The Nile Corniche Project in Cairo: One of the largest ... - Putzmeister

The Nile Corniche Project in Cairo: One of the largest ... - Putzmeister

The Nile Corniche Project in Cairo: One of the largest ... - Putzmeister

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> magaz<strong>in</strong>e by <strong>Putzmeister</strong> Hold<strong>in</strong>g GmbH 82<br />

Innovative backfill<strong>in</strong>g<br />

<strong>of</strong> annual space at<br />

pumped-storage hydropower<br />

plant <strong>in</strong> Vianden<br />

Sewage sludge <strong>in</strong>stead<br />

<strong>of</strong> concrete: Stationary<br />

boom at sewage treatment<br />

plant <strong>in</strong> Prague<br />

<strong>Putzmeister</strong> Brasil<br />

on <strong>the</strong> upsw<strong>in</strong>g<br />

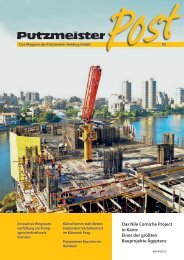

<strong>The</strong> <strong>Nile</strong> <strong>Corniche</strong> <strong>Project</strong><br />

<strong>in</strong> <strong>Cairo</strong>:<br />

<strong>One</strong> <strong>of</strong> <strong>the</strong> <strong>largest</strong> construction<br />

projects <strong>in</strong> Egypt<br />

PM 4432 GB<br />

1

Content Content/Trade fair dates<br />

Title story<br />

<strong>The</strong> <strong>Nile</strong> <strong>Corniche</strong> <strong>Project</strong> <strong>in</strong> <strong>Cairo</strong>:<br />

<strong>One</strong> <strong>of</strong> <strong>the</strong> <strong>largest</strong> construction projects <strong>in</strong> Egypt 4<br />

50 questions<br />

How does <strong>Putzmeister</strong> guarantee <strong>the</strong> quality <strong>of</strong> its products? 10<br />

On site<br />

Pumped-storage hydroelectric plant <strong>in</strong> Vianden / Luxembourg<br />

Reth<strong>in</strong>k<strong>in</strong>g pays <strong>of</strong>f: Innovative solution for<br />

backfill<strong>in</strong>g <strong>the</strong> annular space <strong>in</strong> a pressure shaft 12<br />

Jeddah / Saudi Arabia:<br />

Reach<strong>in</strong>g for <strong>the</strong> sky by <strong>the</strong> Red Sea 16<br />

System technology<br />

Autocor®<br />

Economical and flexible solution for<br />

supply<strong>in</strong>g concrete to several precast plant build<strong>in</strong>gs 20<br />

<strong>Putzmeister</strong> Solid Pumps<br />

Sewage treatment plant <strong>in</strong> Prague / Czech Republic<br />

Stationary boom gone astray:<br />

Sewage sludge <strong>in</strong>stead <strong>of</strong> concrete 22<br />

In brief<br />

Brasil believes <strong>in</strong> hydroelectric power 25<br />

<strong>Putzmeister</strong> Brasil<br />

Committed team <strong>in</strong> an emerg<strong>in</strong>g market 26<br />

<strong>Putzmeister</strong> Brasil<br />

User-friendl<strong>in</strong>ess is paramount:<br />

<strong>The</strong> <strong>in</strong>novative control for small concrete pumps 27<br />

<strong>Putzmeister</strong> Services<br />

Clean and safe concret<strong>in</strong>g 28<br />

Photo credits 2<br />

Impr<strong>in</strong>t / Trade fair dates 3<br />

4<br />

20<br />

<strong>Nile</strong> <strong>Corniche</strong>:<br />

Large project <strong>in</strong> Egypt<br />

Precast plants<br />

are becom<strong>in</strong>g<br />

more flexible<br />

Photo credits:<br />

All illustrations are subject to copyright <strong>of</strong> <strong>Putzmeister</strong><br />

Hold<strong>in</strong>g GmbH unless o<strong>the</strong>rwise stated.<br />

10: egypt_map, Public Doma<strong>in</strong>, CIA · 11: <strong>Cairo</strong>_skyl<strong>in</strong>e_panorama,<br />

Wikimedia Commons, licensed under<br />

CreativeCommons licence by-sa-3.0, Staeiou · 12: A_<br />

Boat_<strong>in</strong>_<strong>the</strong>_<strong>Nile</strong>_River, Public Doma<strong>in</strong>, Mo7amedsalim<br />

· 25, 26: www.seu.lu · 33: Saudi_Arabia_map,<br />

Wikimedia Commons, licensed under CreativeCommons<br />

licence by-sa-3.0, Ras67 · 34: Flag_<strong>of</strong>_Saudi_<br />

Arabia, Public Doma<strong>in</strong>, unknown · 35: Supplicat<strong>in</strong>g_<br />

Pilgrim_at_Masjid_Al_Haram_Mecca_Saudi Arabia,<br />

Wikimedia Commons, licensed under CreativeCommons<br />

licence by-sa-2.5 Generic, Ali Mansuri · 36:<br />

Jeddah_Fountata<strong>in</strong>_1, Wikimedia Commons, licensed<br />

under CreativeCommons licence by-sa-3.0, Mjakhro<br />

· 37: Med<strong>in</strong>a_Road_-_Jeddah_-_Saudi_Arabia, Public<br />

Doma<strong>in</strong>, Ammar shaker · 38: Jeddah-1938, Wikimedia<br />

Commons, licensed under CreativeCommons<br />

licence by-sa-2.5 Generic, courtesy <strong>of</strong> William Facey<br />

· 55 - 60: <strong>Putzmeister</strong> Solid Pumps GmbH · 61: Flag_<br />

<strong>of</strong>_Brazil, Public Doma<strong>in</strong>, Brazilian Government<br />

2 4<br />

12<br />

3 5<br />

22<br />

Sewage sludge:<br />

Stationary boom<br />

16<br />

2 PM 4432 GB PM 4432 GB 3<br />

Impr<strong>in</strong>t:<br />

Published by:<br />

<strong>Putzmeister</strong> Hold<strong>in</strong>g GmbH<br />

Max-Eyth-Str. 10<br />

72631 Aichtal · Germany<br />

Edit<strong>in</strong>g/layout/typesett<strong>in</strong>g:<br />

Petra Montag<br />

<strong>Putzmeister</strong> Hold<strong>in</strong>g GmbH<br />

Pr<strong>in</strong>ted by:<br />

Offiz<strong>in</strong> Scheufele GmbH & Co. KG<br />

Tränkestr. 17<br />

70597 Stuttgart · Germany<br />

Pumped-storage<br />

hydroelectric plant:<br />

Annular r<strong>in</strong>g fill<strong>in</strong>g<br />

gone astray<br />

All rights and technical modifications<br />

reserved.<br />

Despite careful content control we are<br />

not liable for <strong>the</strong> content <strong>of</strong> <strong>the</strong> specified<br />

external websites. <strong>The</strong> operators <strong>of</strong><br />

external websites are solely liable for<br />

<strong>the</strong>ir content.<br />

Some <strong>of</strong> <strong>the</strong> illustrations show special<br />

mach<strong>in</strong>e variants and snapshots<br />

which do not always comply with <strong>the</strong><br />

regulations <strong>of</strong> <strong>the</strong> Industrial Employers'<br />

Liability Insurance Association.<br />

© by <strong>Putzmeister</strong> Hold<strong>in</strong>g GmbH 2012<br />

Pr<strong>in</strong>ted <strong>in</strong> Germany (51204)<br />

Saudi Arabia:<br />

Jeddah is grow<strong>in</strong>g<br />

higher <strong>in</strong>to <strong>the</strong> sky<br />

Trade fair<br />

dates<br />

April to June 2012<br />

16. – 21.04.<br />

Intermat, Paris/France<br />

www.<strong>in</strong>termat.fr<br />

22. – 25.04.<br />

Construction Mach<strong>in</strong>ery Show,<br />

Jeddah/Saudi Arabia<br />

www.constructionmach<strong>in</strong>eryshow.com<br />

07. – 11.05.<br />

IFAT, Munich/Germany<br />

www.ifat.de<br />

29.05. – 02.06.<br />

M&T Expo Brasil,<br />

São Paulo/Brasil<br />

www.mtexpo.com.br<br />

06. – 10.06.<br />

Ankomak, Istanbul/Turkey<br />

www.ankomak.com<br />

6

Rubrik Title story Title Rubrik story<br />

<strong>The</strong> <strong>Nile</strong> <strong>Corniche</strong> <strong>Project</strong> <strong>in</strong> <strong>Cairo</strong>:<br />

<strong>One</strong> <strong>of</strong> <strong>the</strong> <strong>largest</strong> construction<br />

projects <strong>in</strong> Egypt<br />

In a prime location along <strong>the</strong> banks <strong>of</strong><br />

<strong>the</strong> <strong>Nile</strong> on <strong>Nile</strong> <strong>Corniche</strong> Street <strong>in</strong> <strong>Cairo</strong><br />

city centre, construction <strong>of</strong> a build<strong>in</strong>g is<br />

currently underway that will eventually<br />

reach a height <strong>of</strong> 136 m. <strong>The</strong> complex will<br />

<strong>in</strong>clude a five star St. Regis Hotel as well<br />

as exclusive apartments and <strong>of</strong>fices.<br />

<strong>The</strong> project <strong>in</strong>vestor is <strong>the</strong> globally operat<strong>in</strong>g<br />

