vent-free natural gas freestanding pedestal stove system - Desa

vent-free natural gas freestanding pedestal stove system - Desa

vent-free natural gas freestanding pedestal stove system - Desa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

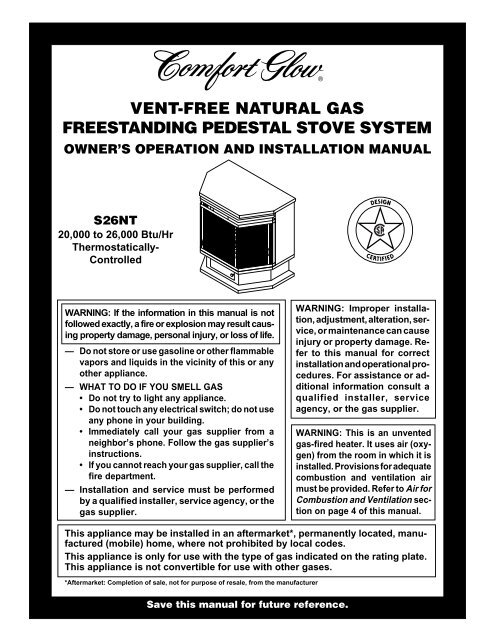

VENT-FREE NATURAL GASFREESTANDING PEDESTAL STOVE SYSTEMOWNER’S OPERATION AND INSTALLATION MANUALS26NT20,000 to 26,000 Btu/HrThermostatically-ControlledWARNING: If the information in this manual is notfollowed exactly, a fire or explosion may result causingproperty damage, personal injury, or loss of life.— Do not store or use <strong>gas</strong>oline or other flammablevapors and liquids in the vicinity of this or anyother appliance.— WHAT TO DO IF YOU SMELL GAS• Do not try to light any appliance.• Do not touch any electrical switch; do not useany phone in your building.• Immediately call your <strong>gas</strong> supplier from aneighbor’s phone. Follow the <strong>gas</strong> supplier’sinstructions.• If you cannot reach your <strong>gas</strong> supplier, call thefire department.— Installation and service must be performedby a qualified installer, service agency, or the<strong>gas</strong> supplier.WARNING: Improper installation,adjustment, alteration, service,or maintenance can causeinjury or property damage. Referto this manual for correctinstallation and operational procedures.For assistance or additionalinformation consult aqualified installer, serviceagency, or the <strong>gas</strong> supplier.WARNING: This is an un<strong>vent</strong>ed<strong>gas</strong>-fired heater. It uses air (oxygen)from the room in which it isinstalled. Provisions for adequatecombustion and <strong>vent</strong>ilation airmust be provided. Refer to Air forCombustion and Ventilation sectionon page 4 of this manual.This appliance may be installed in an aftermarket*, permanently located, manufactured(mobile) home, where not prohibited by local codes.This appliance is only for use with the type of <strong>gas</strong> indicated on the rating plate.This appliance is not convertible for use with other <strong>gas</strong>es.*Aftermarket: Completion of sale, not for purpose of resale, from the manufacturerSave this manual for future reference.

VENT-FREE NATURAL GAS PEDESTAL STOVESAFETYINFORMATIONWARNING ICON G 001WARNINGSIMPORTANT: Read this owner’smanual carefully and completelybefore trying to assemble, operate,or service this heater. Improperuse of this heater can causeserious injury or death from burns,fire, explosion, electrical shock,and carbon monoxide poisoning.DANGER: Carbon monoxidepoisoning may lead to death!Carbon Monoxide Poisoning: Early signs ofcarbon monoxide poisoning resemble the flu,with headaches, dizziness, or nausea. If youhave these signs, the heater may not be workingproperly. Get fresh air at once! Haveheater serviced. Some people are more affectedby carbon monoxide than others. Theseinclude pregnant women, people with heart orlung disease or anemia, those under the influenceof alcohol, and those at high altitudes.Natural Gas: Natural <strong>gas</strong> is odorless. Anodor-making agent is added to the <strong>gas</strong>. Theodor helps you detect a <strong>gas</strong> leak. However,the odor added to the <strong>gas</strong> can fade. Gas maybe present even though no odor exists.Make certain you read and understand allwarnings. Keep this manual for reference. Itis your guide to safe and proper operation ofthis heater.WARNING: Any change to thisfireplace or its controls can bedangerous.WARNING: Do not allow fansto blow directly into the heater.Avoid any drafts that alter burnerflame patterns. Ceiling fans cancreate drafts that alter burnerflame patterns. Altered burnerpatterns can cause sooting.WARNING: Do not use ablower insert, heat exchangerinsert, or other accessory not approvedfor use with this heater.Due to high temperatures, theappliance should be located outof traffic and away from furnitureand draperies.Do not place clothing or otherflammable material on or nearthe appliance. Never place anyobjects in the fireplace.Heater becomes very hot whenrunning fireplace. Keep childrenand adults away from hot surfacesto avoid burns or clothing ignition.Fireplace will remain hot for a timeafter shutdown. Allow surfaces tocool before touching.Carefully supervise young childrenwhen they are in the roomwith fireplace.You must operate this heater withthe heater screen in place. Makesure heater screen is in placebefore running heater.Keep the appliance area clear and<strong>free</strong> from combustible materials,<strong>gas</strong>oline, and other flammable vaporsand liquids.1. This appliance is only for use with thetype of <strong>gas</strong> indicated on the rating plate.This appliance is not convertible for usewith other <strong>gas</strong>es.2. If you smell <strong>gas</strong>• shut off <strong>gas</strong> supply• do not try to light any appliance• do not touch any electrical switch; donot use any phone in your building• immediately call your <strong>gas</strong> supplierfrom a neighbor’s phone. Follow the<strong>gas</strong> supplier’s instructions• if you cannot reach your <strong>gas</strong> supplier,call the fire department3. This heater shall not be installed in abedroom or bathroom.4. Do not use this heater as a wood-burningheater. Use only the logs providedwith the heater.5. Do not add extra logs or ornamentssuch as pine cones, vermiculite, or rockwool. Using these added items cancause sooting. Do not add lava rockaround base. Rock and debris could fallinto the control area of heater.6. This log heater is designed to be smokeless.If logs ever appear to smoke, turnoff heater and call a qualified serviceperson. Note: During initial operation,slight smoking could occur due to logcuring and heater burning manufacturingresidues.7. To pre<strong>vent</strong> the creation of soot, followthe instructions in Cleaning and Maintenance,page 13.8. Before using furniture polish, wax, carpetcleaners, or similar products, turnheater off. If heated, the vapors fromthese products may create a white powderresidue within burner box or onadjacent walls or furniture.9. This heater needs fresh, outside air <strong>vent</strong>ilationto run properly. This heater hasan Oxygen Depletion Sensing (ODS)safety shutoff <strong>system</strong>. The ODS shutsdown the heater if not enough fresh airis available. See Air for Combustionand Ventilation, pages 4 through 6. Ifheater keeps shutting off, see Troubleshooting,pages 14 through 16.10. Do not run heater• where flammable liquids or vaporsare used or stored• under dusty conditions11. Do not use this <strong>stove</strong> to cook food orburn paper or other objects.12. Do not use heater if any part has beenexposed to or under water. Immediatelycall a qualified service technician to inspectthe room heater and to replace anypart of the control <strong>system</strong> and any <strong>gas</strong>control which has been under water.13. Do not operate heater if any log is broken.Do not operate heater if a log ischipped (dime-sized or larger).14. Turn heater off and let cool before servicing.Only a qualified service personshould service and repair heater.15. Operating heater above elevations of4,500 feet could cause pilot outage.For more information, visit www.desatech.com2 105683

