blue plains advanced wastewater treatment plant - DC Water

blue plains advanced wastewater treatment plant - DC Water blue plains advanced wastewater treatment plant - DC Water

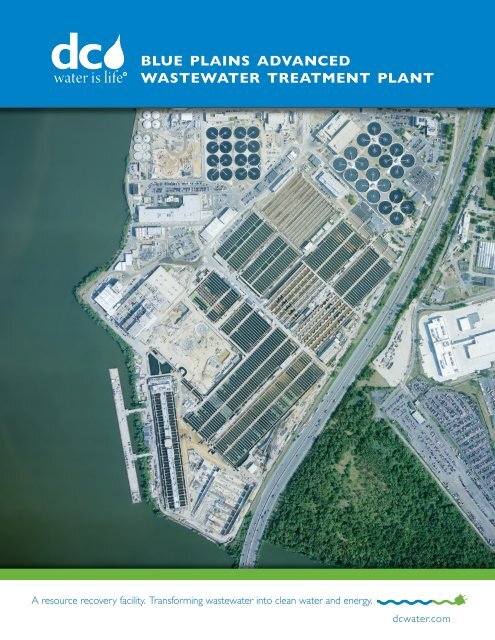

lue plains advancedwastewater treatment plantA resource recovery facility. Transforming wastewater into clean water and energy.dcwater.com

- Page 4: Evolution of Wastewater Treatment T

- Page 10: Next Generation ProjectsEnhanced Nu

lue <strong>plains</strong> <strong>advanced</strong><strong>wastewater</strong> <strong>treatment</strong> <strong>plant</strong>A resource recovery facility. Transforming <strong>wastewater</strong> into clean water and energy.dcwater.com

