36 Operator's Manual.. - Marlow-Hunter, LLC

36 Operator's Manual.. - Marlow-Hunter, LLC

36 Operator's Manual.. - Marlow-Hunter, LLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

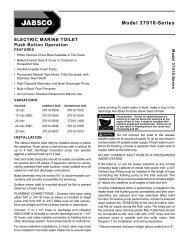

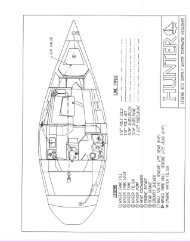

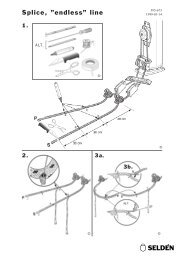

HUNTER OWNER’S MANUALTABLE OF CONTENTSINTRODUCTION· Warranty Registration Form………………………………………· <strong>Hunter</strong> Warranty………………………………………….…………· Brief History………………………………………………………….· Glossary of Sailing Terms….………………………………………· Explanation of Symbols and Labels………………………………GENERAL HANDLING AND OPERATION· Safe Boating Tips…………………………………………………..· Pre-Departure Checklist……………………………………………· Float Plan……………………………………………………………· After Sailing Check List………………………………….…………· Docking and Anchoring…………………………………………….· Diesel Engine and Motoring……………………………………….· Electrical System……………………………………………………· Cook Stove…………………………………………………………..· Toilet…….……………………………………………………………· Opening Hull Ports………………………………………………….· Pumps………………………………………………………………..· Water System Operation………………………………….……….· Waste Discharge………………………………………….………..· Environmental Considerations…………………………………….MAINTENANCE· Instructions for Preparation for Bottom Painting………………...· Engine, Transmission, and Drive train……………………………· Compasses………………………………………………………….· Steering Systems…………………………………………………..· Electrical Systems………………………………………………….· Plumbing Systems………………………………………………….· Fuel Systems………………………………………………………..· General Care………………………………………………………..· Fabric Care………………………………………………………….· Electrolysis and Galvanic Protection……………………………..· Teak Care……………………………………………………………· Storage/Winterization……………………………………………...· Certification Details…………………………………………………· Lightning Warning…………………………………………………..PAGE12-345-8910-111213141516-1717-18191919202021222324-25262626272728-2929303031-3334351 of 3

HUNTER OWNER’S MANUALTABLE OF CONTENTS (CONT’D)DESCRIPTION OF MODEL· Profile with Rig and Sail Dimensions……………………………..· Dimensions, Capacities, etc……………………………………….· Deck Plan and Hardware…………………………………………..· Deck Hardware Parts Listing………………………………………· Accommodation Plan……………………………………………….· Dinette Table Operation……………………………………………· Lifting Points…………………………………………………………· Running Rigging Layout……………………………………………· Mainsheet Rigging………………………………………………….· Arch Installation……………………………………………………..· Boom and Reefing Details…………………………………………· Running Rigging Specifications…………………………………..· Rig Description……………………………………………………..· Standing Rigging Layout……...……………………………………· Spreader Details…………………………………………………….· Standing Rigging Specifications…………………………………..· Standing Rigging Attachments…………………………………….· Rig Tuning Instructions…………………………………………….· Spinnaker Details…………………………………………………...· Engine Compartment Details……………………………………...· Shaft and Propeller…………………………………………………SYSTEMS AND CIRCUITS· Potable Water System……………………………………………..· Waste System……………………………………………………….· Bilge Pumping System……………………………………………..· Through Hulls, Seacocks, and Valves……………………………· Fuel System…………………………………………………………· Propane System…………………………………………………….· Electrical System(See Electrical System Table Of Contents)………· Steering System…………………………………………………….· Anchoring Arrangement……………………………………………· Index………………………………………………………………….PAGE<strong>36</strong>37383940A-40C41A41B42A-1&243444546474849505152-53545556PAGE57585960616263A-166-6869702 of 3

HUNTER OWNER’S MANUALTABLE OF CONTENTS (CONT’D)EQUIPMENT MANUALS AND INFORMATION· Engine <strong>Manual</strong>· Knotmeter and Depthsouder· VHF Radio (except where not provided)· Compass Information· Stereo <strong>Manual</strong>· Furling System <strong>Manual</strong>· Marine Rigging Guide· Winch Maintenance Guide· Steering Maintenance Guide· Sail Maker Information· Water Strainer· Bilge Pump· Toilet <strong>Manual</strong>· Stove <strong>Manual</strong>· Hot Water <strong>Manual</strong>· Microwave <strong>Manual</strong> (except where not provided)· Other:3 of 3

Welcome toTHE HUNTER MARINE FAMILYCongratulations on your new sailing yachtmanufactured by <strong>Hunter</strong> Marine. We haveengineered and constructed your boat to be asfine a yacht as any afloat. In order to get the bestperformance and most enjoyment from your boatyou should be familiar with its various elementsand their functions. For your sailing pleasure andsafety, please take time to study this manual.We stand behind the quality of your boat with awarranty, which you should review. To insure thevalidity of your warranty, please complete theattached card and send it to us within ten (10)days of the purchase date. Section 15 of the U.S.Federal Boat Safety Act requires registration of aboat’s first owner. The warranty data should alsobe recorded in the space below for your ownreference.This manual has been compiled to help youoperate your craft with safety and pleasure. Itcontains details of the craft; equipment suppliedor fitted, systems, and information on operationand maintenance. Please read it carefully, andfamiliarize yourself with the craft before using it. Ifthis is your first sailboat or you are changing to atype of craft you are not familiar with, pleaseensure that you obtain proper handling andoperating experience before you assumecommand of the craft. Your dealer or nationalsailing federation or yacht club will be pleased toadvise you of local sea schools or competentinstructors.PLEASE KEEP THIS MANUAL IN A SAFEPLACE AND HAND IT OVER TO THE NEWOWNER IF YOU SELL THE CRAFT.You should also complete the warranty cards foryour engine, stove, head, electric water pumpand other accessories. These are enclosed in themanufacturers’ manuals that are packaged withyour owner’s manual.OWNER INFORMATION CARDHULL IDENTIFICATION NUMBER IS ON THE STARBOARD AFT SIDE OF THE HULL OR TRANSOM.THIS NUMBER MUST BE GIVEN IN ALL NECESSARY CORRESPONDENCE.HULL NO.DATE DELIVERED TO OWNERYACHT NAMEOWNER NAMESTREET ADDRESSCITY STATE/COUNTRY ZIP CODEHOME PORTENGINE MODEL SERIAL NO. PROPELLER SIZEDEALERPHONESTREET ADDRESSCITY STATE/COUNTRY ZIP CODEPAGE 1

<strong>Hunter</strong> Marine warrants to the first-usepurchaser and any subsequent owner duringthe warranty period, that any partmanufactured by <strong>Hunter</strong> will be free ofdefects caused by faulty workmanship ormaterials<strong>Hunter</strong> warrants to the first-use purchaserand any subsequent owner during thewarranty period that the hull of each boat willbe free from structural defects in materialsand workmanship for a period of five (5)years from the date of delivery to the firstusepurchaser under normal use andservice.This limited warranty applies only to thestructural integrity of the hull and supportingpan/grid or stringer system. Hulls, pan/gridor stringers modified in any way or poweredwith engines other than the type and sizeinstalled or specified by <strong>Hunter</strong> are notcovered by this limited warranty. Theobligation of <strong>Hunter</strong> under this limitedwarranty is restricted to the repair orreplacement of hulls that are determined tobe structurally defective.<strong>Hunter</strong> also warrants to the first-usepurchaser and any subsequent owner duringthe warranty period that the boat will be freefrom gel-coat blistering on underwatersurfaces of the hull, excluding the keel andrudder, for a period of five (5) years from thedate of delivery to the first-use purchaserHUNTER MARINELIMITED WARRANTYLIMITED ONE-YEAR WARRANTYLIMITED FIVE-YEAR HULL STRUCTUREAND BOTTOM BLISTER WARRANTYfor a period of twelve (12) months from thedate of delivery to the first-use purchaserunder normal use and service. During thisperiod, <strong>Hunter</strong> will repair or replace any partjudged to be defective by <strong>Hunter</strong>.under normal use and service. During thisperiod, <strong>Hunter</strong> will supply or reimburse anauthorized <strong>Hunter</strong> dealer for all of the partsand labor required to repair a blisteredunderwater surface of the hull. The laborcost reimbursement will be based on theLabor Allowance Schedule established by<strong>Hunter</strong>. However, if a non-<strong>Hunter</strong> dealerperforms the repair, the repair cost must beauthorized by <strong>Hunter</strong> in advance and bebased on a reasonable number of hours asdetermined by <strong>Hunter</strong>. Transportation,hauling, launching, bottom paint, storage,dockage, cradling rental, rigging andderigging, or other similar costs will not bepaid by <strong>Hunter</strong>. We recommend that therepair be done during a seasonal haul outfor service or storage.The bottom blister warranty is void underthe following circumstances:(1) If the gel-coat has been sanded,sandblasted, or subjected to abrasion orimpact.(2) If the instructions provided in the<strong>Hunter</strong> Owner’s manual regarding bottompreparation techniques are not followed.RESTRICTIONS APPLICABLE TO WARRANTIESThese limited warranties do not cover thefollowing:(1) Paint, window glass, gel-coat,upholstery, engines, engine parts, bilgepumps, stoves, blowers, pressure waterpumps, propellers, shafts, rudders, controls,instruments, keels and equipment notmanufactured by <strong>Hunter</strong>. Any warrantymade by the manufacturer of such items willbe, if possible, given on to the first-usepurchaser.(2) Problems caused by impropermaintenance, storage, cradling, blocking,normal wear and tear, misuse, neglect,accident, corrosion, electrolysis or improperoperation.THIS WARRANTY IS EXPRESSLY IN LIEUOF ANY AND ALL OTHER REMEDIESAND WARRANTIES EXPRESSED ANDIMPLIED, INCLUDING THE WARRANTIESOF MERCHANTABILITY AND FITNESS.SOME STATES OR COUNTRIES DO NOTALLOW LIMITATIONS ON HOW LONG ANIMPLIED WARRANTY LASTS, SO THEABOVE LIMITATION MAY NOT APPLY TOYOU. THE PURCHASERPAGE 2