OWNER’S MANUALPRODUCTIDENTIFICATIONScreenStoveCabinetPRODUCTFEATURESSAFETY PILOTThis heater has a pilot with an Oxygen DepletionSensing (ODS) safety shutoff <strong>system</strong>.The ODS/pilot is a required feature for <strong>vent</strong><strong>free</strong>room heaters. The ODS/pilot shuts offthe heater if there is not enough fresh air.PIEZO IGNITION SYSTEMThis heater has a piezo ignitor. This <strong>system</strong>requires no matches, batteries, or othersources to light heater.LogsHeater Controls(Inside Door)Figure 1 - Vent-Free Natural Gas StoveLOCAL CODESInstall and use heater with care. Follow alllocal codes. In the absence of local codes, usethe latest edition of The National Fuel GasCode, ANS Z223.1, also known as NFPA 54*.*Available from:American National Standards Institute, Inc.1430 BroadwayNew York, NY 10018National Fire Protection Association, Inc.Batterymarch ParkQuincy, MA 02269This heater is designed for <strong>vent</strong>-<strong>free</strong> operation.State and local codes in some areasprohibit the use of <strong>vent</strong>-<strong>free</strong> heaters.UNPACKING1. Remove top inner pack.2. Tilt carton so that <strong>stove</strong> is upright.3. Remove protective side packaging.4. Slide <strong>stove</strong> out of carton.5. Remove protective plastic wrap.6. Remove screen by lifting and then pullingforward.7. Remove log set by cutting plastic ties.8. Carefully unwrap log.9. Check for any shipping damage. If<strong>stove</strong> or log is damaged, promptly informdealer where you bought <strong>stove</strong>.1056833For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVEAIR FORCOMBUSTION ANDVENTILATIONWARNING: This heater shallnot be installed in a confined spaceor unusually tight constructionunless provisions are providedfor adequate combustion and <strong>vent</strong>ilationair. Read the following instructionsto insure proper freshair for this and other fuel-burningappliances in your home.Today’s homes are built more energy efficientthan ever. New materials, increasedinsulation, and new construction methodshelp reduce heat loss in homes. Homeowners weather strip and caulk aroundwindows and doors to keep the cold air outand the warm air in. During heating months,home owners want their homes as airtightas possible.While it is good to make your home energyefficient, your home needs to breathe. Freshair must enter your home. All fuel-burningappliances need fresh air for proper combustionand <strong>vent</strong>ilation.Exhaust fans, heaters, clothes dryers, andfuel burning appliances draw air from thehouse to operate. You must provide adequatefresh air for these appliances. Thiswill insure proper <strong>vent</strong>ing of <strong>vent</strong>ed fuelburningappliances.PROVIDING ADEQUATEVENTILATIONThe following are excerpts from NationalFuel Gas Code, NFPA 54/ANS Z223.1, Section5.3, Air for Combustion and Ventilation.All spaces in homes fall into one of the threefollowing <strong>vent</strong>ilation classifications:1. Unusually Tight Construction2. Unconfined Space3. Confined SpaceThe information on pages 4 through 6 willhelp you classify your space and provideadequate <strong>vent</strong>ilation.Unusually Tight ConstructionThe air that leaks around doors and windowsmay provide enough fresh air forcombustion and <strong>vent</strong>ilation. However, inbuildings of unusually tight construction,you must provide additional fresh air.Unusually tight construction is definedas construction where:a. walls and ceilings exposed to theoutside atmosphere have a continuouswater vapor retarder witha rating of one perm (6 x 10 -11 kgper pa-sec-m 2 ) or less with openings<strong>gas</strong>keted or sealed andb. weather stripping has beenadded on openable windows anddoors andc. caulking or sealants are appliedto areas such as joints aroundwindow and door frames, betweensole plates and floors, betweenwall-ceiling joints, betweenwall panels, at penetrationsfor plumbing, electrical, and<strong>gas</strong> lines, and at other openings.If your home meets all of the threecriteria above, you must provide additionalfresh air. See Ventilation AirFrom Outdoors, page 6.If your home does not meet all of thethree criteria above, proceed to DeterminingFresh-Air Flow For HeaterLocation, page 5.Confined and Unconfined SpaceThe National Fuel Gas Code, ANS Z223.1defines a confined space as a space whosevolume is less than 50 cubic feet per 1,000Btu per hour (4.8 m 3 per kw) of the aggregateinput rating of all appliances installedin that space and an unconfining space as aspace whose volume is not less than 50cubic feet per 1,000 Btu per hour (4.8 m 3 perkw) of the aggregate input rating of allappliances installed in that space. Roomscommunicating directly with the space inwhich the appliances are installed*, throughopenings not furnished with doors, are considereda part of the unconfined space.This heater shall not be installed in a confinedspace or unusually tight constructionunless provisions are provided for adequatecombustion and <strong>vent</strong>ilation air.* Adjoining rooms are communicating onlyif there are doorless passageways or <strong>vent</strong>ilationgrills between them.For more information, visit www.desatech.com4 105683

