building - IFET College of Engineering

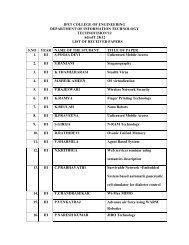

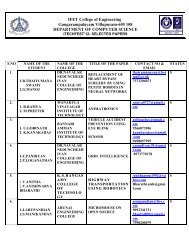

building - IFET College of Engineering

building - IFET College of Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<strong>IFET</strong> COLLEGE OF ENGINEERINGDEPARTMENT OF CIVIL ENGINEERINGADVANCED CONSTRUCTION TECHNIQUESFOR ECO- BUILDINGPRESENTED BY:R.MANIMARAN&K. GUNASEKAR

ABSTRACTEco <strong>building</strong> is also sometimesknown as "sustainable <strong>building</strong>" or"Bioclimatic <strong>building</strong> ―or ―green<strong>building</strong>‖, although there are slightdifferences in the definitions. Thepractice <strong>of</strong> bioclimatic <strong>building</strong> can leadto benefits including reduced operatingcosts by increasing productivity andusing less energy and water, improvedpublic and occupant health due toimproved indoor air quality, and reducedenvironmental impacts. Bioclimatic<strong>building</strong> is an essential component <strong>of</strong> therelated concepts <strong>of</strong> sustainable design,sustainable development. Low costhousing involves the construction usingspecial type <strong>of</strong> bond like rat trap bondfor brick masonary and filler slabtechniques for ro<strong>of</strong> slabs. The methodsgive a difference <strong>of</strong> 20-30 % <strong>of</strong> costvariation between the low cost house andthe traditional <strong>building</strong>. Other than thesemethods many such new technologiesare adopted to make the <strong>building</strong> rich inall aspect and economical cost wise.This paper discusses some environmentfriendlyand low cost <strong>building</strong>techniques. The concept <strong>of</strong> bioclimatic<strong>building</strong> deals with the maximum usage<strong>of</strong> the naturally available resource in thei<strong>building</strong> which will make theconstruction <strong>of</strong> <strong>building</strong> economical.Introducing low cost constructiontechniques for bioclimatic <strong>building</strong> is toprovide the required durability which areavailable in traditional <strong>building</strong> in aneconomical way. The paper concludesby emphasizing the importance <strong>of</strong> lowcost construction methods andconsideration <strong>of</strong> the environmentalaspects which leads to an economicaland effective construction <strong>of</strong> a <strong>building</strong>with full efficiency.

INTRODUCTIONBioclimatic Building is thepractice <strong>of</strong> increasing the efficiency withwhich <strong>building</strong>s and their sites use andharvest energy, water, and materials, andreducing <strong>building</strong> impacts on humanhealth and the environment, throughbetter sitting, design, construction,operation, maintenance, and removal —the complete <strong>building</strong> life cycle. Green<strong>building</strong> is also sometimes known as"sustainable <strong>building</strong>" or "environmental<strong>building</strong>", although there are slightdifferences in the definitions. Thepractice <strong>of</strong> green <strong>building</strong> can lead tobenefits including reduced operatingcosts by increasing productivity andusing less energy and water, improvedpublic and occupant health due toimproved indoor air quality, and reducedenvironmental impacts by, for example,by lessening storm water run<strong>of</strong>f and theheat island effect. Low cost housinginvolves the construction using specialtype <strong>of</strong> bond like rat trap bond for brickmasonary and filler slab techniques forro<strong>of</strong> slabs. The methods give adifference <strong>of</strong> 20-30 % <strong>of</strong> cost variationbetween the low cost house and thetraditional <strong>building</strong>. Other than thesemethods many such new technologiesiiare adopted to make the <strong>building</strong> richin all aspect and economical cost wise.OBJECTIVEThe main points to be consideredwhile designing a bioclimatic <strong>building</strong>are• To minimize the operating costby increasing the productivityand using lessEnergy and water.• To reduce the environmentalimpact on the <strong>building</strong>.• To minimize heat gained in daytime and maximize the heat lossin night time inHot season and reverse in coldseason.• To minimize the internal heat• To select the site, according tothe climatic criteria.• To optimize the <strong>building</strong>structure.• To control solar radiation.• To regulate air circulation.TECHNOLOGY FEATURESBrick wall with 'rat-trap bond' Strength is equal to standard 9"(229mm) brick wall, butconsumes 20% less bricks.

It completely cuts <strong>of</strong>f the use <strong>of</strong>timber for ro<strong>of</strong>ing, contributingto solve one <strong>of</strong> the majorenvironmental issues - cuttingtrees.Reduction on the use <strong>of</strong> concretetoo saves cement & metal about40%.The s<strong>of</strong>fit <strong>of</strong> this slab givesan attractive look and therefore, aceiling is not needed. If it is 4"(100mm) thick, 100 square feet(9.3 sq m) <strong>of</strong> this slab will costOnly Rs.13003/- as against thetraditional slab that costsRs.16958/-.The saving on cost <strong>of</strong> this slabcompared to the traditional slabis about 23%.ivstandard for energy use in <strong>building</strong>s. Itresults in ultra low energy <strong>building</strong> thatrequires little energy for space heating.A similar standard, MINERGIE-P®, isused in Switzerland. The first Passivehouse <strong>building</strong>s were built in Darmstadt,Germany, in 1990, and occupied thefollowing year. In September 1996 thePassivhouse-Institut was founded inDarmstadt to promote and control thestandard. Since then more than 6,000Passive house <strong>building</strong>s have beenconstructed in Europe, most <strong>of</strong> them inGermany and Austria, with others invarious countries world-wide. Despitethe name, the standard is not confinedonly to houses.THE PASSIVE STANDARDThe Passive house standard requires thatthe <strong>building</strong> is within the followinglimits:TILE SHOWING THE AIR GAPUSED FOR THERMALINSULATIONPASSIVE HOUSEThe term Passive house(Passivhaus in German) refers to therigorous, voluntary, passive houseThe <strong>building</strong> must not use morethan (≤) 15 kWh/m²a (4,755Btu/ft²/yr) in heatingEnergy.The specific heat load for the heatingsource at design temperature must beless than 10 W/m²

