Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

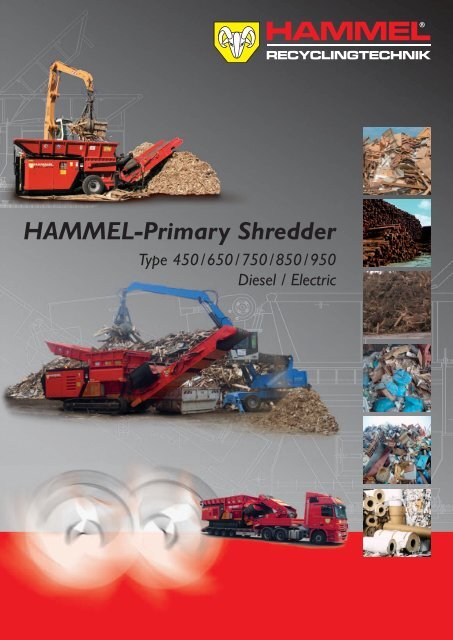

<strong>HAMMEL</strong>-<strong>Primary</strong> <strong>Shredder</strong>Type 450/650/750/850/950Diesel / Electric

„We proof power” –Technical specificationsThe <strong>HAMMEL</strong>- primary shredder processesextremely difficult materials like waste wood,railway sleepers, root stems, green waste,industrial- and bulky waste, paper rolls, tyres andcar bodies, etc. Due to its robust and clearconstruction the <strong>HAMMEL</strong>- shredder is reliablefor volume reduction. It is equipped with a slowspeed2-shaft-system. These shafts turn with aspeed of approx. max. 46 rpm.Therefore the <strong>HAMMEL</strong>- shredder belongs tothe extremely slow running shredders and has ahuge number of advantagesEngine performances450 D/DK 140 hp 450 E 110 kW650 D/DK 280 hp 650 E 160 kW750 D/DK 350 hp 750 E 260 kW850 D/DK 480 hp 850 E 320 kW950 DK 710 hp 950 E 500 kWWeights450 D/E 8t 450 DK 11 t650 D/E 16 t 650 DK 19 t750 D/E 17 t 750 DK 20 t850 D/E 25 t 850 DK 30 t950 E 30 t 950 DK 42 t

23*approx. valuesworking length* overall length(folded band)*Type 450: 7,50 m 6,05 mType 650: 9,70 m 8,03 mType 750: 9,70 m 8,18 mType 850: 11,40 m 9,64 mType 950: 15,00 m 12,67 m**overall height*Type 450: 2,10 mType 650: 2,70 mType 750: 2,70 mType 850: 3,00 mType 950: 3,20 moverall width*Type 450: 1,70 mType 650: 2,50 mType 750: 2,50 mType 850: 2,50 mType 950: 3,00 mADVANTAGES***high performancevery low noiseminimum of dust generationlong life time of the shredding toolsno projectilesno fire hazardcustomizedknives are welded on, not screwed on**illustration incl. special equipment***as special equipment available

The patented„2-shaft system“The special, counter-rotating shafts withaggressive hooks and knives pull in thematerial directly loaded onto the shafts.The input material is ripped, torn andcut and discharges directly from theshafts onto the conveyor belt.When extremely difficult material like carpetsand mattresses or root stems are processedand a hydraulic end pressure is reached, thehydraulically controlled shafts switchautomatically into reverse. Therefore theshafts turn backwards, and break thematerial again, clean the shaft from material,switch automatically again into the forwardmode and the normal shredding stage can becontinued without even being noticed by theoperator. This function guarantees that allmaterial was shredded before it enters thedischarge conveyor belt, and rolling up of anystringy material is avoided through this specialand fully automatic roll up protection.The shafts alwaysclean themselves. The finalsize of the shredded end productdepends on various shaft configuratons,<strong>HAMMEL</strong> can provide you with. Generally, anend product size between approx. 120–500 mm is achieved. Thanks to our long-termexperience in the wood and waste sector theshafts have a long life span of more thanthousand operating hours before refurbishingis needed.The shaft configuration is defined according to the input materialand the end product specifications of the customer.

