productive harvesting - Rovaltra

productive harvesting - Rovaltra

productive harvesting - Rovaltra

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

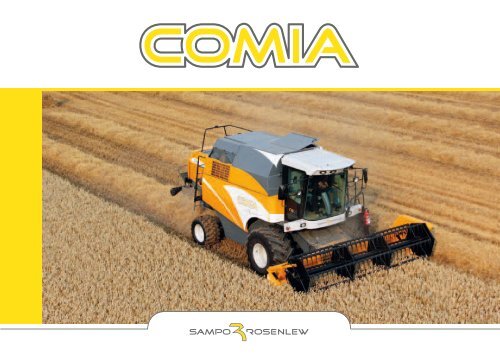

<strong>productive</strong> <strong>harvesting</strong>Efficient cutting table for improved productivitysubtle powerSame power, less fuel consumptionpioneer in cleaningMarket’s easiest and fastest combine to cleancareful separationHighest separation capacity in its size classadvanced driving ergonomicsOne-hand control2

Efficient cutting table for improved productivity.The result of years of pioneering product development, theComia cutting table delivers reliable performance with all croptypes and in all conditions.Productive threshing is ensured by the widest threshingcylinder in its size class. In addition, the pre-threshing cylinderfeatured in the C8 model increases the threshing capacity by20% – without making the combine wider.4

<strong>productive</strong> <strong>harvesting</strong>5

subtle power7

Highest separation capacity in its classThe new Sampo Comia features a number of improvements typical of bigger size class combinesthat increase <strong>harvesting</strong> performance.The Comia harvests the crop in efficiently, processes it gently, and retains only the separatedgrain. For its size class, the Comia has the largest number of straw walkers, the widest threshingcylinder, the largest shaker shoe area, the most efficient CSP separation drum, and large graintanks.10

One-hand controlThe new quiet and vibration-free cab isdesigned for long work days.The traction lever and control consoleintegrated into the armrest provideergonomic and easy one-hand control.The gauges are located on a monitorpillarat eye-level, ensuring unobstructedvisibility of the crop.12

advanced driving ergonomics13

COMIA gets the job doneSubtle powerThe new engine produces the same output at 10% lower fuel consumption.The self-cleaning and rotating engine inlet screenUninterrupted operation in all field conditions.Advanced driving ergonomicsThe new quiet cab is designed for long work days.One-hand controlThe traction lever and control console integrated into the armrest.Higher capacity with a pre-threshing cylinderPre-concave adjustment separately, only in this size class.Header widths for different purposesCutting tables widths from 3,45 – 5,1 m.The headers unique geometryIdeal for cutting both long and short crops.14

CUTTING TABLEThe cutting tables of Sampo Rosenlew combines are highly ratedamong combine operators for their superior performance. The uniquetable geometry is the result of years of dedicated product development.16

The table is ideal for cutting both long and short crops due to the optimal distance betweenthe knife and feeder auger. Other properties of the table highlight its excellence. The largediameter of the feeder auger and the plastic tines of the pick-up reel also give the assemblyunsurpassed performance.The Sampo Rosenlew Comia series offers a wide selection of table widths ranging from 3.45to 5.1 metres to suit all operating requirements and field types.KnifeThe Comia series uses modern screw-on knife blades toensure quick and easy replacement in the event of knifedamage.The knife is operated by a belt-driven Wobble Box drive.The WB knife drive is maintenance free.Feeder augerAn even feed is vital to achieving an optimal threshingresult. The large diameter of the feeder auger used in theComia series tables prevents entanglement in even themost demanding conditions. Starting from the 3.9-metretables, the number of fingers along the feeder auger hasbeen increased to cover the entire table width. This ensureseven feed also with wider tables and higher materialvolumes.The header is equipped with a slip clutch, which preventsstones and foreign material entering the feeder auger.Pick-up reelThe Comia’s plastic pick-up reel tinesensure efficient and gentle feedalso when <strong>harvesting</strong> laid-downcrops. If a plastic tine breaks off due,for example, to stone impact, thethreshing mechanism will not bedamaged in any way.All table and pick-up reel functionson the Comia series are controlledelectrically from the cab.Feeder elevatorAll models in the Comia series areequipped with a durable three-chainelevator. The heavy duty suspendedelevator bottom roller is also suitablefor maize <strong>harvesting</strong>.17

