Methodology for the Evaluation of Natural Ventilation in ... - Cham

Methodology for the Evaluation of Natural Ventilation in ... - Cham

Methodology for the Evaluation of Natural Ventilation in ... - Cham

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

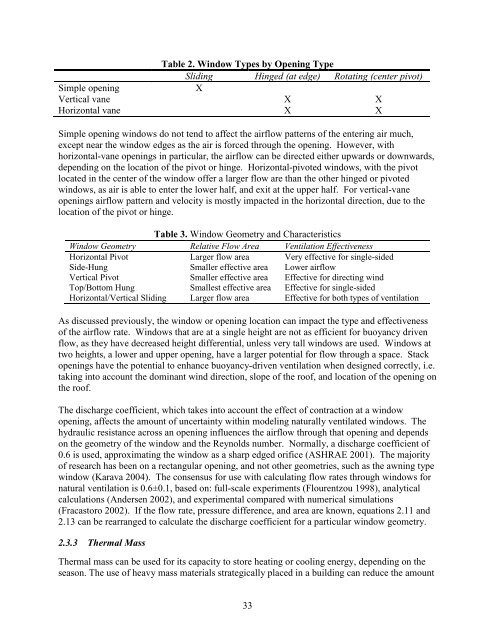

Table 2. W<strong>in</strong>dow Types by Open<strong>in</strong>g TypeSlid<strong>in</strong>g H<strong>in</strong>ged (at edge) Rotat<strong>in</strong>g (center pivot)Simple open<strong>in</strong>gXVertical vane X XHorizontal vane X XSimple open<strong>in</strong>g w<strong>in</strong>dows do not tend to affect <strong>the</strong> airflow patterns <strong>of</strong> <strong>the</strong> enter<strong>in</strong>g air much,except near <strong>the</strong> w<strong>in</strong>dow edges as <strong>the</strong> air is <strong>for</strong>ced through <strong>the</strong> open<strong>in</strong>g. However, withhorizontal-vane open<strong>in</strong>gs <strong>in</strong> particular, <strong>the</strong> airflow can be directed ei<strong>the</strong>r upwards or downwards,depend<strong>in</strong>g on <strong>the</strong> location <strong>of</strong> <strong>the</strong> pivot or h<strong>in</strong>ge. Horizontal-pivoted w<strong>in</strong>dows, with <strong>the</strong> pivotlocated <strong>in</strong> <strong>the</strong> center <strong>of</strong> <strong>the</strong> w<strong>in</strong>dow <strong>of</strong>fer a larger flow are than <strong>the</strong> o<strong>the</strong>r h<strong>in</strong>ged or pivotedw<strong>in</strong>dows, as air is able to enter <strong>the</strong> lower half, and exit at <strong>the</strong> upper half. For vertical-vaneopen<strong>in</strong>gs airflow pattern and velocity is mostly impacted <strong>in</strong> <strong>the</strong> horizontal direction, due to <strong>the</strong>location <strong>of</strong> <strong>the</strong> pivot or h<strong>in</strong>ge.Table 3. W<strong>in</strong>dow Geometry and CharacteristicsW<strong>in</strong>dow Geometry Relative Flow Area <strong>Ventilation</strong> EffectivenessHorizontal Pivot Larger flow area Very effective <strong>for</strong> s<strong>in</strong>gle-sidedSide-Hung Smaller effective area Lower airflowVertical Pivot Smaller effective area Effective <strong>for</strong> direct<strong>in</strong>g w<strong>in</strong>dTop/Bottom Hung Smallest effective area Effective <strong>for</strong> s<strong>in</strong>gle-sidedHorizontal/Vertical Slid<strong>in</strong>g Larger flow area Effective <strong>for</strong> both types <strong>of</strong> ventilationAs discussed previously, <strong>the</strong> w<strong>in</strong>dow or open<strong>in</strong>g location can impact <strong>the</strong> type and effectiveness<strong>of</strong> <strong>the</strong> airflow rate. W<strong>in</strong>dows that are at a s<strong>in</strong>gle height are not as efficient <strong>for</strong> buoyancy drivenflow, as <strong>the</strong>y have decreased height differential, unless very tall w<strong>in</strong>dows are used. W<strong>in</strong>dows attwo heights, a lower and upper open<strong>in</strong>g, have a larger potential <strong>for</strong> flow through a space. Stackopen<strong>in</strong>gs have <strong>the</strong> potential to enhance buoyancy-driven ventilation when designed correctly, i.e.tak<strong>in</strong>g <strong>in</strong>to account <strong>the</strong> dom<strong>in</strong>ant w<strong>in</strong>d direction, slope <strong>of</strong> <strong>the</strong> ro<strong>of</strong>, and location <strong>of</strong> <strong>the</strong> open<strong>in</strong>g on<strong>the</strong> ro<strong>of</strong>.The discharge coefficient, which takes <strong>in</strong>to account <strong>the</strong> effect <strong>of</strong> contraction at a w<strong>in</strong>dowopen<strong>in</strong>g, affects <strong>the</strong> amount <strong>of</strong> uncerta<strong>in</strong>ty with<strong>in</strong> model<strong>in</strong>g naturally ventilated w<strong>in</strong>dows. Thehydraulic resistance across an open<strong>in</strong>g <strong>in</strong>fluences <strong>the</strong> airflow through that open<strong>in</strong>g and dependson <strong>the</strong> geometry <strong>of</strong> <strong>the</strong> w<strong>in</strong>dow and <strong>the</strong> Reynolds number. Normally, a discharge coefficient <strong>of</strong>0.6 is used, approximat<strong>in</strong>g <strong>the</strong> w<strong>in</strong>dow as a sharp edged orifice (ASHRAE 2001). The majority<strong>of</strong> research has been on a rectangular open<strong>in</strong>g, and not o<strong>the</strong>r geometries, such as <strong>the</strong> awn<strong>in</strong>g typew<strong>in</strong>dow (Karava 2004). The consensus <strong>for</strong> use with calculat<strong>in</strong>g flow rates through w<strong>in</strong>dows <strong>for</strong>natural ventilation is 0.6±0.1, based on: full-scale experiments (Flourentzou 1998), analyticalcalculations (Andersen 2002), and experimental compared with numerical simulations(Fracastoro 2002). If <strong>the</strong> flow rate, pressure difference, and area are known, equations 2.11 and2.13 can be rearranged to calculate <strong>the</strong> discharge coefficient <strong>for</strong> a particular w<strong>in</strong>dow geometry.2.3.3 Thermal MassThermal mass can be used <strong>for</strong> its capacity to store heat<strong>in</strong>g or cool<strong>in</strong>g energy, depend<strong>in</strong>g on <strong>the</strong>season. The use <strong>of</strong> heavy mass materials strategically placed <strong>in</strong> a build<strong>in</strong>g can reduce <strong>the</strong> amount33