With the <strong>building</strong> pressurized to50Pa by a blower door, the<strong>building</strong> must not Leak more airthan 0.6 times the house volumeper hour (n50 ≤ 0.6/h). Total primary energyconsumption (primary energy forheating, hot water andElectricity) must not be morethan 120 kWh/(m²a)DESIGN AND CONSTRUCTIONvThese standards are muchhigher than houses built to most normal<strong>building</strong> codes. For comparisons, see theinternational comparisons section below.National partners within the 'consortiumfor the Promotion <strong>of</strong> European PassiveHouses’ (PEP) is thought to have someflexibility to adapt these limits locally.CONSTRUCTION COSTS:In Passive house <strong>building</strong>s, thecost savings from dispensing with theconventional heating system can be usedto fund the upgrade <strong>of</strong> the <strong>building</strong>envelope and the heat recoveryventilation system. Evaluations haveindicated that while it is technicallypossible, the costs <strong>of</strong> meeting thePassive house standard increasesignificantly when <strong>building</strong> in northernScandinavia above 60° latitude.The passivhaus uses a combination <strong>of</strong>low-energy <strong>building</strong> techniques andtechnologies.Achieving the major decrease in heatingenergy consumption required by thestandard Involves a shift in approach to<strong>building</strong> design and construction. Designis carried out with the aid <strong>of</strong> the'Passivhaus Planning Package', and usesspecifically designed computersimulations.PASSIVE SOLAR DESIGNPassive houses can be constructedfrom dense or lightweight materials, butsome internal thermal mass is normallyincorporated to reduce summer peaktemperatures, maintain stable wintertemperatures, and prevent possible over-

heating in spring or autumn beforenormal solar shading becomes effective.SUPERINSULATIONPassivhaus <strong>building</strong>s employsuperinsulation to significantly reducethe heat leakage through the walls, ro<strong>of</strong>and floor compared to conventional<strong>building</strong>s. A wide range <strong>of</strong> thermalinsulation materials can be used toprovide the required high R-values(lowU-value, typically in the 0.10 to0.15 W/m2K range). Special attention isgiven to eliminating thermal bridges.viair quality. Since the <strong>building</strong> isessentially airtight, the rate <strong>of</strong> air changecan be optimized and carefullycontrolled at about 0.4 air-changes perhour. All ventilation ducts are insulatedand sealed for air tightness.A TYPICAL ECONOMICALBUILDING AND ITSMETHODOLOGY- A CASE STUDY.AIRTIGHTNESSThe standard requires the <strong>building</strong>to achieve very high levels <strong>of</strong> airtightness, much higher than are normallyachieved in conventional construction.Air barriers, careful sealing <strong>of</strong> everyconstruction joint in the <strong>building</strong>envelope, and sealing <strong>of</strong> all servicepenetrations through it are all used toachieve this.VENTILATIONMechanical heat recoveryventilation systems, with a heat recoveryrate <strong>of</strong> over 80% and high efficiencyECM motors are employed to maintainAll tests conducted by the South AfricanBureau <strong>of</strong> Standards, have been executedon a 100 mm (4 inch) wall as this is anacceptable norm for in situ cast wallsand is also the standard applicable forlow cost housing units. Thermalconductivity <strong>of</strong> 100 mm moladi wall = 0,54 W/m.KMISSIONCombining shelter and economicdevelopment, moladi is set to change the

FOUNDATIONThe foundation is designed by aPr<strong>of</strong>essional Engineer for local soilConditionsviitradition bound construction industry inorder to allow for the participation,empowerment and development <strong>of</strong>communities on a Global basis.Bucket filled (2 Hours)MortarThe mix consist <strong>of</strong> River Sand,Cement and a specifically designedChemical additive – to aerate,Waterpro<strong>of</strong> and produce wellThermal and sound insulatingPropertiesCASTING OF THE WALLSThe aerated, thermal, waterpro<strong>of</strong>Mortar, can either be pumped orDay 1Doors, windows, electrical andPlumbing fittings, reinforcing as perEngineer, ro<strong>of</strong> ties are located priorTo the filling <strong>of</strong> the 100 or 150 mmThick walls(4 Hours)

Day 2Moladi is removed and canImmediately be re-erected on theNext foundation. The smooth surface <strong>of</strong> the walleliminates the need to plaster the completed<strong>building</strong> is shown above. This method is adoptedin South Africa for cheap and fast construction.This can also adopted for low cost constructionand even green material can be used in thishousing for make in eco-friendly too.iiCONCLUSION:The <strong>building</strong> constructed using low costtechniques fulfills the maximum efficiencywhich traditional <strong>building</strong> gives.Not only the aspect <strong>of</strong> strength andefficiency is fulfilled both the aestheticappearance is also done economically.By the adoption <strong>of</strong> bio climatic <strong>building</strong>technique the healthy environment isprovided for human to live safely.A sustainable environment will be createdbecause <strong>of</strong> this bio climatic <strong>building</strong>.