threshing mechanismHigher capacity with a pre-threshing cylinderThe pre-threshing cylinder enables higher capacity without increasedmachine width. Depending on the conditions, a Comia C8 equippedwith pre-threshing cylinder is up to 20% more effective compared to asingle-cylinder combine. The pre-threshing cylinder significantly evensout the material flow to the main cylinder, enabling more efficientthreshing. Under optimal conditions, up to 40% of threshing takesplace at the pre-threshing cylinder. The resulting smoother threshingprocess notably reduces grain breakage.The concave located under the pre-threshing cylinder has identicalthreshing characteristics as the main cylinder. The advantage overother combines equipped with a pre-threshing cylinder is that Comia’spre-concave can be adjusted separately..The 50 cm diameter and 111 cm wide threshing cylinder separatesthe grain easily and carefully. The Comia’s threshing cylinder with its 8rasp bars and cast iron flanges lives up to its heavy duty reputation. Therobust cylinder never slows, even under peak loads.The Comia’s concave is specially designed for threshing. The concavewires are designed thin for accurate threshing.18

The largest shaker shoe area in its classThe largest shaker shoe area in its class provides clean grain in all conditions. The totalshaker shoe area is 3.40 square metres. The upper sieve is of the modern lamella sievetype. On the RV2 lamella sieve, every other lamella is bent down to efficiently preventstraw fragments from entering the grain tank.The grain sieve is of the hole sieve type. The combine delivery includes three sieves:a 5-mm sieve for <strong>harvesting</strong> turnip rape and other small-grain crops, and 12-mm and16-mm sieves for other crops.An adjustable grain sieve is also available. The adjustable grain sieve is a fine RV3lamella sieve.A large-diameter fan generates sufficient air flow to ensure efficient chaff removal.The fan speed is controlled electrically from the cab.The load on the threshing cylinder can be reduced by transporting the returns via aseparate path through a separate and efficient re-threshing device.19

threshing mechanismCSP SEPARATION drumIf <strong>harvesting</strong> is performed in moist conditions or ifthe crop is green, high straw walker performance isessential. Sampo Rosenlew’s CSP (Cylinder Separation)separation drum is located above the straw walkersand is designed to increase the separation capacityof the walkers. In Northern European <strong>harvesting</strong>conditions, the CSP separation drum increases walkerperformance by up to 20%. The CSP separation isequipped with robust fingers which can be adjustedto suit different field conditions and crop types.Straw walkersSampo Rosenlew combines are famous for their excellent performance in the wettest Northern Europeanconditions. In such conditions, a combine’s performance is almost always determined by its straw walkers. TheComia series straw walker bottoms are made of stainless steel. The Comia series features the four-walker C4 modeland the five-walker C6 and C8 models. Sampo Rosenlew is the only combine manufacturer offering a five-walkercombine in this size class. Threshing tests indicate that adding a straw walker pair can increase walker performanceby up to 10%20

straw chopperThe swinging-knife straw chopper cuts even the thickeststraw layers efficiently. The large straw spreader spreadsthe chopped straw over a wide area.If you practice no-till farming or reduced tillage methods,the high-speed straw chopper is a must. The highspeedstraw chopper operates at 20% higher speed thanstandard choppers. The high-speed straw chopper’s rotordiameter is also larger, resulting in higher circumferentialspeed of the knives.Disabling the straw chopper is easy, e.g. for <strong>harvesting</strong>uncut straw. To obtain long straw, turn the straw spreaderup, lower the straw chopper, remove the drive belt fromthe pulley, and place the belt on the hooks provided.21

cabAs you look around the cab, you will notice that theComia is equipped with many of the features usuallyfound only on larger combines.22