OWNER’S MANUALAIR FORCOMBUSTION ANDVENTILATIONContinuedDETERMINING FRESH-AIR FLOW FOR HEATER LOCATIONDetermining if You Have a Confined or Unconfined SpaceUse this worksheet to determine if you have a confined or unconfined space.Space: Includes the room in which you will install heater plus any adjoining rooms with doorless passageways or <strong>vent</strong>ilation grills betweenthe rooms.1. Determine the volume of the space (length x width x height).Length x Width x Height = ____________________ cu. ft. (volume of space)Example: Space size 20 ft. (length) x 16 ft. (width) x 8 ft. (ceiling height) = 2560 cu. ft. (volume of space)If additional <strong>vent</strong>ilation to adjoining room is supplied with grills or openings, add the volume of these rooms to the total volume ofthe space.2. Divide the space volume by 50 cubic feet to determine the maximum Btu/Hr the space can support._________________ (volume of space) ÷ 50 cu. ft. = (Maximum Btu/Hr the space can support)Example: 2560 cu. ft. (volume of space) ÷ 50 cu. ft. = 51.2 or 51,200 (maximum Btu/Hr the space can support)3. Add the Btu/Hr of all fuel burning appliances in the space.Vent-<strong>free</strong> heater _________________Btu/HrGas water heater* _________________Btu/Hr Example:Gas furnace_________________Btu/Hr Gas water heater 30,000 Btu/HrVented <strong>gas</strong> heater _________________Btu/Hr Vent-<strong>free</strong> heater + 26,000 Btu/HrGas heater logs_________________Btu/Hr Total = 56,000 Btu/HrOther <strong>gas</strong> appliances* + _________________Btu/HrTotal = _________________Btu/Hr* Do not include direct-<strong>vent</strong> <strong>gas</strong> appliances. Direct-<strong>vent</strong> draws combustion air from the outdoors and <strong>vent</strong>s to the outdoors.4. Compare the maximum Btu/Hr the space can support with the actual amount of Btu/Hr used._________________ Btu/Hr (maximum the space can support)_________________ Btu/Hr (actual amount of Btu/Hr used)Example: 51,200 Btu/Hr (maximum the space can support)56,000 Btu/Hr (actual amount of Btu/Hr used)The space in the above example is a confined space because the actual Btu/Hr used is more than the maximum Btu/Hr the space can support.You must provide additional fresh air. Your options are as follows:A. Rework worksheet, adding the space of an adjoining room. If the extra space provides an unconfined space, remove door to adjoiningroom or add <strong>vent</strong>ilation grills between rooms. See Ventilation Air From Inside Building, page 6.B. Vent room directly to the outdoors. See Ventilation Air From Outdoors, page 6.C. Install a lower Btu/Hr heater, if lower Btu/Hr size makes room unconfined.If the actual Btu/Hr used is less than the maximum Btu/Hr the space can support, the space is an unconfined space. You will need noadditional fresh air <strong>vent</strong>ilation.WARNING: If the area in which the heater may be operated is smaller than that defined as an unconfined spaceor if the building is of unusually tight construction, provide adequate combustion and <strong>vent</strong>ilation air by one ofthe methods described in the National Fuel Gas Code, ANS Z223.1, Section 5.3 or applicable local codes.Continued1056835For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVEAIR FORCOMBUSTION ANDVENTILATIONContinuedVENTILATION AIRVentilation Air From InsideBuildingThis fresh air would come from an adjoiningunconfined space. When <strong>vent</strong>ilating to anadjoining unconfined space, you must providetwo permanent openings: one within12" of the ceiling and one within 12" of thefloor on the wall connecting the two spaces(see options 1 and 2, Figure 2). You can alsoremove door into adjoining room (see option3, Figure 2). Follow the National FuelGas Code, NFPA 54/ANS Z223.1, Section5.3, Air for Combustion and Ventilation forrequired size of <strong>vent</strong>ilation grills or ducts.WARNING: Rework worksheet,adding the space of theadjoining unconfined space. Thecombined spaces must haveenough fresh air to supply allappliances in both spaces.Ventilation Air From OutdoorsProvide extra fresh air by using <strong>vent</strong>ilationgrills or ducts. You must provide two permanentopenings: one within 12" of theceiling and one within 12" of the floor.Connect these items directly to the outdoorsor spaces open to the outdoors. These spacesinclude attics and crawl spaces. Follow theNational Fuel Gas Code, NFPA 54/ANSZ223.1, Section 5.3, Air for Combustion andVentilation for required size of <strong>vent</strong>ilationgrills or ducts.IMPORTANT: Do not provide openingsfor inlet or outlet air into attic if attic hasa thermostat-controlled power <strong>vent</strong>.Heated air entering the attic will activatethe power <strong>vent</strong>.VentilationGrillsInto AdjoiningRoom,Option 1Figure 2 - Ventilation Air from Inside BuildingOutletAirInletAirOrRemoveDoor intoAdjoiningRoom,Option3OutletAir12"Inlet AirFigure 3 - Ventilation Air from Outdoors12"Ventilation GrillsInto Adjoining Room,Option 2VentilatedAtticVentilatedCrawl SpaceTo AtticToCrawlSpaceFor more information, visit www.desatech.com6 105683

OWNER’S MANUALINSTALLATIONNOTICE: This heater is intendedfor use as supplemental heat. Usethis heater along with your primaryheating <strong>system</strong>. Do not installthis heater as your primaryheat source. If you have a centralheating <strong>system</strong>, you may run<strong>system</strong>’s circulating blower whileusing heater. This will help circulatethe heat throughout thehouse. In the e<strong>vent</strong> of a poweroutage, you can use this heateras your primary heat source.WARNING: A qualified serviceperson must install heater.Follow all local codes.WARNING: Never install theheater• in a bedroom or bathroom• in a recreational vehicle• where curtains, furniture,clothing, or other flammableobjects are less than 42 inchesfrom the front, top, or sides ofthe heater• in high traffic areas• in windy or drafty areasIMPORTANT: Vent-<strong>free</strong> heaters add moistureto the air. Although this is beneficial,installing heater in rooms without enough<strong>vent</strong>ilation air may cause mildew to formfrom too much moisture. See Air for Combustionand Ventilation, pages 4 through 6.CHECK GAS TYPEUse only <strong>natural</strong> <strong>gas</strong>. If your <strong>gas</strong> supply isnot <strong>natural</strong> <strong>gas</strong>, do not install heater. Calldealer where you bought heater for propertype heater.CLEARANCES TOCOMBUSTIBLES(Vent-Free Operation Only)WARNING: Maintain the minimumclearances. If you can, providegreater clearances fromfloor, ceiling, and adjoining sideand back walls.Front ViewSide Wall12"MinimumCeiling48"MinimumCarefully follow the instructions below. This<strong>stove</strong> is a <strong>free</strong>standing unit designed to setdirectly on the floor. IMPORTANT: Youmust maintain minimum wall and ceilingclearances during installation. The minimumclearances are shown in Figure 4.Measure from outermost point of <strong>stove</strong> top.Minimum Wall and CeilingClearances (see Figure 4)A. Clearances from outermost point of<strong>stove</strong> top to any combustible side wallshould not be less than 12 inches.B. Clearances from outermost point of<strong>stove</strong> top to any combustible back wallshould not be less than 6 inches (Includescorner installations).C. Clearances from the <strong>stove</strong> top to theceiling should not be less than 48inches.12"MinimumSide WallCAUTION: This heater createswarm air currents. Thesecurrents move heat to wall surfacesnext to heater. Installingheater next to vinyl or cloth wallcoverings or operating heaterwhere impurities (such as tobaccosmoke, aromatic candles,cleaning fluids, oil or kerosenelamps, etc.) in the air exist, maydiscolor walls.Side WallTop View12 "MinimumBack Wall6 "Minimum12 "MinimumSide WallCeiling48"MinimumSide ViewCornerWall6 "MinimumFront ofStove Unit6"MinimumBack WallWall6 "MinimumFigure 4 - Minimum Clearance to Walls and CeilingFloorContinued1056837For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVEINSTALLATIONContinuedCONNECTING TO GASSUPPLYWARNING: A qualified serviceperson must connect heater to <strong>gas</strong>supply. Follow all local codes.Installation Items NeededBefore installing heater, make sure you havethe items listed below.• piping (check local codes)• sealant (resistant to propane/LP <strong>gas</strong>)• equipment shutoff valve *• test gauge connection *• sediment trap• tee joint• pipe wrench* An CSA design-certified equipmentshutoff valve with 1/8" NPT tap is an acceptablealternative to test gauge connection.Purchase the optional CSA designcertifiedequipment shutoff valve from yourdealer. See Accessories, page 22.Back ViewWARNING: Never connectheater to private (non-utility) <strong>gas</strong>wells. This <strong>gas</strong> is commonlyknown as wellhead <strong>gas</strong>.CAUTION: Use only new,black iron or steel pipe. Internally-tinnedcopper tubing maybe used in certain areas. Checkyour local codes. Use pipe of 1/2"diameter or greater to allowproper <strong>gas</strong> volume to heater. Ifpipe is too small, undue loss ofpressure will occur.Installation must include an equipmentshutoff valve, union, and plugged 1/8" NPTtap. Locate NPT tap within reach for testgauge hook up. NPT tap must be upstreamfrom heater (see Figure 6).IMPORTANT: Install equipment shutoffvalve in an accessible location. The equipmentshutoff valve is for turning on orshutting off the <strong>gas</strong> to the appliance.From Gas Meter(5" W.C.** to 10.5"W.C. Pressure)Apply pipe joint sealant lightly to malethreads. This will pre<strong>vent</strong> excess sealantfrom going into pipe. Excess sealant in pipecould result in clogged heater valves.CAUTION: Use pipe joint sealantthat is resistant to liquid petroleum(LP) <strong>gas</strong>.We recommend that you install a sedimenttrap in supply line as shown in Figure 6.Locate sediment trap where it is withinreach for cleaning. Install in piping <strong>system</strong>between fuel supply and heater. Locate sedimenttrap where trapped matter is not likelyto <strong>free</strong>ze. A sediment trap traps moistureand contaminants. This keeps them fromgoing into heater controls. If sediment trapis not installed or is installed wrong, heatermay not run properly.CAUTION: Avoid damage toregulator. Hold <strong>gas</strong> regulator withwrench when connecting it to <strong>gas</strong>piping and/or fittings.CSA Design-Certified EquipmentShutoff Valve With 1/8" NPT Tap*Approved Flexible Gas Hose(if allowed by local codes)FrontofStoveUnitSide ViewGas RegulatorInlet ConnectionSedimentTrapTee JointPipeNippleCap3" MinimumGasRegulatorof HeaterFigure 6 - Gas Connection* Purchase the optional CSA design-certified equipment shutoff valve from your dealer.See Accessories, page 22.** Minimum inlet pressure for purpose of input adjustment.Figure 5 - Gas Regulator Location andGas Line Access Into Stove CabinetFor more information, visit www.desatech.com8 105683

