Wise Chem E-115 and E-212-F - English (A4) - Pyrotek

Wise Chem E-115 and E-212-F - English (A4) - Pyrotek

Wise Chem E-115 and E-212-F - English (A4) - Pyrotek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

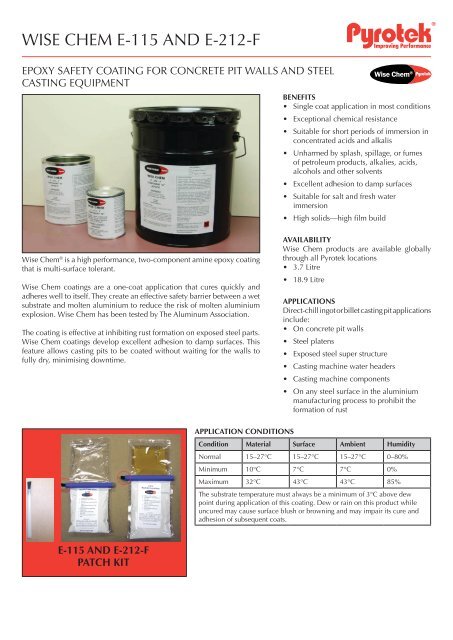

WISE CHEM E-<strong>115</strong> AND E-<strong>212</strong>-FEPOXY SAFETY COATING FOR CONCRETE PIT WALLS AND STEELCASTING EQUIPMENT<strong>Wise</strong> <strong>Chem</strong> ®BENEFITS• Single coat application in most conditions• Exceptional chemical resistance• Suitable for short periods of immersion inconcentrated acids <strong>and</strong> alkalis• Unharmed by splash, spillage, or fumesof petroleum products, alkalies, acids,alcohols <strong>and</strong> other solvents• Excellent adhesion to damp surfaces• Suitable for salt <strong>and</strong> fresh waterimmersion• High solids—high film build<strong>Wise</strong> <strong>Chem</strong> ® is a high performance, two-component amine epoxy coatingthat is multi-surface tolerant.<strong>Wise</strong> <strong>Chem</strong> coatings are a one-coat application that cures quickly <strong>and</strong>adheres well to itself. They create an effective safety barrier between a wetsubstrate <strong>and</strong> molten aluminium to reduce the risk of molten aluminiumexplosion. <strong>Wise</strong> <strong>Chem</strong> has been tested by The Aluminum Association.The coating is effective at inhibiting rust formation on exposed steel parts.<strong>Wise</strong> <strong>Chem</strong> coatings develop excellent adhesion to damp surfaces. Thisfeature allows casting pits to be coated without waiting for the walls tofully dry, minimising downtime.AVAILABILITY<strong>Wise</strong> <strong>Chem</strong> products are available globallythrough all <strong>Pyrotek</strong> locations• 3.7 Litre• 18.9 LitreAPPLICATIONSDirect-chill ingot or billet casting pit applicationsinclude:• On concrete pit walls• Steel platens• Exposed steel super structure• Casting machine water headers• Casting machine components• On any steel surface in the aluminiummanufacturing process to prohibit theformation of rustAPPLICATION CONDITIONSCondition Material Surface Ambient HumidityNormal 15–27°C 15–27°C 15–27°C 0–80%Minimum 10°C 7°C 7°C 0%Maximum 32°C 43°C 43°C 85%The substrate temperature must always be a minimum of 3°C above dewpoint during application of this coating. Dew or rain on this product whileuncured may cause surface blush or browning <strong>and</strong> may impair its cure <strong>and</strong>adhesion of subsequent coats.E-<strong>115</strong> AND E-<strong>212</strong>-FPATCH KIT

WISE CHEM E-<strong>115</strong> AND E-<strong>212</strong>-FPRODUCT SPECIFICATIONS<strong>Wise</strong> <strong>Chem</strong> E-<strong>115</strong>Color White WhiteFinish Flat Flat<strong>Wise</strong> <strong>Chem</strong> E-<strong>212</strong>-FPrimers Self-Priming Self-PrimingTop Coats Not Recommended Not RecommendedWet FilmThicknessConcrete 20 mils (500 microns) wetSteel 10–12 mils (250 microns)Make allowances for loss due to irregular surfaces.Brush out runs.Concrete 20 mils (500 microns) wetSteel 10–12 mils (250 microns)Make allowances for loss due to irregular surfaces.Brush out runs.Solids Content 99% = ± 0.5% by volume 93% = ± 0.5% by volumeCoverageVOC Values 0 grams/litre USA-EPA Method 24 118.6 grams/litre Method 24PerformanceSpecificationAdhesion (ASTM D4541)—ExcellentSalt Spray Resistance (ASTM B117)—Very GoodDirect Impact Resistance (ASTM D 2794)—Very GoodAbrasion Resistance (ASTM D 4060)—Very GoodHumidity Resistance (ASTM D 2247)—ExcellentWater Immersion (ASTM D 1308)—Excellent<strong>Chem</strong>ical Resistance (ASTM D 1308)—Very GoodAdhesion (ASTM D4541)—ExcellentSalt Spray Resistance (ASTM B117)—Very GoodDirect Impact Resistance (ASTM D 2794)—Very GoodAbrasion Resistance (ASTM D 4060)—Very GoodHumidity Resistance (ASTM D 2247)—ExcellentWater Immersion (ASTM D 1308)—Excellent<strong>Chem</strong>ical Resistance (ASTM D 1308)—Very GoodE-<strong>115</strong> CURING SCHEDULESurfaceTemperature<strong>and</strong> 50%RelativeHumidityDry to Recoat<strong>and</strong> TopcoatTime toImmersionFinal Cure7°C 12 hours 24 hours 168 hours16°C 8 hours 16 hours 168 hours24°C 6 hours 12 hours 168 hours32°C 4 hours 6 hours 168 hoursExposure to unacceptably low temperatures <strong>and</strong> / or highhumidities during, or immediately after application may resultin incomplete cure <strong>and</strong> surface contamination that could bedetrimental to subsequent intercoat adhesion.E-<strong>212</strong>-F CURING SCHEDULESurfaceTemperature<strong>and</strong> 50%RelativeHumidityDry to Recoat<strong>and</strong> TopcoatTime toImmersionFinal Cure7°C 48 hours 60 hours 200 hours16°C 16 hours 24 hours 180 hours24°C 8 hours 16 hours 168 hours32°C 6 hours 12 hours 120 hoursExposure to unacceptably low temperatures <strong>and</strong> / or highhumidities during, or immediately after application may resultin incomplete cure <strong>and</strong> surface contamination that could bedetrimental to subsequent intercoat adhesion.HEALTH AND SAFETYPrior to use, refer to the product safety data sheet (SDS) for proper h<strong>and</strong>ling<strong>and</strong> required personal protective equipment (PPE).<strong>Wise</strong> <strong>Chem</strong> ® is a registered trademark of <strong>Wise</strong> <strong>Chem</strong> LLC.Note: The physical <strong>and</strong> chemical properties listed represent typical, average values obtained in accordancewith accepted test methods <strong>and</strong> are subject to normal manufacturing variations. They are supplied as atechnical service <strong>and</strong> are subject to change without notice.Product Type: 109Commodity Code: 07030Contact Information: www.pyrotek.info/locationsPYROTEK INC. • CORPORATE OFFICE • 9503 E. MONTGOMERY AVENUE • SPOKANE VALLEY, WA 99206, USA • P: 509-926-6<strong>212</strong> • F: 509-927-2408www.pyrotek.info • email: info@pyrotek.infoSEP-13-E4-694