ACKNOWLEDGES THAT NO OTHERREPRESENTATIONS WERE MADE TO HIMANY CONSEQUENTIAL DAMAGES THATMAY BE INCURRED ARE EXCLUDED ANDJUDGED DEFECTIVE BY HUNTER.SOMESTATES OR COUNTRIES DO NOTALLOW THE EXCLUSION OF INCIDENTALOR CONSEQUENTIAL DAMAGES, SO THEThese limited warranties shall not beeffective unless the <strong>Hunter</strong> WarrantyRegistration Form and Pre-Delivery ServiceRecord, which are furnished with each newboat, are filled out completely and returnedto <strong>Hunter</strong> within fifteen (15) days of delivery.Responsibility for sending the completedRegistration Form remains with the dealer.It is critical that the Warranty RegistrationForm is signed by both the dealer and theowner and returned to <strong>Hunter</strong>. Warrantycoverage cannot be initiated until <strong>Hunter</strong>receives the completed form. All repairsand/orLimited warranties will be transferred to asubsequent purchaser of the boat if:(1) The subsequent purchaser gives<strong>Hunter</strong> written notice of transfer ofownership within thirty (30) days of thetransfer.(2) The notice shall include thename, address and telephone number of theShould a customer wish to have an epoxybarrier applied to the hull, ( ex. InterluxInterprotect 1000/2000, West Systems, VCTar), this will not void the five-year blisterwarranty. This refers to epoxy barriercoatings as mentioned above, not epoxyprimer paints.During the first year of ownership, the firstpurchaser will receive two CustomerSatisfaction Surveys: the first (CSS #1) willbe received shortly after taking delivery andfocuses on the customer’s experience withthe dealer and commissioning of the boat,and the owner’s initial satisfaction. TheHUNTER MARINELIMITED WARRANTYWARRANTY REGISTRATIONTRANSFER OF LIMITED WARRANTIESEPOXY BARRIER COATCUSTOMER SATISFACTION SURVEYOR HER WITH RESPECT TO THE QUALITYAND FUNCTION OF THE BOAT.ABOVE LIMITATION OR EXCLUSION MAYNOT APPLY TO YOU. THIS WARRANTYGIVES YOU SPECIFIC LEGAL RIGHTS, ANDYOU MAY ALSO HAVE OTHER RIGHTSTHAT VARY FROM STATE TO STATE ORCOUNTRY TO COUNTRY.replacements will be made by an authorized<strong>Hunter</strong> dealer, or at the option of <strong>Hunter</strong>, atthe <strong>Hunter</strong> plant. If the repairs are of such anature that the warranty work must beperformed at the <strong>Hunter</strong> plant, the ownershall pay transportation costs to and fromthe <strong>Hunter</strong> plant. The labor costreimbursement will be based on a laborallowance schedule established by <strong>Hunter</strong>and where not applicable, on a reasonablenumber of hours as determined by <strong>Hunter</strong>.An authorized <strong>Hunter</strong> service representativemust approve any repairs and replacementsinadvance.subsequent purchaser, the date ofpurchase, the hull number, and the name ofthe seller of the boat.<strong>Hunter</strong> will mail notice of expiration dates ofthe limited warranties to the subsequentowner. The transfer of the ownership of thewill not extend the expiration dates of thelimited warranties.If an epoxy barrier coat is applied to a<strong>Hunter</strong> vessel, it must be registered with theWarranty Department prior to application ofthe product. If the dealer applies bottompaint only, sanding will not be allowed andthe no sanding system must be used.second survey (CSS #2) is given nine to tenmonths into ownership, and primarily givesthe customer an opportunity to evaluatedealer service capability and the boat’sfunctional systems and characteristics. Bothsurveys are contingent upon receipt of thefirst purchaser’s Warranty Registration form.PAGE 3

HUNTER MARINE’S OWNER AND FOUNDERWARREN R. LUHRSBRIEF BACKGROUNDWarren Luhrs was born in East Orange,New Jersey in 1944 into a family with anestablished tradition in the maritime andtransportation industries. His greatgrandfather,Henry, was a railroad andclipper-shipping pioneer in America,while his great-uncle John helped buildthe famous St. Petersburg to Moscowrailroad for Czar Alexander II.Henry Luhrs owned shares in twentytwodifferent ocean-going vessels –barks, brigs, and schooners - and wasthe principal owner of the bark SophiaR. Luhrs, named for his wife. He wasalso a partner with Albert Sprout, whomanaged the shipyard where the SophiaR. Luhrs was built in Melbridge, Maine.Warren Luhrs’ father Henry worked at asmall boat manufacturer in Morgan,New Jersey, and later started his owncompany, continuing the Luhrs’ familysea tradition during the greatdepression. During World War II herepaired boats and installed icesheathing on their bows for the CoastGuard.After the War, Henry built 27-foot fishingboats and in 1948 began to constructcustom-built pleasure craft. He thenturned to skiffs and in 1952 incorporatedas Henry Luhrs Sea Skiffs, where heconstructed lapstrake sea skiffs usingassembly-line techniques. Henrypersonally “shook down” his prototypeson family trips up the Hudson River toLake Champlain.The sea skiff is a class of boat that hasbeen very popular, owing to itsseaworthiness. It features a sharp bow,which reduces pounding in surf orchoppy seas, and a hull whose forwardsection is rounded below the waterlineto increase stability in rough water or afollowing sea. Such skiffs can either besmooth sided or of a lapstrakeconstruction.Inspired by Henry Ford, Henry Luhrs’aimed to give the average man theopportunity to enjoy the luxury ofboating by building an affordable andreliable boat. He was both designer andengineer, and his progressive newmodels exhibited his talent forinnovation. He successfully changed theline of the bow from straight to curved ata time when the industry trend was astraight square effect, and he is believedto be the first designer-builder topopularize a small boat with a fly bridge.In 1960, Luhrs acquired the UlrichsenBoat Company of Marlboro, NewJersey. It was here that Luhrs’ Alurafiberglass division was located. In 1965,Henry sold his company to BangorArrostook Railroad, which was tobecome the recreational conglomerateBangor-Punta. It was also during thisperiod that Silverton of Tom’s River,New Jersey was purchased by John andWarren Luhrs.Today, Warren R. Luhrs and his brotherJohn own the Luhrs Group of marinemanufacturers, which consists ofSilverton Marine, Mainship MotorYachts, and Luhrs Fishing Boats with itsAlura division, as well as <strong>Hunter</strong> Marine,which exclusively manufacturessailboats.In January of 1996, the Luhrs familytransferred a portion of the Luhrs Groupto its employees through an ESOPprogram.PAGE 4

