SPE FREEZERS User Manual

SPE FREEZERS User Manual

SPE FREEZERS User Manual

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

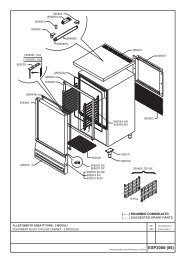

Installation3.5.2004 Rev. 1.05.7 Connections for “Remote cooling”5.7.1 Electrical connectionsThe version with a control panel incorporates an electronic thermostat, switches, warninglights and indicators according to what has been specified under the chapter 3.2 “Construction”section. In this case the unit must be connected to a motor-driven condensingunit.Connect to terminals M on the compressor and on the electric condenser fan.5.7.2 Connecting refrigerant pipesSuction pipesLay down the suction line according to the established layout making sure that the numberof elbows and vertical sections where the refrigerant flows upward is limited to the veryminimum. Weld the suction line to the appliance exits jutting out of the side, provided forthis purpose. The suction pipe is generally to be distinguished from the liquid line by itsdiameter: it is the larger of them. Repeat the operation on the condensing unit. The verticalsections of the suction pipe shall be equipped with a trap and counter- trap to make oiltrapping easier and prevent it from flowing back to the evaporator when the compressoris off due to the thermostatic control.Please bear in mind that the only method applicable to vertical pipe sections where therefrigerant flows upward to make sure the oil returns to the compressor and prevent iffrom seizing due to insufficient lubrication, consists in “pulling” the oil by exploiting gasspeed.Liquid lineLay the liquid line pipes according to the established layout making sure that the numberof elbows and vertical sections where the refrigerant flows upward is limited to the veryminimum. Braze the liquid line pipe to the appliance outlet pipe located where the especiallyprovided protruding section is. The liquid line pipe can generally be distinguishedfrom the suction pipe by its diameter: it is the smaller one. Repeat the operation for thecondensing unit.5.7.3 Suggestions• SLANT: the horizontal sections of the suction pipes shall have a 0.5% slant towardsthe compressor to ensure oil back flow.• ELBOWS: to reduce pressure drops to a minimum, include as few elbows in yourline as possible and if you do, use large radius elbows only.• THERMAL INSULATION: the liquid line shall be insulated if exposed to the sunor if passing through areas where temperature is higher than condenser outlet temperatur12