Qatari Diar Real Estate Investment<br />

Company, which is a 100 % subsidiary <strong>of</strong><br />

<strong>the</strong> state-owned QIA (Qatar Investment<br />

Authority). <strong>The</strong> QIA from Doha, Qatar is<br />

primarily active <strong>in</strong> <strong>the</strong> <strong>in</strong>ternational <strong>in</strong>vestment<br />

bus<strong>in</strong>ess.<br />

<strong>The</strong> Consolidated Contractors Company<br />

(CCC) was commissioned to undertake<br />

<strong>the</strong> <strong>Nile</strong> <strong>Corniche</strong> project. <strong>The</strong> CCC is one<br />

<strong>of</strong> <strong>the</strong> <strong>largest</strong> construction companies<br />

operat<strong>in</strong>g <strong>in</strong> <strong>the</strong> Middle East. Its ma<strong>in</strong><br />

areas <strong>of</strong> bus<strong>in</strong>ess <strong>in</strong>clude oil and gas,<br />

<strong>in</strong>frastructure projects and complex<br />

large-scale construction projects. <strong>The</strong><br />

company headquarters is based <strong>in</strong> A<strong>the</strong>ns,<br />

Greece; <strong>the</strong> annual turnover <strong>of</strong> CCC<br />

<strong>in</strong> <strong>the</strong> 2010 bus<strong>in</strong>ess year was approx.<br />

11.19 billion US $.<br />

<strong>The</strong> overall build<strong>in</strong>g consists <strong>of</strong> three<br />

high-rise towers positioned at close proximity<br />

to one ano<strong>the</strong>r and arranged <strong>in</strong> a Ushape.<br />

<strong>The</strong> basement and <strong>the</strong> first three<br />

floors share <strong>the</strong> same structural shell and<br />

form <strong>the</strong> spacious foyer, conference and<br />

sem<strong>in</strong>ar areas <strong>in</strong> <strong>the</strong> luxury hotel.<br />

Meet<strong>in</strong>g tight deadl<strong>in</strong>es through perfect<br />

plann<strong>in</strong>g<br />

CCC made contact with <strong>Putzmeister</strong><br />

through <strong>the</strong> local dealer IDP as early as<br />

<strong>the</strong> plann<strong>in</strong>g stage.<br />

<strong>The</strong> concrete delivery process was planned<br />

<strong>in</strong> conjunction with CPD and took <strong>in</strong>to<br />

account exist<strong>in</strong>g plans for <strong>the</strong> overall construction<br />

process as well as local factors.<br />

Two <strong>of</strong> <strong>the</strong> ma<strong>in</strong> challenges encountered<br />

when lay<strong>in</strong>g <strong>the</strong> delivery l<strong>in</strong>e were <strong>the</strong><br />

extremely conf<strong>in</strong>ed <strong>in</strong>ner city location <strong>of</strong><br />

<strong>the</strong> construction site and <strong>the</strong> daily placement<br />

<strong>of</strong> specific quantities <strong>of</strong> concrete <strong>in</strong><br />

order to meet <strong>the</strong> tight deadl<strong>in</strong>es.<br />

<strong>The</strong> placement <strong>of</strong> concrete us<strong>in</strong>g a crane<br />

and bucket was quickly rejected dur<strong>in</strong>g<br />

plann<strong>in</strong>g <strong>of</strong> <strong>the</strong> construction process.<br />

u <strong>The</strong> triple towers share <strong>the</strong> structure<br />

<strong>of</strong> <strong>the</strong> build<strong>in</strong>g up to <strong>the</strong> third storey.<br />

<strong>The</strong> towers on <strong>the</strong> right and <strong>in</strong> <strong>the</strong><br />

centre will accommodate a luxury hotel,<br />

whereas <strong>the</strong> left tower will be home to<br />

exclusive <strong>of</strong>fices and apartments.<br />

4 PM 4432 GB PM 4432 GB 5<br />

7<br />

8

Title story<br />

9<br />

10 12<br />

Ä <strong>The</strong> heart <strong>of</strong> <strong>the</strong> Arabic world<br />

beats <strong>in</strong> <strong>Cairo</strong><br />

<strong>Cairo</strong> ("al-Qā hira" <strong>in</strong> Arabic mean<strong>in</strong>g<br />

"<strong>The</strong> Strong <strong>One</strong>" or "<strong>The</strong> Conqueror")<br />

is <strong>the</strong> capital city <strong>of</strong> Egypt and <strong>the</strong> <strong>largest</strong><br />

city <strong>in</strong> Africa and <strong>the</strong> Arabic world.<br />

<strong>Cairo</strong> is <strong>the</strong> political, economic and cultural<br />

centre <strong>of</strong> Egypt and <strong>the</strong> surround<strong>in</strong>g<br />

region. <strong>The</strong> city is home to <strong>the</strong> Egyptian<br />

government, <strong>the</strong> parliament, all<br />

state and religious central authorities as<br />

well as numerous diplomatic missions.<br />

<strong>Cairo</strong> is <strong>the</strong> most important traffic hub<br />

<strong>in</strong> Egypt and boasts numerous universities,<br />

academies, <strong>the</strong>atres, museums and<br />

monuments. <strong>The</strong> historic centre <strong>of</strong> <strong>Cairo</strong><br />

is a Mecca <strong>of</strong> Islamic architecture and<br />

was recognised as a World Heritage Site<br />

by UNESCO <strong>in</strong> 1979.<br />

<strong>The</strong> ma<strong>in</strong> reasons were:<br />

• a limited number <strong>of</strong> cranes available<br />

due to space restrictions on site<br />

• cranes would be reserved for<br />

essent ial shutter<strong>in</strong>g and re<strong>in</strong>forcement<br />

work<br />

• unacceptably long concret<strong>in</strong>g times<br />

due to <strong>the</strong> slow pace <strong>of</strong> <strong>the</strong> crane<br />

bucket method, <strong>in</strong> particular <strong>in</strong> <strong>the</strong><br />

higher stories<br />

Staggered construction <strong>of</strong> <strong>the</strong> three<br />

build<strong>in</strong>g sections<br />

S<strong>in</strong>ce it was not possible to select a central<br />

po<strong>in</strong>t for transferr<strong>in</strong>g ready-mix concrete<br />

to <strong>the</strong> stationary concrete pumps<br />

due to <strong>the</strong> lack <strong>of</strong> space, CCC planned to<br />

position a BSA 2110 HD stationary con-<br />

t <strong>The</strong> CCC team on <strong>the</strong> construction site:<br />

(1st row, from left to right) Mohammed<br />

Nagui, Mohammed Al Areef,<br />

Osama Morris, Nader Ramzi;<br />

(2nd row, f.l.t.r.) Mohamed Elbaz,<br />

Atef Keylani, Sameh Mahmoud,<br />

Atwa Mohammed<br />

<strong>The</strong> adm<strong>in</strong>istrative district <strong>of</strong> <strong>Cairo</strong> has<br />

7.9 million <strong>in</strong>habitants (2008) and <strong>the</strong><br />

metropolitan region has about 16.2 million<br />

<strong>in</strong>habitants (2009), which is <strong>the</strong><br />

second <strong>largest</strong> <strong>in</strong> Africa beh<strong>in</strong>d Lagos<br />

<strong>in</strong> Nigeria. Citizens <strong>in</strong> Egypt are not<br />

obliged to register, however, which is<br />

why <strong>the</strong> number <strong>of</strong> specified <strong>in</strong>habitants<br />

is extrapolated based on <strong>the</strong> population<br />

census figures. Un<strong>of</strong>ficial estimates put<br />

<strong>the</strong> number <strong>of</strong> <strong>in</strong>habitants liv<strong>in</strong>g <strong>in</strong> and<br />

around <strong>Cairo</strong> at 25 million, which corresponds<br />

to almost a third <strong>of</strong> <strong>the</strong> total<br />

population <strong>of</strong> Egypt.<br />

crete pump supplied by a truck mixer<br />

<strong>in</strong> front <strong>of</strong> each <strong>of</strong> <strong>the</strong> three high-rise<br />

towers. Each concrete pump would <strong>the</strong>n<br />

pump concrete to an MX 36-4 stationary<br />

boom with a reach <strong>of</strong> 35.1 m.<br />

This staggered construction process<br />

meant that concrete construction work<br />

could progress <strong>in</strong>dependently on each<br />

section <strong>of</strong> <strong>the</strong> build<strong>in</strong>g and potential delivery<br />

problems at one <strong>of</strong> <strong>the</strong> concrete<br />

unload<strong>in</strong>g po<strong>in</strong>ts would not have an effect<br />

on <strong>the</strong> progress <strong>of</strong> <strong>the</strong> o<strong>the</strong>r sections<br />

<strong>of</strong> <strong>the</strong> build<strong>in</strong>g.<br />

<strong>Putzmeister</strong> Concrete <strong>Project</strong> Division<br />

once aga<strong>in</strong> demonstrated a high level<br />

<strong>of</strong> expertise when plann<strong>in</strong>g and implement<strong>in</strong>g<br />

<strong>the</strong> project<br />

<strong>The</strong> experienced eng<strong>in</strong>eers from <strong>the</strong><br />

<strong>Putzmeister</strong> Concrete <strong>Project</strong> Division<br />

(CPD) actively support <strong>the</strong> local construction<br />

and project managers <strong>in</strong> plann<strong>in</strong>g<br />

<strong>the</strong> construction and build<strong>in</strong>g site<br />

facilities. Successful high rise and tunnel<br />

construction projects as well as projects<br />

<strong>in</strong>volv<strong>in</strong>g <strong>the</strong> pump<strong>in</strong>g <strong>of</strong> concrete to<br />

great depths demonstrate <strong>the</strong>ir level <strong>of</strong><br />

expertise.<br />

<strong>The</strong> <strong>Nile</strong> is <strong>the</strong> longest river on <strong>the</strong> planet<br />

and has played an important role <strong>in</strong><br />

<strong>the</strong> development <strong>of</strong> civilisation and <strong>the</strong><br />

history <strong>of</strong> Egypt. <strong>The</strong> fertile land along<br />

<strong>the</strong> banks <strong>of</strong> <strong>the</strong> <strong>Nile</strong> gave rise to one <strong>of</strong><br />

