Holistic Condition Monitoring for Wind Turbines - Bosch Rexroth

Holistic Condition Monitoring for Wind Turbines - Bosch Rexroth Holistic Condition Monitoring for Wind Turbines - Bosch Rexroth

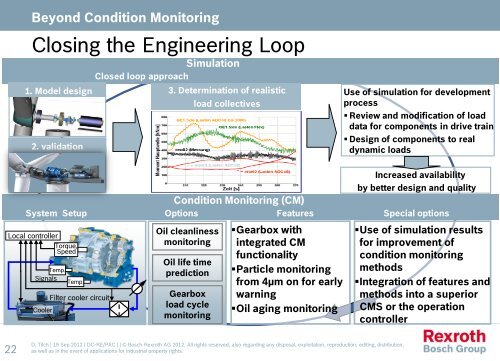

Beyond Condition MonitoringClosing the Engineering LoopSimulationClosed loop approach1. Model design 3. Determination of realisticload collectives2. validationUse of simulation for developmentprocess• Review and modification of loaddata for components in drive train• Design of components to realdynamic loadsLocal controllerTorque,SpeedTemp.SignalsTemp.CoolerFilter cooler circuitCondition Monitoring (CM)Oil cleanlinessmonitoringOil life timepredictionGearboxload cyclemonitoring•Gearbox withintegrated CMfunctionality•Particle monitoringfrom 4µm on for earlywarning•Oil aging monitoringIncreased availabilityby better design and qualitySystem Setup Options FeaturesSpecial options•Use of simulation resultsfor improvement ofcondition monitoringmethods•Integration of features andmethods into a superiorCMS or the operationcontroller22D. Tilch | 19 Sep 2012 | DC-RE/PAC | | © Bosch Rexroth AG 2012. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution,as well as in the event of applications for industrial property rights.

Holistic Condition Monitoring for Wind TurbinesContent• Introduction• Motivation for CMS and current CMS Status• The holistic Approach• Going beyond Condition Monitoring• Conclusion and outlook23D. Tilch | 19 Sep 2012 | DC-RE/PAC | | © Bosch Rexroth AG 2012. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution,as well as in the event of applications for industrial property rights.

- Page 1 and 2: Holistic Condition MonitoringSoluti

- Page 3 and 4: Bosch RexrothOur FocusMobileApplica

- Page 5 and 6: Condition Monitoring for Wind Turbi

- Page 7 and 8: Holistic Condition Monitoring for W

- Page 9 and 10: Holistic Condition Monitoring for W

- Page 11 and 12: Holistic Condition Monitoring for W

- Page 13 and 14: Holistic Condition Monitoring for W

- Page 15 and 16: Holistic Condition Monitoring for W

- Page 17 and 18: Holistic Condition Monitoring for W

- Page 19 and 20: Beyond Condition MonitoringDynamic

- Page 21: Torque [kNm]Beyond Condition Monito

Beyond <strong>Condition</strong> <strong>Monitoring</strong>Closing the Engineering LoopSimulationClosed loop approach1. Model design 3. Determination of realisticload collectives2. validationUse of simulation <strong>for</strong> developmentprocess• Review and modification of loaddata <strong>for</strong> components in drive train• Design of components to realdynamic loadsLocal controllerTorque,SpeedTemp.SignalsTemp.CoolerFilter cooler circuit<strong>Condition</strong> <strong>Monitoring</strong> (CM)Oil cleanlinessmonitoringOil life timepredictionGearboxload cyclemonitoring•Gearbox withintegrated CMfunctionality•Particle monitoringfrom 4µm on <strong>for</strong> earlywarning•Oil aging monitoringIncreased availabilityby better design and qualitySystem Setup Options FeaturesSpecial options•Use of simulation results<strong>for</strong> improvement ofcondition monitoringmethods•Integration of features andmethods into a superiorCMS or the operationcontroller22D. Tilch | 19 Sep 2012 | DC-RE/PAC | | © <strong>Bosch</strong> <strong>Rexroth</strong> AG 2012. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution,as well as in the event of applications <strong>for</strong> industrial property rights.