evaluat<strong>in</strong>g <strong>the</strong> air exchange rate with<strong>in</strong> <strong>the</strong> build<strong>in</strong>gs. The methods used to measure <strong>the</strong>ventilation per<strong>for</strong>mance <strong>of</strong> <strong>the</strong> build<strong>in</strong>g are described <strong>in</strong> this section.Build<strong>in</strong>g location and sit<strong>in</strong>g can <strong>in</strong>fluence <strong>the</strong> ventilation <strong>for</strong> a naturally ventilated build<strong>in</strong>g, but<strong>the</strong> focus <strong>of</strong> <strong>the</strong> assessment was on <strong>the</strong> build<strong>in</strong>g itself and <strong>the</strong> <strong>in</strong>ternal conditions. The w<strong>in</strong>dowgeometry proved to be a challenge. The effect <strong>of</strong> w<strong>in</strong>dow geometry has been studied to a limitedextent (Heiselberg 1999, 2001) but not specifically <strong>for</strong> <strong>the</strong> top hung awn<strong>in</strong>g-type w<strong>in</strong>dows thatare used <strong>in</strong> <strong>the</strong> prototype build<strong>in</strong>g. The awn<strong>in</strong>g-type w<strong>in</strong>dows are h<strong>in</strong>ged at <strong>the</strong> top, and are keptopen by friction at <strong>the</strong> h<strong>in</strong>ge. These w<strong>in</strong>dow types are used both <strong>for</strong> <strong>the</strong> smaller, upper w<strong>in</strong>dowsas well as <strong>for</strong> <strong>the</strong> lower, large occupant controlled w<strong>in</strong>dows. A method <strong>for</strong> determ<strong>in</strong><strong>in</strong>g <strong>the</strong>airflow rate <strong>of</strong> <strong>in</strong>com<strong>in</strong>g air and exhaust air had to be developed because natural ventilation <strong>in</strong>build<strong>in</strong>gs relies on external conditions to provide fresh air and remove <strong>in</strong>ternal heat ga<strong>in</strong>s, andw<strong>in</strong>d speed and direction can change quickly. This characteristic <strong>in</strong>creases <strong>the</strong> complexity <strong>of</strong>evaluat<strong>in</strong>g ventilation effectiveness. Part <strong>of</strong> <strong>the</strong> complexity lies <strong>in</strong> <strong>the</strong> effective open<strong>in</strong>g area <strong>of</strong><strong>the</strong> w<strong>in</strong>dow; it has both a horizontal area, as well as two vertical pieces, that can all affect <strong>the</strong>total airflow rate. Initially velocity measurements were taken <strong>in</strong> <strong>the</strong> horizontal plane us<strong>in</strong>g handheldhot-wire anemometers, as that dimension was determ<strong>in</strong>ed to be <strong>the</strong> largest contributor to<strong>in</strong>com<strong>in</strong>g and outgo<strong>in</strong>g airflow <strong>for</strong> <strong>the</strong> w<strong>in</strong>dow.The stack vents were a key design characteristic that had to be considered when evaluat<strong>in</strong>gventilation per<strong>for</strong>mance. The fans <strong>in</strong>tegrated <strong>in</strong> <strong>the</strong> stack vents were <strong>in</strong>cluded <strong>in</strong> <strong>the</strong> assessment.Hot-wire anemometers were used to measure <strong>the</strong> air velocity just outside <strong>the</strong> louvers from <strong>the</strong>exterior and just below <strong>the</strong> fan <strong>in</strong> <strong>the</strong> <strong>in</strong>terior. Measurements