<strong>the</strong> earliest advanced civilisations. Even<br />

today, <strong>the</strong> river <strong>Nile</strong> is <strong>of</strong> great economical<br />

importance.<br />

<strong>The</strong> <strong>Nile</strong> <strong>Corniche</strong> project is located on<br />

<strong>the</strong> banks <strong>of</strong> <strong>the</strong> river <strong>Nile</strong> <strong>in</strong> <strong>Cairo</strong> nearby<br />

<strong>the</strong> famous Tahir Square. Hundreds<br />

<strong>of</strong> typical sail<strong>in</strong>g boats cross <strong>the</strong> <strong>Nile</strong><br />

daily close to <strong>the</strong> site. Both locals and<br />

tourists regularly use <strong>the</strong> boats to escape<br />

<strong>the</strong> hectic metropolis and enjoy some <strong>of</strong><br />

<strong>the</strong> most spectacular sunsets along <strong>the</strong><br />

majestic flow<strong>in</strong>g river.<br />

6 PM 4432 GB PM 4432 GB 7<br />

Title story<br />

<strong>The</strong> <strong>Nile</strong> <strong>Corniche</strong> project<br />

Height <strong>of</strong> <strong>the</strong> build<strong>in</strong>g<br />

on completion 136 m<br />

Number <strong>of</strong> storeys 31<br />

Surface area 9,500 m2 <strong>Putzmeister</strong> mach<strong>in</strong>es used<br />

Pumps 3 x BSA 2110 HD<br />

Booms 3 x MX 36-4<br />

CCC sent <strong>Putzmeister</strong> <strong>the</strong> plann<strong>in</strong>g documents<br />

for <strong>the</strong> build<strong>in</strong>g and a plan <strong>of</strong><br />

<strong>the</strong> construction site <strong>in</strong> CAD file format<br />

so that <strong>the</strong> stationary concrete pumps<br />

and MX boom could be <strong>in</strong>tegrated <strong>in</strong> <strong>the</strong><br />

build<strong>in</strong>g site facilities plan to scale. <strong>The</strong><br />

position, ranges and 1.00 x 1.00 m recesses<br />

required for <strong>the</strong> climb<strong>in</strong>g columns<br />

on <strong>the</strong> stationary booms were coord<strong>in</strong>ated<br />

with <strong>the</strong> site management and entered<br />

<strong>in</strong> <strong>the</strong> floor plan and section us<strong>in</strong>g<br />

a CAD computer program.<br />

11

Title story<br />

Plann<strong>in</strong>g <strong>of</strong> <strong>the</strong> concrete delivery l<strong>in</strong>es<br />

began once <strong>the</strong> positions <strong>of</strong> <strong>the</strong> concrete<br />

pumps and booms were approved.<br />

CCC personnel set up <strong>the</strong> site with <strong>the</strong> assistance<br />

<strong>of</strong> Ronald Soussan, <strong>Putzmeister</strong><br />

Service Eng<strong>in</strong>eer, who rema<strong>in</strong>ed on site<br />

to oversee commission<strong>in</strong>g <strong>of</strong> <strong>the</strong> mach<strong>in</strong>ery<br />

and supervise <strong>the</strong> first few concrete<br />

placements. <strong>The</strong> concret<strong>in</strong>g team received<br />

<strong>in</strong>tensive <strong>in</strong>struction <strong>in</strong> <strong>the</strong> concret<strong>in</strong>g<br />

processes, <strong>in</strong>itial pump<strong>in</strong>g with<br />

grout, clean<strong>in</strong>g procedures and <strong>the</strong> work<br />

required at <strong>the</strong> end <strong>of</strong> <strong>the</strong> concret<strong>in</strong>g<br />

work.<br />

As a result <strong>of</strong> meticulous forward plann<strong>in</strong>g,<br />

all <strong>the</strong> materials required for <strong>the</strong><br />

delivery l<strong>in</strong>e, <strong>in</strong>clud<strong>in</strong>g all <strong>the</strong> necessary<br />

brackets and accessory components,<br />

were available on site. Installation <strong>of</strong> <strong>the</strong><br />

stationary concrete pump and <strong>the</strong> construction<br />

and commission<strong>in</strong>g <strong>of</strong> <strong>the</strong> MX<br />

boom started on <strong>the</strong> first day and progressed<br />

quickly and succ<strong>in</strong>ctly.<br />

<strong>The</strong> local <strong>Putzmeister</strong> Service partner,<br />

IDP, was on standby for any service<br />

call-outs dur<strong>in</strong>g <strong>the</strong> construction phase<br />

and ensured <strong>the</strong> reliable supply <strong>of</strong> spare<br />

parts.<br />

<strong>The</strong> competent plann<strong>in</strong>g <strong>of</strong> <strong>the</strong> concret<strong>in</strong>g<br />

delivery process, skilled supervision<br />

dur<strong>in</strong>g <strong>the</strong> <strong>in</strong>stallation phase and<br />

<strong>in</strong>struction on handl<strong>in</strong>g <strong>the</strong> mach<strong>in</strong>ery<br />

from <strong>Putzmeister</strong> also made a contribution<br />

to ensur<strong>in</strong>g that <strong>the</strong> concret<strong>in</strong>g work<br />

progressed speedily and was completed<br />

with<strong>in</strong> <strong>the</strong> deadl<strong>in</strong>es. n<br />

p Stationary concrete pump<br />

BSA 2110 HPD<br />

p Hydraulic boom MX 36-4<br />

u Concrete shut-<strong>of</strong>f gate valve GVHM<br />

13<br />

14<br />

p Transition po<strong>in</strong>t between horizontal<br />

and vertical delivery l<strong>in</strong>e<br />

15<br />

Ä International Development<br />

Programmes – IDP<br />

International Development Programmes<br />

company, IDP was established <strong>in</strong> 1974<br />

to become one <strong>of</strong> <strong>the</strong> market leaders <strong>in</strong><br />

<strong>the</strong> field <strong>of</strong> supply and service <strong>of</strong> heavy<br />

construction equipment and mach<strong>in</strong>ery<br />

<strong>in</strong> Egypt.<br />

For more than 35 years, IDP’s name<br />

has been associated with some <strong>of</strong> <strong>the</strong><br />

<strong>in</strong>dustry’s lead<strong>in</strong>g manufacturers. As<br />

a sole agent and representative <strong>of</strong> <strong>in</strong>ternational<br />

equipment manufacturers<br />

universally agreed upon to be among<br />

<strong>the</strong> best <strong>in</strong> <strong>the</strong> <strong>in</strong>dustry, IDP managed<br />

to become a reliable partner, supplier,<br />

know-how and service provider to<br />

Egypt’s base <strong>of</strong> construction, <strong>in</strong>dustrial<br />

and logistics companies. Our deep<br />

knowledge and extensive experience<br />

as well as our reliability, competence<br />

and read<strong>in</strong>ess to serve, all contributed<br />

to mak<strong>in</strong>g IDP not only a market<br />

leader, but a preferred partner to <strong>the</strong><br />

<strong>in</strong>dustry’s best performers.<br />

IDP <strong>of</strong>fers a complete and diversified<br />

range <strong>of</strong> construction and <strong>in</strong>dustrial<br />

equipment and mach<strong>in</strong>ery. Concrete<br />

equipment, hoist<strong>in</strong>g and lift<strong>in</strong>g, material<br />

handl<strong>in</strong>g, earthmov<strong>in</strong>g as well<br />

as road construction equipment and<br />

mach<strong>in</strong>ery.<br />

IDP’s diversity and ability to provide<br />

comprehensive solutions has<br />

allowed us to penetrate <strong>the</strong> market<br />

and become a leader <strong>in</strong> <strong>the</strong> field.<br />

This penetration is driven by a<br />

dedicated team <strong>of</strong> sales eng<strong>in</strong>eers<br />

and representatives who are well<br />

tra<strong>in</strong>ed on all technical aspects<br />

<strong>of</strong> our scope and can provide <strong>the</strong><br />

necessary knowledge to identify <strong>the</strong><br />

particular needs <strong>of</strong> each and every<br />

customer and project. This team is<br />

backed up by an efficient and competent<br />

after sales service department,<br />

<strong>the</strong> focus <strong>of</strong> which is customer<br />

satisfaction.<br />

16 17<br />

p <strong>The</strong> pr<strong>of</strong>essional IDP team:<br />

(back, f.l.t.r) Khaled Soliman, Salah Marwan, Amr Soliman, Hazem Akil<br />

(front, f.l.t.r.): Hosam Akil, Aladd<strong>in</strong> Ghondakly, Ahmed Ezz<br />

8 PM 4432 GB PM 4432 GB 9<br />

Title story

50 questions 50 questions<br />

35<br />

Products · Question 35<br />

How does <strong>Putzmeister</strong> guarantee<br />

<strong>the</strong> quality <strong>of</strong> its products?<br />

A consistent quality management system<br />

ensures that <strong>Putzmeister</strong> mach<strong>in</strong>es satisfy<br />

<strong>the</strong> highest requirements – no matter<br />

where <strong>in</strong> <strong>the</strong> world <strong>the</strong>y are produced.<br />