GLOSSARY OF SAILING TERMSAAback: describes a sail when the windstrikes it on the lee side.Abaft: towards the boat’s stern.Abeam: at right angles to the centerlineof the boat.Aft: at or near the stern.Amidships: the center of the boat,athwartships and fore and aft.Anti-fouling: a poisonous paintcompound used to protect theunderwater part of a hull from marinegrowths.Apparent wind: The direction andspeed of the wind felt by the crew. Itis a combination of true wind and thatcreated by the movement of the boat.Astern: behind the boat; to go asternis to drive the boat in reverse.Athwartships: at right angles to thefore and aft line of the boat.BBack: when a wind backs, it shiftsanticlockwise.Back a sail: to sheet it to windwardso that the wind fills on the side thatis normally to leeward.Backstay: a stay that supports themast from aft and prevents its forwardmovement.Ballast: extra weight, usually lead oriron, placed low in the boat orexternally on the keel to providestability.Ballast keel: a mass of ballast boltedto the keel to increase stability andprevent a keel boat from capsizing.Batten: a light, flexible strip fed into abatten pocket at the leech of the sailto support the roach.Beam: 1, the maximum breadth of aboat; 2, a transverse member thatsupports the deck; 3, on the beammeans that an object is at rightangles to the centerline.Bear away: to steer the boat awayfrom the wind.Bearing: the direction of an objectfrom an observer, measured indegrees true or magnetic.Beat: to sail a zigzag course towardsthe wind, close-hauled on alternatetacks.Delay: to make fast a rope around acleat, usually with a figure-of-eightknot.Bend: 1, to secure a sail to a sparbefore hoisting; 2, to moor a boat; 3,a sleeping place on board.Bight: a bend or loop in a rope.Bilge: the lower, round part inside thehull where the water collects.Block: a pulley in a wooden or plasticcase, consisting of a sheave aroundwhich a rope runs. It is used tochange the direction of pull.Boot-topping: a narrow coloredstripe painted between the bottompaint and the topside enamel.Bottlescrew: see Rigging screw.Broach: when a boat runningdownwind slews broadside to thewind and heels dangerously. It iscaused by heavy following seas orhelmsman’s error.Broad reach: the point of sailingbetween a beam reach and a run,when the wind blows over a quarter.Bulkhead: a partition wall in a boatnormally fitted athwartshipsCCaulk: to make the seams betweenwooden planks watertight by fillingwith cotton, oakum or a compound.Cavitation: the formation of a vacuumaround a propeller, causing a loss inefficiency.Center-board: a board loweredthrough a slot in the keel to reduceleeway.Center-line: center of the boat in afore and aft line.Center of effort (COE): the point atwhich all the forces acting on the sailsare concentrated.Center of lateral resistance (CLR):the underwater center of pressureabout which a boat pivots whenchanging course.Chain pawl: a short lug which dropsinto a toothed rack to prevent theanchor chain running back.Chain plate: a metal plate bolted tothe boat to which the shrouds orbackstays are attached.Chart datum: reference level on achart below which the tide is unlikelyto fall. Soundings are given belowchart datum. The datum level variesaccording to country and area.Chine: the line where the bottom ofthe hull meets the side at an angle.Cleat: a wooden, metal or plasticfitting around which rope is secured.Clevis pin: a locking pin throughwhich a split ring is passed to preventaccidental withdraw.Clew: the after, lower center of a sailwhere the foot and leech meet.Close-hauled: the point of sailingclosest to the wind; see also beat.Close reach: the point of sailingbetween close-hauled and a beamreach, when the wind blows forward ofthe beam.Close-winded: describes a boat ableto sail very close to the wind.Coaming: the raised structuresurrounding a hatch, cockpit, etc.,which prevents water entering.Cotter pin: soft, metal pin folded backon itself to form an eye.Course: the direction in which avessel is steered, usually given indegrees; true, magnetic or compass.Cringle: 1, a rope loop, found ateither end of a line of reef points; 2, aneye in a sail.DDead run: running with the windblowing exactly aft, in line with thecenter-line.Deviation: the difference between thedirection indicated by the compassneedle and the magnetic meridian;caused by object aboard.Displacement: 1, the weight of waterdisplaced by a boat is equal to theweight of the boat; 2, a displacementhull is one that displaces its ownweight in water and is only supportedby buoyancy, as opposed to aplanning hull which can exceed itshull, or displacement, speed.Downhaul: a rope fitted to pull downa sail or spar.Draft: the vertical distance from thewaterline to the lowest point of thekeel.Drag: 1, an anchor drags when it failsto hole; 2, the force of wind on thesails, or water on the hull, whichimpedes the boat’s progress.PAGE 5

GLOSSARY OF SAILING TERMSDrift: 1, to float with the current orwind; 2, US the speed of a current(rate UK); 3, UK: the distance a boatis carried by a current in a given time.Drogue: a sea anchor put over thestern of a boat or life raft to retard drift.Drop keel: a retractable keel whichcan be drawn into the hull, whenentering shallow waters andrecovering on to a trailer.EEye of the wind: direction from whichthe true wind blows.FFair: well-faired line or surface issmoother with no bumps, hollows orabrupt changes in directions.Fairlead: a fitting through which a lineis run to alter the lead of the line.Fathom: the measurement used fordepths of water and lengths or rope. 1fathom = 6 ft. or 1.83m.Fid: a tapered tool used for splicingheavy rope and for sail-making, oftenhollow.Fiddle: a raised border for a cabintable, chart table etc., to preventobjects falling off when the boat heels.Fix: the position of the vessel asplotted from two or more positionlines.Forestay: the foremost stay, runningfrom the masthead to the stemhead,to which the headsail is hanked.Freeboard: vertical distance betweenthe waterline and the top of the deck.GGenoa: a large headsail, in varioussizes, which overlaps the mainsail andis hoisted in light to fresh winds on allpoints of sailing.Gimbals: two concentric rings,pivoted at right angles, which keepsobjects horizontal despite the boat’smotion, e. g. compass and cooker.Go about: to turn the boat through theeye of the wind to change tack.Gooseneck: the fitting attaching theboom to the mast, allowing it to movein all directions.Goosewing: to boom-out the headsailto windward on a run by using awhisker pole to hold the sail on theopposite side to the mainsail.Ground tackle: general term used foranchoring gear.Guard rail: a metal rail fitted aroundthe boat to prevent the crew fallingoverboard.Gudgeon: a rudder fitting. It is the eyeinto which the pintle fits.Guy: a steadying rope for a spar; aspinnaker guy controls the fore and aftposition of the spinnaker pole; theforeguy holds the spinnaker poleforward and down.Gybe: to change from one tack toanother by turning the stern throughthe wind.HHalyard: rope used to hoist and lowersails.Hank: fitting used to attach the luff ofa sail to a stay.Hatch: an opening in the deck givingaccess to the interior.Hawes pipe: see Navel pipe.Head-topwind: when the bows arepointing right into the wind.Headfoil: a streamlined surround to aforestay, with a groove into which aheadsail luff slides.Heads: the toilet.Headway: the forward movement of aboat through the water.Heave-to: to back the jib and lash thetiller to leeward; used in heavyweather to encourage the boat to liequietly and to reduce headway.Heaving line: a light line suitable forthrowing ashore.Heel: to lean over to one side.IIsobars: lines on a weather mapjoining places of equal atmosphericpressure.JJackstay: a line running fore and aft,on both sides of the boat, to whichsafety harnesses are clipped.Jury: a temporary device to replacelost or damaged gear.KKeel: the main backbone of the boatto which a ballast keel is bolted orthrough which the centerboardpasses.Kicking strap: a line used to pull theboom down, to keep it horizontal,particularly on a reach or run.LLanyard: a short line attached to oneobject, such as a knife, with which it issecured to another.Leech: 1, the after edge of a trianglesail; 2, both side edges of a squaresail.Leehelm: the tendency of a boat tobear away from the wind.Lee shore: a shore on to which thewind blows.Leeward: away from the wind; thedirection to which the wind blows.Leeway: the sideways movement of aboat off its course as a result of thewind blowing on one side of the sails.Lifeline: a wire or rope rigged aroundthe deck to prevent the crew fallingoverboard.Limber holes: gaps left at the lowerend of frames above the keel to allowwater to drain to the lowest point ofthe bilges.List: a boat’s more or less permanentlean to one side, owing to theimproper distribution of weight, e.g.,ballast or water.Log: 1, an instrument for measuring aboat’s speed and distance traveledthrough the water; 2, to record in abook the details of a voyage, usuallydistances covered and weather.Luff: the forward edge of a sail. To luffup is to turn a boat’s head right intothe wind.Luff groove: a groove in a wooden ormetal spar into which the luff of aheadsail is fed.Lurch: the sudden roll of a boat.MMarlin spike: a pointed steel orwooden spike used to open up thestrands of rope or wire then splicing.Mast Step: the socket in which thebase of the mast is located.Measured mile: a distance of onenautical mile measured betweenbuoys or transits/ranges ashore, andmarked on the chart.PAGE 6

