (c) Transport <strong>of</strong> stumps from nursery toplanting area 800 m to 1600 m89 (d) Transport <strong>of</strong> seedlings from nursery toplanting area up to 800 m lead0.5 MM 1000 1. Load sufficient number <strong>of</strong> stumps in the head load baskets2. Taking the loaded baskets by head load up to a distance <strong>of</strong>800 m from nursery to the planting site.3. Unload the stumps without damaging them at the plantingsite0.75 MM 1000 1. Load sufficient number <strong>of</strong> stumps in the head load baskets4. Taking the loaded baskets by head load up to a distance <strong>of</strong>800 m to 1600 m from nursery to the planting site.2. Unload the stumps without damaging them at the plantingsite0.75 MM 1000 1. Load sufficient number <strong>of</strong> seedlings in the head loadbaskets2. Taking the loaded baskets by head load up to a distance <strong>of</strong>800 m to the planting site.3. Unload the seedlings without damaging them at theplanting siteThis item is intended for nakedseedlingsC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc29

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks89 (e) Transport <strong>of</strong> seedlings from nursery toplanting area 800 m to 1600 m89 (f) Transport in head loads <strong>of</strong> tube orbasket plants from nursery to plantingsite up to 400 m89 (g) Transport in head loads <strong>of</strong> tube orbasket plants from nursery to plantingsite 400 m to 800 m89 (h) Transport in head loads <strong>of</strong> tube orbasket plants from nursery to plantingsite for every additional 400 m90 (a) Planting stumps or seedlings in crowbarholes 2.5 m X 2.5 m90 (b) Planting stumps for seedlings incrowbar holes 2 m X 2 m1 MM 1000 1. Load sufficient number <strong>of</strong> seedlings in the head loadbaskets2. Taking the loaded baskets by head load up to a distance <strong>of</strong>800 m to 1600 m to the planting site.3. Unload the seedlings without damaging them at theplanting site0.5 MM1 MM10001000Description given in 88 (f)Description given in 88 (g)Not required as alreadycovered <strong>under</strong> <strong>items</strong> 88 (f),88 (g) and 88 (h) and hencethese <strong>items</strong> can be deleted.0.25 MMextra1000 Description given in 88 (h)2.5 MM 1000 1. Remove stake from planting point2. Dig with crowbar a hole <strong>of</strong> depth equal to the length <strong>of</strong> the<strong>of</strong> the stump3. Place one stump in the hole almost flush with the ground4. Compact the soil inside the hole by driving the crowbararound the hole and pressing the soil into it, so that thestump is firmly held vertically in the hole with only a smallportion <strong>of</strong> the shoot butting above the ground level5. Re-fix the stake in a slanting position near the stump6. Occasionally check whether the stump is firm, by gentlypulling the shoot portion up2 MM 1000 1. Remove stake from planting point2. Dig with crowbar a hole <strong>of</strong> depth equal to the length <strong>of</strong> the<strong>of</strong> the stump3. Place one stump in the hole almost flush with the ground4. Compact the soil inside the hole by driving the crowbararound the hole and pressing the soil into it, so that thestump is firmly held vertically in the hole with only a smallportion <strong>of</strong> the shoot butting above the ground level5. Re-fix the stake in a slanting position near the stump6. Occasionally check whether the stump is firm, by gentlypulling the shoot portion upMinimum wages rate (f) ismore and hence minimumwages rate is to be allowedi.e., 2.437 mazdoors can beallowed and this item can beomitted.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc30

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks90 (c) S<strong>of</strong>twood planting in crowbar holes3 m X 3 m90 (d) S<strong>of</strong>twood planting in crowbar holes7 m X 3 m90 (e) Under planting species like Mahagony,etc., by cutting lines 1 m in diameter10 m apart and planting 10 m apart inlines90 (f) Forming mounds and planting seedlingsor sowing seed3.5 MM 1000 1. Remove stake from planting point2. Dig with crowbar a hole <strong>of</strong> depth equal to the length <strong>of</strong> the<strong>of</strong> the stump3. Place one stump in the hole almost flush with the ground4. Compact the soil inside the hole by driving the crowbararound the hole and pressing the soil into it, so that thestump is firmly held vertically in the hole with only a smallportion <strong>of</strong> the shoot butting above the ground level5. Re-fix the stake in a slanting position near the stump6. Occasionally check whether the stump is firm, by gentlypulling the shoot portion up4 MM 1000 1. Remove stake from planting point2. Dig with crowbar a hole <strong>of</strong> depth equal to the length <strong>of</strong> the<strong>of</strong> the stump3. Place one stump in the hole almost flush with the ground4. Compact the soil inside the hole by driving the crowbararound the hole and pressing the soil into it, so that thestump is firmly held vertically in the hole with only a smallportion <strong>of</strong> the shoot butting above the ground level5. Re-fix the stake in a slanting position near the stump6. Occasionally check whether the stump is firm, by gentlypulling the shoot portion up4.942 MM 1000 1. Fix 10 m points along a baseline2. Weed 0.5 m on either side <strong>of</strong> this point to get a plantingline <strong>of</strong> width 1 m.3. Along this planting line, at every 10 m, plant the seedling3 MM 100mounds1. Forming mounds 45 cm diameter and 30 cm high2. Planting seedlings or sowing seeds on the mounds91 (a) Replacing casualties - Teak 0.617 MM Ha 1. Locating the points <strong>of</strong> causality2. Planting stump in crowbar holes at the located points91 (b) Replacing casualties - S<strong>of</strong>twood 1.235 MM Ha 1. Locating the points <strong>of</strong> casualty2. Planting stumps / seedlings in crowbar holes at the locatedpointsThis is not in practice. In thedescription, the word diameterseems to be intended forwidthC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc31