The threshing mechanism, cutting table and unloadingare activated by electrical switches. The threshingcylinder and fan speed controls are also convenientlylocated on the armrest.The rotational speed display, driving speed display, andwarning lights are optimally positioned on the frontright-hand monitor pillar. In the event of a warning, theComia alerts you with an audible alarm and a visualwarning light. The pillar also houses the engine controldisplay. The display enables you to monitor key enginedata such as fuel consumption, temperature values, andfluid levels.The Comia’s control centre, the control console, is integratedin the right-hand armrest of the ergonomic operator’s seat.All controls and switches related to the <strong>harvesting</strong> operationhave been positioned with careful consideration. With themulti-function lever, you can control the cutting table andthe combine’s driving direction, as well as manage the whole<strong>harvesting</strong> operation with ease. The armrest-integratedcontrol lever makes light work of even the longest day in thefield.The Comia’s cab is notably quieter than the previousmodels. For instance, making phone calls during <strong>harvesting</strong>is easy with the handy hands-free system, which comesas a standard feature. The cab is also wide enough toaccommodate two persons.In addition to the impressive standard equipment list, awide range of optional cab equipment is also available toboost performance and make <strong>harvesting</strong> even easier.The most popular options include air conditioning,LH500Plus or Maximum threshing monitors, and tableheight control DHC. Remember to check your options listwith your dealer.23

grain tankThe easiest to clean grain tank on the market. Thisis a key feature that all Sampo Rosenlew operatorshave come to appreciate and to demand. TheComia’s grain tank can be cleaned without tools infield conditions.26

The Comia can be fitted with a range of grain tanksizes. It can be fitted with 3,700 to 5200 litre graintanks, depending on the model.A large cab window ensures excellent visibility ofthe tank from the cab. Visibility is further enhancedby a grain tank working light, which can be switchedon from the cab. The tank features a diaphragm-typelevel sensor with audible alarm system.The standard unloading height for all Comia models is 3.40 m,although a 4-metre unloading height option is also available.The unloading pipe can be turned and discharge started via thecontrol console integrated in the armrest. This makes unloadingnotably easier, especially when carried out while driving. The functionallows you to concentrate on the <strong>harvesting</strong> operation, withoutshifting your focus from the crop.27

engine and transmissionThe Comia’s self-cleaning, rotating engine inlet screenensures uninterrupted operation in all field conditions.The engines of the new Comia models meet even thestrictest emission standards. Thanks to the powerfuland modern Sisu Power engine with SCR technology,fuel cost savings up to 10% can be achieved. Theengine revolts just 2,000 rpm, as the threshingmechanism runs notably smoother at lower speed. Theoutput range extends from 150 to 210 hp.The latest SCR technology equipped engines areenvironmentally friendly and cost-effective.Exhaust gases are controlled with AdBlue solution,which ensures no noticeable difference in performancecompared to older diesel engine technology.A display is provided in the cab for monitoring AdBlueconsumption.28

TransmissionDurable hydrostatic traction transmissionensures smooth and reliable driving in allconditions. Driving couldn’t be easier – simplytilt the multi-function lever to drive the Comiaforwards and backwards.Comia combines are equipped with wide tyresas standard. Wide tyres reduce surface pressureand prevent soil compaction. Even wider tyresare also available from the options list.The Comia can also be optionally equippedwith a hydraulic 4WD system. Its tractioncharacteristics can also be improved with anoptional differential lock which is controlledelectrically from the cab.29

CLEANING AND MAINTENANCEThe most easy to clean combine on the market.Sampo Rosenlew combines are renowned fortheir cleanability.The Comia models are no exception. When acombine is made easy to clean it can be cleanedproperly, and only a clean combine can deliver anoptimal result.The Comia has several unique features thatcannot be found in other combines. For example,cleaning doors are optimally positioned, suchas under the grain auger and return auger. Thedoors can also be opened without going underthe combine. You can also easily and quicklyopen the doors using the handles on the leftside of the machine. The grain elevator, verticalreturn auger, and threshing cylinder can alsobe accessed by opening the appropriate quickreleasedoors.30

When it comes to grain tank cleaning, Comia is in a class of its own. Almost all of the tank augers can be pulled out without usingtools. This feature is especially appreciated by seed breaders, as it enables tanks to be easily cleaned in the field.When <strong>harvesting</strong> in moist or otherwise difficult conditions, material tends to accumulate under the concave on the front sectionof the grain pan. In such situations it is important that the grain pan segments can be removed for cleaning. In the Comia seriescombines, you can easily remove the grain pan segments one by one. This also applies to the chaffer and grain sieves and strawwalker bottoms. All this can be done in field conditions using the tools supplied with the combine.A large capacity stone trap is located on the upper end of the elevator. The trap can be easily cleaned without going under theelevator. Large inspection doors provide easy access to the maintenance points.31