"Made by <strong>Putzmeister</strong>" is an <strong>in</strong>ternationally<br />

recognised quality label. To ensure<br />

<strong>the</strong> cont<strong>in</strong>uation <strong>of</strong> this, <strong>the</strong> company<br />

pursues a strict, globally applicable<br />

quality strategy: All core processes at<br />

<strong>Putzmeister</strong> are subject to strict quality<br />

criteria. <strong>The</strong>se criteria are b<strong>in</strong>d<strong>in</strong>g for<br />

all employees at all locations <strong>in</strong> all production<br />

companies <strong>of</strong> <strong>the</strong> <strong>Putzmeister</strong><br />

Group.<br />

As <strong>the</strong> world's first manufacturer <strong>of</strong><br />

concrete pumps <strong>Putzmeister</strong> obta<strong>in</strong>ed<br />

certification <strong>in</strong> accordance with DIN<br />

ISO 9001 <strong>in</strong> 1994. This certificate is an<br />

<strong>in</strong>ternationally recognised quality label.<br />

Whoever receives such a certificate documents<br />

that he has established a function<strong>in</strong>g<br />

quality management system. In<br />

addition, <strong>in</strong> some countries such as Ch<strong>in</strong>a<br />

and <strong>the</strong> USA it is necessary to provide<br />

additional quality certificates.<br />

Why <strong>Putzmeister</strong> has itself audited<br />

every year<br />

Auditors from an <strong>in</strong>dependent certification<br />

body <strong>of</strong> <strong>the</strong> TÜV Cert check each<br />

year whe<strong>the</strong>r <strong>Putzmeister</strong> meets <strong>the</strong><br />

standards <strong>of</strong> DIN ISO 9001. <strong>The</strong>y exam<strong>in</strong>e<br />

all quality-relevant processes from<br />

procurement <strong>of</strong> <strong>in</strong>dividual parts to manufactur<strong>in</strong>g<br />

and assembly to <strong>the</strong> delivery<br />

<strong>of</strong> mach<strong>in</strong>es to customers.<br />

This is important not least because<br />

<strong>Putzmeister</strong> produces mach<strong>in</strong>es which<br />

are subject to def<strong>in</strong>ed safety standards.<br />

<strong>The</strong> company must be able to demonstrate<br />

at any time that it complies with<br />

<strong>the</strong>se standards for each <strong>in</strong>dividual<br />

mach<strong>in</strong>e.<br />

To f<strong>in</strong>d out whe<strong>the</strong>r <strong>Putzmeister</strong> can do<br />

this <strong>the</strong> auditors mention any mach<strong>in</strong>e<br />

number for example. <strong>The</strong> company must<br />

<strong>the</strong>n show that <strong>the</strong>y know everyth<strong>in</strong>g<br />

<strong>the</strong>re is to know about this mach<strong>in</strong>e:<br />

When was it built? Where? Who worked<br />

on <strong>the</strong> mach<strong>in</strong>e? Who checked <strong>the</strong> mach<strong>in</strong>e?<br />

What customer representative<br />

18<br />

<strong>in</strong>spected and approved <strong>the</strong> mach<strong>in</strong>e<br />

<strong>in</strong> <strong>the</strong> factory? When was it delivered?<br />

What customer is us<strong>in</strong>g <strong>the</strong> mach<strong>in</strong>e<br />

at <strong>the</strong> moment? Where is <strong>the</strong> mach<strong>in</strong>e<br />

now?<br />

<strong>The</strong> development <strong>of</strong> each mach<strong>in</strong>e<br />

is documented cont<strong>in</strong>uously<br />

<strong>Putzmeister</strong> is able to answer such questions<br />

quickly thanks to this cont<strong>in</strong>uous<br />

documentation. <strong>The</strong> mach<strong>in</strong>e documentation<br />

and clear operat<strong>in</strong>g <strong>in</strong>structions<br />

also ensure that <strong>the</strong> customer can use<br />

<strong>the</strong> mach<strong>in</strong>e immediately and without<br />

any risks. And it should rema<strong>in</strong> like this.<br />

Quality management <strong>in</strong>cludes <strong>the</strong> suppliers.<br />

Suppliers are supported by quality<br />

assurance employees at <strong>Putzmeister</strong>.<br />

Each <strong>in</strong>dividual supplier must prove<br />

that he can guarantee top quality at all<br />

times. If a supplier becomes sloppy,<br />

he is <strong>the</strong>n removed from <strong>the</strong> list <strong>of</strong><br />

<strong>Putzmeister</strong> suppliers.<br />

Incidentally: <strong>Putzmeister</strong> doesn't just<br />

do all it can to ensure compliance<br />

with <strong>the</strong> various quality standards.<br />

<strong>The</strong> company also helps to set such<br />

standards. <strong>The</strong> <strong>Putzmeister</strong> management<br />

team works <strong>in</strong> cooperation<br />

with several bodies on standardisation,<br />

certification and quality assurance.<br />

<strong>Putzmeister</strong> was responsible<br />

for <strong>the</strong> development <strong>of</strong> <strong>the</strong> European<br />

concrete pump standard EN 12001 for<br />

example. <strong>The</strong> company assigned <strong>the</strong><br />

chairman <strong>of</strong> <strong>the</strong> responsible standardisation<br />

committee <strong>in</strong> Brussels. n<br />

t This employee measures <strong>the</strong> contours<br />

<strong>of</strong> a water tank us<strong>in</strong>g a laser system.<br />

p Quality confirmed by documents:<br />

This certificate is evidence that <strong>Putzmeister</strong>'s<br />

quality management system<br />

functions.<br />

u Us<strong>in</strong>g this 3D coord<strong>in</strong>ate measurement<br />

mach<strong>in</strong>e <strong>Putzmeister</strong> checks <strong>the</strong><br />

dimensions <strong>of</strong> supplied parts.<br />

10 PM 4432 GB PM 4432 GB 11<br />

19<br />

p In <strong>the</strong> precision measurement room: A quality assurance employee<br />

checks wear parts with a hardness test<strong>in</strong>g unit.<br />

20<br />

21

On site<br />

Reth<strong>in</strong>k<strong>in</strong>g pays <strong>of</strong>f:<br />

Innovative solution for<br />

backfill<strong>in</strong>g <strong>the</strong> annular<br />

space <strong>in</strong> a pressure shaft<br />

An additional 200 megawatt turb<strong>in</strong>e is<br />

be<strong>in</strong>g <strong>in</strong>stalled at <strong>the</strong> Vianden pumpedstorage<br />

hydroelectric plant <strong>in</strong> <strong>the</strong> Luxembourgish<br />

Ardennes, tak<strong>in</strong>g <strong>the</strong> total<br />

<strong>of</strong> mach<strong>in</strong>es at <strong>the</strong> plant to 11. <strong>The</strong> <strong>in</strong>stallation<br />

requires <strong>the</strong> construction <strong>of</strong> a new<br />

cavern <strong>in</strong>clud<strong>in</strong>g a water pressure shaft.<br />

<strong>The</strong> power house is located 300 m below<br />

<strong>the</strong> surface <strong>of</strong> <strong>the</strong> reservoir <strong>in</strong>side<br />

<strong>the</strong> mounta<strong>in</strong>. <strong>The</strong> <strong>in</strong>let to <strong>the</strong> pressure<br />

shaft is positioned at <strong>the</strong> centre<br />

<strong>of</strong> <strong>the</strong> reservoir lake. <strong>The</strong> pressure l<strong>in</strong>e<br />

consists <strong>of</strong> a vertical section approximately<br />

300 m <strong>in</strong> length with a bend at<br />

<strong>the</strong> end that br<strong>in</strong>gs <strong>the</strong> l<strong>in</strong>e horizontal.<br />

<strong>The</strong> vertical section <strong>of</strong> <strong>the</strong> shaft is <strong>the</strong><br />

trickiest part to backfill because <strong>the</strong><br />

concrete must be transported to extreme<br />

depths.<br />

Difficult task, <strong>in</strong>novative solution<br />

<strong>The</strong> annular space between <strong>the</strong> vertical<br />

steel pipe <strong>in</strong> <strong>the</strong> future pressure shaft<br />

and <strong>the</strong> rock is backfilled with self-compact<strong>in</strong>g<br />

concrete.<br />

<strong>The</strong> process for fill<strong>in</strong>g <strong>the</strong> horizontal section<br />

<strong>of</strong> <strong>the</strong> water pressure shaft was actually<br />

developed at <strong>the</strong> ARGE pumpedstorage<br />

plant at Vianden.<br />

p <strong>The</strong> new <strong>Putzmeister</strong> method ensures<br />

a high degree <strong>of</strong> quality even when fill<strong>in</strong>g<br />

to depths <strong>of</strong> 300 m<br />

22 24<br />

p <strong>The</strong> spread <strong>of</strong> self-compact<strong>in</strong>g concrete<br />

is approx. 760 mm<br />

t <strong>The</strong> BSA 1405 E stand<strong>in</strong>g on <strong>the</strong> bank<br />

<strong>of</strong> <strong>the</strong> reservoir first pumps <strong>the</strong> concrete<br />

along a 70 m horizontal l<strong>in</strong>e up to <strong>the</strong><br />

<strong>in</strong>let <strong>of</strong> <strong>the</strong> pressure shaft <strong>in</strong> <strong>the</strong> middle<br />

<strong>of</strong> <strong>the</strong> lake. <strong>The</strong> image on <strong>the</strong> left shows<br />

<strong>the</strong> steel pipe segments that are lowered<br />

<strong>in</strong>to <strong>the</strong> shaft, welded toge<strong>the</strong>r and <strong>the</strong>n<br />

backfilled to later form <strong>the</strong> pressure l<strong>in</strong>e.<br />