1 234 5 645All inclusiveEvery <strong>HAMMEL</strong> - primary shredder is equipped with a high quality basic configuration tomeet your requirements.Basic configuration1. driveelectric or diesel engine2. transportabilitystationary build on hook lift frame3. pulling drawbarprovides a fast conversion ofthe shredder on the factory premises14. low sound emissionnoise-reducing construction5. remote controlwith different customizedfunctions6. tilting hopperfor ideal feeding2

We are born in wood!In 1984 the first <strong>HAMMEL</strong>-machine for shredding root stemswas developed. The wood waste recycling market has challengedus until today, so that our shredding technology has been adaptedto today s demands and makes the <strong>HAMMEL</strong>-shredder to aleading primary shredder for all kind of wood in the recyclingsector.We pass on our years of experience by finding the most suitableshaft configuration for every customer and needs.Very low wear and tear and energy consumption as well as highperformances are reached by sophisticated engineering andperfectly matching shafts.Innovation - Experience - Economy - Satisfaction

67Performance CharacteristicsRecyclingmaterial<strong>HAMMEL</strong> <strong>Shredder</strong> Typeprimary shredder *450 D/E 650 D/E 750 D/E 850 D/E 950 D/Ewood waste/demolition woodpalletsmixed woodcable drumsrailway sleeperstelephone polesroot stemsgreen waste* performances until approx.** up to Ø 400 mm*** up to Ø 1.000 mm10 t/h 30 t/h 60 t/h 120 t/h 230 t/h8 t/h 25 t/h 50 t/h 90 t/h 200 t/h12 t/h 30 t/h 60 t/h 100 t/h 190 t/h***6 t/h 25 t/h 40 t/h 60 t/h 130 t/h15 t/h 25 t/h 50 t/h 70 t/h15 t/h 25 t/h 50 t/h 70 t/h**8 t/h 25 t/h 40 t/h 50 t/h 90 t/h15 t/h 25 t/h 50 t/h 80 t/h 120 t/hWith a <strong>HAMMEL</strong>-primary shredder an end product size between 120 mm – 500 mmcan be reached depending on the selected shaft configuration.

„Contact us beforeyou drown in waste!”At the beginning of the 90's the <strong>HAMMEL</strong>-shredder has beenmodified according to the demands of the waste-shredding sector.Due to our long term experience in processing of different kindsof waste the <strong>HAMMEL</strong>-shredder was developed further to one of,if not the market leader.Various shaft configurations make it possible that the inputmaterials are pre-shredded to the requested end product size.Our <strong>HAMMEL</strong>-primary shredders find its use in incinerationplants - for fuel production and as primary shredders beforesorting lines or just for volume reduction. The input material ispre-shredded to a homogeneous end product by the 2-shaftsystemand is therefore perfectly prepared for furtherapplications.Volume Reduction - Renewable Energy - Profit

89Performance CharacteristicsRecyclingmaterial<strong>HAMMEL</strong> <strong>Shredder</strong> Typeprimary shredder *450 D/E 650 D/E 750 D/E 850 D/E 950 D/Edomestic wasteindustrial/commercial wastebulky wasteC&Dpaperpaper rollsused tyresaluminium profilescar bodieshigh caloric fuels 150 mm* performances up to approx.10 t/h 20 t/h 50 t/h 100 t/h 200 t/h45 t/h 80 t/h 150 t/h30 t/h 60 t/h 110 t/h35 t/h 80 t/h 150 t/h10 t/h 20 t/h 45 t/h 70 t/h10 t/h 15 t/h 30 t/h 60 t/h20 t/h 30 t/h 50 t/h5 t/h 12 t/h 20 t/h 40 t/h50 t/h20 t/h 30 t/h 70 t/hWith a <strong>HAMMEL</strong>-primary shredder an end product size between120 mm - 500 mm can be reached depending on the selected shaft configuration.

1 236 7 8 9Our innovations –Your choiceFor best resultsthe right equipment

5 59 10 111011Options1. metal separationpermanent- over belt magnet thatselects ferrous metal parts2. hopper extensiona higher volume avoids the droppingof the input material3. chassisstationary,wheel axle, track system4. breaker barwith and without combs or breaker basket,to produce a smaller end product5. water sprinkling systemfor dust minimisation6. particulate filterfor all diesel machines7. sickle fanprovides additionalnoise reduction8. hydraulically heightadjustment of the discharge beltfor a perfect adjustment of the dischargeheight for optimising of the discharge quantity9. alternative fuelalteration for use of bio-diesel,rape oil, etc.10. special paintingaccording to your company colour11. stone crusher specificationfor the shredding of stonesand concrete ties4444

<strong>HAMMEL</strong> – in GermanyBad Salzungen1104-0622/englisch/Hammel/H0054<strong>HAMMEL</strong> Recyclingtechnik GmbHLeimbacher Straße 103D-36433 Bad Salzungenphone: +49 (0) 36 95/69 91-0fax: +49 (0) 36 95/69 91-93Internet: www.hammel.dee-mail: info@hammel.de