OWNER’S MANUALINSTALLATIONContinuedCHECKING GASCONNECTIONSWARNING: Test all <strong>gas</strong> pipingand connections for leaksafter installing or servicing. Correctall leaks at once.WARNING: Never use an openflame to check for a leak. Apply amixture of liquid soap and waterto all joints. Bubbles forming showa leak. Correct all leaks at once.Pressure Testing Gas SupplyPiping SystemTest Pressures In Excess Of 1/2 PSIG(3.5 kPa)1. Disconnect appliance with its appliancemain <strong>gas</strong> valve (control valve) and equipmentshutoff valve from <strong>gas</strong> supply piping<strong>system</strong>. Pressures in excess of 1/2psig will damage heater regulator.2. Cap off open end of <strong>gas</strong> pipe whereequipment shutoff valve was connected.3. Pressurize supply piping <strong>system</strong> by eitherusing compressed air or openingmain <strong>gas</strong> valve located on or near <strong>gas</strong>meter.4. Check all joints of <strong>gas</strong> supply piping<strong>system</strong>. Apply mixture of liquid soapand water to <strong>gas</strong> joints. Bubbles formingshow a leak.5. Correct all leaks at once.6. Reconnect heater and equipmentshutoff valve to <strong>gas</strong> supply. Check reconnectedfittings for leaks.Test Pressures Equal To or Less Than1/2 PSIG (3.5 kPa)1. Close equipment shutoff valve (see Figure7).2. Pressurize supply piping <strong>system</strong> by eitherusing compressed air or openingmain <strong>gas</strong> valve located on or near <strong>gas</strong>meter.3. Check all joints from <strong>gas</strong> meter toequipment shutoff valve (see Figure 8).Apply mixture of liquid soap and waterto <strong>gas</strong> joints. Bubbles forming show aleak.4. Correct all leaks at once.ONPOSITEquipmentShutoffValveOPOS ClosedFigure 7- Equipment Shutoff ValveGas MeterOpenEquipment ShutoffValveFigure 8 - Checking Gas JointsControl Valve LocationPressure Testing Heater GasConnections1. Open equipment shutoff valve (see Figure7).2. Open main <strong>gas</strong> valve located on or near<strong>gas</strong> meter.3. Make sure control knob of heater is inthe OFF position.4. Check all joints from equipment shutoffvalve to control valve (see Figure 8).Apply mixture of liquid soap and waterto <strong>gas</strong> joints. Bubbles forming showa leak.5. Correct all leaks at once.6. Light heater (see Operating Heater,pages 11 and 12). Check all other internaljoints for leaks.7. Turn off heater (see To Turn Off Gas toAppliance, page 12).1056839ContinuedFor more information, visit www.desatech.com

LOHIONOFFPILOTVENT-FREE NATURAL GAS PEDESTAL STOVEINSTALLATIONContinuedINSTALLING LOGSWARNING: Failure to positionthe parts in accordance with thesediagrams or failure to use onlyparts specifically approved withthis heater may result in propertydamage or personal injury.CAUTION: After installation andperiodically thereafter, check to ensurethat no flame comes in contactwith any log. With the heater set toHigh, check to see if flames contactany log. If so, reposition logs accordingto the log installation instructionsin this manual. Flamescontacting logs will create soot.It is very important to install the logs exactlyas instructed. Do not modify logs. Only uselogs supplied with heater.Place one-piece log set on grate to fit asillustrated in Figure 9. Make sure log sits flaton firebox floor (see Figure 9).IMPORTANT: Make sure log does not coverany burner ports (see Figure 10).One PieceLog SetINSTALLING BLOWERACCESSORY - GA3750Tools required: Phillips screwdriverNOTICE: Shut off <strong>gas</strong> heater duringthe following blower installation.1. Remove top panel of <strong>stove</strong> by removingthree screws from under top lip oneach side of <strong>stove</strong> (see Figure 11).2. Facing front of <strong>stove</strong>, carefully slide toppanel forward until it is completely removedfrom <strong>stove</strong> (see Figure 11).3. Disconnect power cord wires from blowermotor (if connected) (see Figure 12).4. Disconnect green ground wire fromblower housing (if connected) by removingscrew holding wire terminal(see Figure 12).Figure 11 - Removing Stove Top PanelWhite Powercord WireBlack Powercord Wire5. Install one plastic bushing provided inblower kit into the 1 1 /2" hole in the leftrear of firebox floor. Access holethrough the rectangular opening in therear panel (see Figure 13).6. Remove the two blower mountingbrackets from the rear panel by removingtwo screws each (see Figure 14).7. Attach the two mounting brackets toblower housing using four screws providedin blower kit (2 for each bracket)(see Figure 14). Tighten screws securely.Place blower assembly temporarilyon top of firebox.8. Working from the rear of the <strong>stove</strong>,place entire power cord, includingspeed control housing, in lower controlcompartment.9. Route ends of 3-wire power cord upfrom the lower control compartmentthrough the plastic bushing, then up tothe upper cavity of <strong>stove</strong> (see Figure 15).10. Attach the terminal ends of the whiteand black power cord wires to the terminalson the blower motor (see Figure14). Push firmly.11. Attach the terminal end of the greenpower cord wire to the front tab of theblower housing using screw provided(see Figure 12).12. Using the four screws previously removed,mount blower assembly to<strong>stove</strong> by reattaching blower brackets torear panel (see Figure 14). Tightenscrews securely.BlowerBracketFirebox FloorFigure 9 - Installing One-Piece Log SetScrewGreenGround WireFigure 12 - Removing Wires from BlowerBlowerBurner PortsOne Piece Log SetFigure 10 - Installing One-Piece Log set(Top View)Figure 13 - Installing BushingFirebox TopFigure 14 - Removing Blower Bracketsfrom Stove and Attaching to BlowerFor more information, visit www.desatech.com10 105683

