BI Comb SGM.GB

BI Comb SGM.GB

BI Comb SGM.GB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

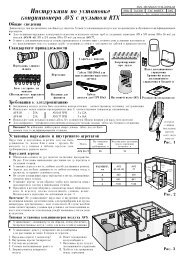

4.2 MAIN COMPONENTSThe feeder / mobile grate system is essentially made up of:- Storage hopper for granular fuel- Feed screw with relative motor and drive mechanisms- <strong>Comb</strong>ustion air fans with relative ducts- Furnace in combustion chamber- Mobile grate and its motor and drive mechanisms- Ash discharge screw with its movement mechanisms andash dump outlet damper4.2.1 STORAGE HOPPER FOR GRANULAR FUELFeaturing a cylindrical shape, it is fitted at the base with aleaf-spring scraper, driven by a gear motor. To remove thescraper in the event of breakage or blockage, simply removethe lower disk (pos. 6). Then, from inside the hopper, lift thescraper itself. To remove the gear motor, loosen the bolts(pos. 8) and remove the lower disk.Fig. 51 SMIM SEAL RING2 BUSH3 SPACER FLANGE4 SMIM STOP FLANGE5 GEAR MOTOR SHAFT6 LOWER DISK7 LOWER DISK FASTENING SCREW8 GEAR MOTOR FASTENING BOLTS9 LEAF SPRING SUPPORT WHEEL10 LEAF SPRING PACK11 LEAF SPRING FASTENING PLATES12 GEAR MOTOR13 UPPER LEVEL CONTROLLER14 LOWER LEVEL CONTROLLER15 LEVEL INSPECTION PORTHOLE16 ACCESS HATCH17 SEAL GASKET18 HATCH CLOSED LIMIT SWITCH19 PLATE FOR SETTING AUTO FEED20 INSPECTION AND EMPTYING DOOR21 SEAL GASKET22 DISCHARGE OUTLETThe maximum and minimum level sensors are rotating paddletype, flanged on corresponding stubs. The specific installationand operation booklets are enclosed with the documentation.A timer works together with the lower level controller to activatea fuel alarm. For the relative operating logic, see thewiring diagram.9