12 PM 4432 GB PM 4432 GB 13<br />

23<br />

9<br />

10<br />

12<br />

7<br />

8<br />

6<br />

5<br />

11<br />

<strong>The</strong> power plant at Vianden generates<br />

a rated output <strong>of</strong> 1096 megawatts<br />

(MW) and is one <strong>of</strong> <strong>the</strong> most powerful<br />

pump-storage power plants <strong>in</strong> Europe.<br />

<strong>The</strong> power plant was constructed<br />

to provide power dur<strong>in</strong>g peak<br />

times throughout <strong>the</strong> day. Dur<strong>in</strong>g <strong>the</strong><br />

day, water flows from <strong>the</strong> reservoir<br />

<strong>in</strong>to <strong>the</strong> nearby river Our, generat<strong>in</strong>g<br />

power along <strong>the</strong> way, and <strong>the</strong> water<br />

is pumped back to <strong>the</strong> top at night<br />

when energy costs are low.<br />

<strong>The</strong> plant was built between 1954 and<br />

1964, but <strong>the</strong> plann<strong>in</strong>g started as far<br />

back as 1925.<br />

<strong>The</strong> eleventh turb<strong>in</strong>e M11 is currently<br />

be<strong>in</strong>g <strong>in</strong>stalled. <strong>The</strong> construction<br />

work started at <strong>the</strong> beg<strong>in</strong>n<strong>in</strong>g <strong>of</strong> 2010.<br />

<strong>The</strong> turb<strong>in</strong>e is scheduled for service<br />

at <strong>the</strong> end <strong>of</strong> 2013. <strong>The</strong> overall cost<br />

<strong>of</strong> <strong>the</strong> additional mach<strong>in</strong>e 11 will be<br />

somewhere <strong>in</strong> <strong>the</strong> region <strong>of</strong> € 150m.<br />

<strong>The</strong> necessary extension <strong>of</strong> <strong>the</strong> reservoir<br />

will cost about € 10m.<br />

Ä www.seo.lu<br />

4<br />

3<br />

1<br />

2<br />

Technical data<br />

M11<br />

1 Inlet structure 4<br />

2 Vertical pressure l<strong>in</strong>e<br />

3 Horizontal pressure l<strong>in</strong>e<br />

4 Mach<strong>in</strong>e cavern<br />

5 Transformer cavern<br />

6 Auxiliary tunnels<br />

7 Access tunnels 3<br />

8 Underwater tunnels 3<br />

9 Portal structure<br />

10 Outlet structure<br />

11 Mach<strong>in</strong>es 1 – 9<br />

12 Mach<strong>in</strong>e 10<br />

On site<br />

Pressure shaft<br />

Height <strong>of</strong> vertical shaft 300 m<br />

Horizontal distance between pump<br />

and <strong>in</strong>let to <strong>the</strong> pressure shaft 70 m<br />

Diameter <strong>of</strong> <strong>the</strong> steel pipes 4.8 m<br />

Diameter <strong>of</strong> <strong>the</strong> rock excavation 5.4 m<br />

Length <strong>of</strong> a steel pipe section 12 m<br />

Concrete volume for each constructed<br />

section (12 m height) approx. 60 m³<br />

Concrete cycle per week: 1 x 60m³<br />

Concrete mix type SCC<br />

M11<br />

Nom<strong>in</strong>al drop height (net) 280 m<br />

Nom<strong>in</strong>al flow rate 78.2 m³/s<br />

Turb<strong>in</strong>e output (rated) 194.9 MW<br />

(max.) 203.3 MW<br />

Speed 333.3 rpm<br />

Flywheel diameter 4.3 m<br />

25<br />

26

On site On site<br />

✘Disadvantages<br />

<strong>of</strong> <strong>the</strong> conventional<br />

process <strong>of</strong> backfill<strong>in</strong>g<br />

from bottom to top:<br />

• Danger <strong>of</strong> los<strong>in</strong>g both delivery<br />

l<strong>in</strong>es through blockages before<br />

<strong>the</strong> job is complete. Once this<br />

happens, <strong>the</strong> space can only be<br />

filled us<strong>in</strong>g buckets from above.<br />

• <strong>The</strong> equipment costs are much<br />

higher than <strong>the</strong> backfill<strong>in</strong>g<br />

process developed by CPD:<br />

more powerful pumps are<br />

required, costs for <strong>the</strong> delivery<br />

l<strong>in</strong>es are higher<br />

<strong>The</strong> team from <strong>the</strong> <strong>Putzmeister</strong> Concrete<br />

<strong>Project</strong> Division devised a system for fill<strong>in</strong>g<br />

<strong>the</strong> vertical section from above. If <strong>the</strong><br />

traditional approach to concret<strong>in</strong>g pressure<br />

shafts is adopted, <strong>the</strong> pump is located<br />

on <strong>the</strong> same level as <strong>the</strong> power house<br />

and conveys concrete upwards. Usually<br />

two delivery l<strong>in</strong>es (one for delivery, one<br />

as a replacement) are laid <strong>in</strong> <strong>the</strong> annular<br />

space and extended as <strong>the</strong> steel pipes advance.<br />

On completion, <strong>the</strong> delivery l<strong>in</strong>es<br />

are concreted <strong>in</strong>to <strong>the</strong> filled void.<br />

✔<br />

Advantages <strong>of</strong> backfill<strong>in</strong>g<br />

from top to bottom:<br />

• <strong>The</strong> delivery l<strong>in</strong>e (only one<br />

required!) is accessible at all<br />

times. If a blockage forms,<br />

backfill<strong>in</strong>g can cont<strong>in</strong>ue once<br />

<strong>the</strong> blocked segment <strong>in</strong> <strong>the</strong><br />

l<strong>in</strong>e is replaced.<br />

• A smaller pump is adequate<br />

to complete <strong>the</strong> job. Only one<br />

mach<strong>in</strong>e is required<br />

• More economical and reliable<br />

<strong>Putzmeister</strong> is break<strong>in</strong>g new ground<br />

If one considers <strong>the</strong> disadvantages <strong>of</strong> <strong>the</strong><br />

conventional process <strong>of</strong> backfill<strong>in</strong>g annular<br />

spaces from bottom to top, such as<br />

los<strong>in</strong>g <strong>the</strong> delivery l<strong>in</strong>e at <strong>the</strong> end <strong>of</strong> concret<strong>in</strong>g,<br />

<strong>the</strong> logical step would be to reverse<br />

<strong>the</strong> process and concrete <strong>the</strong> void<br />

from top to bottom. <strong>The</strong> task is not an<br />

easy one because problems such as concrete<br />

segregation may arise. However,<br />

<strong>the</strong> team from <strong>the</strong> <strong>Putzmeister</strong> Concrete<br />

<strong>Project</strong> Division has found a successful<br />

solution.<br />

27<br />

<strong>The</strong> BSA 1405 E stationary pump is located<br />

on <strong>the</strong> bank <strong>of</strong> <strong>the</strong> reservoir lake.<br />

From <strong>the</strong>re, a 70 m horizontal delivery<br />

l<strong>in</strong>e is laid across a bridge to <strong>the</strong> <strong>in</strong>let<br />

<strong>in</strong> <strong>the</strong> middle <strong>of</strong> <strong>the</strong> lake and bends<br />

downwards <strong>in</strong>to a vertical delivery l<strong>in</strong>e<br />

secured to <strong>the</strong> rock wall <strong>in</strong> <strong>the</strong> pressure<br />

shaft that leads 300 m <strong>in</strong>to <strong>the</strong> depths.<br />

<strong>The</strong> diameter <strong>of</strong> <strong>the</strong> horizontal and vertical<br />

delivery l<strong>in</strong>e is 100 mm because <strong>the</strong><br />

l<strong>in</strong>e must <strong>of</strong>fer additional resistance to<br />

prevent segregation and unexpected acceleration<br />

<strong>of</strong> <strong>the</strong> concrete that is pumped<br />

downwards.<br />

<strong>The</strong> pipe <strong>in</strong>stallation <strong>in</strong> <strong>the</strong> shaft<br />

consists <strong>of</strong>:<br />

• a vent valve to prevent a vacuum<br />

from develop<strong>in</strong>g <strong>in</strong> <strong>the</strong> l<strong>in</strong>e,<br />

• a pressure sensor that monitors<br />

<strong>the</strong> fill level <strong>of</strong> <strong>the</strong> concrete <strong>in</strong> <strong>the</strong><br />

delivery l<strong>in</strong>e and<br />

• a fixture for anchor<strong>in</strong>g <strong>the</strong> vertical<br />

pipel<strong>in</strong>e.<br />

<strong>The</strong> follow<strong>in</strong>g equipment is located at<br />

<strong>the</strong> site <strong>of</strong> concrete placement:<br />

• a 3-stage steel platform that is<br />

adjusted (<strong>in</strong> 12 m <strong>in</strong>crements) as<br />

work progresses. <strong>The</strong> height <strong>of</strong> <strong>the</strong><br />

platform is adjusted us<strong>in</strong>g a cable<br />

w<strong>in</strong>ch located <strong>in</strong> <strong>the</strong> shaft, which is<br />

secured at reservoir level and connected<br />

to <strong>the</strong> <strong>in</strong>stalled pipe section<br />

via guide rollers.<br />

t <strong>The</strong> shut-<strong>of</strong>f valves are controlled<br />

automatically<br />

<strong>The</strong> follow<strong>in</strong>g equipment is used for<br />

concrete distribution on <strong>the</strong> platform:<br />

• two hydraulic gate valves GVH,<br />

• distribution equipment,<br />

• one hydraulic power pack and<br />

• one automatic control unit for<br />

<strong>the</strong> shut-<strong>of</strong>f valve.<br />

<strong>The</strong> shut-<strong>of</strong>f valve opens and closes automatically<br />

accord<strong>in</strong>g to changes <strong>in</strong> pressure<br />

detected by <strong>the</strong> sensor and controls<br />

<strong>the</strong> fill level <strong>in</strong> <strong>the</strong> l<strong>in</strong>e to prevent segregation<br />

and acceleration <strong>of</strong> <strong>the</strong> concrete<br />

and ensure steady, efficient backfill<strong>in</strong>g.<br />

Special thanks goes to <strong>the</strong> staff at <strong>the</strong><br />

ARGE pump-storage power plant <strong>in</strong> Vianden<br />

for <strong>the</strong>ir constructive collaboration<br />

and pr<strong>of</strong>essional support dur<strong>in</strong>g <strong>the</strong><br />

commission<strong>in</strong>g <strong>of</strong> <strong>the</strong> new system. n<br />