OWNER’S MANUALINSTALLATIONContinued13. Install plastic control knob onto outputshaft of speed control housing (see Figure15). Place speed control housingjust inside control compartment doorin front of <strong>stove</strong> (see Figure 16).14. Using two screws provided in blowerkit, mount blower speed control housingto mounting tab in left side of lowercontrol compartment (see Figure 16).15. Check to make sure that the power cord iscompletely clear of blower wheel and thereare no foreign objects in blower wheel.16. Carefully replace <strong>stove</strong> top panel. Alignholes and replace six screws removedin step 1.17. Peel off the backing paper and stickthe supplied wiring diagram decal onthe <strong>stove</strong> floor bottom as shown inFigure 15.18. Plug power cord into a convenient 3-pronggrounded wall receptacle near the <strong>stove</strong>.ControlKnobSpeed ControlHousingPowerCordWiringDiagramDecalWARNING: ELECTRICALGROUNDING INSTRUCTIONSThis appliance is equipped with athree-prong (grounding) plug foryour protection against shockhazard and should be pluggeddirectly into a properly groundedthree-prong receptacle.19. Using speed control knob, turn bloweron and check for operation.20. All remaining parts from blower kitmay be discarded.Blower SpeedControl HousingFigure 16 - Installing Blower Control HousingWARNING: Never attempt to service heater while itis plugged in, operating, or hot. Burns and electricalshock could result. Only a qualified service personshould service or repair heater.If any of the original wire as supplied with the appliance must bereplaced, it must be replaced with 105°C wire or it’s equivalent.WARNING: Label all wires prior to disconnectionwhen servicing controls. Wiring errors can cause improperand dangerous operation. Verify proper operationafter servicing.110/115V.A.C.BlackGreenWhiteVariableFan SwitchOffBlackBlack120 Vac. 60 Hz. . 78 AmpsDESA International, Bowling Green, KYOnBlackWhiteBlowerMotor101584-05OPERATING HEATERFOR YOUR SAFETYREAD BEFORELIGHTINGWARNING: If you do not followthese instructions exactly, afire or explosion may result causingproperty damage, personalinjury or loss of life.A. This appliance has a pilot which mustbe lighted by hand. When lighting thepilot, follow these instructions exactly.B. BEFORE LIGHTING smell allaround the appliance area for <strong>gas</strong>. Besure to smell next to the floor becausesome <strong>gas</strong> is heavier than air and willsettle on the floor.WHAT TO DO IF YOU SMELL GAS• Do not try to light any appliance.• Do not touch any electric switch; donot use any phone in your building.• Immediately call your <strong>gas</strong> supplierfrom a neighbor’s phone. Followthe <strong>gas</strong> supplier’s instructions.• If you cannot reach your <strong>gas</strong> supplier,call the fire department.C. Use only your hand to push in or turnthe <strong>gas</strong> control knob. Never use tools.If the knob will not push in or turnby hand, don’t try to repair it, call aqualified service technician or <strong>gas</strong>supplier. Force or attempted repairmay result in a fire or explosion.D. Do not use this appliance if any parthas been under water. Immediately calla qualified service technician to inspectthe appliance and to replace any partof the control <strong>system</strong> and any <strong>gas</strong> controlwhich has been under water.Figure 15 - Routing Power Cord10568311ContinuedFor more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVEOPERATINGHEATERContinuedLIGHTINGINSTRUCTIONSNOTICE: During initial operationof new heater, burning logs willgive off a paper-burning smell.Orange flame will also be present.Open a window to <strong>vent</strong> smell. Thiswill only last a few hours.1. STOP! Read the safety information,page 11, column 3.2. Make sure equipment shutoff valveis fully open.3. Turn control knob clockwise Clockwiseto the OFF position.4. Wait five (5) minutes to clear out any<strong>gas</strong>. Then smell for <strong>gas</strong>, includingnear the floor. If you smell <strong>gas</strong>,STOP! Follow “B” in the safety information,page 11, column 3. If youdon’t smell <strong>gas</strong>, go to the next step.5. Turn control knob counterclockwiseC-clockwise to the PILOT position.Press in control knob for five (5) seconds(see Figure 17). Note: You maybe running this heater for the firsttime after hooking up to <strong>gas</strong> supply.If so, the control knob may need tobe pressed in for 30 seconds or less.This will allow air to bleed from the<strong>gas</strong> <strong>system</strong>.6. With control knob pressed in, pressand release ignitor button. This willlight pilot. The pilot is attached to thefront burner. If needed, keep pressingignitor button until pilot lights.Note: If pilot does not stay lit, contacta qualified service person or <strong>gas</strong>supplier for repairs. Until repairs aremade, light pilot with match. To lightpilot with match, see Manual LightingProcedure.Ignitor ButtonControl KnobFigure 17- Control Knob and IgnitorButton Location7. Keep control knob pressed in for 30seconds after lighting pilot. After 30seconds, release control knob.• If control knob does not pop out whenreleased, contact a qualified serviceperson or <strong>gas</strong> supplier for repairs.Note: If pilot goes out, repeat steps 3through 7. This heater has a safety interlock<strong>system</strong>. Wait one (1) minute for <strong>system</strong>to reset before lighting pilot again.8. Turn control knob counterclockwiseC-clockwise to desired heating level. Theburners should light. Set control knobto any heat level between HI and LO.Ignitor ElectrodeThermocouplePilot BurnerFigure 18 - PilotCAUTION: Do not try to adjustheating levels by using the equipmentshutoff valve.TO TURN OFF GASTO APPLIANCEShutting Off HeaterTurn control knob clockwise Clockwise tothe OFF position.Shutting Off Burners Only (pilotstays lit)Turn control knob clockwise Clockwise tothe PILOT position.THERMOSTAT CONTROLOPERATIONThe thermostat control knob can be set toany comfort level between Hi and Lo. Thethermostat will gradually modulate the heatoutput and flame height from higher tolower settings, or pilot, in order to maintainthe comfort level you select. The ideal comfortsetting will vary by household dependingupon the amount of space to be heated,the output of the central heating <strong>system</strong>, etc.Note: Selecting the Hi setting with thecontrol knob will cause the burners toremain fully on, without modulating downin most cases.MANUAL LIGHTINGPROCEDURE1. Follow steps 1 through 5 under LightingInstructions.2. Depress control knob and light pilotwith match.3. Keep control knob pressed in for 30seconds after lighting pilot. After 30seconds, release control knob. Nowfollow step 8 in column 2.INSPECTINGBURNERSCheck pilot flame pattern and burner flamepatterns often.PILOT FLAME PATTERNFigure 19 shows a correct pilot flame pattern.Figure 20 shows an incorrect pilotflame pattern. (Note: Appearance of pilotassembly may vary by model). The incorrectpilot flame is not touching the thermocouple.This will cause the thermocouple tocool. When the thermocouple cools, the heaterwill shut down.If pilot flame pattern is incorrect, as shownin Figure 20• turn heater off (see To Turn Off Gas toAppliance)• see Troubleshooting, pages 14 through 16ThermocouplePilot BurnerFigure 19 - Correct Pilot Flame PatternThermocouplePilot BurnerFigure 20 - Incorrect Pilot Flame PatternFor more information, visit www.desatech.com12 105683