GLOSSARY OF SAILING TERMSMember: a part of the skeleton of thehull, such as a stringer laminated intofiberglass hull to strengthen it.Meridian: an imaginary line encirclingthe Earth that passes through thepoles and cuts at right angles throughthe Equator. All lines of longitude aremeridians.Mizzen: 1, the shorter, after-mast on aketch or yawl; 2, the fore and aft sailset on this mast.NNavel pipe: a metal pipe in theforedeck through which the anchorchain passes to the locker below.Noon Sight: a vessel’s latitude canbe found, using a sextant, when aheavenly body on the observer’smeridian is at its greatest altitude. Thesight of the sun at noon is the onemost frequently taken.OOff the wind: with the sheets slackedoff, not close-hauled.On the wind: close-hauled.Out haul: a rope used to pull out thefoot of a sail.Overall length (LOA): the boat’sextreme length, measured from theforemost past of the bow to theaftermost part of the stern, excludingbowspirt, self-steering gear etc.PPainter: the bow line by which adinghy, or tender, is towed or madefast.Pintle: a rudder fitting with a long pinthat fits into the gudgeon to form ahinged pivot for the rudder.Pitch: 1, the up and down motion ofthe bows of a boat plunging over thewaves; 2, the angle of the propellerblades.Point of sailing: the different anglesfrom which a boat may sail; the boat’scourse relative to the direction of thewind.Port: the left-hand side of the boat,looking forward (opp. of starboard).Port tack: a boat is on a port tackwhen the wind strikes the port sidefirst and the mainsail is out tostarboard. A boat on the port tackgives way to a boat on a starboardtack.Position line/ Line of position: a linedrawn on a chart, as a result of takinga bearing, along which the boat’sposition must be i.e. Two positionlines give a fix.Pulpit: a metal guard rail fitted at thebows of a boat to provide safety forthe crew.Pushpit: a metal guard rail fitted atthe stern.QQuarter: the portion of the boatmidway between the stern and thebeam; on the quarter means about 45degrees abaft the beam.RRake: the fore and aft deviation fromthe perpendicular of a mast or otherfeature of a boat.Range: 1, see transit; 2, of tides, thedifference between the high and lowwater levels of a tide; 3, the distanceat which a light can be seen.Rating: a method of measuringcertain dimensions of a yacht toenable it to take part in handicapraces.Reach: to sail with the windapproximately on the beam; all sailingpoints between running and closehauled.Reef: to reduce the sail area byfolding or rolling surplus material onthe boom or forestay.Reefing pennant: strong line withwhich the luff or leech cringle is pulleddown to the boom when reefing.Rhumb line: a line cutting allmeridians at the same angle; thecourse followed by a boat sailing in afixed direction.Riding light to anchor light: an allaroundwhite light, usually hoisted onthe forestay, to show that a boat under50 ft. (15m.)is at anchor. It must bevisible for 2 mls. (3 km.).Rigging screw: a deck fitting withwhich the tensions of standing rigging,e.g. stays, shrouds, etc. are adjusted.Roach: the curved part of the leech ofa sail that extends beyond the directline from head to clew.Run: to run with the wind aft and withthe sheets eased well out.Running rigging: all the movinglines, such as sheets and halyards,used in the setting and trimming ofsails.SScope: the length of rope or cablepaid out when mor anchoring.Scuppers: 1, holes in the toe rail thatallow water to drain off the deck; 2,drain cockpit through hull.Seacock: a valve that shuts off anunderwater inlet or outlet passingthrough the hull.Seize: to bind two ropes together, or arope to a spar, with a light line.Serve: to cover and protect a splice orpart of a rope with twine bound tightlyagainst the lay.Serving mallet: tool with a groovedhead, used when serving a rope tokeep the twine at a constant and hightension.Set: 1, to hoist a sail; 2, the way inwhich the sails fit; 3, the direction oftidal current or steam.Shackle: a metal link with aremovable bolt across the end; ofvarious shapes: D, U.Sheave: a grooved wheel in a blockor spar for a rope to run on.Sheet: the rope attached to the clewof a sail or to the boom, enabling it tobe controlled or trimmed.Shrouds: ropes or wires, usually inpairs, led from the mast to the chainplates at deck level to prevent themast falling sideways; part of thestanding rigging.Sloop: a single-masted sailing boatwith a mainsail and one head sail.Spar: a general term for any woodenor metal pole, e.g., mast or boom,used to carry or give shape to sails.Spindrift: spray blown along thesurface of the sea.Spinnaker: a large, light, balloonshaped sail set when reaching orrunning.Splice: to join ropes or wire byunlaying the strands and interweavingthem.Split pin: see cotter pin.PAGE 7

EXPLANATION OF SAFETY PRECAUTIONSThis manual contains safety precautions that must be observed whenoperating or servicing your boat.Review and understand these instructions.Denotes an extreme intrinsic hazard exists which wouldresult in high probability of death or irreparable injury if properprecautions are not takenDenotes a hazard exists which can result in injury or death ifproper precautions are not takenDenotes a reminder of safety practices or directs attention tounsafe practices which could result in personal injury ordamage to the craft or componentsPAGE 9

SAFE BOATINGTIPSBE PREPAREDTake a safe boating course. In the U.S.,contact your local Boating Industry fordetails.Carry all safety equipment required by thelaws that apply to your area.Requirements are generally available fromthe Coast Guard or your local boatingindustry.As the owner of the craft,obtaining and maintainingnecessary safety equipment is yourresponsibility. For moreinformation about equipmentrequired, contact local boatingauthoritiesMINIMUM RECOMMENDED SAFETY EQUIPMENTRequired life saving equipment,including life vests and throwablesRequired fire extinguishingequipmentFirst Aid kitEmergency Position IndicatingRadio Beacon (EPIRB)<strong>Manual</strong> bailing deviceAnchor with sufficient line and/orchainFlashlight with good batteriesBinocularsVHF radioAppropriate navigational chartsFlaresFog bellNoise emitting deviceRadar reflectorSufficient food and waterprovisionsAuxiliary starting batterySpare fuses and bulbsSunglasses and blockBlanketThe legally required on-board safetyequipment may vary by region or bodyof water. Please check with localauthorities prior to departure for asafety examination.LIFE JACKETSA life jacket may save your life, butonly if you wear it. Keep jackets in areadily accessible place – not in aclosed compartment or stored underother gear. Remove them from anypackaging, and keep throwablefloatation devices ready for immediateuse.Approved fire extinguishers arerequired on most boats, localauthorities can provide details. Allpassengers should know the locationand operating procedure of each fireextinguisher. Fire extinguishers arenormally classified according to firetype. Be familiar with the type of fireextinguishers you have on board.FIRE EXTINGUISHERSIt is very important that children,handicapped people, and non-swimmerswear lifejackets at all times. Make sure allpassengers are properly instructed in useof life saving gearYour boat has been equipped withan Automatic Fire Extinguisher. Inthe event of a fire in your enginecompartment, this unit willautomatically discharge. Please readyour SEA-FIRE manual for operatinginstructions, maintenance andprecautionary information.PAGE 10

SAFE BOATINGTIPSFLARESMost boats operating on coastalwaters are required to carryapproved visual distress signals,therefore check with your localauthorities as to which types arerequired.FIRE/EXPLOSION HAZARD;Pyrotechnic signaling devices cancause injury and property damage if nothandled properly. Follow manufacturer’sdirections regarding the proper use ofsignaling devices.DRUGS AND BOATINGConsumption of alcohol whileboating is not recommended. Thecombination of noise, sun, wind, andmotion act to produce fatigue on thewater, and can exaggerate theeffects of alcohol.IMPAIRED OPERATION HAZARDOperating any boat while is intoxicatedor under the influence of drugs is bothdangerous and illegal. Impaired visionor judgment on the water can lead toaccidents and personal injuryBEFORE GETTING UNDERWAYLeave a float plan (example onp. 13)Perform a pre-departurechecklist (example on p. 12)Check the weather. Do notventure out if the weather is, orwill be, threatening.WHILE UNDERWAYKeep a good lookout. Keep awatch to the leeward under theheadsail. Keep away fromswimmers, divers, and skiers.Know and obey local boatinglaws.Respect bad weather, and beprepared for quickly changingconditions.COLLISION HAZARDUse extra caution in shallow water orwhere underwater/floating objects maybe present. Hitting an object at speed orsevere angle can seriously injure peopleand damage your boatPAGE 11

PRE-DEPARTURE CHECKLISTCheck bilge for extra waterCheck weather conditions and tidesCheck food supplyFoul weather gearLinen, sleeping bagsFuelWaterSunscreens and sunglassesToolsDocking and anchor gearCheck radio operationsNavigation charts and instrumentsFloat plans to a friend or Coast Guard (see next page)Fuel for stoveCooking and eating utensilsCheck battery water levelOil level, tight Vp-beltsCheck for loose electrical connections in engine compartmentSecure tools or any loose equipment in engine compartment so asnot to get fouled in engineAC systems off; electrical cord stowedDoors and drawers securedCheck steering lock to lockCheck mast for rigging irregularities and tightnessHalyards and sheets are clear and ready to runNo lines or other obstructions near propeller or bowAnchor ready to runCheck lifelines for tightnessTurn on fuel and waterlinesStow all loose gearOpen engine cooling water intake thru-hull valvePAGE 12

FLOAT PLAN1. Name of person reporting and telephone number:2. Description of boatNAMETYPEMAKE LENGTH REGISTRATION#HULL COLOR STRIPE COLOR DECK COLOROTHER DISTINGUISHING MARKS3. Number of Persons aboardNAME AGE PHONE #ADDRESSNAME AGE PHONE #ADDRESSNAME AGE PHONE #ADDRESS4. EngineTYPE H.P. FUEL CAPACITY5. Safety equipmentPFDs Flares Mirror FlashlightFood Water EPIRB Raft/Dinghy6. RadioTYPEFREQUENCIES7. Trip ExpectationsDEPARTURE TIME DATE FROMDESTINATION RETURN DATE NO LATER THAN8. Automobile:LICENSE # STATE MAKECOLOR9. If not returned by-PARKED ATContact the Coast Guard or-CALL -AT-PAGE 13

AFTER SAILING CHECKLISTWhen leaving your <strong>Hunter</strong> at the dockfor more than a short time, it is a goodidea to review the following checklist tomake sure everything is in order. Thiswill help protect the various parts of yourboat and add considerably to theirattractiveness and usable life.Flake or furl mainsail and cover, or remove and bag.Remove and stow all portable deck hardware such as snatch blocks, winchhandles, etc.Secure the boom to the topping lifts and set it firmly amidships with the mainsheet purchase. (It is also a good idea to rig a line from the steering wheel ortiller to a convenience cleat to keep the rudder from swinging back and forthwith the motion of the water or employ the wheel brake if so equipped.)Attach the shackle ends of all halyards to convenient fittings and take upslack. Find a location leading away from the mast to keep the halyard fromslapping the mast.Coil and stow all lines in line lockersCover the winches and steering pedestal when leaving the boat for severaldays or moreClose all fuel lines and seacocksSwitch off the electrical systemPump out the bilgeCheck air vents, secure ports and hatches, swab the deck, and clean deckstainless, particularly if you have operated in saltwater.Make a final check of mooring lines, chafing gear, fenders, etc.PAGE 14