Ä Cavern structure M 11<br />

<strong>Putzmeister</strong> was <strong>in</strong>volved <strong>in</strong> build<strong>in</strong>g<br />

<strong>the</strong> cavern structure for mach<strong>in</strong>e 11:<br />

<strong>The</strong> company Hans Eib<strong>in</strong>ger – a <strong>Putzmeister</strong><br />

agent from Austria – erected<br />

<strong>the</strong> boom. <strong>The</strong> pump orig<strong>in</strong>ated from<br />

ARGE.<br />

<strong>The</strong> stationary boom on tubular<br />

column MXR 32-4 T and concrete<br />

pump BSA 1408 E located <strong>in</strong> one <strong>of</strong><br />

<strong>the</strong> access tunnels pumped a total <strong>of</strong><br />

20,000 m³ <strong>of</strong> concrete <strong>in</strong>to <strong>the</strong> cavern.<br />

<strong>The</strong> stationary boom was raised to a<br />

f<strong>in</strong>al tubular column length <strong>of</strong> 34 m.<br />

Dimensions <strong>of</strong> <strong>the</strong> cavern<br />

Length 52 m<br />

Width 25 m<br />

Height 48 m<br />

p Clear advantage: <strong>One</strong> stationary concrete pump such as <strong>the</strong> BSA 1405 E is totally<br />

adequate for this method <strong>of</strong> fill<strong>in</strong>g<br />

14 PM 4432 GB PM 4432 GB 15<br />

30<br />

Technical data<br />

BSA 1405 E<br />

Max. output 55 m³/h<br />

Max. concrete pressure 106 bar<br />

Drive (electric) 75 kW<br />

Delivery cyl<strong>in</strong>der dia. 200 mm<br />

Piston stroke 1,400 mm<br />

Delivery l<strong>in</strong>e<br />

Model ZX 100 HD<br />

Max. pressure 130 bar<br />

Initial length approx. 380 m<br />

(shortened by 12 m after each<br />

steel shell is concreted <strong>in</strong> place)<br />

28<br />

29

On site On site<br />

Reach<strong>in</strong>g for<br />

<strong>the</strong> sky by<br />

<strong>the</strong> Red Sea<br />

Spectacular high-rise build<strong>in</strong>gs are currently<br />

under construction <strong>in</strong> <strong>the</strong> Saudi<br />

Arabian city <strong>of</strong> Jeddah. <strong>The</strong>y will accommodate<br />

luxurious apartments, hotels,<br />

<strong>of</strong>fices and shopp<strong>in</strong>g centres at a dream<br />

location along <strong>the</strong> <strong>Corniche</strong> Road directly<br />

beside <strong>the</strong> Red Sea. <strong>Putzmeister</strong> on-site<br />

representative Bastian Dreher visited<br />

two <strong>of</strong> <strong>the</strong> large project sites and spoke<br />

to <strong>the</strong> respective site managers.<br />

33<br />

Ä Jeddah by <strong>the</strong> Red Sea …<br />

… is <strong>the</strong> second <strong>largest</strong> city <strong>in</strong> Saudi<br />

Arabia and <strong>the</strong> gate to Mecca, <strong>the</strong> holy<br />

city <strong>of</strong> Islam located about 72 km <strong>in</strong>land<br />

towards <strong>the</strong> east. Every year, an<br />

endless stream <strong>of</strong> pilgrims arrives <strong>in</strong><br />

Jeddah, predom<strong>in</strong>antly across <strong>the</strong> Red<br />

Lamar<br />

Towers<br />

31<br />

34<br />

Sea from Africa and by air from Indonesia<br />

and Pakistan. Unlike Mecca, visitors<br />

<strong>of</strong> all religions have taken up residence<br />

<strong>in</strong> Jeddah. Many Africans, Persians,<br />

Turks, Yemenis and Indians all form part<br />

<strong>of</strong> <strong>the</strong> local population. Most <strong>of</strong> <strong>the</strong>m<br />

work <strong>in</strong> <strong>the</strong> oil <strong>in</strong>dustry.<br />

<strong>The</strong> Lamar Towers are designed as tw<strong>in</strong><br />

towers. <strong>The</strong> taller <strong>of</strong> <strong>the</strong> two will reach a<br />

height <strong>of</strong> 350 m, becom<strong>in</strong>g <strong>the</strong> highest<br />

build<strong>in</strong>g <strong>in</strong> Jeddah (for <strong>the</strong> time be<strong>in</strong>g at<br />

least). <strong>The</strong> towers will accommodate hotels,<br />

apartments, shopp<strong>in</strong>g centres and<br />

<strong>of</strong>fices cover<strong>in</strong>g a total area <strong>of</strong> 415,500<br />

square metres. <strong>The</strong> structure will have already<br />

reached 100 m when this article is<br />

pr<strong>in</strong>ted and <strong>the</strong> towers are scheduled for<br />

completion <strong>in</strong> 2013. About 2000 people<br />

are work<strong>in</strong>g on <strong>the</strong> vast construction site.<br />

35 36 37<br />

Jeddah has around 3 million <strong>in</strong>habitants<br />

and operates <strong>the</strong> most important<br />

export port for petroleum products and<br />

livestock (goats, sheep and camels) <strong>in</strong> <strong>the</strong><br />

region.<br />

<strong>The</strong> city is approximately 300 years old<br />

and has witnessed tremendous development<br />

s<strong>in</strong>ce 1947: back <strong>the</strong>n, <strong>the</strong> popula-<br />

Ehab Sobhy Mohamed – site manager<br />

from <strong>the</strong> construction company Turner<br />

International Construction – talked with<br />

Bastian Dreher, <strong>Putzmeister</strong> Middle East<br />

about <strong>the</strong> concret<strong>in</strong>g work that started<br />

<strong>in</strong> 2008. Four powerful <strong>Putzmeister</strong> stationary<br />

pumps are on site: 1x BSA 14000<br />

HP-D, 1x BSA 14000 SHP-D, 2x BSA 2110<br />

HP-D and four type MX 32-4 T stationary<br />

booms. A total <strong>of</strong> 2.5 km <strong>of</strong> ZX 125 delivery<br />

l<strong>in</strong>es have been laid (<strong>of</strong> which 1.6<br />

km at 200 bar and 0.9 km at 130 bar).<br />

About 245,000 cubic metres <strong>of</strong> concrete<br />

are required for <strong>the</strong> foundation, ceil<strong>in</strong>gs<br />

on each floor and rema<strong>in</strong><strong>in</strong>g structural<br />

elements.<br />

"Based on <strong>in</strong>ternational experience and<br />

previous projects, Turner decided to use<br />

<strong>Putzmeister</strong> equipment from <strong>the</strong> outset",<br />

expla<strong>in</strong>s Mohamed. "Subcontractor<br />

SBM (Saudi Build<strong>in</strong>g Material) and<br />

<strong>Putzmeister</strong> mach<strong>in</strong>es have kept <strong>the</strong> project<br />

runn<strong>in</strong>g on schedule. We have also<br />

received good support from Medco and<br />

<strong>Putzmeister</strong>." n<br />

tion was only 30,000 and people were restricted<br />

to liv<strong>in</strong>g with<strong>in</strong> a small area <strong>in</strong>side<br />

<strong>the</strong> city walls. <strong>The</strong> "<strong>Corniche</strong>" boulevard<br />

l<strong>in</strong>ed with hotels and palaces that stretch<br />

along 60 km <strong>of</strong> Red Sea coastl<strong>in</strong>e provides<br />

<strong>the</strong> best overall picture <strong>of</strong> exactly<br />

how large <strong>the</strong> city is. Jeddah is nestled<br />

between <strong>the</strong> sea and <strong>the</strong> Asir mounta<strong>in</strong>s.<br />

p Podium <strong>of</strong> <strong>the</strong> Lamar Towers<br />

pView <strong>of</strong> <strong>the</strong> podium and one <strong>of</strong> <strong>the</strong> tw<strong>in</strong> Lamar Towers p Model <strong>of</strong> <strong>the</strong> Lamar Towers<br />

p <strong>The</strong> Lamar tw<strong>in</strong> towers will reach a height <strong>of</strong> about 350 m<br />

16 PM 4432 GB PM 4432 GB 17<br />

39<br />

40<br />

38

On site On site<br />

Headquarter<br />

Bus<strong>in</strong>ess Park<br />

SBM is work<strong>in</strong>g on <strong>the</strong> construction <strong>of</strong><br />

Headquarter Bus<strong>in</strong>ess Park at ano<strong>the</strong>r<br />

large site along Jeddah's <strong>Corniche</strong> Road.<br />

<strong>The</strong> floor plan <strong>of</strong> <strong>the</strong> unconventional<br />

complex consists <strong>of</strong> a narrow rectangle<br />

with a comparatively low build<strong>in</strong>g<br />

<strong>of</strong> 13 storeys positioned along <strong>the</strong> side<br />

overlook<strong>in</strong>g <strong>the</strong> city. <strong>The</strong> approximately<br />