OWNER’S MANUALINSPECTINGBURNERSContinuedBURNER FLAME PATTERNFigure 21 shows a correct burner flame pattern.Figure 22 shows an incorrect burnerflame pattern. If burner flame pattern isincorrect,• turn heater off (see To Turn Off Gas toAppliance, page 12)• see Troubleshooting, pages 14 through 16Approx. 3-6" AboveTop of LogsFigure 21 - Correct Flame Pattern withControl Knob Set to High Flame.More Than 8"Above Top of LogsFigure 22 - Incorrect Flame Pattern withControl Knob Set to High FlameCLEANING ANDMAINTENANCEWARNING: Turn off heaterand let cool before cleaning.CAUTION: You must keep controlareas, burner, and circulatingair passageways of heater clean.Inspect these areas of heater beforeeach use. Have heater inspectedyearly by a qualified serviceperson. Heater may need morefrequent cleaning due to excessivelint from carpeting, bedding material,pet hair, etc.CLEANING BURNERINJECTOR HOLDER ANDPILOT AIR INLET HOLEThe primary air inlet holes allow the properamount of air to mix with the <strong>gas</strong>. This providesa clean burning flame. Keep these holesclear of dust, dirt,lint, and pet hair. Clean theseair inlet holes prior to each heating season.Blocked air holes will create soot. We recommendthat you clean the unit every threemonths during operation and have heater inspectedyearly by a qualified service person.We also recommend that you keep the burnertube and pilot assembly clean and <strong>free</strong> of dustand dirt. To clean these parts we recommendusing compressed air no greater than 30 PSI.Your local computer store, hardware store, orhome center may carry compressed air in acan. You can use a vacuum cleaner in theblow position. If using compressed air in acan, please follow the directions on the can.If you don't follow directions on the can, youcould damage the pilot assembly.1. Shut off the unit, including the pilot.Allow the unit to cool for at least thirtyminutes.2. Inspect burner, pilot, and primary airinlet holes on injector holder for dustand dirt (see Figure 23).3. Blow air through the ports/slots andholes in the burner.4. Check the injector holder located at theend of the burner tube again. Remove anylarge particles of dust, dirt, lint, or pet hairwith a soft cloth or vacuum cleaner nozzle.5. Blow air into the primary air holes onthe injector holder.6. In case any large clumps of dust havenow been pushed into the burner repeatsteps 3 and 4.Clean the pilot assembly also. A yellow tip onthe pilot flame indicates dust and dirt in the pilotassembly. There is a small pilot air inlet holeabout two inches from where the pilot flamecomes out of the pilot assembly (see Figure 24).With the unit off, lightly blow air through the airinlet hole. You may blow through a drinkingstraw if compressed air is not available.BurnerTubeInjector HolderPrimary AirInlet HolesFigure 23 - Injector Holder On OutletBurner TubeBurnerTubePilotAssemblyPilot AirInletHoleFigure 24 - Pilot Inlet Air HolePorts/SlotsCABINETAir Passageways• Use a vacuum cleaner or pressurized airto clean.Exterior• Use a soft cloth dampened with a mildsoap and water mixture. Wipe the cabinetto remove dust.LOGS• If you remove logs for cleaning, refer toInstalling Logs, page 10, to properly replacelogs.• Replace log(s) if broken or chipped(dime-sized or larger).MAIN BURNERPeriodically inspect all burner flame holeswith the heater running. All slotted burnerflame holes should be open with yellowflame present. All round burner flame holesshould be open with a small blue flamepresent. Some burner flame holes may becomeblocked by debris or rust, with no flamepresent. If so, turn off heater and let cool.Either remove blockage or replace burner.Blocked burner flame holes will create soot.Review your video included with your heaterfor additional cleaning instructions.10568313For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVETROUBLESHOOTINGNote: For additional help, visit DESAInternational’s technical service web siteat www.desatech.com.Note: All troubleshooting items are listed inorder of operation.OBSERVED PROBLEMWhen ignitor button is pressed, there is nospark at ODS/pilotWARNING: Turn off heaterand let cool before servicing. Onlya qualified service person shouldservice and repair heater.POSSIBLE CAUSE1. Ignitor electrode not connected to ignitorcable2. Ignitor cable pinched or wet3. Piezo ignitor nut is loose4. Broken ignitor cable5. Bad piezo ignitor6. Ignitor electrode broken7. Ignitor electrode positioned wrongCAUTION: Never use a wire,needle, or similar object to cleanODS/pilot. This can damage ODS/pilot unit.REMEDY1. Reconnect ignitor cable2. Free ignitor cable if pinched by anymetal or tubing. Keep ignitor cable dry3. Tighten nut holding piezo ignitor to basepanel of log set. Nut is located behindbase panel4. Replace ignitor cable5. Replace piezo ignitor6. Replace piezo ignitor7. Replace piezo ignitorWhen ignitor button is pressed, there isspark at ODS/pilot but no ignitionODS/pilot lights but flame goes out whencontrol knob is released1. Gas supply turned off or equipmentshutoff valve closed2. Control knob not in PILOT position3. Control knob not pressed in while inPILOT position4. Air in <strong>gas</strong> lines when installed5. ODS/pilot is clogged6. Gas regulator setting is not correct1. Control knob not fully pressed in2. Control knob not pressed in long enough3. Equipment shutoff valve not fully open4. Pilot flame not touching thermocouple,which allows thermocouple to cool,causing pilot flame to go out. This problemcould be caused by one or both ofthe following:A) Low <strong>gas</strong> pressureB) Dirty or partially clogged ODS/pilot5. Thermocouple connection loose at controlvalve6. Thermocouple damaged7. Control valve damaged1. Turn on <strong>gas</strong> supply or open equipmentshutoff valve2. Turn control knob to PILOT position3. Press in control knob while in PILOTposition4. Continue holding down control knob.Repeat igniting operation until air is removed5. Clean ODS/pilot (see Cleaning andMaintenance, page 13) or replace ODS/pilot assembly6. Replace <strong>gas</strong> control1. Press in control knob fully2. After ODS/pilot lights, keep controlknob pressed in 30 seconds3. Fully open equipment shutoff valve4. A) Contact local <strong>natural</strong> <strong>gas</strong> companyB) Clean ODS/pilot (see Cleaning andMaintenance, page 13) or replace ODS/pilot assembly5. Hand tighten until snug, then tighten 1/4turn more6. Replace thermocouple7. Replace control valvewww.desatech.comFor more information, visit www.desatech.com14 105683

