Trend-Setting Technology Point Machine HW(E)61.1 - Hanning & Kahl

Trend-Setting Technology Point Machine HW(E)61.1 - Hanning & Kahl

Trend-Setting Technology Point Machine HW(E)61.1 - Hanning & Kahl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

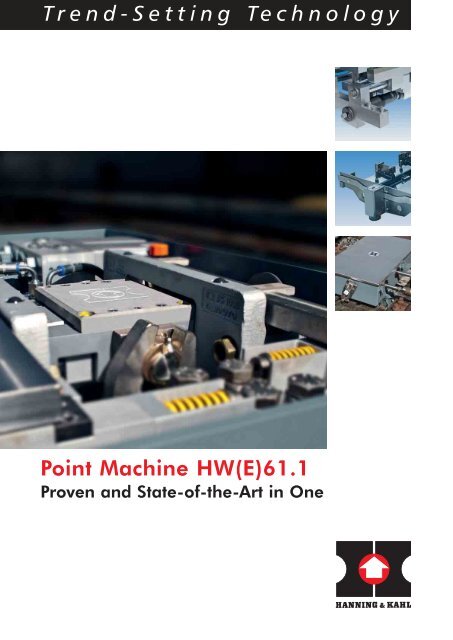

<strong>Trend</strong>-<strong>Setting</strong> <strong>Technology</strong><strong>Point</strong> <strong>Machine</strong> <strong>HW</strong>(E)<strong>61.1</strong>Proven and State-of-the-Art in One

<strong>Point</strong> <strong>Machine</strong> <strong>HW</strong>(E)<strong>61.1</strong>The innovations of the new series.Safety and reliability in rail-based transportation have always been HANNING &KAHL's main concerns. We are now proud to present the <strong>HW</strong>(E)<strong>61.1</strong> point machine.The consistent upgrade of the world–wide proven <strong>HW</strong>(E)61 is distinguished bymaximum reliability, functionality, economic efficiency and unmatched performance.With the <strong>HW</strong>(E)<strong>61.1</strong>, HANNING & KAHL sets yet another milestone on theway to maximum transport safety and operating efficiency.CompatibilityCombining proven technology with state-of-the-art, plus compatibility with the<strong>HW</strong>(E)61 were our fundamental objectives when developing the new product toensure that "older" installations could also be equipped with all the advantages ofthe "newest“ technology. Most of the main components of the <strong>61.1</strong> can also bedeployed in point machines of the 61 series.

<strong>Trend</strong>-<strong>Setting</strong> <strong>Technology</strong>New fabric-reinforced bellows/alternative rod openingRod openings have been protected by bellows for decades.We have enhanced the tenacity of this tried and trusted solutionwith new, fabric-reinforced bellows.Under certain conditions, direct rod openings can be an expedientalternative to bellows.For such cases, HANNING & KAHL now offers a rod openingwith hydraulic sealing elements for ingress protection IP67which can be deployed without limitation on 1435-mmgauge.Housing with new cable guidance andcover attachmentAll cables are safely guided through conduits and protectedwith clips mounted to spacer bolts.The cover is attached to the housing with a new, captive,quick-acting screw connection and removed simply by undoingand tilting the screws to the side. The Niro screws andbrass nuts can be quickly and simply replaced if necessary.Sturdier lever boxThe setting lever slot is particularly robust. Covers protect thelever box switches, cables and cable entry from damagefrom setting levers. The screwed stainless steel constructionguarantees maximum corrosion protection.

Optimised hydraulic cylinderDesign advancements reduce strain on sealing and bearingbushes. Cylinder mounting has been improved, the pistonrod diameter has been enlarged, and bleeding is now possibledirectly on the cylinder.Along with a new sealing concept this means less wear andlonger service life. A parts kit is available to retrofit existing<strong>HW</strong>E61 point machines.New, more compact hydrauliccouplingsHigh-quality, compact clean-break couplings are deployedin the <strong>HW</strong>E<strong>61.1</strong>. With flexible hoses and compact assembly,the couplings and surrounding components are easily accessible.For maintenance work, the hydraulic unit can be easilydisconnected without oil loss. The hydraulic cylinder canalso be bypassed. Manual setting is no problem even whenthe hydraulic unit is removed.New hydraulic unit – now also for750 V DC operationThe new hydraulic unit works in reverse operation. This eliminatessolenoid valves, simplifies set-up and increases availability.All 3-phase motor drives deployed in the <strong>HW</strong>E61series are possible. In combination with a new 750 V DCmotor, the aggregate is also a fitting alternative to the double-actingmagnet. As electric connection is made by a threewirecable, the electro-hydraulic and the electro-magnetic<strong>HW</strong>(E)<strong>61.1</strong> are 100% compatible.New damping unit forelectro-magnetic versionTwo long-lasting industrial shock absorbers in the electromagneticpoint machines of the <strong>HW</strong><strong>61.1</strong> series ensure longservice life. Convenient accessibility from the top and separatesetting for both directions are further plus points.Existing point machines can be retrofitted simply by replacingthe setting unit.