SAFE BOATING TIPSDocking your boat should be handledcarefully to avoid potential damage.Under normal wind and waterconditions, the following considerationsshould be made:1. Whenever possible, your approachshould be made against the prevailingwind and current to assist in stoppingthe boat. Where these conditions arecontrary, the strongest should be usedto determine approach.2. Approaching the dock: dock linesshould be at ready, loose gear stowedand decks cleared. Determine thedirection of the wind and current andwhen you decide which side of the boatwill be against the dock, rig dock linesand fenders on the appropriate side.Your <strong>Hunter</strong> comes with an on deckanchor well and a Danforth type anchoras standard equipment. The anchor isselected to suit the size and weight ofyour boat under normal anchoringconditions, and is most effective inmuddy or sandy bottoms.When anchoring, pay particular attentionto the scope of your anchor rode (therelationship between of the water andthe length of the rode). A good rule ofthumb is to allow a scope of about 7:1 (arode seven times as long as the verticaldistance from the bow to the bottom). Ahelpful aid is to mark the rode every 20feet or so with knots or other types ofindicators. Before dropping anchor,make sure the bitter end is secured tothe cleat in the anchor well. Also, besure to consider wind direction, currents,DOCKINGANCHORINGOne dock line should be attached to thebow cleat, another to the stern cleatopposite the side that will lie against thedock. NOTE: If the boat is to lie againsta piling, rig a fender board across two ormore pilings.3. Tying up: attach bow and stern linesto dock, hauling boat in with fendersagainst dock. Rig crossing spring linesto limit motion forward and aft. Be sureto allow some slack in all lines tocompensate for tidal activity if present.Never use bow rail, stern rail, orstanchions to secure a vessel, even forbrief periods. For other types ofmoorings, or for abnormal wind or waterconditions, consult an approved boatingguide.mean low tide depths and other localconditions when anchoring, as well aspositions of any boats already anchorednearby.To weigh anchor, motor or sail (undermain only) forward slowly. When at apoint directly above the anchor, a quicktug should free it from the bottom. Takecare not to damage the topsides whenhauling.Anchoring in unusual water/ and orweather conditions will require additionalprecautions. Consult an approved guidefor suggestionsPAGE 15

SAFE BOATING TIPSDIESEL ENGINEAn engine owner's manual is suppliedwith your boat and should be readthoroughly. It contains technicalspecifications, running instructions anda maintenance schedule on lubricantsand fluids. For long engine life, followroutine maintenance schedules.You should check engine oil,transmission fluid and coolant levels.Water, rust, scale and dirt will causeserious damage to the injectors ondiesel engines. You should check yourfilters frequently and change whennecessary. Check fuel line connectionsfor proper tightness.EXPLOSION/FIRE HAZARD – Fuelsystem connections that are to loose or totight can leak, resulting in fuel loss,environmental pollution and explosion/firehazard.EXTREME HAZARD: carbon monoxidegas (CO) is colorless, odorless andextremely dangerous. All engines andfuel burning appliances produce CO asexhaust. Direct and prolonged exposureto CO will cause BRAIN DAMAGE orDEATH. Signs of exposure to CO includenausea, dizziness and drowsiness. Referto BOATING SAFETY for moreinformation.When you start your engine, run it aminimum of 15 minutes to bring it up tooperating temperature. This insures thatany condensation is evaporated. Yourengine should “run out” at ¾ throttle atleast once a month to clean out carbonbuildup and moisture.FUELING YOUR DIESEL ENGINEEXPLOSION/FIRE HAZARDStore flammable material in safetyapprovedcontainers. Keep containers ina locker designed by the boatmanufacturer for that purpose. Neverstore flammable material in a non-ventedspace.Observe “No-Smoking” while fueling.Run exhaust blower at least 4 minutesbefore starting engine. Check bilge andengine compartments for fumes.Keep ventilation system free ofobstructions. Never modify the ventsystem.Fill less than the rated capacity of thetank. Allow for fuel expansion.If fuel enters bilge, do not start engine.Determine cause and severity. Contact aknowledgeable marine service to removefuel. Do not pump overboard. ContactCoast Guard for additional advice (SeeEnvironmental Considerations Fuel & OilSpillage.) Inspect fuel system regularly for leaks.Follow engine manufacturer’srecommendations for types of fuel andoil. Use of improper products candamage the engine and void thewarranty.Notice: Use fresh fuel. Fuel that hasbeen in a tank too long can form gumand varnish, which may affectperformance.Inspect diesel fuel filters regularly.Diesel fuel must be kept as clean aspossible. Keep fuel tank full.PAGE 16

SAFE BOATING TIPSSTARTING YOUR DIESEL ENGINE1. Visually check engine compartment tosee that the throttle linkage, shiftingcontrols, electrical connections and fuellines are properly secured.2. Before each start check oil in engineand transmission.3. Insure that the engine shut-off cable isproperly secured and operating.4. Place the shift lever in the neutralposition. Pull out the button beside theshift lever to disengage the shift. Onsingle lever controls, lift the collar underthe shift lever knob and move the leverforward to advance the throttle forneutral warm-up.5. Insert the starter key and turn to the“on” position.6. Press the starter button and hold untilengine starts, then release. The buzzerand/or light should then go off. Pressthe starter button no longer than 5seconds continuously.7. Allow cold engine to warm up aminimum of five minutes.8. When warm-up is completed, return thehand lever to neutral position, and pushthe button back to re-engage the shift.The shift is ready for shift and throttleoperation.9. Check that the lube oil pressurewarning light and the charge lamp gooff. If any of the warning lamps do notgo off above 1,000 rpm, the engine ismalfunctioning and should be stoppedimmediately. Consult your nearestengine dealer.NOTE: The H386 and below are equippedwith an “engine stop” pull lever. Whenpulled all the way out, this will stop theengine at any time.Follow engine manufacturer’srecommendations for types of fuel andoil. Use of improper products candamage the engine and void thewarranty.MOTORING YOUR DIESEL ENGINEBefore departure, remember to unplug theshore power. When the engine is warm,but prior to releasing the dock lines, movethe shift lever to forward and to reverse toinsure that it is working properly. Toincrease RPMs, push throttle leverforward and pull back to decrease RPMs.IMPORTANT: When sailing, it is best tostart the engine before the sails arelowered. This way, it is possible tomaneuver if the engine should not start.ELECTRICAL SYSTEMYour <strong>Hunter</strong> is fitted with an electricalsystem designed for both AC and DC.While in port, you can operate any tool,appliance or other device designed tofunction on regular house current simplyby plugging your dockside power cord intoa convenient outlet on shore and turningyour AC main breaker on.Your rigging will conduct electricity.Always check for overhead high tensionwires before proceeding. Once clear,you may increase your speed in areasonable and safe manner asdesired.ELECTROCUTION HAZARD: If polarityis reversed, DO NOT use the shorepower source. Immediately turn off thepower source and disconnect the shorepower cord. Reversed polarity is adangerous and potentially lethalcondition that may cause shock,electrocution, or death.PAGE 17

SAFE BOATING TIPSELECTRICAL SYSTEM (continued)To minimize shock hazard, connect anddisconnect cable as follows:1. Turn off the boat’s shore powerconnection before connecting ordisconnecting shore power cable.2. Connect shore power cable at theboat first.3. If polarity warning indicator isactivated, immediately disconnectcable and have the fault corrected bya qualified electrician.4. Disconnect shore power cable atshore outlet first.5. Close inlet cover tightly.DO NOT ALTER SHORE POWERCABLE CONNECTORS.Storage: Your shore power cable set isintended for use outdoors. To prolongthe life of the set, store indoors whennot in use.General: The metallic parts of yourcable set are made to resist corrosion.In a salt-water environment, periodicallywiping the exposed parts with freshwater, drying and spraying with amoisture repellent can increase life ofthe product.A soiled cable can be cleaned with agrease cutting household detergent. Aperiodic application of vinyl protector toboth ends will help to maintain cablesoriginal appearance.In case of salt water immersion, rinseplug end and/or connector endthoroughly in fresh water, shake or blowout excess water and allow to dry. Spraywith moisture repellent before re-use.Do not allow your dockside power cordto come in contact with the water. Neveroperate any AC power tool or otherelectrical equipment while you or thedevice are in contact with the water, asthis may cause electrocution resulting inshock or death.When leaving port, disconnect thedockside power cord and turn the mainDC breaker on. This allows you to usethe ship’s lights and other equipmentdesigned to operate on direct current.Keep in mind that your DC powersource is a 12-volt battery, just as withyour automobile, and it must be chargedregularly by operating the engine (or byrunning the battery charger, if you havethat option installed). Unless a state ofcharge is maintained, there may not beenough power to operate the startermotor. Dangerous situations can result ifthe engine cannot be started whenneeded.Make a regular visual check of batteriesto insure proper water level and inspectterminals for signs of corrosion. If yourboat sits for long periods without use, itis often a good idea to remove thebatteries and attach them to a tricklecharger to keep them fully charged andready to use.EXPLOSION/FIRE HAZARD – ensureadequate ventilation of battery toprevent buildup of gases, especiallyhydrogen.WHEN CHARGING THE BATTERY:Battery electrolyte contains sulfuricacid. Protect your eyes, skin andclothing. In case of contact, flushthoroughly with water and get promptmedical attention, especially if youreyes are affected.Batteries generate hydrogen gas thatcan be highly explosive. Do not smokeor allow flames or sparks near a battery,especially during charging.Charge the battery in a fully ventilatedplace.PAGE 18