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks92 First year – First weeding (in May-June)mamatty weeding entire area93 First year – Second weeding (August-September) clear knife weedingincluding uprooting lantena, bamboos,etc.94 First year – Third weeding (December-January) clear knife weeding includinguprooting lantena, bamboos, etc. andscraping 30 cm around all plants about60 cm and soil working around plantsbelow 60 cm and mulching for allplantsNote: The above works are necessary ifthere is no Ponam cultivation wherethere is Ponam cultivation only item94 is to be done by the Department94 (a) Cutting back double leaders andpruning in the first and second year29.625 MM Ha 1. Scrape with mammaty the entire area, cutting <strong>of</strong>f theroots <strong>of</strong> all the weeds2. Heap the debris between planting lines along contours3. Cut and remove all the climbers which are twining onplants4. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds14.826 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Uproot all the lantana and bamboos4. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds9.884 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Uprooting lantana and bamboos4. Scraping 30 cm around plants above 60 cm in height5. Soil working and mulching for all plants6. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds4.942 MM Ha 1. With a sharp knife, cut <strong>of</strong>f with a slanting cut all theshoots except the most promising leading shoot, withoutdamaging the bark <strong>of</strong> the remaining shoot2. Avoid tearing away the half-cut shoots, instead make asecond cut and completely remove the cut shootsOnly weeding is possible withthe rate. Uprooting lantanaand bamboo is not workablewith the ratesIn the description <strong>of</strong> this item,uprooting lantana andbamboos, scraping 30 cm andsoil working 60 cm aroundplants are given. But if theseworks are also to be done, therate given will be tooinsufficient. Only weeding canbe done with this rateAs per Circular No. 12-23683/76 <strong>of</strong> the ChiefConservator <strong>of</strong> <strong>Forest</strong>s,pruning is banned. As perOrder No. P3-48876/80 dated13-08-1981 the ChiefConservator <strong>of</strong> <strong>Forest</strong>sclarified that this rate can beallowed for cutting backdouble leaders alone even ifpruning is not carried out.C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc32

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks94 (b) Additional weeding when foundnecessary4.942 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweedsThe rate is insufficient. Ratehas to be provided according tointensity <strong>of</strong> weeds95 Contingencies for ropes 0.25 MM Ha This item is to be deleted as itrelates to contingencies whichcan be decided by the DFO orthe CF concerned on the basis<strong>of</strong> local necessitiesSecond Year Weeding96 First weeding (in May-June) clear knifeweeding and uprooting bamboo,lantena etc.97 Second weeding (in August-September)clear knife weeding and uprootingbamboo, lantena etc.98 Third weeding (in December-January)knife weeding in line 60 cm on eitherside <strong>of</strong> the plant9.984 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Uproot all the lantana and bamboos4. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds7.413 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Uproot all the lantana and bamboos4. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds4.942 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible along the planting line to a width <strong>of</strong> 60 cm oneither side <strong>of</strong> the plants2. Cut and remove all the climbers which grew onto theplants3. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweedsUprooting lantana and bamboois not possibleUprooting lantana and bamboois not possibleThis type <strong>of</strong> line weeding isnot useful for the plantationand normally not practical alsoC:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc33

Sl. No. Description <strong>of</strong> Work Labour Unit <strong>Job</strong> Description Remarks98 (a) Additional weeding when foundnecessaryThird Year Weeding99 First weeding (in May-June) clear knifeweeding with uprootal <strong>of</strong> lantena,bamboo, etc.100 Second weeding (November-December)line weeding 60 cm on either side100 (a) Knife weeding eupatorium area afterthird year3.706 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds9.884 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Uproot all the lantana and bamboos4. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds3.706 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible along the planting line to a width <strong>of</strong> 60 cm oneither side <strong>of</strong> the plants2. Cut and remove all the climbers which grew onto theplants3. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds1. Heavy weed growth 24.710 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweeds2. Moderate weed growth 18.532 MM Ha 1. Cut <strong>of</strong>f the weeds with knife as close to the ground aspossible2. Cut and remove all the climbers which grew onto theplants3. Keep the immediate vicinity <strong>of</strong> the plants cleared <strong>of</strong>f allweedsIn practice, it is seen that rateis not workable. Weeding is tobe allowed as per intensity <strong>of</strong>the weeds.Uprooting lantana and bamboois not possibleThis type <strong>of</strong> line weeding isnot useful for the plantationand normally not practical alsoThis is applicable to densegrowth <strong>of</strong> Eupetorium withmore than 1.5 m height anddensity more than 0.8.This is applicable to densegrowth <strong>of</strong> Eupetorium withheight ranging from 1 m to1.5 m and density 0.4 to 0.8C:\Users\user1\Desktop\NTSajan\FSR Circular Plg2-18304 Dt 20-11-2004.doc34