OWNER’S MANUALTROUBLESHOOTINGContinuedOBSERVED PROBLEMBurner does not light after ODS/pilot is litPOSSIBLE CAUSE1. Burner orifice clogged2. Inlet <strong>gas</strong> pressure is too low3. Burner orifice diameter is too small4. Thermopile leads disconnected or improperlyconnected5. Burners will not come on in remote positionREMEDY1. Clean burner (see Cleaning and Maintenance,page 13) or replace burner orifice2. Contact local <strong>natural</strong> <strong>gas</strong> company3. Replace burner orifice4. Reconnect leads (see wiring diagram)5. Replace battery in transmitter and receiverDelayed ignition burnerBurner backfiring during combustionSlight smoke or odor during initial operationMoisture/condensation noticed on windowsHeater produces a whistling noise whenburner is litDark residue on logs or inside of fireplaceWhite powder residue forming within burnerbox or on adjacent walls or furniture1. Manifold pressure is too low2. Burner orifice clogged1. Burner orifice is clogged or damaged2. Damaged burner3. Gas regulator defective1. Not enough air2. Gas regulator defective3. Residues from manufacturing processesand logs curing1. Not enough combustion/<strong>vent</strong>ilation air1. Turning control knob to HI position whenburner is cold2. Air in <strong>gas</strong> line3. Air passageways on heater blocked4. Dirty or partially clogged burner orifice1. Improper log placement2. Drafts or other air currents affectingflame pattern3. Air holes at burner inlet blocked4. Burner flame holes blocked1. When heated, vapors from furniture polish,wax, carpet cleaners, etc. turn intowhite powder residue1. Contact local <strong>natural</strong> <strong>gas</strong> company2. Clean burner (see Cleaning and Maintenance,page 13) or replace burner orifice1. Clean burner (see Cleaning and Maintenance,page 13) or replace burner orifice2. Replace damaged burner3. Replace <strong>gas</strong> control1. Check burner for dirt and debris. If found,clean burner (see Cleaning and Maintenance,page 13)2. Replace <strong>gas</strong> control3. Problem will stop after a few hours ofoperation1. Refer to Air for Combustion and Ventilationrequirements (page 4)1. Turn control knob to LO position and letwarm up for a minute2. Operate burner until air is removed fromline. Have <strong>gas</strong> line checked by local <strong>natural</strong><strong>gas</strong> company3. Observe minimum installation clearances(see pages 7 through 9)4. Clean burner (see Cleaning and Maintenance,page 13) or replace burner orifice1. Properly locate logs (see Installing Logs,page 10)2. Eliminate source of drafts around heater3. Clean out air holes at burner inlet. Periodicallyrepeat as needed4. Remove blockage or replace burner1. Turn heater off when using furniture polish,wax, carpet cleaners, or similarproductswww.desatech.comContinued10568315For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVETROUBLESHOOTINGContinuedWARNING: If you smell <strong>gas</strong>• Shut off <strong>gas</strong> supply.• Do not try to light any appliance.• Do not touch any electrical switch; do not use any phone in yourbuilding.• Immediately call your <strong>gas</strong> supplier from a neighbor’s phone. Follow the<strong>gas</strong> supplier’s instructions.• If you cannot reach your <strong>gas</strong> supplier, call the fire department.IMPORTANT: Operating heater where impurities in air exist may create odors. Cleaningsupplies, paint, paint remover, cigarette smoke, cements and glues, new carpet or textiles,etc., create fumes. These fumes may mix with combustion air and create odors. These odorswill disappear over time.OBSERVED PROBLEMHeater produces a clicking/ticking noisejust after burner is lit or shut offHeater produces unwanted odorsHeater shuts off in use (ODS operates)Gas odor even when control knob is in OFFpositionGas odor during combustionBurner flame is excessively large and isvery near or touches the top of fireboxPOSSIBLE CAUSE1. Metal expanding while heating or contractingwhile cooling1. Heater burning vapors from paint, hairspray, glues, cleaners, chemicals, newcarpet, etc. (See IMPORTANT statementabove)2. Gas leak. See Warning statement attop of page1. Not enough fresh air is available2. Low line pressure3. ODS/pilot is partially clogged1. Gas leak. See Warning statement attop of page2. Control valve defective1. Foreign matter between control valveand burner2. Gas leak. See Warning statement attop of page1. Excessive line or manifold pressure2. Dirty primary air holesREMEDY1. This is common with most heaters. Ifnoise is excessive, contact qualified serviceperson1. Open window and <strong>vent</strong>ilate room. Stopusing odor causing products while heateris running2. Locate and correct all leaks (see CheckingGas Connections, page 9)1. Open window and/or door for <strong>vent</strong>ilation2. Contact local <strong>natural</strong> <strong>gas</strong> company3. Clean ODS/pilot (see Cleaning andMaintenance, page 13)1. Locate and correct all leaks (see CheckingGas Connections, page 9)2. Replace control valve1. Take apart <strong>gas</strong> tubing and remove foreignmatter2. Locate and correct all leaks (see CheckingGas Connections, page 9)1. Check manifold pressure and correct asneeded2. Clean burner air holes (see Cleaning andMaintenance, page13).www.desatech.comFor more information, visit www.desatech.com16 105683

OWNER’S MANUALSPECIFICATIONSBtu (Variable) 20,000/26,000Type GasNatural OnlyIgnitionPiezoManifold Pressure 3.0" W.C.Inlet Gas Pressure(in. of water) *Maximum 10.5"Minimum 5"Dimensions, Inches (H x W x D)Stove 24 x 27 1 /4 x 17 1 /4Carton 22 x 31 x 31 1 /2Weight, poundsStove 66 lbs.Shipping 80 lbs.* For purposes of input adjustmentSERVICE HINTSWhen Gas Pressure Is Too Low• pilot will not stay lit• burners will have delayed ignition• heater will not produce specified heat• natual <strong>gas</strong> supply may be lowWhen Gas Quality Is Bad• pilot will not stay lit• burners will produce flames and soot• heater will backfire when litYou may feel your <strong>gas</strong> pressure is too low or<strong>gas</strong> quality is bad. If so, contact your local<strong>natural</strong> <strong>gas</strong> supplier.TECHNICALSERVICEYou may have further questions about installation,operation, or troubleshooting.If so, contact DESA International’s TechnicalService Department at 1-800-DESA LOG(1-800-337-2564).You can also visit DESA International’stechnical services web site atwww.desatech.com.PARTS CENTRALSThese Parts Centrals are privately owned businesses. They have agreed to support ourcustomer’s needs by providing original replacement parts and accessories.Baltimore Electric1348 Dixwell AvenueHamden, CT 06514-03221-800-397-7553203-248-7553Parts DepartmentPortable Heater Parts342 N. County Rd. 400 EastValparaiso, IN 46383-9704All States219-462-74411-800-362-6951sales@portableheaterparts.comtechservice@portableheaterparts.comFBD1349 Adams StreetBowling Green, KY 42103-3414270-846-11991-800-654-8534Fax: 1-800-846-0090franktalk@aol.comMaster Parts Dist.1251 Mound Ave NWGrand Rapids, MI 49504-2672616-791-05051-800-446-1446Fax: 616-791-8270www.nbmc.comWasher Equipment Co.1715 Main StreetKansas City, MO 64108-2195KS, MO, AR816-842-3911www.washerparts.comEast Coast Energy Products707 BroadwayW. Long Branch, NJ 07764-1542732-870-88091-800-755-8809www.njplaza.com/ecepDayton HardwareP.O. Box 275North Dayton StationDayton, OH 45404-0275All States937-258-3721OH 1-800-762-3426Halco Enterprises208 Carter Drive, Unit 21West Chester, PA 19382-4500610-430-77171-800-368-0803www.halcoenterprises.comLaporte’s Parts & Service2444 N. 5th StreetHartsville, SC 29550-7704803-332-0191Parts DepartmentCans Unlimited, Inc.P.O. Box 645Taylor, SC 29687-0013All States803-879-30091-800-845-5301cuisales@aol.com10568317For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVEILLUSTRATEDPARTSBREAKDOWNS26NT12610375413981014121115For more information, visit www.desatech.com18 105683