SAFE BOATING TIPSELECTRICAL SYSTEM (continued)<strong>Hunter</strong> Marine recommends that on allboats with either/both a house and startbattery, the cables be disconnectedduring winter storage or any time theboat is out of the water for an extendedperiod of time. Because of thecontinuous electrical drain placed on the12 volt system by certain electricalcomponents such as stereos and COmonitors you will be preserving yourbatteries life expectancies.We recommend that owners who leavetheir boats in the water during the sailingseason charge the boats internalbatteries at least once every seven daysduring the sailing season (we do notrecommend leaving power connected tothe boat if it is unattended). Completelydepleting a batteries internal charge candrastically shorten its life span. Thisincludes gel cell and glass mat batteries.For owners who live aboard or wish toleave their boat battery switches in theon position while unattended (again, wedo not recommend this) should considerinstalling a N20504W Nicro Solar vent toreduce the chances of the CO monitor’ssounding. Only exchanging the airinside the boat on a regular basis orleaving the battery switches in the offposition totally eliminates the falsesounding of the monitors while 12-voltsystems are operating.EXPLOSION/FIRE/ASPHYXIATIONHAZARDOpen flame cooking appliances consumeoxygen. This can cause asphyxiation ordeath.Maintain open ventilation.Liquid fuel may ignite, causing severeburns.Use fuel appropriate for type of stove.Turn off stove burner before filling.Do not use stove for comfort heating.Use special care with flames or hightemperatures near urethane foam. Onceignited, it burns rapidly, producingextreme heat, releasing hazardousgasses and consuming a large amount ofoxygen.COOKING STOVECarefully read and understand themanufacturer’s instructions prior tooperating your stove. Save theinstructions for review, and also to passon to any subsequent owners.Use only the fuel recommended by themanufacturer, and store the fuel in anapproved container.Do not smoke while working with fuel.Immediately clean up any spilled fuel.PAGE 19

IMPORTANT: When not in use, levermust be left in the “dry” position to preventflooding.Before using, place the lever in the “wet”position and pump slowly to partly fill andwet the inside of the bowl. Return to the“dry” position.After using, return the lever to the “wet”position for flushing and pump until thebowl is thoroughly cleaned. Continue withseveral more full strokes to flushdischarge lines. Return lever to “dry”position and pump slowly until bowl isempty.SAFE BOATING TIPSTOILET There is a possibility of being fined forhaving an operable direct overboarddischarge of waste in some waters.Removing seacock handle, in closedposition, or other means must be used toavoid fine.It is illegal for any vessel to dump plastictrash anywhere in the ocean or navigablewaters of the United States.Do not place facial tissue, papertowels or sanitary napkins in head.Such material can damage thewaste disposal system and theenvironment.OPENING HULL PORTSIf your boat is equipped with opening hullports, they must remain closed andsecured while under sail. Your boat couldtake on water when it heels, causingdamage to the interior due to flooding oreven possible sinking of your vessel.All hull ports must remain closed andsecure while sailing.PUMPSAll pumps should be checked frequently toinsure proper operation. This is anespecially important regular maintenanceitem since a properly operating pumpcould save your vessel from seriousdamage.Inspect all bilge pump hoses for chafingand dry rot. See that all hose clamps aretight. Check that the bilge pump impellerarea is clean and free of obstructions.Inspect electrical wiring for corrosion.Ensure that the float switch functionsproperly.Run pump only as long as necessary toremove water. Dry running can damagethe pump motorSINKING HAZARD – Ensure proper bilgepump operation.PAGE 20

SAFE BOATING TIPSWATER SYSTEM OPERATIONFill fresh water tank at deck fill. The tankfiller cap will be marked “water”. Whentank is full, water will back up through thevent hose and exit through a vent locatedon the side of the hull. Use tank gauge forfilling. D.C. main should be turned on first.To activate the water system, turn on D.C.main, flip the “water pressure” switch onthe electrical panel. This will start thepump and pressurize the system. Whenthe pressure builds, the pump will shut off.With continued use of fresh water thepressure in the system is reduced,automatically restarting the pump. Makesure there is water in the system whilepump is in operation to prevent damage tothe motor. The pump will also run if a leakdevelops in the system.NOTE: Intermittent operation of thefreshwater pump while all faucets areclosed usually indicates a leaksomewhere in the lines. Trace the lines tolocate the leak and repair.Run pump only as long as necessary toremove water. Dry running can damagethe pump motorThe water heater operates either on 120or 240 volts AC or when the engine isrunning. To obtain hot water from theengine, it must run a minimum of one-halfhour.Pressure water pumps are the demandtype. Once the circuit breaker switch is on,opening the faucet will produce water flow.To operate shower, turn on hot and coldfaucets until desired temperature isreached, while the showerhead isretracted at sink. Pull the showerhead outand use. The faucets must be turned off toprevent system drainage.Opening the faucet will allow the pump toempty the tank. Flushing the tank andlines will be necessary for winterization.Refer to Maintenance & Winterizationsection for more information.SINKING HAZARD –To ensure the safetyof your vessel, always disconnect shorewater and power connections whenleaving your boat unattended.WASTE DISCHARGEThe <strong>Hunter</strong> is equipped with a headwaste holding tank, hose lines, and thurfittingsfor either overboard discharge,using the standard equipped handpump, deck pump out at dockside orMacerator Pump. Tank levels will beindicated on the gauge located belowthe main electrical panel. Familiarizeyourself with the locations of the deckpump out, overboard discharge thurhull,and vent locations pictured in theWaste Water System section, as well asyour local boating regulationsconcerning the overboard discharge ofraw sewage.PAGE 21

ENVIRONMENTAL CONSIDERATIONSFUEL AND OIL SPILLAGEThe spilling of fuel or oil into ourwaterways contaminates theenvironment and is dangerous towildlife. Never discharge or dispose offuel or oil into the water. It is dangerousand unlawful. Two common types ofaccidental discharge are overfilling thefuel tank and pumping contaminatedbilge water into the sea.EXPLOSION/FIRE/POLLUTIONHAZARD:Fill fuel tank to less than rated capacity.Overfill forces fuel out the tank vents,which can cause explosion fire, orenvironmental pollution. Also allow forfuel expansionDISCHARGE AND DISPOSAL OF WASTEWaste means all forms of garbage,plastics, recyclables, food wood,detergents, sewage, and even fish partsin certain waters. We recommend thatyou bring back everything you take outwith you for proper disposal ashore.Hydrocarbon exhaust emissions polluteour water and air. Keep your engineEXHAUST EMISSIONSANTI-FOULING PAINTSThe use of anti-fouling paints iscommon for boats kept in water. Beaware of environmental regulationsthat may govern your paint choice.These regulations may affect whichpaint may be used, and also theapplication or removal. Contact yourlocal boating authorities for moreinformationCleaning chemicals should be usedsparingly and not discharged intowaterways. Never mix cleaners andbe sure to use plenty of ventilation inenclosed areas. Do not use productsthat contain phosphates, chlorine,solvents, non-biodegradable orpetroleum-based products.CLEANING CHEMICALSYour marine holding tank (if soequipped) must, in many areas, bepumped out by an approved pump-outfacility normally found at marinas.properly tuned to reduce emissions andimprove performance and economy.EXPLOSION/FIRE/HAZARD:Ventilate when painting or cleaning.Ingredients may be flammable and/orexplosive.Common households cleaningagents may cause hazardousreactions. Fumes can last for hours,and chemical ingredients can attackpeople, property and theenvironment.PAGE 22

INSTRUCTIONS FOR PREPARATION FORBOTTOM PAINTINGDo not use any sanding,sandblasting or other abrasivereparation of the bottom, as this willChoose a bottom paint system thatsuits the environment in your area.Follow the procedure recommendedby the manufacturer of the paint,while making sure not to void the<strong>Hunter</strong> Hull Blistering Warranty. TheSanding of the gel coat bottomsurface will be permitted should acustomer wish to have an epoxybarrier coat applied to the hull,(example Interlux Interprotect 1000,2000, West System or VCTar). Thiswill not void the Five-Year BlisterWarranty.<strong>Hunter</strong> Marine refers to epoxy barriercoatings as mentioned above, notepoxy primer paints.If an epoxy barrier coat is applied toa <strong>Hunter</strong> vessel, it must beregistered with the WarrantyWARNING!BOTTOM PAINTINGEPOXY BARRIER COATvoid your hull blistering warranty.See the warranty information at thebeginning of this manual.procedure for preparing and paintingthe bottom varies between paintmanufacturers, but should alwaysinclude dewaxing, etching andsometimes priming of the surface.Department prior to application of theproduct. If the dealer applies bottompaint only, sanding will not beallowed and the no sanding systemmust be used.Cleaning agents and paint ingredientsmay be flammable and/or explosive, ordangerous to inhale. Be sure to useadequate ventilation, and appropriatesafety clothing.(gloves, safety glasses,respiration,etc)PAGE 23