Evolution of Wastewater Treatment The Cost of Environmental StewardshipBefore 1937, <strong>wastewater</strong> flowed through the District inopen sewers and discharged untreated to the nearestwaterway. Before sewers, disposal methods wereeven more primitive, contributing to epidemics ofcholera and dysentery that caused a high death rate.Sewage conveyance and <strong>treatment</strong>, and the sanitationthey brought to the District, were heralded for publichealth, quality of life and economic benefits. Blue Plains’<strong>treatment</strong> provided the first barrier to protect theenvironment from <strong>wastewater</strong> generated by those livingor working in the region.Half a century later, local waterways were suffering from the population growth of the District and upstream suburbs.Urban and suburban runoff, agricultural runoff and <strong>wastewater</strong> degraded the health of the Potomac and Anacostia rivers,Rock Creek and the Chesapeake Bay. The Blue Plains Advanced Wastewater Treatment Plant remains the best protectionfor our waterways, as it cleanses the <strong>wastewater</strong> generated by more than 2 million people, every minute of every day.The <strong>plant</strong> serves as a barrier to the receiving waters, minimizing the environmental impact of the things we do in our dailylives—not only using the toilet, but washing our clothes, our cars, our dishes, our food, our bodies and our teeth. It is agreat service for the region.Environmental protection is an ongoing commitment. The engineers at <strong>DC</strong> <strong>Water</strong> continually examine <strong>wastewater</strong>technology and facilities to remain on the cutting edge and to implement innovative solutions. <strong>DC</strong> <strong>Water</strong> has three massiveenvironmental <strong>wastewater</strong> programs underway, totaling $4 billion. We are committed to improving the health of localwaterways, and generating sustainable energy from the <strong>wastewater</strong> <strong>treatment</strong> process.DIFFERENTIAL COST PER POUNDOF TOTAL NITROGEN REMOVEDDifferential cost per additional lb$50.00$40.00$30.00$20.00$10.000$0.84 per lb14.0 mg/Lto 7.5 mg/L$3.69 per lb7.5 mg/Lto 5.0 mg/LNitrogen concentration achieved2011 NITROGEN LOADS TO THE BAYBY JURISDICTION mil lbs/yr2011 NITROGEN LOADS TO THE BAYBY SOURCE mil lbs/yr40% agriculture25% atmospheric deposition3% septic46% PA25% VA20% MD4% NY2% WV2% DE1% <strong>DC</strong>17% <strong>wastewater</strong> <strong>treatment</strong> <strong>plant</strong>sBlue Plains less than 2%15% urban / suburban runoff$51.49 per lb5.0 mg/Lto 3.9 mg/LThe cost of innovation and stewardship is significant. For example, theBlue Plains discharge permit issued by the United States EnvironmentalProtection Agency (U.S. EPA) has three times required the Authority todramatically reduce the level of nitrogen. This has been achieved throughtechnological and engineering projects. As the nitrogen limits are furtherreduced, the price increases exponentially. The enhanced nitrogen removalproject that is now underway will cost close to $1 billion and is at the limitof technology.<strong>DC</strong> <strong>Water</strong> joined the Chesapeake Bay Agreement and was the first in thewatershed to meet its voluntary program goals for nutrient removal of 40percent of the 1985 levels, or 7.5 mg/L, two years ahead of schedule. Withthe current construction of enhanced nutrient removal facilities, the <strong>plant</strong> ison track to meet its nitrogen goals under the Chesapeake Bay Agreement2000. The <strong>plant</strong> already meets its phosphorus goals, as phosphorus iscaptured in primary and secondary <strong>treatment</strong> and stored in biosolids whichare land applied, recycling this valuable nutrient back to the land. <strong>DC</strong> <strong>Water</strong>continues to meet or exceed performance levels set by the U.S. EPA.Customers bear the bulk of the costs of these environmental protections.<strong>DC</strong> <strong>Water</strong> has received federal funding in the tens of millions of dollars forthe three current environmental projects under construction at Blue Plains,but their ultimate price tag is about $4 billion.It is important to note that even if nitrogen levels at Blue Plains werereduced to zero, local waterways and the Chesapeake Bay would still beimpaired by other sources of nitrogen. Blue Plains contributes less than twopercent of the estimated nitrogen load to the Chesapeake Bay. AlthoughBlue Plains is the largest single point-source discharger of nitrogen, the vastmajority of the nitrogen in the Bay is from non-point sources.It is imperative that other sources of nitrogen, including agriculturalrunoff, and urban and suburban runoff, are addressed to improve the healthof local waters. States in the Chesapeake Bay watershed are formulatingwatershed implementation plans to do just that, but manyare finding the solutions to be cost-prohibitive.State-of-the-Art Technology and Innovative ResearchAs part of the nearly $1 billion <strong>plant</strong>-wide upgrades in the 2000s, theAuthority streamlined operations by automating many processes andbuilt a state-of-the-art operations center, where performance of theentire <strong>plant</strong> can be monitored.Blue Plains is world-renowned for its research programs that analyzetechnologies years before they are put into practice. <strong>DC</strong> <strong>Water</strong>’sengineering team is recognized for innovation, exploring technologiesthat have not been adopted in the United States. In fact, delegations ofinternational <strong>wastewater</strong> engineers visit Blue Plains all year long to learnmore about <strong>DC</strong> <strong>Water</strong>’s management, engineering, finance, researchand technology.23