OWNER’S MANUALPARTS LISTS26NTThis list contains replaceable parts used in your heater. When ordering parts, follow theinstructions listed under Replacement Parts on page 22 of this manual.KEY PARTNO. NUMBER DESCRIPTION QTY.1 106039-01 Log Set 12 14285-01 ODS Pilot (NG) 13 098249-01 ODS Nut 24 105973-01 Burner Outlet Tube 15 105737-01 Injector Holder 16 102843-01 Burner Clip 17 099056-27 Burner Orifice Injector 18 101329-25 Gas Control Valve 19 102980-01 Burner 110 099387-09 Pilot Tube 111 098271-07 Ignitor Cable 112 101381-01 Piezo Ignitor and Cover 113 L98515-01 Pilot Shield 114 L98303-01 Regulator 115 105972-01 Inlet Tube 1PARTS AVAILABLE — NOT SHOWN100563-01 Warning Plate 1101054-01 Lighting Instructions Plate 110568319For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVEILLUSTRATEDPARTSBREAKDOWNS26NT 151018116849171216231571413For more information, visit www.desatech.com20 105683

OWNER’S MANUALPARTS LISTS26NTThis list contains replaceable parts used in your heater. When ordering parts, follow the instructionslisted under Replacement Parts on page 22 of this manual.KEYNO. PART NO. DESCRIPTION QTY.1 105666-01 Top Panel, Stove 12 105656-01 Pedestal Stove 13 105655-01 Stove Base 14 105654-01 Stove Back Panel 15 105653-01 Louver Panel 16 105657-01 Blower Bracket 27 105658-01 Door 18 105659-01 Firebox Back Panel 19 105660-01 Firebox Floor 110 105661-01 Firebox Top Assembly 111 105970-01 Screen Assembly 112 101382-01 Valve Bracket 113 105672-01 Brass Trim, Bottom 114 105673-01 Brass Trim, Firebox 115 106754-01 Knob 116 105971-01 Door Hinge 117 099230-02 Shoulder Screw 418 106020-01 Heat Deflector 1PARTS AVAILABLE — NOT SHOWN101054-01 Lighting Instructions Plate 1100563-01 Warning Plate 1104310-10 Information Video 1104108-06 Touch-Up Paint Kit (12 oz. can) 110568321For more information, visit www.desatech.com

VENT-FREE NATURAL GAS PEDESTAL STOVEREPLACEMENTPARTSNote: Use only original replacement parts.This will protect your warranty coveragefor parts replaced under warranty.PARTS UNDER WARRANTYContact authorized dealers of this product.If they can’t supply original replacementpart(s) call DESA International’s TechnicalService Department at 1-800-323-5190 forreferral information.When calling DESA International, have ready• your name• your address• model and serial numbers of your heater• how heater was malfunctioning• type of <strong>gas</strong> used (propane/LP or <strong>natural</strong> <strong>gas</strong>)• purchase dateUsually, we will ask you to return the defectivepart to the factory.PARTS NOT UNDERWARRANTYContact authorized dealers of this productor Parts Central (see page 17). If they can’tsupply original replacement part(s) callDESA International’s Parts Department at1-800-972-7879 for referral information.When calling DESA International, have ready• model number of your heater• the replacement part numberACCESSORIESPurchase these heater accessories from yourlocal dealer or Parts Central (see page 17). Ifthey cannot supply these accessories callDESA International’s Sales Department at1-800-458-2472 for referral information.You can also write to the address listed onthe back page of this manual.EQUIPMENT SHUTOFFVALVE - GA5010Equipment shutoff valve with 1/8" NPT tap.MANUALLY-CONTROLLEDBLOWER KIT - GA3750Provides better heat distribution. Featuresvariable speed control knob.CLEANING KIT - CCK(Not Shown)Your <strong>vent</strong>-<strong>free</strong> <strong>gas</strong> appliance requires regularcleaning and maintenance to pre<strong>vent</strong>performance problems. This kit gives youthe tools and instructions to make it easy toclean all critical areas of your appliance.For more information, visit www.desatech.com22 105683

NOTESOWNER’S MANUAL______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________10568323For more information, visit www.desatech.com

WARRANTY INFORMATIONKEEP THIS WARRANTYModelSerial No.Date PurchasedAlways specify model and serial numbers when communicating with the factory.We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standardwritten warranty. We make no other warranty, expressed or implied.LIMITED WARRANTYVENT-FREE NATURAL GAS PEDESTAL STOVEDESA International warrants this product to be <strong>free</strong> from defects in materials and components for two (2) years from the dateof first purchase, provided that the product has been properly installed, operated and maintained in accordance with allapplicable instructions. To make a claim under this warranty the Bill of Sale or cancelled check must be presented.This warranty is extended only to the original retail purchaser. This warranty covers the cost of part(s) required to restore thisheater to proper operating condition and an allowance for labor when provided by a DESA Authorized Service Center. Warrantypart(s) MUST be obtained through authorized dealers of this product and/or DESA International who will provide originalfactory replacement parts. Failure to use original factory replacement parts voids this warranty. The heater MUST be installedby a qualified installer in accordance with all local codes and instructions furnished with the unit.This warranty does not apply to parts that are not in original condition because of normal wear and tear, or parts that fail orbecome damaged as a result of misuse, accidents, lack of proper maintenance or defects caused by improper installation. Travel,diagnostic cost, labor, transportation and any and all such other costs related to repairing a defective heater will be theresponsibility of the owner.TO THE FULL EXTENT ALLOWED BY THE LAW OF THE JURISDICTION THAT GOVERNS THE SALE OF THEPRODUCT; THIS EXPRESS WARRANTY EXCLUDES ANY AND ALL OTHER EXPRESSED WARRANTIES ANDLIMITS THE DURATION OF ANY AND ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MER-CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE TO TWO (2) YEARS ON ALL COMPONENTSFROM THE DATE OF FIRST PURCHASE; AND DESA INTERNATIONAL’S LIABILITY IS HEREBY LIMITED TOTHE PURCHASE PRICE OF THE PRODUCT AND DESA INTERNATIONAL SHALL NOT BE LIABLE FOR ANYOTHER DAMAGES WHATSOEVER INCLUDING INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES.Some states do not allow a limitation on how long an implied warranty lasts or an exclusion or limitation of incidental orconsequential damages, so the above limitation on implied warranties, or exclusion or limitation on damages may not apply to you.This warranty gives you specific legal rights, and you may also have other rights that vary from state to state.For information about this warranty write:INTERNATIONAL2701 Industrial DriveP.O. Box 90004Bowling Green, KY 42102-9004www.desatech.com105683 01NOT A UPC105683-01Rev. C09/00