<strong>Trend</strong>-<strong>Setting</strong> <strong>Technology</strong>Improved corrosion protection ofcomponentsAll structural steel and cast parts are protected from corrosionwith the latest coating technology, guaranteeing allroundprotection. All components also passed the 720-h saltspray test intact, making the <strong>HW</strong>(E)<strong>61.1</strong> suitable for deploymentin extreme climatic conditions – for example wherehumidity is high and where condensation forms.New earthcaseThe new standard case is simple, symmetric and easier tohandle; when installed in the tongue device, the earthcasecan be turned 180 degrees on site to align gradient to drainage.The side covers can be removed separately, making themain cover lighter; the over-dimensioned case can be adaptedmore easily to the installation location. The bearingheight can be adjusted with exchangeable bearing blocks.Integrated diagnostic systemWhen you equip the <strong>HW</strong>(E)<strong>61.1</strong> with the optional sensorpackage, you see exactly what is going on! The most importantparameters (number of setting and trailing procedures,setting times, water penetration) are recorded and evaluatedby a low-cost diagnostic module directly in the switch machine.Wireless data read-out is possible on site. You decidewhether maintenance or repair are necessary, and condition-basedwork save time and costs.This system can be extended by modules from our FADISroute diagnosis system. FADIS facilitates extensive remotediagnosis and unsurpassed transparency in infrastructuremanagement.

The innovations of the <strong>HW</strong>(E)<strong>61.1</strong>at a glance:••••••••••new fabric-reinforced bellows / alternative rod opening with hydraulic sealingelementshousing with new cable guidance and optimised cover attachmentsturdier lever boxmore optimised hydraulic cylindernew, compact hydraulic couplingsnew damping device with industrial shock absorbers in the electro-magneticversionnew hydraulic unit now also for 750 V DC operationimproved corrosion protection of all componentsnew earthcaseintegrated diagnostic systemWhen requirements increase,the <strong>HW</strong>(E)<strong>61.1</strong> expands.Modular design of the <strong>HW</strong>(E)<strong>61.1</strong> means thatone series can cater for all transport authorityrequirements:<strong>HW</strong>(E)<strong>61.1</strong> O-OThe basic version <strong>HW</strong> <strong>61.1</strong> O-O is without positivelock and tongue detector. <strong>Point</strong> tongues areheld in end position by integrated long-lastingredundant spring assembles and in-lying pointposition switches.<strong>HW</strong>(E)<strong>61.1</strong> O-ZThis version comes with a tongue detector forindependent monitoring of point tongues.These two types cater for all applications ondepots and on lines with permissible speeds ofless than 15km/h.<strong>HW</strong>(E)61 AVV-ZVVThis version is designed for deployment onopen track and has positive locking of driverods and an independent detector lock device.This means maximum safety up to SIL 4 in allconditions.Drive type can be selected for all versions: electro-magnetic,central-hydraulic or electrohydraulic.All common operating voltages canbe catered for. A four-wire control version isavailable for deployment in EOW electric locally-setinstallations or electronic interlocking inmainline applications.Another name for safety -<strong>HW</strong>(E)<strong>61.1</strong>.Current regulations demand that the movableparts of a point are held in end positions withpositive locking when faced at speeds greaterthan 15 km/h. Here, the <strong>HW</strong>(E)<strong>61.1</strong> falls backon the patented locking system of the <strong>HW</strong>(E)61proven in thousandfold operation. This systemmeets all safety requirements, is certified forcompliance with SIL4 - DIN EN 50129 and registeredfor an international patent.The locking system acts on the drive and tonguedetector rods which are uncoupled mechanically.The positive lock can be trailable or non-trailable.The locking system is safely monitored bysignals and virtually wear-free.