The Wastewater Treatment ProcessScreening and grit removalWastewater comes to Blue Plainsthrough 1,800 miles of sewers fromaround the District and from thePotomac Interceptor, a large sewerthat begins at Dulles Airport, bringingwith it <strong>wastewater</strong> from suburbsalong the way.At the headworks, the sewage ispumped up from below ground for<strong>treatment</strong> at the <strong>plant</strong>. A series ofscreens removes objects and largeparticles. The grit chamber removesrocks and other non-degradableparticles. These are loaded intotrucks and taken to a landfill. The<strong>wastewater</strong> then flows to the nextstage of <strong>treatment</strong>.Primary clarifiersPrimary <strong>treatment</strong> is a physicalprocess that takes place in a coneshapedtank. Solid particles settleout and fall to the bottom, while the<strong>wastewater</strong> flows outward, over a setof weirs. An arm skims the fats, oilsand grease (FOG) off the top whilethe solids settle to the bottom. ThisFOG is sent to landfills, while the solidsare treated for reuse.Secondary reactors andsedimentationSecondary <strong>treatment</strong> is a biologicalprocess that uses microbes to treatorganic material (fats, sugars, shortchaincarbon molecules). At BluePlains, activated sludge is the processused to achieve secondary <strong>treatment</strong>.For the process to be most effective,the microbes need both oxygen andfood. Blue Plains supplies the oxygenby pumping air into the tanks withbubble diffusers. The <strong>wastewater</strong>contains the food (organic matter,or carbon). The microbes consumethis food and grow more microbes.The added oxygen causes the<strong>wastewater</strong> in secondary reactors tohave a bubbling, active appearanceand the microbes cause a reddishbrowncolor.It is a delicate environment thatrequires diligent monitoring toensure the health of the microbialcolonies. Once they have donetheir duty, the bugs are settled outfrom the <strong>wastewater</strong> in secondarysedimentation tanks. A portion ofthe settled microbes are then reintroducedto secondary reactorsto sustain the process, with theremainder recycled with the biosolids.Many <strong>wastewater</strong> <strong>treatment</strong> <strong>plant</strong>sstop <strong>treatment</strong> here. But Blue Plainsdischarges to the Potomac, a tributaryto the Chesapeake Bay, and nitrogenmust be further removed to protectthe watersheds.Nitrification, denitrification, filtrationand disinfection establish Blue Plainsas an <strong>advanced</strong> <strong>wastewater</strong><strong>treatment</strong> facility.NitrificationThe first step of tertiary <strong>treatment</strong> isoxidizing the nitrogen from ammoniato nitrate. This is achieved throughanother biological process usingmicrobes in the nitrification reactorswith a large amount of air.DenitrificationThe second step to nitrogen removalrequires converting the nitrate tonitrogen gas, which releases thenitrogen safely into the atmosphere.This step does not add oxygen, whichcauses the microbes to consume theoxygen in nitrates. The process isachieved in the same type of tanksas nitrification, but the nitrificationsection is aerated (aerobic), whilethe denitrification section is notaerated (anoxic). The microbes requirea carbon source as food. Methanolis added in this process as thecarbon source.Multimedia filtrationand disinfectionThe treated <strong>plant</strong> flow is filteredthrough sand and anthracite in theworld’s largest <strong>wastewater</strong> filtrationfacility. The flow is disinfectedwith sodium hypochlorite-basedchlorination at the filter influent, andthe residual chlorine is removed beforedischarge with sodium bisulfite. Thefinal <strong>plant</strong> effluent after processinglooks the same as drinking water.Sludge Thickening, DewateringIn the <strong>treatment</strong> processes, sludge isremoved from process tanks. In theprimary clarifiers, this sludge is sentto screening and grit removal, andthen sent to gravity thickeners forthickening. Secondary or final effluentis used for dilution water for thegravity thickening process.Sludge that comes from the secondaryand nitrification processes is sent todissolved air flotation tanks where aprocess using supersaturated air is ableto float the sludge to the surface.This secondary sludge is skimmed offthe surface and combined with thegravity thickened sludge in a blend tankand then fed to centrifuges to removeas much liquid as possible, leaving abiosolid cake. This process is calleddewatering and is achieved by sendingthe sludges through high-speedcentrifuges that separate out the waterand solids.Biosolids End UseFor many years, the final processfor biosolids has involved treatingthem with lime to stabilize the solidsand reduce residual pathogensbefore loading onto trucks andhauled to farmlands. The biosolidsare land-applied, recycling thecarbon and nutrients—nitrogenand phosphorus—back to the soil.The biosolids meet Class B qualitystandards, allowing for land applicationwith strict requirements includingbuffer zones and a access limitation.The future for biosolids at <strong>DC</strong> <strong>Water</strong>is even brighter with the constructionof new facilities to process them andgenerate combined heat and power.The biosolids will be batch treated athigh temperatures and pressure andthen fed to anaerobic digesters. Thedigester will capture methane andburn it in a turbine, providing net 10MW of electricity and steam to heatthe process.45