were taken under two conditions;with <strong>the</strong> fans on and <strong>of</strong>f. In addition, smoke pencils were used when tak<strong>in</strong>g measurements at <strong>the</strong>exterior to determ<strong>in</strong>e <strong>the</strong> direction <strong>of</strong> <strong>the</strong> airflow.Ano<strong>the</strong>r method employed to determ<strong>in</strong>e <strong>the</strong> ventilation rate <strong>of</strong> <strong>the</strong> prototype build<strong>in</strong>g was <strong>the</strong>monitor<strong>in</strong>g <strong>of</strong> carbon dioxide (CO 2 ) levels with<strong>in</strong> <strong>the</strong> occupied spaces us<strong>in</strong>g a Tel-Aire carbondioxide sensor, comb<strong>in</strong>ed with a HOBO® H8 series data recorder. Measur<strong>in</strong>g CO 2 can be used todeterm<strong>in</strong>e air exchange rates, and to evaluate <strong>in</strong>door air quality. Several groups have def<strong>in</strong>edmaximum acceptable levels <strong>of</strong> CO 2 <strong>for</strong> <strong>of</strong>fice spaces. Levels above 1,000 ppm can lead tolethargy and headaches (ems, 2004). However, both <strong>the</strong> United States OSHA (OccupationalSafety and Health Association) and <strong>the</strong> United K<strong>in</strong>gdome BSRIA (Build<strong>in</strong>g Services Researchand In<strong>for</strong>mation Association) have def<strong>in</strong>ed maximum exposure limits to be 800 ppm over aneight-hour period <strong>for</strong> <strong>of</strong>fice areas. The CO 2 level is dependent on <strong>the</strong> ventilation distribution,occupant density, and amount <strong>of</strong> outside air be<strong>in</strong>g <strong>in</strong>troduced <strong>in</strong>to <strong>the</strong> space (ASHRAE 2001).When evaluat<strong>in</strong>g <strong>the</strong> <strong>in</strong>door environment with respect to occupant health, ASHRAE suggeststhat an <strong>in</strong>door level <strong>of</strong> CO 2 650 ppm above <strong>the</strong> outside level is representative <strong>of</strong> an air exchangerate <strong>of</strong> 20 cubic feet per m<strong>in</strong>ute, with an occupant density <strong>of</strong> 100 ft 2 per person (ASHRAE 1997).Occupant com<strong>for</strong>t is also affected by higher CO 2 levels, with 20 percent <strong>of</strong> people dissatisfied atCO 2 concentrations <strong>of</strong> 650 ppm above <strong>the</strong> outdoor level (Liddament, 1996). In <strong>of</strong>fices, carbondioxide levels are primarily due to <strong>the</strong> respiration <strong>of</strong> <strong>the</strong> occupants. Initially <strong>the</strong> CO 2 andtemperature monitor was place outside, away from <strong>the</strong> build<strong>in</strong>g <strong>in</strong> order to record <strong>the</strong> externalconditions as a basel<strong>in</strong>e. Then <strong>the</strong> CO 2 sensor was placed at desk level, away from directexposure from an occupant, <strong>in</strong> <strong>the</strong> second floor <strong>of</strong>fice area and data recorded every fifteenm<strong>in</strong>utes over <strong>the</strong> twelve-month monitor<strong>in</strong>g period. On site visits, <strong>the</strong> number <strong>of</strong> people <strong>in</strong> each<strong>of</strong>fice area was logged over <strong>the</strong> period <strong>of</strong> <strong>the</strong> day and compared to <strong>the</strong> data recorded <strong>for</strong> that day.50