ENGINE, TRANSMISSION & DRIVETRAINFollow the fuel and lubrication requirementsin the Engine <strong>Manual</strong>. Check the engine oillevel before and after operation and use aquality motor oil (refer to Engine <strong>Manual</strong>).Be certain the proper amount of oils is in thecrankcase at all timesEngine Alignment: the engine should bealigned by experienced marine servicepersonnel. Final alignment should be doneafter launching, with all normal gear aboard.A description of the procedure follows:The coupling flanges must come togetherevenly at all points, a feeler gauge is used tocheck the gap. If adjustment is necessary,the engine is tilted up or down and/or sideto-sideuntil the flanges meet evenly. Severevibration will result from misalignment andcan cause strut bearing and shaft damage.Alignment should be checked again afterseveral weeks of use. Routine checks ofcoupling bolts are a must to ensure they aretight.Shaft Alignment:1. Separate the coupling, move the shaftend back to clear the pilot in the center.Follow the lubrication requirements of theengine manual. The oil level should beThe stuffing box is held to the stern bearingby a rubber hose secured with hose clamps.(See the Shaft and Propeller section). Theclamps should be tight and no water shouldleak from this location. While underway aslight drip from the stuffing box at the shaftexit is necessary (three to five drops aminute) and is normal. To adjust, loosen thelocknut, tighten the gland nut one-quarterENGINETRANSMISSIONSTUFFING BOX2. Establish the shaft in the center of theshaft log by raising the shaft until it touchesthe top of the log – note position – lower theshaft until it touches the bottom of the log –note position – repeat sideways and locateshaft in the center; block shaft in thisposition, using a block of wood under theshaft packing gland.3. Now, adjust the engine mounts to allowthe pilot on the coupling halves to sliptogether without moving shaft up down orsideways.4. Adjust the engine mounts as necessaryuntil a .004” feeler gauge will not enteranywhere along the edge of the flangebetween the faces.5. Tighten the locks on the adjustablemounts6. Recheck coupling with feeler, readjust ifnecessary.7. Check stuffing box (allow to drip 3 to 5drops per minute).Any questions or problems concerning theengine, please contact the U.S. distributor,Mastery Marine at (727) 522-9471, or yourlocal Yanmar service agent.checked immediately after operation.turn, a retighten the locknut. If excessivewater flow persists after adjustment, replacethe packing with 3/16” (or 5mm) square flaxpacking and then adjust as above.NOTE: Some models use a packlesssealing system. Page 56 or Pages 56A, B,C, reflects the type of stuffing box usedon this model.PAGE 24

A boat compass rarely exists in anenvironment that is completely free frommagnetic materials or influences.The compass on your boat should beadjusted by a certified compass adjusterand have a deviation table made for it.MAINTENANCECOMPASSESSTEERINGRefer to the manufacturer’s instructionfor maintaining pedestal steeringsystem. Routinely inspect steeringsystem components.If you must depend solely on yourcompass for navigation, make a quickcheck for any objects near the compassthat may cause additional, unmeasureddeviation. Typical objects that may fall inthis category include: knives, smallradios, flashlights or other tools.CONTROL HAZARD – Inspect andmaintain steering system regularly. Animproperly maintained system may fail,causing sudden loss of steering control,resulting in personal injury and propertydamage.ELECTRICAL SYSTEMSThe electrical system is a 12-volt,negative ground installation, plus ashore power system of either 120v or220v. The owner should inspectbatteries, terminals and cables weeklyfor signs of corrosion, cracks, andelectrolyte leakage. Battery terminalsare to be kept clean and greased. Referto separate instructions on batteries,wiring diagram, and electronics.SHOCK/FIRE HAZARDReplace breaker or fuse with the sameamperage device. Never alter overcurrent protection.SHOCK/FIRE HAZARDDisconnect electrical system from itspower source before performingmaintenance. Never work on theelectrical system while it is energized.Electrical appliances must be withinthe rated amperage of the boatscircuits.Observe boat carefully while theelectrical components that can be leftunattended are the automatic bilgepump, fire protection and alarm circuits.Only a qualified marine electricaltechnician may service the boat’selectrical system.Turn off engine before inspecting orservicing battery.Disconnect battery cables beforeworking on electrical system to preventarcing or damage to alternator.PAGE 26

All pumps should be checked frequentlyto insure proper operation. This is anespecially important regularmaintenance item since properfunctioning of a pump could save yourvessel from serious damage in thefuture.Inspect all hoses for chafing anddeterioration. See that hose clamps aretight. Check that the pump impeller areais clean and free of obstructions.Inspect electrical wiring for corrosion.Make sure float switches move freelyand are making an electrical connection.The owner should become familiar withthe layout of the water and wasteThe owner should inspect the conditionof fuel lines for cracks or leaks. Aprimary source of fuel-related problemsis water in the system. The ownershould use only well maintained fuelingfacilities and make sure fuel fill caps aretightly secured after filling. Check andmaintain fuel filters periodically. Refer toMAINTENANCEPLUMBING SYSTEMSFUEL SYSTEMSsystems by walking through the boatwith the diagrams provided in thismanual. It is especially important thatthe owner knows all the thru-hull valvelocations and inspects for leaksfrequently. Refer to plumbing diagramsin Specifications and Technical sectionof this manual.General Thru-hull Lists (varies from boatto boat---see diagrams in Systems andCircuits section).1) Engine cooling system2) Galley sink3) Head sink4) Head toilet (water intake)5) Holding tank discharge6) Scupper drainsyour Engine <strong>Manual</strong> for additionalinformation. Periodically, add biocide toprevent bacteria and fungi fromcontaminating diesel fuel that maycontain some water. Carefully followmanufacturer’s instructions and cleanfilter regularly.PAGE 27

MAINTENANCECLEANING FIBERGLASS SURFACESFiberglass surfaces should be cleanedregularly. Normal accumulations ofsurface dirt can be removed simply byoccasional rinsings with water. If youoperate your boat in salt water, morefrequent rinsing will be required. Toremove stubborn dirt, grease or oil, usea mild detergent and a soft brush. Rinsewith fresh clean water. Avoid theplexiglass companionway slider,windshield, deck hatches and fixed portswhen using a deck brush, since thesesurfaces can scratch.CLEANING ACRYLICUse only mild soap and water to cleanacrylics. Do not use products containingsolvents such as ammonia, which isfound in many window cleaners.Sunlight is a sail’s worst enemy, so coverthe mainsail when not in use. Anultraviolet guard, fitted down the leech of aroller headsail will protect the exposed partfrom the weathering effect of the sun andfrom dirt and grit.Mildew, can be prevented by storing sailsdry and by hand washing twice a season.Check all sails regularly for chafe,particularly where they chafe on deck fittingsSAIL CAREIt is a good idea to wax the fiberglassonce or twice a year to maintain a deep,glossy appearance. Your local marinesupply should be able to provide anappropriate wax.EXPLOSION/FIRE HAZARDCleaning agents and paint ingredientsmay be flammable and/or explosive,and dangerous to inhale. Be sure to useadequate ventilation, and appropriatesafety clothing (gloves, safety glasses,respirator, etc.)Use care when cleaning acrylic.Dry cloth and many glasscleaners will scratch. Solventswill attack the surface.or rigging, at reef points, batten sleeves andthe foot of the headsail. Sail batten pocketsshould be inspected on a regular basis.To stow the mainsail, start at the leech andflake it onto the boom, left and right, in about18-in. (46 cm) folds, while pulling the leechaft. Secure with a sail tie and continue to theluff. Lash to the boom with sail ties or shockcord.GENERAL HARDWARE MAINTENANCECheck all fittings regularly to be surescrews are tight. Occasionally lubricate(use silicone lubricants) all moving partson such fittings as blocks, turnbucklesand cam cleats, as well as the lockingpins of snatch blocks, track slides,spinnaker poles, etc. Inspect cleat andfairleads for roughness and smooth withFollow the maintenance instructionsprescribed by winch manufacturer.WINCH MAINTENANCEfine-grained emery paper if necessary.Also, replace any missing or damagedcotter pins in turnbuckles and shackles,and either tape them or use them or useprotective covers manufactured for thatpurpose. Grease winches a minimum ofonce yearly.We recommend a minimum of anannual cleaning and light greasing.PAGE 28