RELIABLE SERVICE NETWORKSampo service and spare parts – always close to handThere is a world wide service chain responsible for the service of the Sampo Rosenlewcombines. The mechanics are trained at the factory. They are always ready to drive to thefarm in their well-equipped service vans and service your combine using their latest knowhowand appropriate special tools and gauges. We strongly recommend that you shoulduse these professionals when you need either periodic maintenance or service after thethreshing season.15:5016:0516:2016:45Stone damage during<strong>harvesting</strong> somewherein Europe.Customer contacts localdealer.Order received atSampo-Rosenlew.The spare part order isprepared at spare partwarehouse.32

Use genuine spare partsThe genuine spare parts recommended by Sampo Rosenlew meet the strictquality demands made by the manufacturer. Genuine spare parts ensurethe best possible functioning and reliability of your combine. The mechanicsrecommended by the manufacturer use genuine spare parts only.Filter and belt packageAsk from your local dealer for genuine Comia filter and belt kits. The filterpackage comes in a cardboard box, which contains the annual maintenancefilters for your combine. You need only the chassis number. Belt kits containingall the belts for your combine can be purchased from your local dealer also.19:00The shipment is taken toairport terminal.11:30Customer receives theshipment.14:00Harvesting continues.33

COMIA modelsC8• 6-cylinder Sisu Power engine, 210 hp• 4.5 metre cutting table• Premium Plus cab• air conditioning• LH500Plus threshing monitor• threshing cylinder with 8 rasp bars• TS pre-threshing cylinder system• 5,200 litre grain tank• four-step straw walkers,5 pcs• CSP separation drum• straw chopper, 3,300 rpm• front tyres 600/65R34• rear tyres 420/65R20C6• 6-cylinder Sisu Power engine, 185 hp• 4.2 metre cutting table• Premium Plus cab• threshing cylinder with 8 rasp bars• 4,200 litre grain tank• four-step straw walkers, 5 pcs• CSP separation drum• straw chopper, 3,300 rpm• front tyres 600/65R34• rear tyres 420/65R20C4• 4-cylinder Sisu Power engine, 150 hp• 3.9-metre cutting table• Premium Plus cab• threshing cylinder with 8 rasp bars• 3,700 litre grain tank• four-step straw walkers, 4 pcs• straw chopper, 3,300 rpm• front tyres 520/70R34• rear tyres 360/70R2036

AccessoriesVertical knifeStone arrestorThe stone arrestor is an option that can be fitted to anytable model. The stone arrestor is fastened beneath thebolts on the knife double fingers.Table trailerThe cutting table is easy to transport on a table trailermade by Sampo Rosenlew. The trailer can be adjustedto be the same width as the table. At the beginning ofthreshing, the table is easy to attach to the end of thecrop elevator straight from the trailer.DHCThe table stubble automation (Direct Height Control) isactivated on the control panel in the cab. Stubble height isset on the scale on the stubble gauge. To move the table tothe set height, press the table down switch on the hydrolever.A vertical knife can be installed also on a normal headerin order to ease the feeding and avoidtable lossesHigh-speed chopperA heavy-duty chopper is the right choice if the farmingmethods of light tilling or no tilling are applied. This modelsrevolution speed is 3900 rpm. The diameter of the chopper’rotor is also bigger, so the circumferential velocity is alsobigger than in the standard chopper.Chaff spreaderAs the cutting table increases in width, there is also an increasein the chaff volume coming from the shaker shoe. In orderto spread the chaff wide enough, the combine needs to beequipped with a chaff spreader.Grain loss monitorThere are two models of grain loss monitors availablefor the combines in the SR Comia series. The basicmodel has the regular loss monitor functions and themore sophisticated model features a wide range ofadvanced functions. On the outside the models areidentical.4m unloading pipeBy changing the pipe’s angle with the optional spacerplate, the uploading height rises to 4,0 m.Reversing cameraA 7-inch screen can be installed in the cab to show whatis behind the combine. The camera is on top of the strawhood. An additional camera can be connected to the screento be able to monitor reversing of the table trailer behindthe combine, e.g.4 wdWhen necessary, a four-wheel drive can be fitted to facilitate drivingin wet or sloped fields. The hub motors that can be fitted to the rearwheels are of the robust Black Bruin® quality. With four-wheel driveengaged, the rear wheels have 25% of the traction power. Fourwheeldrive is engaged electrically in the cab.Differential gear lockThe electrically controlled differential gear lock is availablefor every model of the Comia series. The lock is used to fastenthe traction wheels by pushing a button from the cab. Thedifferential gear lock is a great accessory when threshing on softand soggy field.Air conditioningThe cab can be equipped with a cooling air conditioning.37