F<strong>in</strong>ally, airflow visualization was <strong>in</strong>cluded as part <strong>of</strong> <strong>the</strong> assessment <strong>of</strong> <strong>the</strong> build<strong>in</strong>g to improveunderstand<strong>in</strong>g <strong>of</strong> <strong>the</strong> characteristics <strong>of</strong> natural ventilation <strong>in</strong> <strong>the</strong> build<strong>in</strong>g design. Smoke pencilswere used <strong>for</strong> localized flow patterns throughout <strong>the</strong> build<strong>in</strong>g. These experiments proved to beuseful supplemental <strong>in</strong><strong>for</strong>mation <strong>in</strong> determ<strong>in</strong><strong>in</strong>g <strong>the</strong> airflow paths at <strong>the</strong> <strong>in</strong>let conditions, with<strong>in</strong><strong>the</strong> occupied space and atrium, and at <strong>the</strong> exhaust, but cannot be quantified reliably outside <strong>of</strong>laboratory conditions. Ano<strong>the</strong>r method with ‗neutrally buoyant‘ helium balloons was used totrack <strong>the</strong> airflow patterns with<strong>in</strong> <strong>the</strong> build<strong>in</strong>g. The neutrally buoyant balloons were made neutralat a selected height, which corresponded with a specific temperature. When <strong>the</strong> balloon wouldmove to an area <strong>of</strong> a different temperature, it would oscillate until reach<strong>in</strong>g <strong>the</strong> neutraltemperature aga<strong>in</strong> (Glicksman 2004). The balloons were <strong>the</strong>n released near <strong>the</strong> <strong>in</strong>let w<strong>in</strong>dows,and allowed to travel with<strong>in</strong> <strong>the</strong> build<strong>in</strong>g. The balloons normally ended up near <strong>the</strong> ro<strong>of</strong> <strong>of</strong> <strong>the</strong>atrium, <strong>the</strong> warmest location with<strong>in</strong> <strong>the</strong> build<strong>in</strong>g. However, this method did not producerepeatable results <strong>for</strong> specific streaml<strong>in</strong>es. The balloons were able to follow larger, macroscopicflow patterns with<strong>in</strong> <strong>the</strong> space, but had difficulty with low velocity airflow and detailed flowpatterns visible us<strong>in</strong>g <strong>the</strong> smoke pencils.3.3.1.3 Energy UsageThe occupancy schedule and energy usage pr<strong>of</strong>ile can be determ<strong>in</strong>ed by monitor<strong>in</strong>g <strong>the</strong> energyconsumption and usage patterns with<strong>in</strong> a build<strong>in</strong>g. The more detailed <strong>the</strong> meter<strong>in</strong>g <strong>of</strong> <strong>the</strong> electricenergy us<strong>in</strong>g equipment, <strong>the</strong> more thorough is <strong>the</strong> understand<strong>in</strong>g <strong>of</strong> <strong>the</strong> build<strong>in</strong>g energyper<strong>for</strong>mance. For <strong>the</strong> prototype build<strong>in</strong>g, not only <strong>the</strong> overall energy usage, but also a substantialamount <strong>of</strong> detailed monitor<strong>in</strong>g was completed. This detailed monitor<strong>in</strong>g <strong>in</strong>cluded data collectionon each floor level by orientation, miscellaneous build<strong>in</strong>g services, lifts, atrium fans andexternal/outside lights to determ<strong>in</strong>e <strong>the</strong>ir energy consumption. The energy usage <strong>for</strong> each floorcould not be separated out <strong>in</strong> more detail, e.g. lights versus plug loads, due to problems with<strong>in</strong>stallation <strong>of</strong> <strong>the</strong> data loggers <strong>in</strong> <strong>the</strong> electrical closets. Current transducers (CTs) were also<strong>in</strong>stalled on <strong>the</strong> actuators <strong>for</strong> <strong>the</strong> boiler so that <strong>the</strong>re was a measure <strong>of</strong> how <strong>of</strong>ten <strong>the</strong> boilers were<strong>in</strong> operation and <strong>the</strong>ir schedule <strong>of</strong> operation. Enernet K-20 electric energy data loggers were<strong>in</strong>stalled along with CTs <strong>of</strong> various sizes rang<strong>in</strong>g from 50 amps to 500 amps to capture energyusage data. CTs were <strong>in</strong>stalled on each <strong>of</strong> <strong>the</strong> three phases <strong>for</strong> each sub-system. Though <strong>the</strong> datawere recorded over <strong>the</strong> eighteen-month period, <strong>the</strong>re was still a 10 percent marg<strong>in</strong> <strong>of</strong> errorbetween <strong>the</strong> monitored data and <strong>the</strong> monthly energy bills. S<strong>in</strong>ce <strong>the</strong>re were a limited number <strong>of</strong>locations to <strong>in</strong>stall <strong>the</strong> K-20s, it is assumed that not every load was measured. Additionally, <strong>the</strong>total energy consumption was not recorded due to <strong>the</strong> limitation <strong>in</strong> size <strong>of</strong> CTs available and <strong>the</strong>location <strong>of</strong> <strong>the</strong> <strong>in</strong>com<strong>in</strong>g power supply. As a validation <strong>for</strong> <strong>the</strong> recorded data, energy us<strong>in</strong>gequipment and systems were <strong>in</strong>ventoried by a walk-through assessment <strong>of</strong> Houghton Hall <strong>for</strong>comparison.3.4 Issues with Assess<strong>in</strong>g a <strong>Natural</strong>ly Ventilated Build<strong>in</strong>gOverall naturally ventilated build<strong>in</strong>gs are more difficult to assess than <strong>the</strong>ir mechanicallyventilated counterparts, as <strong>the</strong>y have more temperature variation, vary<strong>in</strong>g ventilation rates thatare dependent on environmental conditions and w<strong>in</strong>dow geometry and less controlled airflowpatterns. This requires additional attention when determ<strong>in</strong><strong>in</strong>g air exchange rates, and <strong>in</strong> this case,<strong>the</strong> development and construction <strong>of</strong> a device to fit completely over <strong>the</strong> w<strong>in</strong>dow to obta<strong>in</strong> moreaccurate volume flow rate measurements.51