VINYL CAREThese patterns, like all upholstery fabricsand vinyl, require a regularly scheduledcleaning program. A thorough cleaningshould be administered on a daily, weekly ormonthly basis depending on use andexposure to dirt and/or staining agents. It isimportant to begin treatment of a stain assoon as possible after a spill. It is importantthat efforts begin immediately after a spill toremove any potential staining agent. It isadvisable to clean these products as soonas the first signs of dinginess occur,otherwise, delaying clean up will require amuch greater effort to restore the product toits original appearance.Regular cleaning requires the use of a mildcleaner such as Murphy’s Oil soap andwater. In situations where the vinyl has notbeen washed regularly and there is a buildup of dirt, stronger vinyl cleaners such asSimonize’s Tuff Stuff or Turtle Wax’svinyl/fabric cleaner are recommended. Wedo not recommended the use of any othercleaners. The use of cleaners other thanthose recommended may result inirreparable damage to the product.In order for the above listed cleaningsolutions to work effectively on stubbornstains, please allow time for the cleaningsolution to soak in thoroughly. Be sure toremove the cleaning solution before it hastime to dry. Regardless of the type ofcleaner used, it is necessary to finish up witha thorough rinse using fresh water on aclean sponge or rag. A soft bristled nylon ornatural fiber brush can be used to removebuilt-up dirt and staining agents.Finally, please remember that all our fabricgrain vinyls require a greater cleaning effortto maintain than comparable smooth grainvinyls. These products will provide anattractive and durable alternative toconventional fabrics and vinyls if properlymaintained. One must realize that the properinstallation and use of our fabric grain vinylsrequire additional attention to theestablishment and maintenance of a wellthought out cleaning program.Vinyl: Clean with mild soap and water. Wipewith vinyl or upholstery cleaner monthly, andespecially before and after storage.Leather: Mild soap water. Blot dry. Do notscrub as this will stretch and scratch. Wipewith leather cleaner/oil to preserve and helpprevent cracks before and after storage.Fabric: Blot dry. Do not machine wash. Useonly mild soap and water. Wipe with a cleanwhite cloth. If stain persists, dry clean. Besure to treat cleaned surfaces with scotchguard. Stretched or loose covers may beDo not use acetone or other harsh cleaners on the vinylsoft headliner. Use soapy water or other mild detergentto avoid damage to the vinyl.FABRIC CAREsteam cleaned. If foam is removed, it willrestuff more easily if wrapped with thinplastic.Storage: Cover with airflow fabric to reducedust build up. Do not use plastic, as this willcause cushions to sweat and mildew.Cushions: If wet, prop cushions vertically topromote airflow around each cushion.Cushions can be cleaned by most drycleaners. Dry clean only.REPAIR OF POLTURETHANE (MINWAX) FLOORSSurface Scratches: Sand floor with 220 grit sandpaper. Remove all dust with clean cotton clothor blow off with air. Apply one coat of minwax evenly over sanded floor. Let dry completely, atleast 24 hoursDeep Scratches: Remove all blemishes by sanding floor with 220, until all minwax is removedand you have a raw floor. Remove all dust with clean cloth or blow off with air. Apply one coatevenly over floor. Let dry four to six hours. Repeat steps one and four. Apply third coat of minwaxonly if needed by repeating steps one and four.) After final coat, let floor dry completely at leastone day.PAGE 29

ELECTROLYSIS AND GALVANIC PROTECTIONSalt water allows electric current to flow fromanodic to cathodic material. For any twometals from two components, their relativepositions in the galvanic rating table, willdetermine which loses material (the anode)and which remains largely undisturbed (thecathode). The distance between the twometals on the galvanic table determines therate of wear. Thus a sacrificial zinc anode isoften fitted to the underwater area of a boatto attract any destructive currents away frombronze or steel propeller shafts, for example.It is not enough to know that your boat doesnot suffer from electrolysis; a newcomer inthe adjacent marina berth may start a toofriendlyassociation with metal componentson it. An easy place to fit an anode is on thepropeller shaft, or covering the propeller nut.The anode should not be painted; this wouldrender it ineffective.To prevent electrolysis in seawater, thedifference between the voltages of the twoadjacent metals should not exceed 0.20 V.For example, zinc and carbon steel usedtogether risk corrosion, while lead and activestainless steel are compatible. Metals with ahigh voltage corrode faster and need alarger area to diffuse the electrochemicalreaction.TEAK CARE (240,260,and 270 ONLY)Teak wood is a high quality, extremelydurable wood with high oil content. In orderto help you protect the original beauty ofyour teak interior, we have sealed the woodwith a 3 to 4 coat system of high qualitySeafin Teak Oil, manufactured by Dalys.This material is penetrating oil that dries to alow sheen to seal and protect the wood fromWhen oiled surfaces requirerenewing, simply wipe the surfacearea free of loose dirt, dust or othercontaminants. Dampen a cloth withthe Seafin Teal Oil and wipe on. LetWhen woodwork is damaged from scrapesor abrasions that go into or thru the finish,take the following steps:1. Take 180 to 200 grit wet/dry sand paperto smooth out rough spots.2. Wipe clean of dust and dirt with a cleanrag. Note: before applying oil, wood surfacemust be dry.3. Wipe or brush on oil, allow to penetrate 5-15 minutes while surface is still wet.4. Sand until smooth with 400A wet/drysandpaper.5. Wipe dry with a clean rag. Allow 8-12hours drying time.MAINTENENCEREPAIRSmoisture and weathering. It creates adurable, nonslip surface to repel water andresist wear. It won’t chip, peel or blister. Itreduces work and maintenance costbecause it is easy to repair and maintainand repair. With proper maintenance it willoutlive urethane varnish on interior and evenexteriorsurfacesstand for 5-15 minutes, then polishdry. If your dinette table has anepoxy finish, clean with furniturepolish6. Apply second coat, sand, and repeatprocedure.This procedure may be repeated as manytimes as needed to bring damaged areaback to its original finish. If you have troublewith getting the same sheen, you may use asoaked and wrung out cloth to apply a verylight coat to get an even sheen.For more information about the productcontact:Dalys3525 Stoneway NorthSeattle, WA 98103(206) 633-4200PAGE 30A

INTERIOR FURNITURE & BULKHEAD SPRAY FINISHTeak wood is a high quality, extremelydurable wood with a high oil content. In orderto help you protect the original beauty of yourteak, we have sealed the interior with a (3 to4) spray coat finish, using sealer and varnishfor marine cabinets. The materials areTEAK CAREREPAIRSmanufactured by “Chemcraft InternationalInc”. This material will seal and protect thewood from moisture and weathering. It iseasy to maintain and reduces work andmaintenance costs.When woodwork is damaged from scrapes or abrasions (that go into or through the finish), takethe following steps:1) Sanding with the grain, take 320 grit sand paper to smooth out rough spots. If the spot isdown to the raw wood, rag (100% cotton) wipe the spot with acetone and allow to dry.(Note: acetone only needs to be applied to the raw teak).2) Reseal raw wood with Mohawk Spray Sealer (aerosol can) and allow to dry.3) Lightly sand with 320 grit, sanding larger than original spot.4) Wipe clean of dust and dirt with a clean rag.5) Using Mohawk touch up and repair supplies, use clear lacquer spray (aerosol can). Apply(1) coat on the spot evenly and allow to dry.6) This process (steps 3 – 5) may be repeated as many times needed to bring damagedarea back up to its original finish. On your final spraying, be sure to feather into exsistingfinish.SOP FOR POLYURETHANE (MINWAX) FLOORSSURFACE SCRATCHES1) Sand floor with 220 grit sandpaper until all scratches are removed.2) Remove all dust with a clean cotton cloth or blow off with an air gun, then wipe down witha tack cloth.3) Apply one coat of minwax evenly over the sanded area.4) Let the minwax dry completely (at least one day)DEEP SCRATCHES1) Sand floor with 220 grit sandpaper until all the minwax is removed and down to raw wood,removing all blemishes.2) Remove all dust with a clean cotton cloth or blow off with an air gun then wipe down witha tack cloth.3) Apply one coat of minwax evenly over the floor.4) Let minwax dry 4-6 hours5) Repeat steps 1-4, light sand6) Apply a 3 rd coat if needed by repeating steps 1-4.7) Let the minwax dry completely (at least one day)Chemcraft InternationalTelephone: 910-723-1846U.S. Watts: 1-800-334-8556Mohawk Finishing Products, Inc.U.S. Watts: 1-800-545-0047PAGE 30B

STORAGE/WINTERIZATIONIMPORTANTWinter storage is recommended to be done in one of the following threeways, either: 1) by blocking the boat via a cradle 2) with chained stands onlevel ground; or 3) by storing the boat in the water with a bubbler system toprevent icing. Damage to your boat, including engine misalignment causedby twisting, is not covered by the warranty.SAILSSails should be properly folded andstowed in a dry, well-ventilatedplace. Many sailboat owners sendtheir sails back to the sailmanufacturer at the end of eachseason. The sailmaker will check thestitching and sailcloth for wear andstore the sails until the start of thenext season.ELECTRICALRemove battery from boat (Refer toEngine <strong>Manual</strong>) and charge. It is agood idea to also remove theelectronics (radio, radar, etc) andstore in a safe place.CUSHIONSCushions should be removed andstored at home if possible. If not,prop them vertically to promote airflow around each cushion. Dry cleanonly!HATCHESTenting the deck during storage willhelp prevent ice from forming anddamaging hatches and deck fittings.The installation of a passive vent willhelp with ventilation while the boat isin storage.WATER SYSTEMOpen a faucet and allow the pump toempty the tank. Then addapproximately two gallons (7.6L) ofnon-toxic antifreeze solution to thetank and repeat the pumping outprocedure.A second method is to disconnectthe hoses at the pump, allowingthem to drain. Find the lowest pointin the system and disconnect thefitting. Open all faucets to allow thelines to drain. If possible, use a shortsection of hose on the faucet to blowthrough the lines to clear all water. Adiluted solution with baking soda willhelp freshen the system.WATER SYSTEMOpen valve and drain fully leavevalve open during lay-up time.TOILET AND HOLDING TANKDrain and flush toilet. Using nontoxic antifreeze in a 50/50 mixturewith water, pump through toilet andinto holding tank.OUTBOARD ENGINETake it home and store it in a safeplace. Be very careful storing the gastank as the gasoline is veryflammable. Refer to Engine <strong>Manual</strong>for specific maintenance schedule.INBOARD ENGINEWinterizing Fresh Water CooledDiesel Engines1. Drain crankcase and transmissionand refill with fresh lubricant asspecified in Engine <strong>Manual</strong>.2. Drain and clean all fuel filters andchange elements, gaskets, andseals. Bleed all air from fuelsystems.3. Start engine and bring up tooperating temperature.4. Close the sea cock, remove theraw water pickup hose from the rawwater pump and immerse one endinto a 5-gallon (19L) bucket ofPAGE 31