240 m, 50-storey tower tapers upwards<br />

and appears to lean towards <strong>the</strong> Red Sea.<br />

<strong>The</strong> front <strong>of</strong> <strong>the</strong> tower will be partially<br />

constructed from glass that absorbs m<strong>in</strong>imal<br />

sunlight and <strong>of</strong>fers shad<strong>in</strong>g properties.<br />

With an efficient power and water<br />

supply, <strong>the</strong> Headquarter Bus<strong>in</strong>ess Park<br />

will be one <strong>of</strong> <strong>the</strong> few environmentally<br />

friendly build<strong>in</strong>gs <strong>in</strong> Saudi Arabia. <strong>The</strong><br />

exclusive <strong>of</strong>fices <strong>of</strong> numerous company<br />

headquarters will be ready for occupancy<br />

on schedule at <strong>the</strong> end <strong>of</strong> 2012 and<br />

<strong>the</strong> site will <strong>of</strong>fer a total <strong>of</strong> 1700 park<strong>in</strong>g<br />

spaces.<br />

View <strong>of</strong> <strong>the</strong> "<strong>Corniche</strong>" (promenade)<br />

<strong>in</strong> Jeddah<br />

42 43<br />

41<br />

SBM started <strong>the</strong> concret<strong>in</strong>g work <strong>in</strong><br />

2009 with two BSA 2110 HP-D and two<br />

MX 32-4 T as well as a ZX 125 delivery<br />

l<strong>in</strong>e (130 bar). A total <strong>of</strong> 105,000 cubic<br />

metres <strong>of</strong> concrete will be required for<br />

<strong>the</strong> structure (C60) and <strong>the</strong> floors (C40),<br />

as well as <strong>the</strong> large volume <strong>of</strong> concrete<br />

needed for <strong>the</strong> elaborate deep pile foundation<br />

because <strong>of</strong> <strong>the</strong> water table level<br />

<strong>of</strong> only 70 cm and numerous voids <strong>in</strong> <strong>the</strong><br />

ground (caused by coral!).<br />

p Complex column geometry p (right to left): Eng<strong>in</strong>eer Ahmed Mahmoud Hammad (<strong>Project</strong> Manager Freyss<strong>in</strong>et Saudi<br />

Arabia), Bastian Dreher (<strong>Putzmeister</strong> <strong>Project</strong> Manager), Qasim Darwish (Medco Sales Manager)<br />

Eng<strong>in</strong>eer and project manager Ahmed<br />

Mahmoud Hammad from <strong>the</strong> construction<br />

company Freyss<strong>in</strong>et Saudi Arabia<br />

gave details <strong>of</strong> <strong>the</strong> concret<strong>in</strong>g work:<br />

"<strong>The</strong> deep pile foundation alone took<br />

10 months to complete. <strong>The</strong> anchor<strong>in</strong>g<br />

system for <strong>the</strong> entire build<strong>in</strong>g consists <strong>of</strong><br />

360 piles 1.20 m <strong>in</strong> diameter and 40 m <strong>in</strong><br />

length and 267 piles 0.9 m <strong>in</strong> diameter<br />

and 25 m <strong>in</strong> length." <strong>The</strong> placement <strong>of</strong><br />

concrete was difficult <strong>in</strong> some areas, e.g.<br />

<strong>the</strong> jo<strong>in</strong> between <strong>the</strong> 8th and 9th floor<br />

which forms <strong>the</strong> transitional po<strong>in</strong>t from<br />

<strong>the</strong> podium to <strong>the</strong> tower.<br />

Eng<strong>in</strong>eer Hammad added "<strong>The</strong> tapered<br />

shape <strong>of</strong> <strong>the</strong> build<strong>in</strong>g was extremely difficult<br />

to concrete. On <strong>the</strong> 42nd floor, a<br />

stationary boom was dismounted from<br />

<strong>the</strong> slop<strong>in</strong>g side <strong>of</strong> <strong>the</strong> build<strong>in</strong>g. Not an<br />

easy task."<br />

Hammad is impressed with <strong>the</strong> reliability<br />

<strong>of</strong> <strong>Putzmeister</strong> pumps and concluded<br />

"<strong>The</strong> customer service provided <strong>in</strong> Saudi<br />

Arabia is exemplary." n<br />

p BSA 2110 HP-D on <strong>the</strong> construction site<br />

pu Stationary boom MX 32-4 T on new<br />

tubular column system RS850<br />

u Model <strong>of</strong> <strong>the</strong> Headquarter Bus<strong>in</strong>ess Park<br />

q View <strong>of</strong> <strong>the</strong> Lamar Towers from <strong>the</strong><br />

<strong>Corniche</strong> Road<br />

44 45<br />

18 PM 4432 GB PM 4432 GB 19<br />

46<br />

47

System technology<br />

Economical and flexible solution with<br />

Autocor® for supply<strong>in</strong>g concrete to<br />

several precast plant build<strong>in</strong>gs<br />

Traditionally <strong>in</strong> precast plants <strong>the</strong>re are<br />

bucket conveyors or a bucket for fill<strong>in</strong>g<br />

<strong>the</strong> formwork with concrete. If, however,<br />

both a flexible and economical system is<br />

required, <strong>the</strong> solution us<strong>in</strong>g a compact<br />

concrete pump is considered first and<br />

foremost.<br />

Often a bucket conveyor is <strong>the</strong> l<strong>in</strong>k between<br />

<strong>the</strong> mixer and <strong>the</strong> concret<strong>in</strong>g<br />

stations <strong>in</strong> a precast plant. In a smaller<br />

plant generally a bucket is filled and<br />

transported to <strong>the</strong> formwork by a forklift<br />

or <strong>in</strong>door crane. Both systems are <strong>in</strong>deed<br />

well-eng<strong>in</strong>eered, but also have <strong>the</strong>ir disadvantages.<br />

A bucket conveyor requires<br />

an elaborate rail system and is <strong>the</strong>refore<br />

<strong>in</strong>flexible if for example new concret-<br />

<strong>in</strong>g stations are added, formworks are<br />

to be filled at alternat<strong>in</strong>g locations <strong>in</strong><br />

<strong>the</strong> factory or a new production hall is<br />

constructed. <strong>The</strong> transport <strong>of</strong> a bucket<br />

with a forklift or <strong>in</strong>door crane is timeconsum<strong>in</strong>g<br />

and obstructs work such as<br />

<strong>the</strong> transport <strong>of</strong> re<strong>in</strong>forcements or f<strong>in</strong>ished<br />

elements.<br />

<strong>The</strong> flexible solution: a transport system<br />

compris<strong>in</strong>g a concrete pump, delivery<br />

l<strong>in</strong>e and if necessary a boom. This<br />

can also be useful <strong>in</strong> connection with a<br />

bucket conveyor. This solution is flexible<br />

because a pipel<strong>in</strong>e can be laid quickly<br />

and simply and thus at peak times for<br />

example makes possible outdoor production<br />

with a pipel<strong>in</strong>e fitted temporarily.<br />

<strong>The</strong> delivery l<strong>in</strong>e is laid underneath<br />

Stationary concrete pump Autocor<br />

1005 E AC with buffer storage and DVH<br />

gate valve. In this precast concrete<br />

plant it delivers 9 m³ <strong>of</strong> concrete per<br />

hour, approx. 60 m³ per day.<br />

48<br />

<strong>the</strong> ground <strong>in</strong> a duct for space-sav<strong>in</strong>g<br />

reasons or secured to <strong>the</strong> hall wall at<br />

<strong>the</strong> side. If concrete is delivered to various<br />

production halls, gate valves (DVH)<br />

are used. <strong>The</strong> operator switches <strong>the</strong> gate<br />

valves to <strong>the</strong> correspond<strong>in</strong>g position us<strong>in</strong>g<br />

<strong>the</strong> remote control. Normally <strong>the</strong>re<br />

is a sequential process, i.e. a concret<strong>in</strong>g<br />

station is supplied with concrete until all<br />

<strong>the</strong> formworks are filled, <strong>the</strong>n a switchover<br />

to <strong>the</strong> next l<strong>in</strong>e is effected. If <strong>the</strong> concrete<br />

has a correspond<strong>in</strong>g sett<strong>in</strong>g time,<br />

two concret<strong>in</strong>g stations can be supplied<br />

alternately.<br />

A gate valve, however, has ano<strong>the</strong>r key<br />

function. After all formworks are filled<br />

at <strong>the</strong> concret<strong>in</strong>g station, <strong>the</strong> gate valve<br />

must be dra<strong>in</strong>ed and cleaned, <strong>of</strong> course<br />

without <strong>in</strong>terrupt<strong>in</strong>g production.<br />

Clean<strong>in</strong>g<br />

Clean<strong>in</strong>g connections are already filled<br />

with sponge balls and mounted at <strong>the</strong><br />

gate valve at <strong>the</strong> concrete preparation<br />

stage. If <strong>the</strong> concret<strong>in</strong>g is completed at<br />

<strong>the</strong> first location, <strong>the</strong> gate valve switches<br />

over to <strong>the</strong> second l<strong>in</strong>e. Concrete can<br />

be delivered to <strong>the</strong> next concret<strong>in</strong>g station<br />

without <strong>in</strong>terruption to production.<br />

At <strong>the</strong> same time, <strong>the</strong> clean<strong>in</strong>g connections<br />

are now positioned <strong>in</strong> front <strong>of</strong> <strong>the</strong><br />

first hose. A collection conta<strong>in</strong>er is connected<br />

at <strong>the</strong> end <strong>of</strong> <strong>the</strong> delivery l<strong>in</strong>e for<br />