- Page 2 and 3: Thesis Committee:Leon R. Glicksman,

- Page 4 and 5: Table of ContentsTable of Contents

- Page 6 and 7: 7.1.3 Full Model Case .............

- Page 8 and 9: Figure 41. Wind Direction Data for

- Page 10 and 11: List of TablesTable 1. Energy End U

- Page 12 and 13: Table 64. Comparison of Dimensionle

- Page 15 and 16: Chapter 1.0IntroductionEnergy consu

- Page 17 and 18: insulated building envelopes with t

- Page 19 and 20: energy usage and efficient design.

- Page 21 and 22: Figure 3. European Patent Office Bu

- Page 23: selecting boundary conditions) to e

- Page 26 and 27: 2.2.1 Buoyancy-Driven VentilationVe

- Page 28 and 29: Figure 7. Neutral Pressure Level fo

- Page 30 and 31: Combined wind-buoyancy flow is more

- Page 32 and 33: design. The depth of natural ventil

- Page 34 and 35: of cooling required by 30 percent o

- Page 36 and 37: considered when determining how the

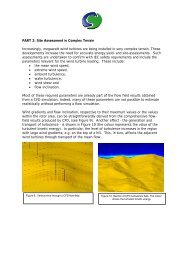

- Page 38 and 39: environmental conditions are examin

- Page 40 and 41: As natural ventilation is prevalent

- Page 43 and 44: Chapter 3.0Evaluation of Prototype

- Page 45 and 46: Figure 12. Interior Atrium ViewFigu

- Page 47 and 48: Table 8. Prototype Building Window

- Page 49: Figure 15. HOBO® H8 Series Tempera

- Page 53 and 54: only is the airflow almost never at

- Page 55 and 56: Table 10. Window Bag Device Measure

- Page 57 and 58: Mon 7-21Tue 7-22Wed 7-23Thu 7-24Fri

- Page 59 and 60: 12:00 AM1:00 AM2:00 AM3:00 AM4:00 A

- Page 61 and 62: 27-Jul27-Jul28-Jul28-Jul29-Jul30-Ju

- Page 63 and 64: A range of air exchange rates was f

- Page 65 and 66: the windows on the second floor, or

- Page 67 and 68: Total Electric (kWh/m2)Total Gas (k

- Page 69 and 70: movement, Houghton Hall has much le

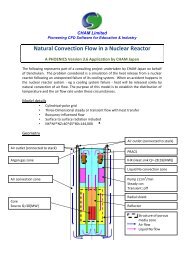

- Page 71 and 72: Chapter 4.0Modeling and Visualizati

- Page 73 and 74: for future design of similar type b

- Page 75 and 76: lower and upper openings and natura

- Page 77 and 78: the acceptable diffusion rate, or

- Page 79 and 80: applications involving full-scale b

- Page 81 and 82: digital camera with both manually o

- Page 83 and 84: Chapter 5.0Dimensional Analysis and

- Page 85 and 86: u oHgHT2uocu Hpo1Re Ar1Re Pr(5.7)(5

- Page 87 and 88: X HM X HP(5.16)5.3.2 Kinematic Sim

- Page 89 and 90: Radiation was found to have an impa

- Page 91: height is used for the full-scale b

- Page 94 and 95: 6.3 Model Descriptions6.3.1 Physica

- Page 96 and 97: Figure 30. Floor Plan of the Protot

- Page 98 and 99: Figure 31. North Facade of Model wi

- Page 100 and 101:

