Industrial Festooning Systems - Duct-O-Wire

Industrial Festooning Systems - Duct-O-Wire

Industrial Festooning Systems - Duct-O-Wire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

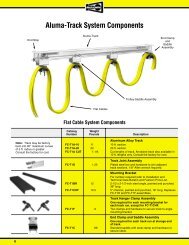

Aluma-Track System ComponentsEnd StopAluma-TrackEnd ClampandSaddleAssemblyTrolley-Saddle AssemblyFlat CablesFlat Cable System ComponentsCatalog WeightNumber Pounds DescriptionNote: Track may be factorybent into 90° maximum curvesof 5 ft. radius or greater.Consult the factory for cost.Aluminum Alloy TrackFC-T1A-10 11 10 ft. section.FC-T1A-20 22 20 ft. section.FC-T1A CUT 1.1/ft. Cut lengths of track. Anodized track also available in10 ft. lengths only. Consult the factory for cost.Track Joint AssemblyFC-T1D 1.25 Plated steel bar and hardware to join adjacenttrack sections. 1/8" Allen wrench required.Mounting BracketFor number required refer to Installation andTechnical Data Bulletin and Festoon Price List.FC-T1BR 12 2-1/2 x 2-1/2-inch steel angle, painted and punched,36" long.FC-T1CHF 10.5 5" channel, painted and punched, 18" long. ReplacesFC-T1D and FC-T1F assemblies.Track Hanger Clamp AssemblyOne required for each mounting bracket foreach track run, except for FC-T1CHF.FC-T1F .9 Two clamps and hardware to secure track to anglemounting bracket.End Clamp and Saddle AssemblyOne required for each track run at storage endof track.FC-T1C .88 Standard saddle with steel clamp and hardware tosecure cable.8