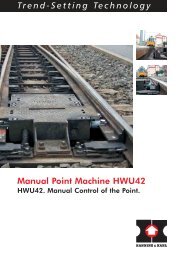

<strong>Trend</strong>-<strong>Setting</strong> <strong>Technology</strong>HANNING & KAHL point-setting systemsSafety All Along the Line.DataGaugeThe <strong>HW</strong>(E) <strong>61.1</strong> - at home inevery location.Greater safety and more operating ease on therails – and not just for new or planned pointinstallations. Compact design means the<strong>HW</strong>(E)<strong>61.1</strong> can be installed in every existingtype of point and every HANNING & KAHLearthcase with a corresponding adapter frame -and also in other makes of earthcases.The <strong>HW</strong>(E) <strong>61.1</strong> adapts.Progressively.The <strong>HW</strong>(E) <strong>61.1</strong> can be deployed in all conventionalpoint constructions. The point openingcan be set progressively between 32 and 100mm. <strong>Setting</strong> is performed directly on the<strong>HW</strong>(E)<strong>61.1</strong> on the spot, without replacing components,so the point machine can be deployedin identical technology in grooved-rail, deepbedand flat-bottomed points.Technical dataValues900 mm<strong>Point</strong>-setting systems made by HANNING &KAHL set technical standards and are successfullydeployed all over the world. Our partnersare transport authorities, operators of secondaryrailways, ports and industrial enterprises,point manufacturers and consultants, none ofwhom are prepared to compromise on safety.Our point-setting systems are the result of successfulsymbioses of economically-efficientseries production and bespoke design. Thisleads to technically precise and reliable onestopsolutions with fast returns for operators.You, too, will be convinced by HANNING &KAHL's committed and reliable service:- Short lead times, flexibility- Speedy supply of spare parts- 24-hour on-call service: +49 1713360360- Authoritative documentation- Instructional workshopsTechnical options and servicesWorking closely together with transport authoritiesand vehicle manufacturers, HANNING & KAHLhas developed practical testing and serviceequipment specially designed for the requirementsof the rail sector, e. g.:<strong>Point</strong> openingTrailing force of the open point tongueSpring pressing forceForce required for manual settingSmallest setting timeLock and end-position monitoringElectro-magnetic drive(<strong>Setting</strong> force approx. 5000 N)Electro-hydraulic drive(<strong>Setting</strong> force approx. 5000 N)Housing protection class when properlymounted and servicedSafety integrity level<strong>HW</strong><strong>61.1</strong>:<strong>HW</strong>E<strong>61.1</strong>:7000 N32 to 70 mm32 to 100 mmmin. 1000 N, progressively adjustable up to3500 N< 400 Nm0.5 s, depends on point openingContact-free proximity switches or mechanicallimit switchesDC 600 / 750 V (+20 %, -30 %)DC 600 V / 750 V (+20 %, -30 %)AC 115 V / 208 V (3 Ph) +10 %, -15 %AC 230 V / 400 V (3 Ph) +10 %, -15 %AC 120 V (1 Ph) +10%, -15 %AC 230 V (1Ph) +10%, -15 %More alternatives possibleEU: IP 67 (EN 60529)USA: NEMA Type 6 (250-1997)SIL 3 and 4 in compliance with SN EN 50129- Tongue-force measuring devices- Measuring setting lever- Tool kit for maintenance and upkeep workThis equipment offers optimum support whentrouble-shooting, recording test results andplanning service work.Whether assembling or commissioning, inspectingor performing maintenance work, repairingor overhauling – HANNING & KAHL testing andservice equipment, and our on-site service helpyou to identify malfunction sources early andavoid unnecessary costs. So you are always onestep ahead – technically and financially.

<strong>Trend</strong>-<strong>Setting</strong> <strong>Technology</strong><strong>Point</strong> <strong>Machine</strong> <strong>HW</strong>(E)<strong>61.1</strong>Proven and State-of-the-Art in OneRudolf-Diesel-Straße 633813 OerlinghausenDeutschlandPhone +49 5202 707-600Fax + 49 5202 707-629info@hanning-kahl.comwww.hanning-kahl.com09/2010