Monitoring data collected from the

- Page 102 and 103:

By default, there was no accounting

- Page 104 and 105:

40-location card inserted into the

- Page 106 and 107:

6.5 ExperimentsTo evaluate the mode

- Page 108 and 109:

modified to determine the impact of

- Page 110 and 111:

Figure 39. Two Heated Zone ModelWit

- Page 112 and 113:

minute interval, the model was assu

- Page 114 and 115:

Figure 42. Cross-Section of Wind-Ge

- Page 116 and 117:

Table 25. Wind-Assisted Ventilation

- Page 118 and 119:

Figure 44. Heaters and Zones for a)

- Page 120 and 121:

Height from Floor (m)Height from Fl

- Page 122 and 123:

Where V is the outlet velocity, A o

- Page 124 and 125:

Table 32. Conduction Heat Loss for

- Page 126 and 127:

a) Air Modelb) Water ModelFigure 50

- Page 128 and 129:

Height from Floor (m)The temperatur

- Page 130 and 131:

Height from Floor (m)In the atrium

- Page 132 and 133:

First NorthUpper Window 0.17 m/s -0

- Page 134 and 135:

Height from Floor (m)the column at

- Page 136 and 137:

Height from Floor (m)Height from Fl

- Page 138 and 139:

Height from Floor (m)3.53.02.52.01.

- Page 140 and 141:

was less than 12 percent. These val

- Page 142 and 143:

Table 39. Variation of Outlet Wind

- Page 144 and 145:

temperature of the air was the same

- Page 146 and 147:

3.532.521.55m/s4m/s3m/s2m/s1m/s1.5m

- Page 148 and 149:

3.532.521.55m/s4m/s3m/s2m/s1m/s1.5m

- Page 150 and 151:

The average and exhaust internal bu

- Page 152 and 153:

Table 43. Calculated Wind and Buoya

- Page 154 and 155:

In the last two lines, for both the

- Page 156 and 157:

Figure 80. CFD Simulation of the Te

- Page 158 and 159:

uoyancy case the air from the groun

- Page 160 and 161:

160

- Page 162 and 163:

windows of naturally ventilated bui

- Page 164 and 165:

difficult to select the boundary co

- Page 166 and 167:

simulations are able to do would al

- Page 168 and 169:

Bordass, W.T., A.K.R. Bromley and A

- Page 170 and 171:

Linddament, M. 1996. Why CO2? Air I

- Page 172 and 173:

172

- Page 174 and 175:

MODEL: K20-8SERIAL: 10047RECORDER_I

- Page 176 and 177:

2 Boiler-3 50.00 C1 N1 1.0 ON ON OF

- Page 178 and 179:

|PW|DESCRIP |KW |KWH|KVA|KVH|------

- Page 180 and 181:

2:5 ;day_ofYr17:P30 ;EOT = 0.000075

- Page 182 and 183:

2:3136:P30 ;DUM2 = -0.040891:-4.089

- Page 184 and 185:

;7:21 ;input location;8:0 ;mulptipl

- Page 186 and 187:

;79:P22 ;EXC w/DELAY (only for dela

- Page 188 and 189:

1:45 ;port5 (homeSense)2:31 ;exit l

- Page 190 and 191:

13:P95 ;ENDIF14:P95 ;ENDIF15:P3 ;pu

- Page 192 and 193:

2:20 ;RH30:P70 ;sample1:12:20 ;RH31

- Page 194 and 195:

194

- Page 196 and 197:

Five Windows Open: Upper versus Low

- Page 198 and 199:

One Window Open: Upper versus Lower

- Page 200 and 201:

25 cm / 3 m 24.33 26.62 22.68 22.93

- Page 202 and 203:

25 cm / 3 m 24.07 25.26 22.65 22.78

- Page 204 and 205:

Two Stacks Open Temperature Stratif

- Page 206 and 207:

Stacks Closed Temperature Stratific

- Page 208 and 209:

2.3 24.31 24.65 24.781.4 23.35 23.6

- Page 210 and 211:

0.6 20.56 20.67 20.94 21.22 21.41 2