technical specificationsCOMIA C4 COMIA C6 COMIA C8CUTTING TABLEStandard width m 3,90 4,20 4,50optional widths m 3,45/4,20 3,90/4,50 4,20/4,80Cutting height m - 0,20...+1,20 - 0,20...+1,20 - 0,20...+1,20Knife speed strokes/min 1020 1020 1020Header reverse type elec. elec. elec.REELDiameter m 1,05 1,05 1,05Speed range rpm 15...49 15...49 15...49Speed adjustment elec. elec. elec.Electric for/aft adjustment std std stdPRE-THRESHING CYLINDERWidth/diameter m 1,11/0,40Rate rpm 600...1300Concave area m² 0,34THRESHING CYLINDERWidth/diameter m 1,11/0,50 1,11/0,50 1,11/0,50HD -cylinder std std stdNumber of rasp bars pcs 8 8 8Rasp bar type changeable changeable changeableSpeed range rpm 600…1300 600…1300 600…1300Speed adjustment elec. elec. elec.CONCAVEArea m² 0,51 0,51 0,51Angle of wrap º 105 105 105Number of rasp bars pcs 12 12 12Steppless adj.range mm 6…42 6…42 6…42Concave adjustment stepless stepless elec.STRAW WALKERSNumber pcs 4 5 5Total separation area m² 4,80 4,80 4,80CSP-separating drum not available std stdSHAKER SHOETop sieve m² 1,74 + 0,33 1,74 + 0,33 1,74 + 0,33Bottom sieve m² 1,33 1,33 1,33Total area m² 3,40 3,40 3,40Fan speed adjustment elec. elec. elec.38

COMIA C4 COMIA C6 COMIA C8STRAW CHOPPERSwining knife type std std stdGRAIN TANKCapacity m 3 3,70 4,20 5,20Discharge height m 3,40 3,40 3,40optional m 4,00 4,00 4,00ENGINESisu Power Sisu Power Sisu PowerPower kW/hv 110/150 136/185 154/210Rpm/cylinder 2000/4 2000/6 2000/6Fuel tank capacity l 200 350 350TRANSMISSIONHydro Hydro HydroFinal drives closed final drives closed final drives closed final drivesTIRESFront 520/70R34 600/65R34 600/65R34Rear 360/70R20 420/65R20 420/65R20cabPremium Plus Premium Plus Premium PlusSeat model Grammer Grammer GrammerExtra seat std std stdHeater std std stdAir conditioning option option stdRadio/CD std std stdWEIGHTStandard header and chopper kg 7100 8000 9000DIMENSIONSLenght with std header w/o dividers m 8,68 8,68 9,10Transport height m 3,65 3,65 3,65Transport width with std header m 4,30 4,60 4,90Transport width w/o header with std tires m 2,96 3,12 3,12Clearance m 0,43 0,43 0,43PLENTY OF OPTIONS AND ACCESSORIESThe product development of the Sampo Rosenlew combines continues. Therefore the Company reserves the right to modify the products without prior notice and without obligation to makethe same modifications to combines previously manufactured. The pictures in this brochure are selected from globally used material, due to which some details may vary from country tocountry. Check the information with your dealer.39

Sampo-Rosenlew OyKonepajanranta 2P.O. Box 50FI-28101 PORI, FINLANDTel. +358 207 550 555Fax. +358 2 632 6546www.sampo-rosenlew.fiwww.sampocomia.fi