Download Spec Sheet PDF - X-Rite

Download Spec Sheet PDF - X-Rite Download Spec Sheet PDF - X-Rite

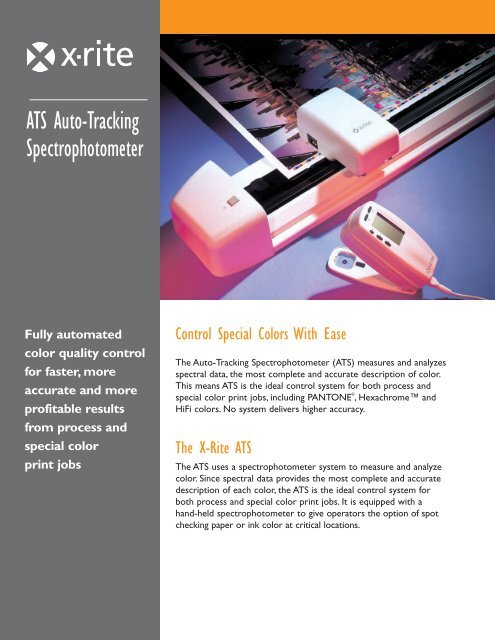

ATS Auto-TrackingSpectrophotometerFully automatedcolor quality controlfor faster, moreaccurate and moreprofitable resultsfrom process andspecial colorprint jobsControl Special Colors With EaseThe Auto-Tracking Spectrophotometer (ATS) measures and analyzesspectral data, the most complete and accurate description of color.This means ATS is the ideal control system for both process andspecial color print jobs, including PANTONE ® , Hexachrome andHiFi colors. No system delivers higher accuracy.The X-Rite ATSThe ATS uses a spectrophotometer system to measure and analyzecolor. Since spectral data provides the most complete and accuratedescription of each color, the ATS is the ideal control system forboth process and special color print jobs. It is equipped with ahand-held spectrophotometer to give operators the option of spotchecking paper or ink color at critical locations.

ATS Auto-Tracking<strong>Spec</strong>trophotometerFully automatedcolor quality controlfor faster, moreaccurate and moreprofitable resultsfrom process andspecial colorprint jobsControl <strong>Spec</strong>ial Colors With EaseThe Auto-Tracking <strong>Spec</strong>trophotometer (ATS) measures and analyzesspectral data, the most complete and accurate description of color.This means ATS is the ideal control system for both process andspecial color print jobs, including PANTONE ® , Hexachrome andHiFi colors. No system delivers higher accuracy.The X-<strong>Rite</strong> ATSThe ATS uses a spectrophotometer system to measure and analyzecolor. Since spectral data provides the most complete and accuratedescription of each color, the ATS is the ideal control system forboth process and special color print jobs. It is equipped with ahand-held spectrophotometer to give operators the option of spotchecking paper or ink color at critical locations.

Features• Put complete and accurate color informationat your fingertips.The systems allow you tozero-in on shop standard or customer suppliedcolor targets at make-ready, then keepthe color on-spec throughout the press run.When you need to repeat a run, the systemdatabase provides the color data required toget the reprint started and finished fast.• Help press crews set standard densities forany process color job.• Allow operators to select from industrystandard Status T, Status E or Status Idensity response.• Offer one-button measurement of one ormultiple color bars providing the operatorfeedback on all printing units at a singleglance.The display automatically alerts presscrews to determine if a single ink key needsreadjustment or if the sweep needs to bechanged across a unit.• Automatically find and measure the colorbar, even if the press sheet is misaligned.• Display measured versus standard densitiesfor all ink keys at a glance.• At the end of each run, automatically generatecustomer verification reports detailingcritical color information, including colorreproduction data, color tolerances andmuch more.• Hand-held spectrophotometer,allowing operatorsto measure anycustomersuppliedsampleas a standardcolor.BenefitsATS allows operators to set target densitiesfor non-process and special colors using acustomized density response based on eachink’s unique color properties.This lets youmonitor and control special colors using familiardensitometer functions like density and dot gain.<strong>Spec</strong>tral color measurement and advanced datareporting and exporting capabilities make this asystem you can build on as you invest in newpress models and print technologies.Because a substrate can have a dramatic impacton printed ink colors, paper color can also beanalyzed throughout a press run. <strong>Spec</strong>ial colormatching to PANTONE ® references can be easilycompared by using the reference library providedwith the ATS system.<strong>Spec</strong>ificationsProduct includes Windows ® -baseddata acquisition software, and severalstandard, measurable test-image files.System Requirements450Mhz or higher classcomputer running Windows ®98/NT4/2000, hard drive space forapplication and data, and free serialport for connection to ATS hardware.Measuring Geometry45°/0° per ANSI PH2.17Light SourceGas Pressure @ 2850°K<strong>Spec</strong>tral SensorDRS Technology (31pt)<strong>Spec</strong>tral Range400nm - 700nmReflectance Range0 - 200%RRepeatability On White0.2 DE max. ±0.01 Density max.0.4 DE max. ±0.01 Density max. PolarizedDensity Reproducibility±0.02 Density @ 1.5 DensityDensity Range0-2.5DCalibrationAutomaticScan Spot Size(Total Scanned Spot)3.0mm (.118") x 3.5mm (.138") Large2.3mm (.091") x 3.5mm (.138") Med1.2mm (.047") x 3.5mm (.138") SmallPolarization FilterFactory option for Large andMedium apertures only.Patch Width (along scan path)3.8mm (.15") min.Patch Height5.0mm (.20") min. Large3.2mm (.128") min. Med2.0mm (.078") min. SmallPaper Thickness1.5mm (.06") max.Scanning Rate150mm/sec. (6.8mm patch)100mm/sec. (4.8 mm patch)Scanning Width AvailableATS40 standard: 1016mm (40")Other sizes available to fitcommon press configurations.Color Bar LocationPaper edge to 38mm (1.5")from edgeColor Bar AlignmentAutomatic centering ofmeasurement on color bar.Paper set against stop.Paper Hold DownVacuum activated withmeasurement commandPower Required Station110 / 240 VAC, 50-60 Hz, 4/2APump115 / 230 VAC, 50-60 Hz, 4/2AINFORMATION PROVIDED IN THIS DOCUMENT IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED WARRANTIES OFMERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE. The user assumes the entire risk as to the accuracy and the use of this information. Alltext must be copied without modification and all pages must be included. All components of this information must be distributed together. This informationmay not be distributed for profit. X-<strong>Rite</strong>® are registered trademarks of X-<strong>Rite</strong>, Incorporated. Other brand and product names are trademarks of their respectiveholders. All trademarks may be registered in the United States and/or other countries. Product design and specifications subject to change without notice.© X-<strong>Rite</strong>, Incorporated 2006.X-RITE GLOBAL HEADQUARTERSGrandville, Michigan USA • +1 616 534-7663 • +1 800 248-9748 • FAX +1 616 534-8960xrite.comL7-123 (07/06)4 3 2 1 X 75% 50% 75% 50% 75% 50% 75% 50% 4 3 2 1 P 2+4 2+3 3+4 P 1 2 3 4 50% 75% 50% 75% 50% 75% 50% 75% X 1X-<strong>Rite</strong> ® 2.0mm © 2001