Next Generation ProjectsEnhanced Nutrient RemovalThe enhanced nutrient removal project’s mission is toreduce the level of nitrogen from the cleansed <strong>wastewater</strong>that <strong>DC</strong> <strong>Water</strong> discharges to the Potomac River. Nitrogencan act as a fertilizer in the Potomac River and ChesapeakeBay, creating unruly grasses that deplete oxygen needed bymarine life to live and thrive.Once the $950 million project is complete, Blue Plainswill produce effluent with some of the lowest levels ofnitrogen in the country. At 4 milligrams per liter (mg/L),it is extremely low, and is considered near the limit ofconventional <strong>treatment</strong> technology. The facilities includemore than 40 million gallons of additional anoxic reactorcapacity for nitrogen removal, new post-aeration facilities,an 890 mgd lift station, new channels and conveyancestructures, and new facilities to store and feed methanoland alternative carbon sources.Thermal Hydrolysis and Anaerobic Digestion<strong>DC</strong> <strong>Water</strong> will be the first utility in North America touse thermal hydrolysis for <strong>wastewater</strong> <strong>treatment</strong>. Whencompleted, it will be the largest thermal hydrolysis <strong>plant</strong> inthe world. Though thermal hydrolysis has been employedin Europe, the water sector in North America has not yetadopted this technology. Industry leaders across the continenteagerly await the results for the potential of using thistechnology.The process pressure-cooks the solids left over after<strong>wastewater</strong> <strong>treatment</strong> to produce combined heat andpower—generating a net 10 MW of electricity. <strong>DC</strong> <strong>Water</strong> isthe largest single source consumer of electricity in the District,and the digesters should cut consumption up to a third. Theprocess will also create a Class A biosolid that has many morereuse options as a soil amendment than the current Class Bproduct. The solids product is a smaller volume, and evenwhen land-applied, will reduce hauling and emissions, furtherreducing the <strong>plant</strong>’s carbon footprint by a third.How much energy is 10 MW?That’s enough to power 8,000 homes.As in many older cities, about onethirdof the District has a combinedsewer system, meaning one pipecarries both <strong>wastewater</strong> and stormrunoff. A combined-sewer overflow(or CSO) occurs during heavy rain when the mixture ofsewage and stormwater cannot fit in the sewer pipes andoverflows to the nearest water body. CSOs direct about2.5 billion gallons of combined sewage into the Anacostiaand Potomac rivers and Rock Creek in an average year.CSOs contain bacteria and trash that can be harmful tothe environment.<strong>DC</strong> <strong>Water</strong> has already reduced CSOs to the AnacostiaRiver by 40 percent with improvements to the existingsewer system. To achieve a 98 percent capture rate, theClean Rivers Project will consist of massive undergroundtunnels to store the combined sewage during rain events,releasing it to Blue Plains after the storms subside.The first and largest tunnel system will serve the AnacostiaRiver. This tunnel will be 23 feet in diameter and will runmore than 100 feet deep, along the Potomac and underthe Anacostia.The tunnel segments south of RFK Stadium, together withtheir surface hydraulic facilities and a tunnel dewateringpump station, are scheduled to begin operating in 2018,providing relief to the Anacostia River first.<strong>DC</strong> <strong>Water</strong> is proposing a pilot Green Infrastructure (GI)program to test the ability of GI—trees, tree boxes, rainbarrels, porous pavers, rain gardens, etc.— to controlenough runoff that the final two tunnels may be minimized.A GI solution would benefit the District with a lowercost solution along with green jobs, a greener <strong>DC</strong>, andcleaner waterways.8

dcwater.com