<strong>the</strong> sponge balls. Us<strong>in</strong>g compressed air<br />

<strong>the</strong> sponge balls are pushed through <strong>the</strong><br />

l<strong>in</strong>e towards <strong>the</strong> formwork and push <strong>the</strong><br />

concrete from <strong>the</strong> l<strong>in</strong>e, which can almost<br />

be used completely. If <strong>the</strong> sponge balls<br />

are pushed through <strong>the</strong> entire l<strong>in</strong>e, <strong>the</strong>y<br />

are held <strong>in</strong> <strong>the</strong> collection tank. <strong>The</strong> compressed<br />

air beh<strong>in</strong>d <strong>the</strong>m cannot escape.<br />

<strong>The</strong> l<strong>in</strong>e can be depressurised at <strong>the</strong><br />

dra<strong>in</strong> cock <strong>of</strong> <strong>the</strong> clean<strong>in</strong>g connections.<br />

49<br />

p <strong>The</strong> delivery l<strong>in</strong>e can also be laid under<br />

<strong>the</strong> ground to save space. <strong>The</strong> duct<br />

cover plates are not visible <strong>in</strong> <strong>the</strong> image.<br />

Longer delivery l<strong>in</strong>es must be cleaned<br />

us<strong>in</strong>g water as high pressure can cause<br />

<strong>the</strong> concrete to "push through". For example:<br />

A 100 m l<strong>in</strong>e with a diameter <strong>of</strong><br />

125 mm is filled with approx. 2,900 kg<br />

<strong>of</strong> concrete.<br />

<strong>The</strong> entire delivery l<strong>in</strong>e does not have<br />

to be filled with water, but a "clean<strong>in</strong>g<br />

package", compris<strong>in</strong>g a sponge<br />

ball / water / sponge ball or pig, can be<br />

pushed through <strong>the</strong> delivery l<strong>in</strong>e us<strong>in</strong>g<br />

compressed air. <strong>The</strong> clean separation <strong>of</strong><br />

<strong>the</strong> media between concrete and clean<strong>in</strong>g<br />

water is important so that no blockages<br />

occur dur<strong>in</strong>g <strong>the</strong> clean<strong>in</strong>g process.<br />

<strong>The</strong> water rema<strong>in</strong>s <strong>in</strong> <strong>the</strong> pipel<strong>in</strong>e and is<br />

pushed back <strong>in</strong>to a collection tank connected<br />

beside <strong>the</strong> concrete pump us<strong>in</strong>g<br />

compressed air. No water escapes <strong>in</strong>to<br />

<strong>the</strong> production hall. <strong>The</strong> delivery l<strong>in</strong>e is<br />

empty and clean.<br />

Due to <strong>the</strong>ir m<strong>in</strong>imal spatial requirement,<br />

concrete pumps can be easily retr<strong>of</strong>itted<br />

and/or adapted to modified production<br />

processes <strong>in</strong> <strong>the</strong> case <strong>of</strong> renovations to<br />

production plants. <strong>Putzmeister</strong> provides<br />

support dur<strong>in</strong>g <strong>the</strong> process plann<strong>in</strong>g<br />

stage and ensures smooth, long-term<br />

and economical production. n<br />

System technology<br />

50 51<br />

p <strong>The</strong> concrete flow is distributed to two<br />

delivery l<strong>in</strong>es with help <strong>of</strong> a DVH gate<br />

valve. <strong>The</strong> prepared, already connected<br />

clean<strong>in</strong>g connections can be seen <strong>in</strong> <strong>the</strong><br />

image.<br />

Ä Advantages <strong>of</strong> Autocor®:<br />

• Cont<strong>in</strong>uous and clean<br />

delivery <strong>of</strong> concrete<br />

• Suitable for all pumpable<br />

concrete and self-compact<strong>in</strong>g<br />

concrete<br />

• Delivery rates up to 53 m³/h,<br />

delivery range over 200 m<br />

• Load<strong>in</strong>g possible directly from<br />

<strong>the</strong> mixer by a bucket conveyor<br />

or truck mixer<br />

• Clean production channels<br />

• Higher productivity<br />

• Improved utilisation <strong>of</strong> operat<strong>in</strong>g<br />

equipment, area and crane<br />

t Knecht <strong>in</strong> Metz<strong>in</strong>gen, Germany<br />

uses Autocor® for <strong>the</strong> manufacture<br />

<strong>of</strong> its high-quality concrete prefabricated<br />

parts.<br />

u A collection tank holds <strong>the</strong> sponge<br />

balls at <strong>the</strong> end <strong>of</strong> <strong>the</strong> delivery l<strong>in</strong>e.<br />

q <strong>The</strong> clean<strong>in</strong>g connections are<br />

filled with sponge balls or pigs and<br />

connected to <strong>the</strong> gate valve before<br />

concret<strong>in</strong>g.<br />

Compressed air or water is used for<br />

dra<strong>in</strong><strong>in</strong>g and clean<strong>in</strong>g <strong>the</strong> delivery<br />

l<strong>in</strong>e.<br />

20 PM 4432 GB PM 4432 GB 21<br />

53<br />

52<br />

54

<strong>Putzmeister</strong> Solid Pumps<br />

Boom arm gone astray:<br />

Sludge <strong>in</strong>stead <strong>of</strong> concrete<br />

<strong>The</strong> sewage treatment plant <strong>in</strong> <strong>the</strong> city <strong>of</strong><br />

Prague, Czech Republic operated by Veolia,<br />

is equipped with four centrifuges for<br />

dra<strong>in</strong><strong>in</strong>g <strong>the</strong> accumulat<strong>in</strong>g sludge. <strong>The</strong><br />

sludge is loaded onto a truck and taken<br />

to <strong>the</strong> dump<strong>in</strong>g ground. This amounts to<br />

75,000 tons <strong>of</strong> sludge each year.<br />

In <strong>the</strong> past <strong>the</strong> sludge was transported<br />

to <strong>the</strong> storage silo us<strong>in</strong>g a screw conveyor.<br />

<strong>The</strong> wear and <strong>the</strong> ma<strong>in</strong>tenance<br />

costs were so high that <strong>the</strong> city <strong>of</strong> Prague<br />

decided to pump <strong>the</strong> dra<strong>in</strong>ed sludge directly<br />

<strong>in</strong>to truck conta<strong>in</strong>ers us<strong>in</strong>g <strong>Putzmeister</strong><br />

piston pumps and a modified<br />

stationary boom.<br />

<strong>The</strong> dewatered sludge comes out from<br />

<strong>the</strong> centrifuge build<strong>in</strong>g via a s<strong>in</strong>gleshaft<br />

screw conveyor <strong>in</strong>to <strong>the</strong> pump.<br />

<strong>The</strong> sludge has a temperature <strong>of</strong> approx.<br />

50 °C and dry matter content <strong>of</strong> approx.<br />

30 % TS.<br />

<strong>The</strong> sludge is stored <strong>in</strong> a temporary shaft<br />

before it is supplied us<strong>in</strong>g <strong>the</strong> powerful<br />

feed<strong>in</strong>g equipment with a double hydraulic<br />

drive <strong>of</strong> <strong>the</strong> solids pump, type<br />

KOS 1050 HP.<br />

Use <strong>of</strong> pumps with S-transfer tubes<br />

Of all <strong>the</strong> different types <strong>of</strong> <strong>Putzmeister</strong><br />

pumps only <strong>the</strong> KOS pump is worth<br />

consider<strong>in</strong>g for this application. <strong>The</strong><br />

pumped material is hot and viscous. It<br />

may also conta<strong>in</strong> foreign matter which<br />

may pass through <strong>the</strong> large, open crosssections<br />

<strong>of</strong> <strong>the</strong> S-transfer tube unobstructed.<br />

For o<strong>the</strong>r pump systems <strong>the</strong><br />

special characteristics <strong>of</strong> <strong>the</strong> material<br />

may cause a process fault or even destroy<br />

<strong>the</strong> pump unit.<br />

Boom with fully automatic system<br />

<strong>The</strong> space-sav<strong>in</strong>g and low-pr<strong>of</strong>ile design,<br />

<strong>in</strong> comparison to <strong>the</strong> silo, plays a<br />

decisive role <strong>in</strong> <strong>the</strong> use <strong>of</strong> <strong>the</strong> boom for<br />

load<strong>in</strong>g sludge <strong>in</strong>to <strong>the</strong> conta<strong>in</strong>er. Each<br />

conta<strong>in</strong>er is set up at a fixed position<br />

for load<strong>in</strong>g. <strong>The</strong> sludge is distributed<br />

automatically to <strong>the</strong> conta<strong>in</strong>er. Sensors<br />

share <strong>the</strong> status <strong>of</strong> <strong>the</strong> conta<strong>in</strong>er with <strong>the</strong><br />

boom over which it is located:<br />

<strong>Putzmeister</strong> Solid Pumps<br />

55 56<br />

p Schematic diagram <strong>of</strong> <strong>the</strong> system:<br />

<strong>The</strong> stationary boom can easily reach each<br />

po<strong>in</strong>t on all six conta<strong>in</strong>ers. Alternatively <strong>the</strong><br />

sludge, also <strong>in</strong> <strong>the</strong> silo, can be conveyed to<br />

<strong>the</strong> direct truck load<strong>in</strong>g unit (right).<br />

• Conta<strong>in</strong>er at station Yes / No<br />

• Conta<strong>in</strong>er lid open Yes / No<br />